Post-loading monitoring method for composite pile

A rear-mounted, combined pile technology, which is applied in the direction of measuring force, measuring devices, and infrastructure tests, can solve the problems of lack of reliable support for distributed optical fibers, inability to control temperature of distributed optical fibers, and damage and failure of distributed optical fibers. Achieve the effects of simple installation process, convenient measurement, and small impact on the measurement environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as figure 1 As shown, a post-installation monitoring method for composite piles, the specific steps are as follows:

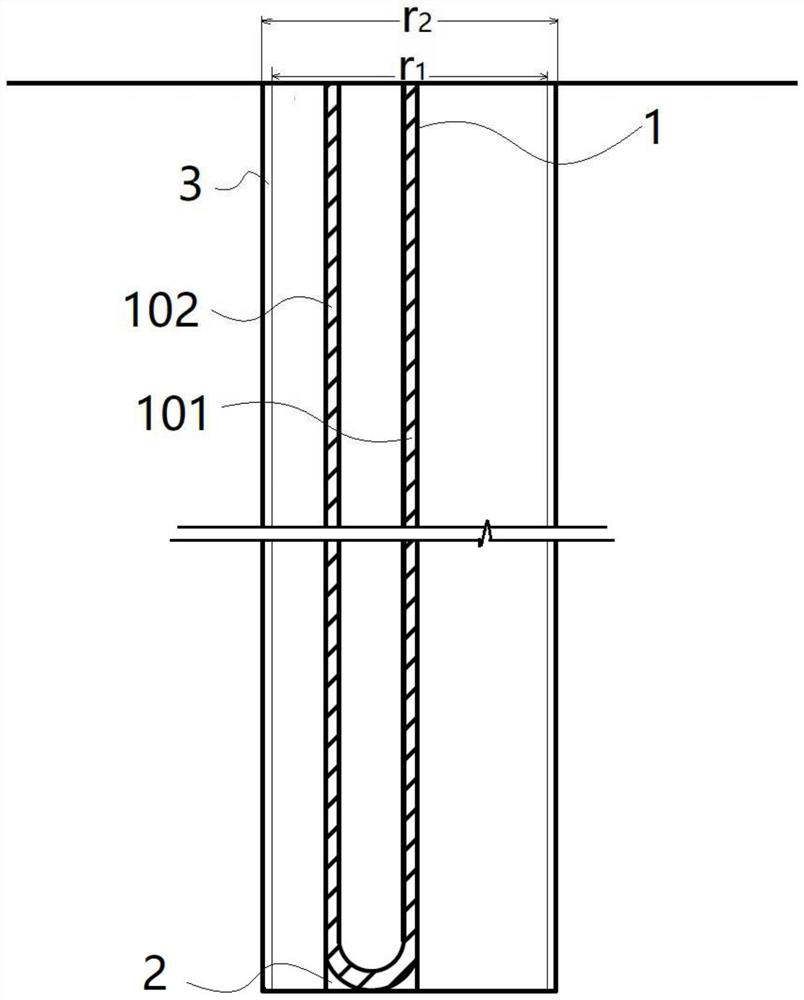

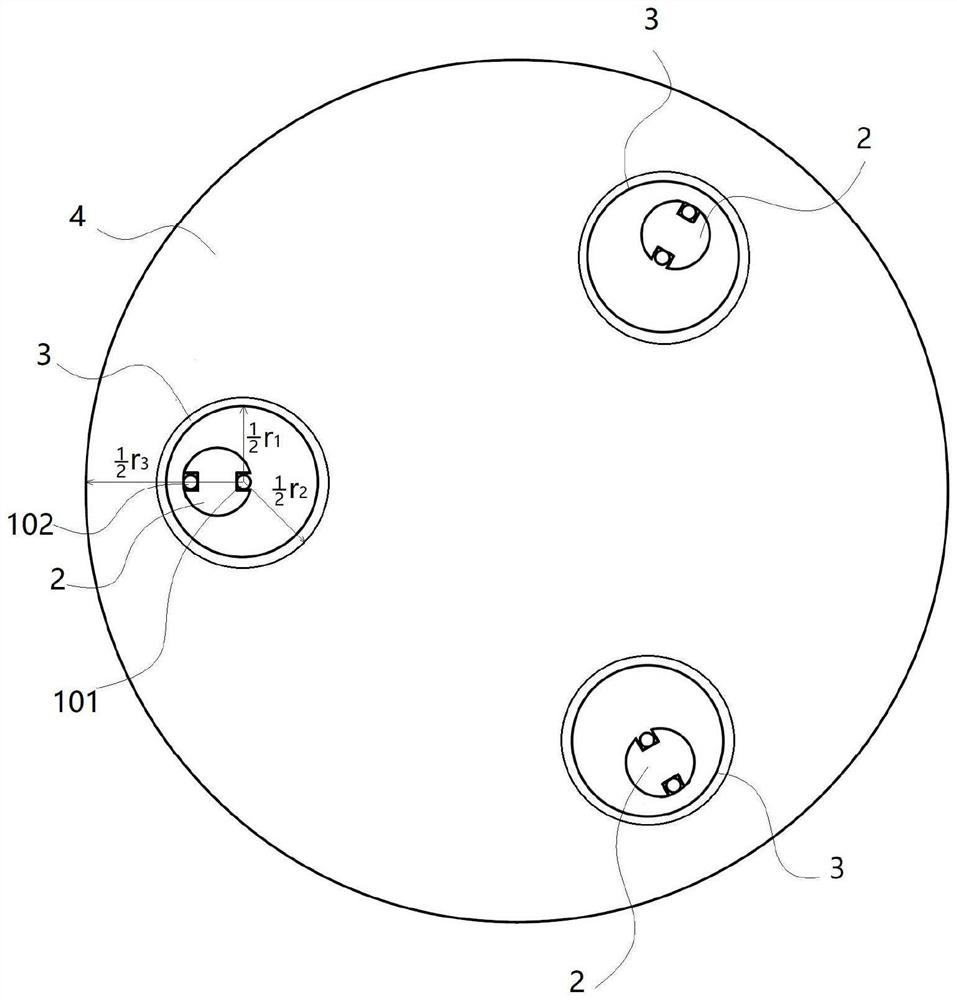

