Device for automatic spinning start in an open-end spinning machine

An automatic threading and free-end technology, which is applied in the direction of open-end spinning machines, spinning machines, continuous winding spinning machines, etc., can solve the problem of optimal alignment of yarn processors, difficult to feed yarn components, Faulty finished yarn and other problems, to achieve the effect of saving space, optimizing positioning, and reducing faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

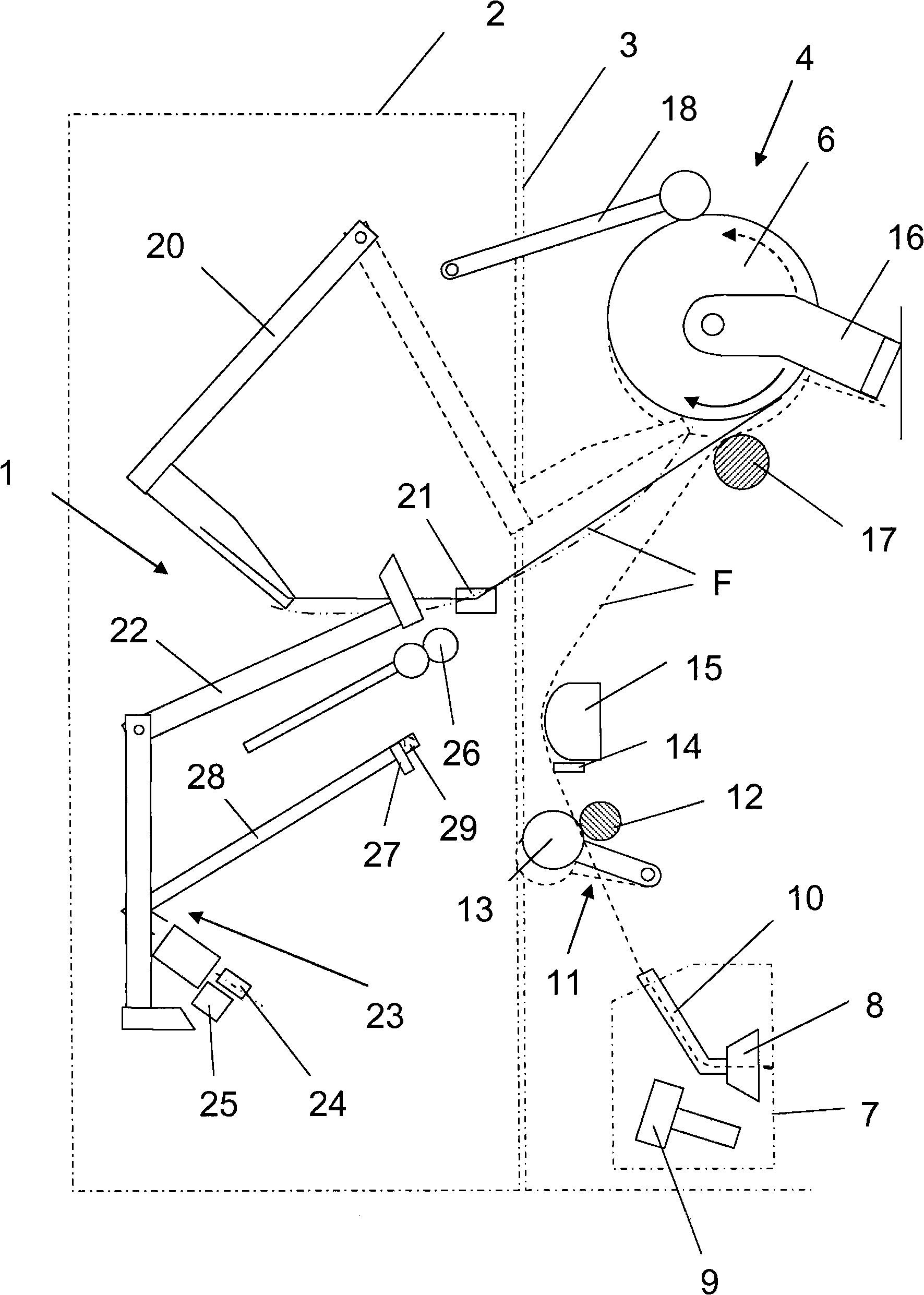

