Method and system for exporting waste heat of reactor core in containment

A technology for waste heat removal system and core waste heat, applied in the field of nuclear industry, can solve the problems of high construction and operation and maintenance costs, and cannot meet the requirements of mutual independence, so as to reduce construction and operation and maintenance costs, simplify safety facilities, and improve safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

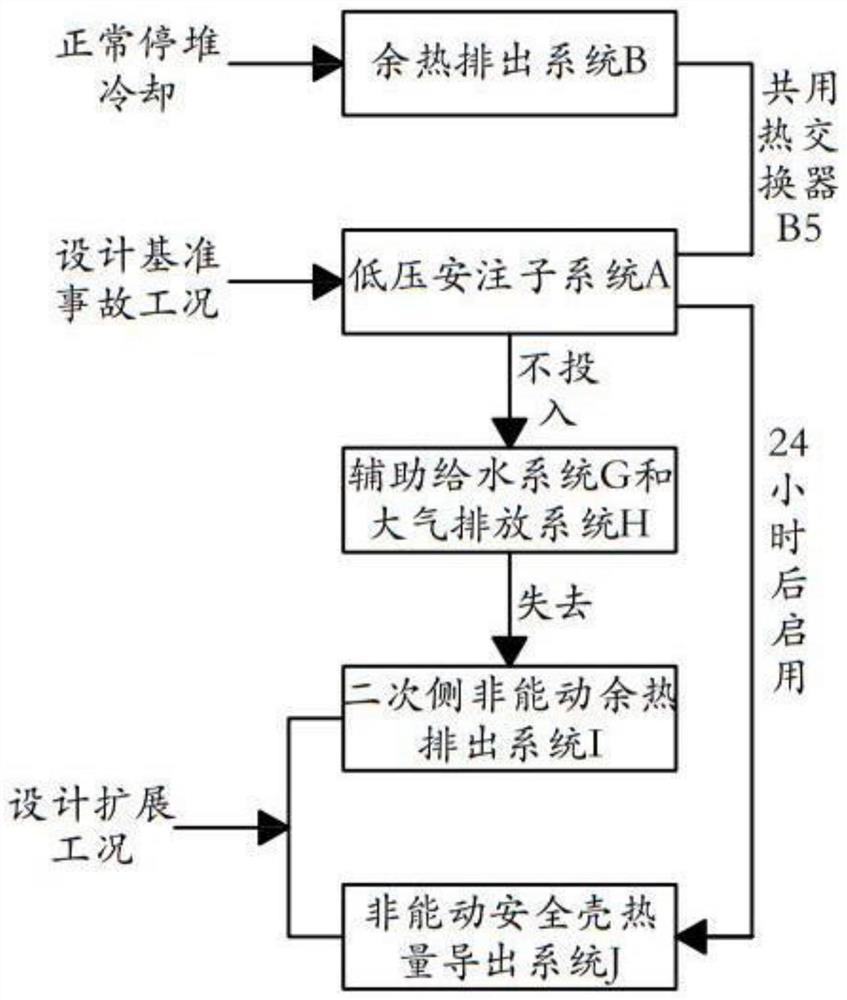

[0061] Such as figure 1 with 2 As shown, Embodiment 1 of the present invention provides a method for deriving residual heat from the core in the containment, the method comprising:

[0062] Under the design basis accident conditions, the low-pressure safety injection subsystem A of the safety injection system is connected with the heat exchanger B6 of the waste heat removal system B. When the primary circuit reaches the injection pressure of the low-pressure safety injection system A, the low-pressure safety injection subsystem A Inject the built-in refueling water tank / pit E boron-containing water (that is, coolant F1) into the core K2, and the coolant F1 that has absorbed the waste heat of the core K2 flows out from the breach of the primary circuit and returns to the built-in refueling water tank / pit E, and then exported from the low-pressure safety injection subsystem A to the heat exchanger B6 for heat exchange and cooling, and the coolant F1 after the heat exchange and ...

Embodiment 2

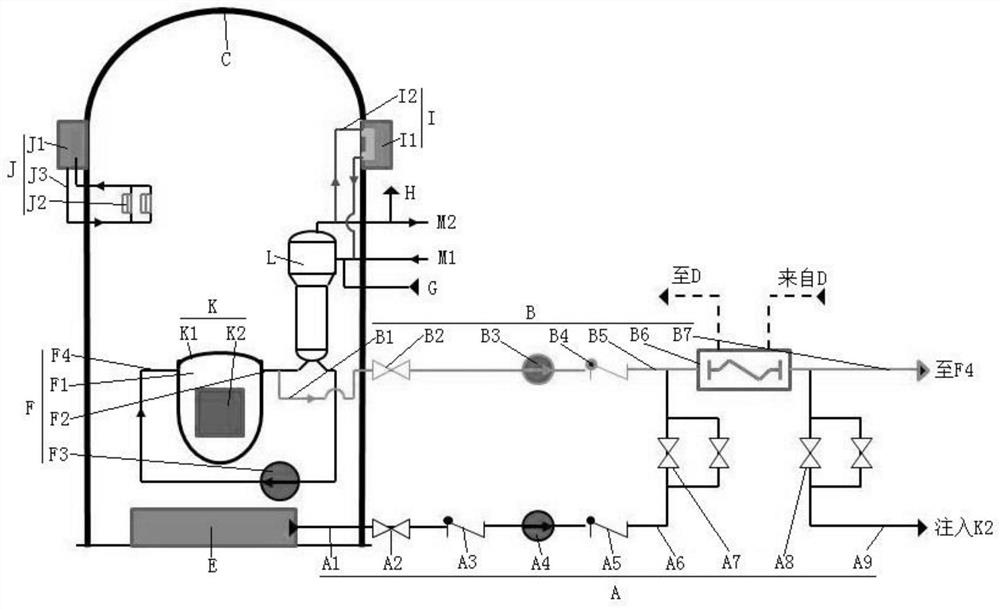

[0068] Such as figure 2 As shown, Embodiment 2 of the present invention provides a core residual heat export system in the containment vessel, including:

[0069] Containment C, whose volume meets the design basis accident conditions, and when the low-pressure safety injection subsystem A is put into use, the pressure inside it shall not exceed its design pressure value for at least 24 hours. This design requirement will be combined with the low-pressure safety injection Subsystem A introduces its specific working principle and function.

[0070] Specifically, a reactor K is arranged in the containment C, and the reactor K includes a reactor pressure vessel K1 and a core K2 arranged in the reactor pressure vessel K1, and the reactor pressure vessel K1 is filled with coolant F1. In a specific embodiment, Coolant F1 can use boron-containing cooling water (also known as boric acid water, boron-containing water, which is one of the commonly used coolants in nuclear reactors), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com