Detection sensor and detection method for angle of rocker arm of coal cutter

An angle sensor and angle detection technology, which is applied in the direction of instruments, measuring devices, earthwork drilling and mining, etc., can solve the problems of high anti-interference ability and precision requirements of sensors, difficult installation and maintenance, and unsuitable interfaces, so as to realize automatic measurement , not easy to break down, and achieve convenient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

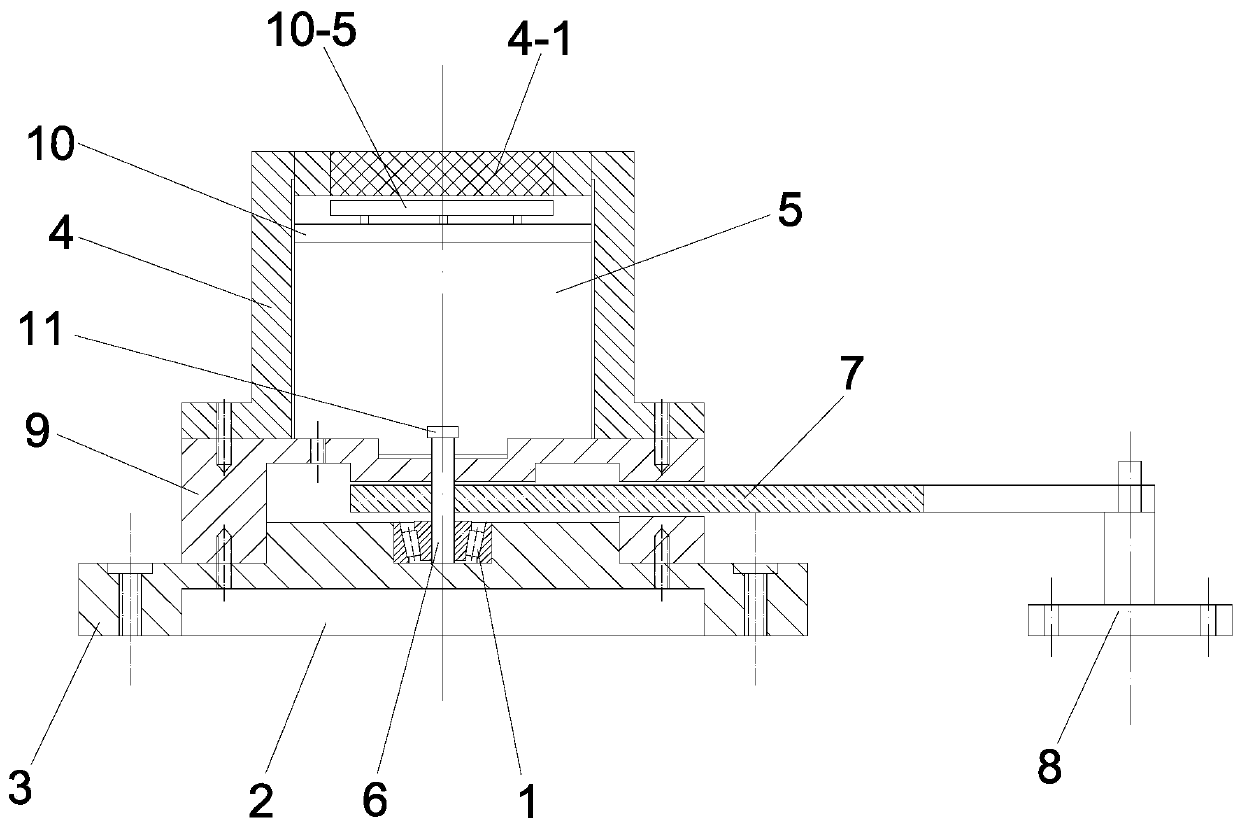

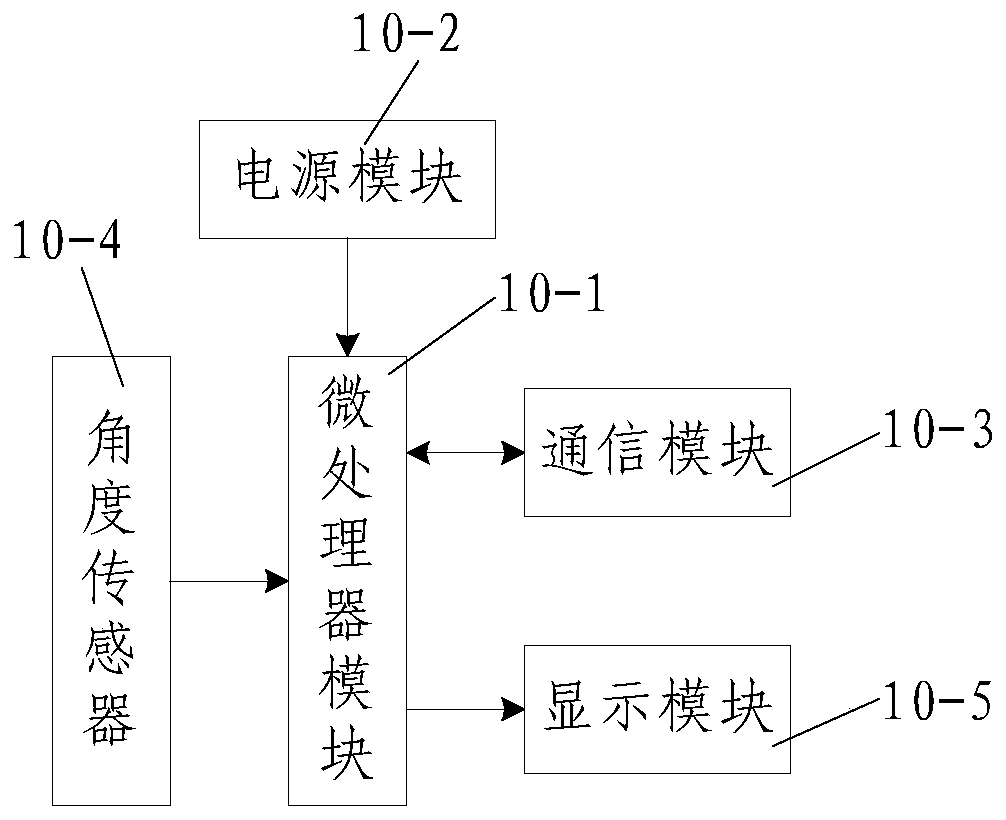

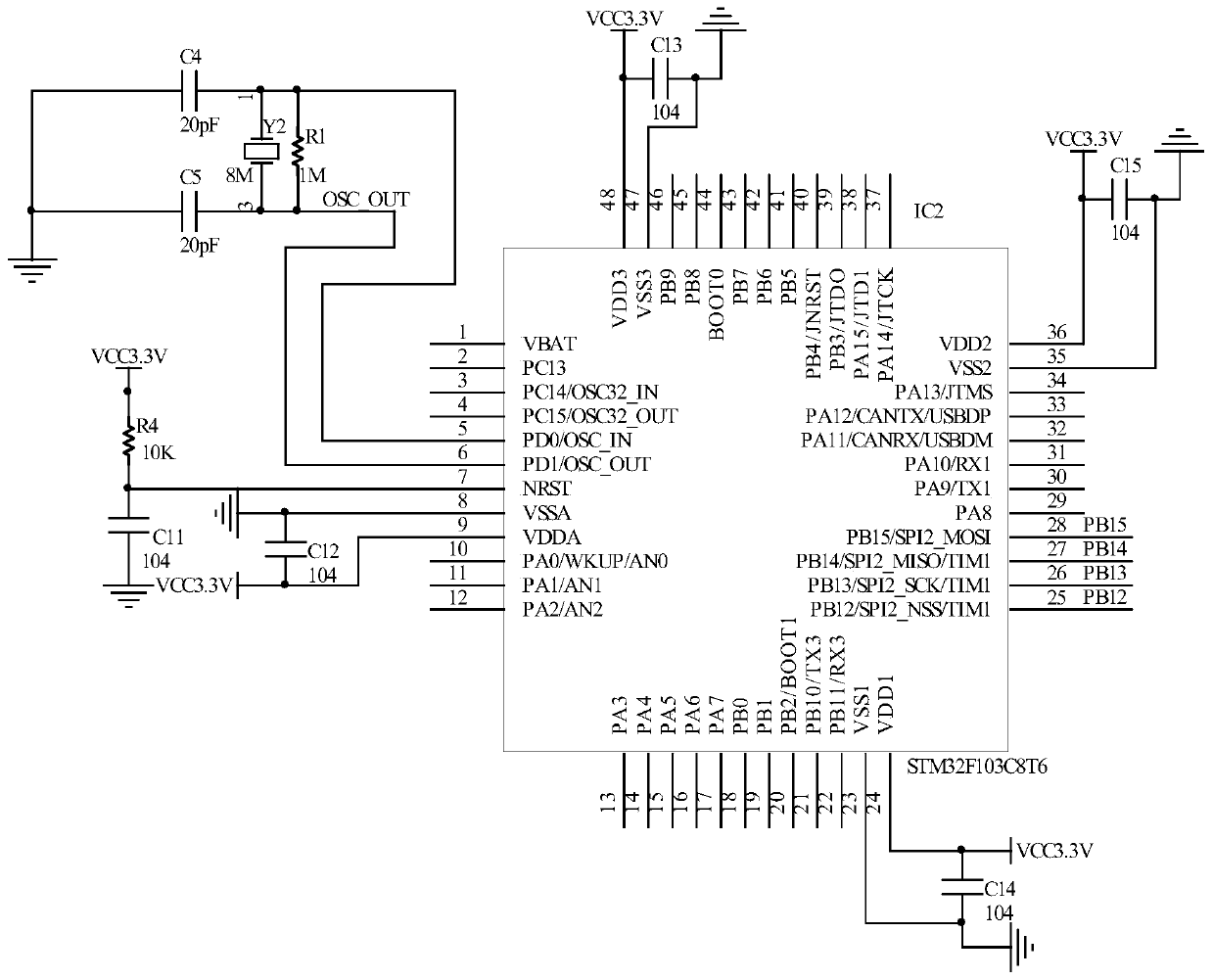

[0038] Such as figure 1 As shown, the rocker arm angle detection sensor of the present invention includes a base 3 and a base top cover 9 installed on the top of the base 3, and one end is arranged between the base top cover 9 and the base 3, and the other end passes through the base top. The rocking bar 7 outside the cover 9; the base 3 is rotatably connected with a rotating shaft 6 extending out of the base top cover 9 through a bearing 1, and the rocking bar 7 is fixedly connected with the rotating shaft 6, and the rocking bar 7 is not connected with the rotating shaft 6. One end of the fixed connection of the rotating shaft 6 is connected with a connecting seat 8 for connecting with the rocker arm of the coal shearer. The top of the rotating shaft 6 passes through the outside of the base top cover 9 and is provided with a circular magnetic steel 11. The base top cover 9 The top is connected with a sensor protective case 4, the inner cavity of the sensor protective case 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com