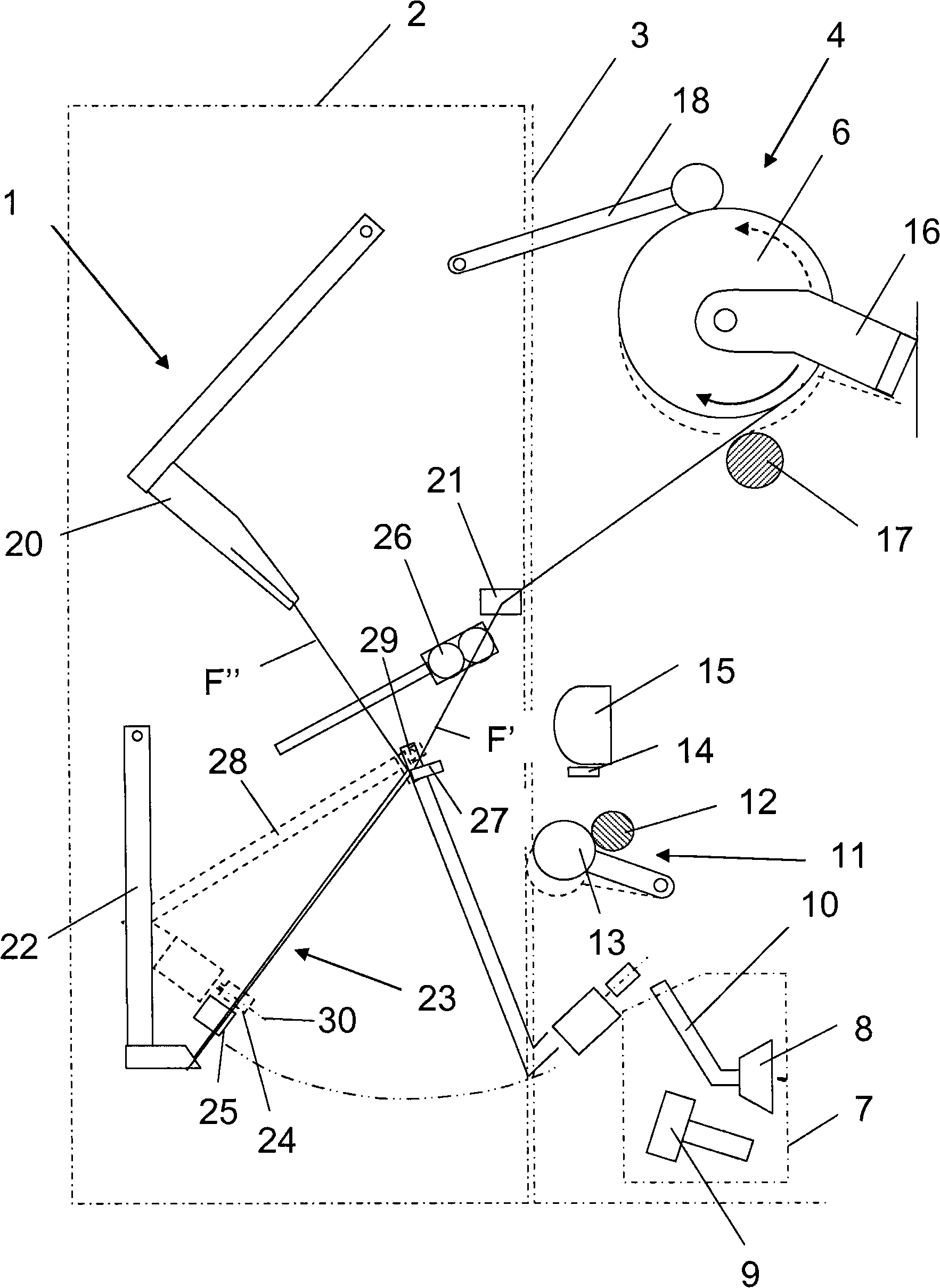

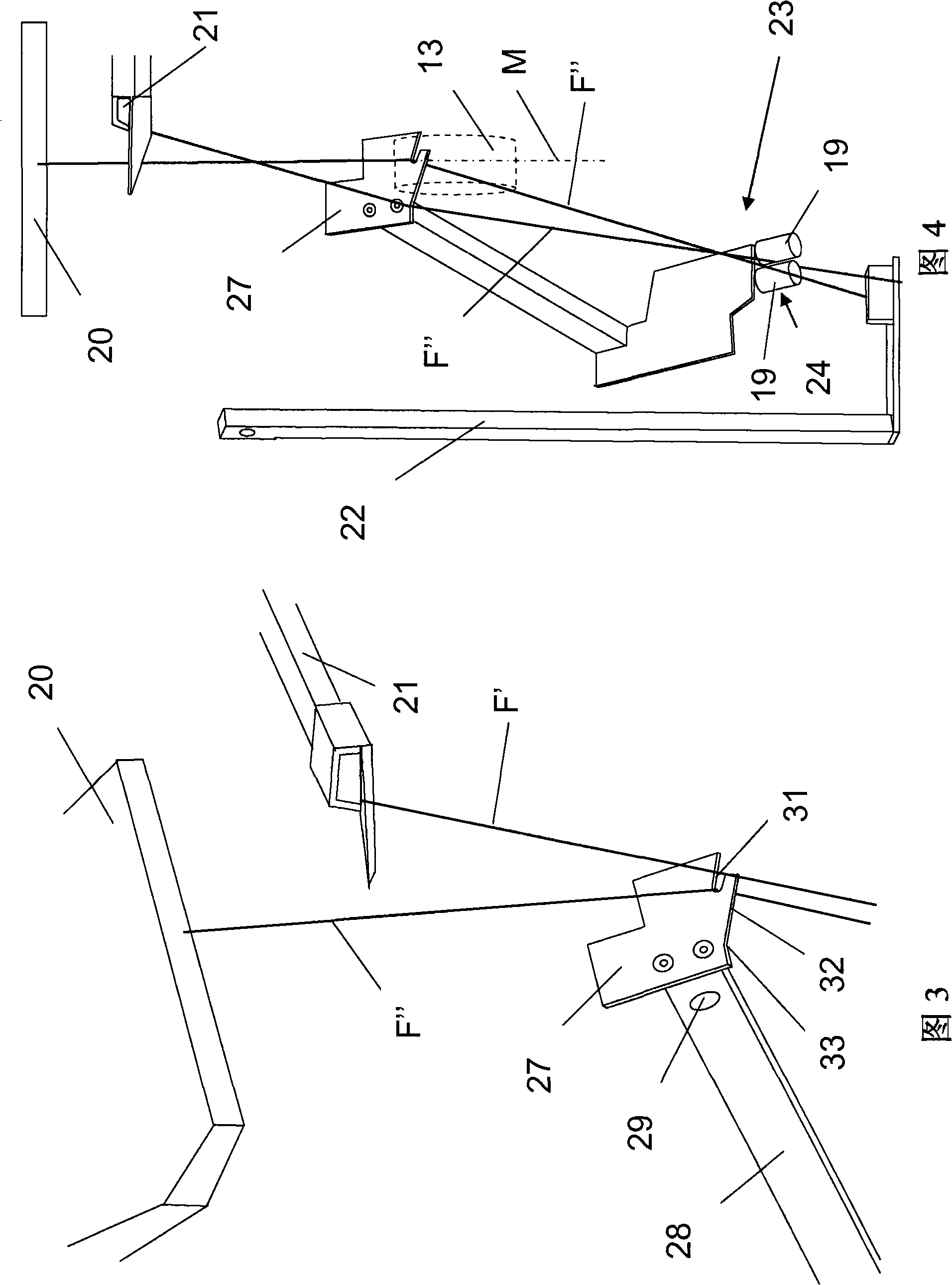

[0025] figure 1 shows an automatic spinning-in device 1 according to the invention, which is arranged in a movable maintenance device 2 (indicated by dotted lines in the figure). On the right, an open-end spinning machine 3 is also shown with dotted lines, which has many identical stations 4 arranged side by side, along which the maintenance device 2 can be moved so that Each station 4 can be maintained when needed. For this reason, maintenance device 2 has various tools, so that replace a full bobbin with for example an empty bobbin (not shown in the figure), the yarn of empty bobbin is started up, or after yarn breakage The yarn is threaded up and the spinning operation is restarted. According to another embodiment of the invention, the automatic spinning-in device 1 is not arranged on a movable maintenance device 2 , but each station 4 of the open-end spinning machine 3 has an automatic spinning-in device 1 .

[0026] Each station 4 of the open-end spinning machine 3 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com