[0046] S1, fix, fix the distributed optical fiber 1 on the specified position of the PVC pipe 2, the PVC pipe 2 is respectively provided with a sealing groove 201 and an open groove 202, a section of the distributed optical fiber 1 is installed in the open groove 202, and the distributed optical fiber 1 The other section is installed in the sealing groove 201;

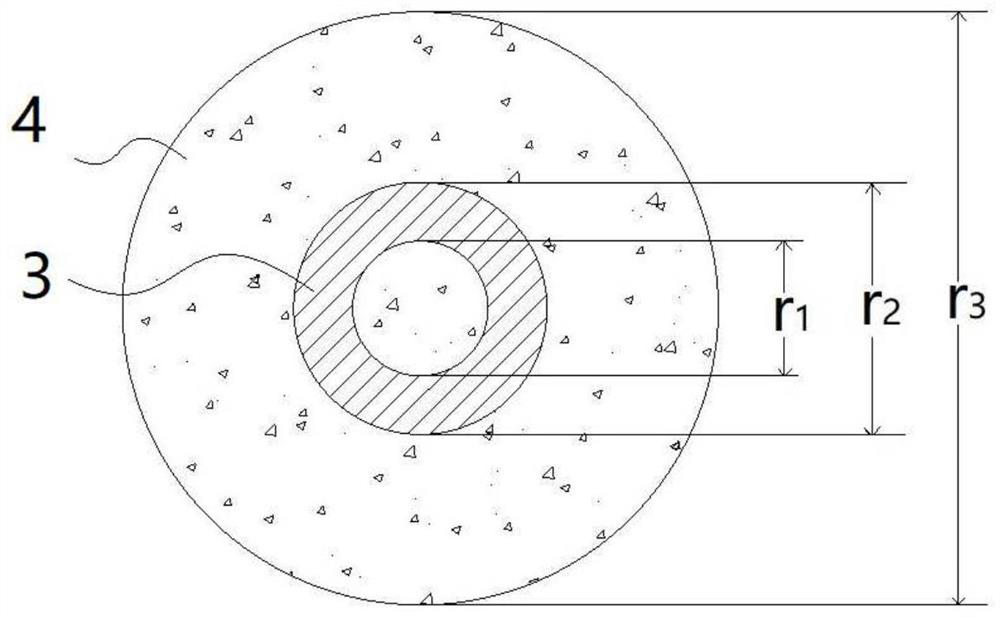

[0047] S2, installation, bonding and combining the PVC pipes into a specified length, then inserting the PVC pipe into the acoustic measuring tube 3 of the first cast-in-place pile 4, and then inserting the PVC pipe with distributed optical fiber 1 into the next cast-in-place pile 4 In the acoustic measuring pipe 3, the PVC pipe is fixed by grouting through the mouth of the PVC pipe 2; a section of the distributed optical fiber 1 is installed in the open groove 202, and after the grouting, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com