A Multipurpose Heat Pipe Stack Prototype

A multi-purpose, heat pipe technology, applied in the direction of hot gas variable displacement engine devices, mechanical equipment, machines/engines, etc., can solve the problems of staying in a single component, integrated integration characteristics need further research, lack of coupling characteristics of heat pipe reactors, etc. Achieve the effect of simplifying the core structure and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

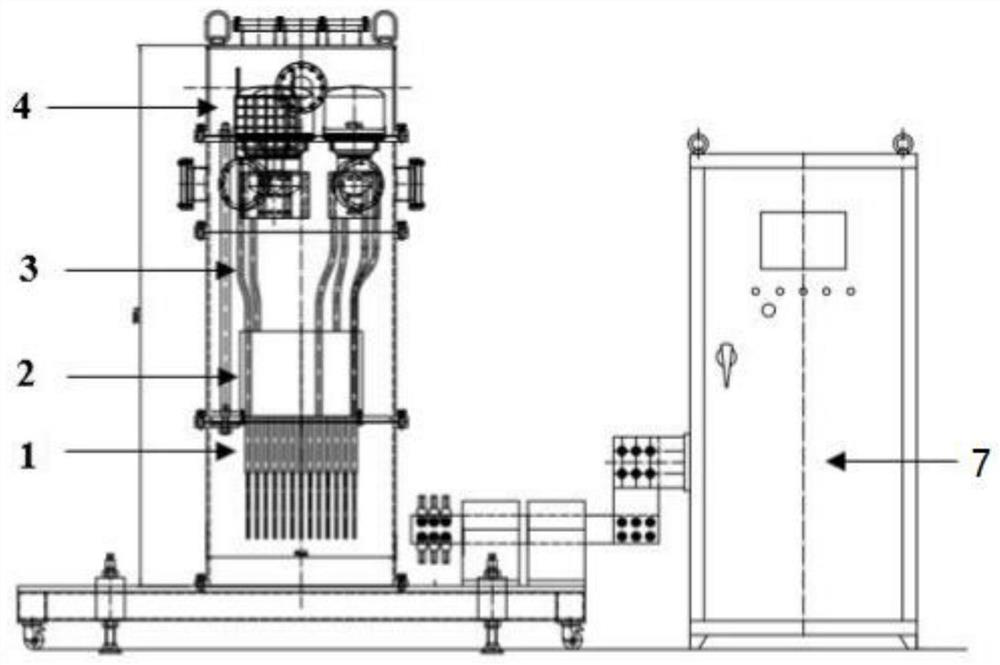

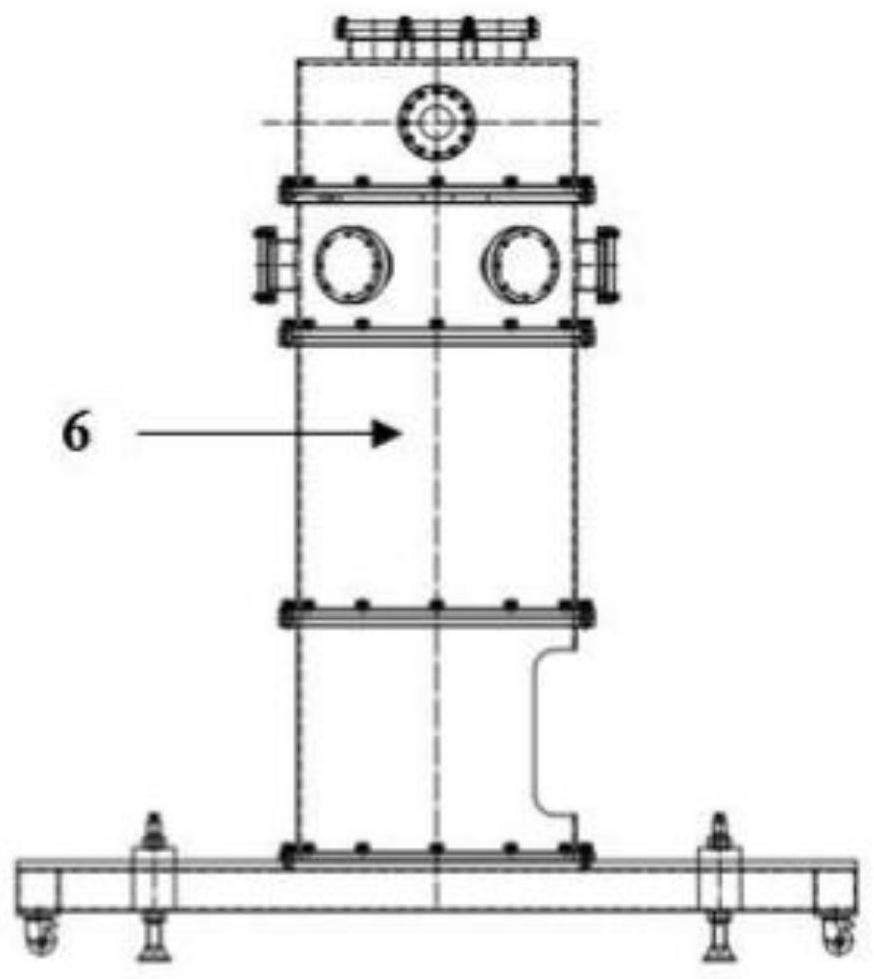

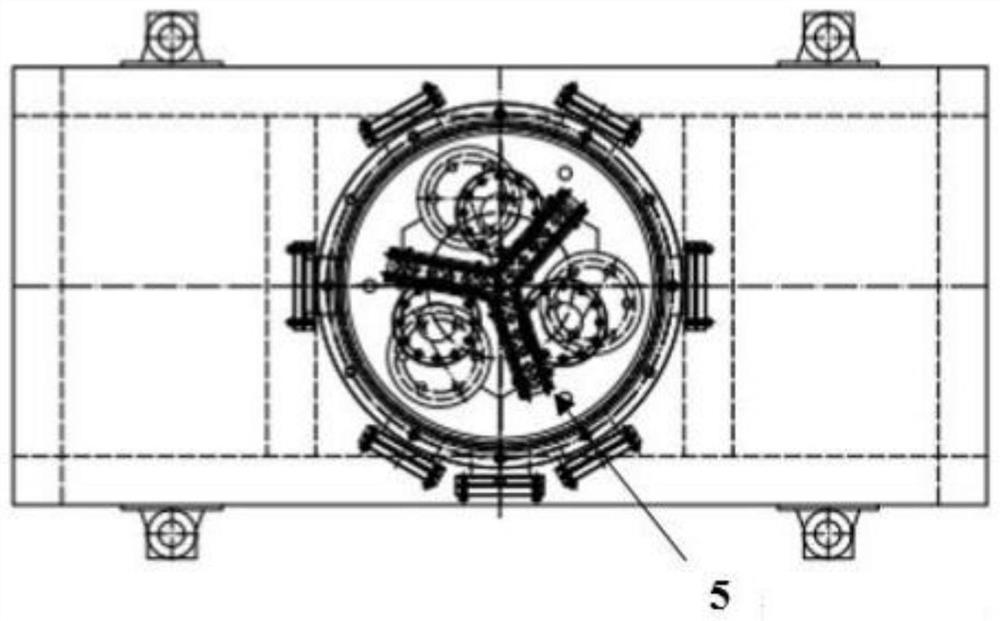

[0031] A multi-purpose heat pipe stack prototype, including a hexagonal base 2, multiple heating rods 1, a Stirling thermoelectric converter 4, a silent thermoelectric converter 5, multiple high-temperature alkali metal heat pipes 3 and a pressure-bearing protective shell 6 .

[0032] The hexagonal matrix 2 is used to simulate the solid core of the heat pipe stack.

[0033] A plurality of heating rods 1 are inserted in the hexagonal matrix 2 for simulating the reactor fuel rod bundle, and by adjusting the power of the heating rods 1 , the power distribution and power variation of the core are simulated.

[0034] Stirling Thermoelectric Converter 4 for modeling dynamic thermoelectric conversion processes.

[0035] The silent thermoelectric converter 5 is used to simulate the static thermoelectric conversion process.

[0036] A plurality of high-temperature alkali metal heat pipes 3 are used to simulate the core cooling and energy transmission process; wherein, the high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com