Pipe fitting length integrated detection device

A detection device and an integrated technology, which is applied in the field of pipe fitting length integrated detection devices, can solve the problems of low detection efficiency in the production line, cumbersome manual detection process, high error rate, etc., so that errors are not easy to occur, the process time is short, and the error rate is reduced. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The integrated pipe length detection device of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] The model of the PLC control system is CP1E-N60SDR-A, and the brand is Omron.

[0021] The model of the coms displacement sensor is IL030, and the brand is Keyence.

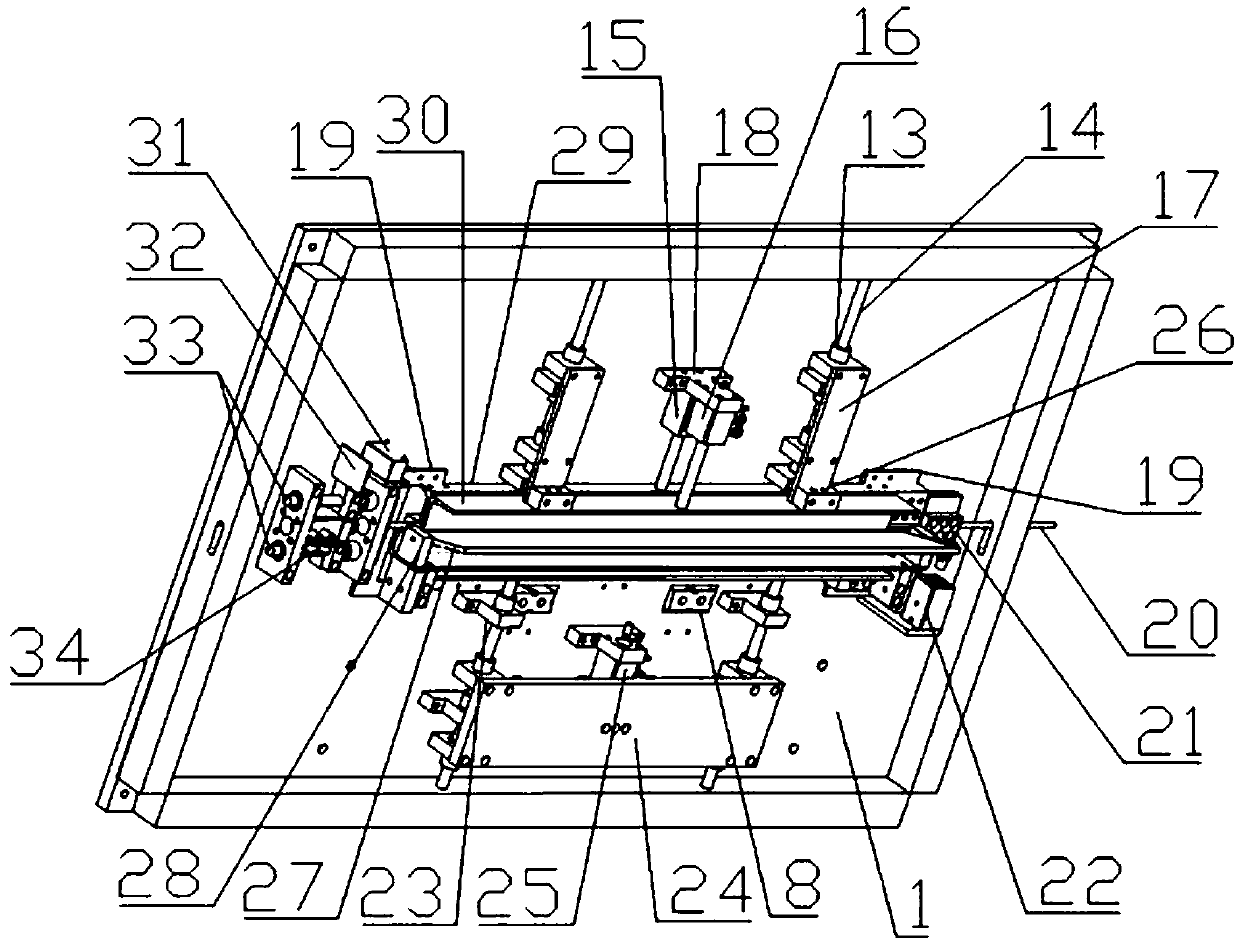

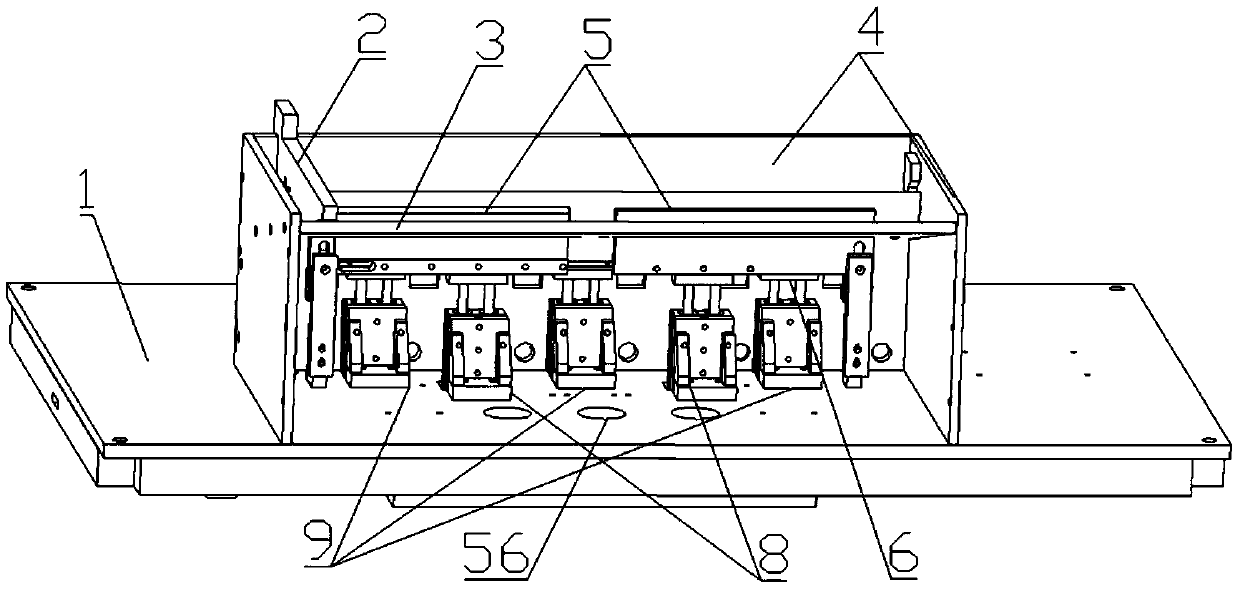

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, the integrated detection device for the length of pipe fittings includes a cap platform 1 equipped with a complete set of automatic detection devices. The cap platform 1 is provided with a feeding mechanism for normal and orderly control of pipe fitting transmission. Mechanism and limit fixing mechanism, the bottom surface of cap platform 1 is also provided with a measuring mechanism for measuring the length of pipe fittings; the feeding mechanism is provided with a vertical drop passage 7; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com