Patents

Literature

105results about How to "Realize non-contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

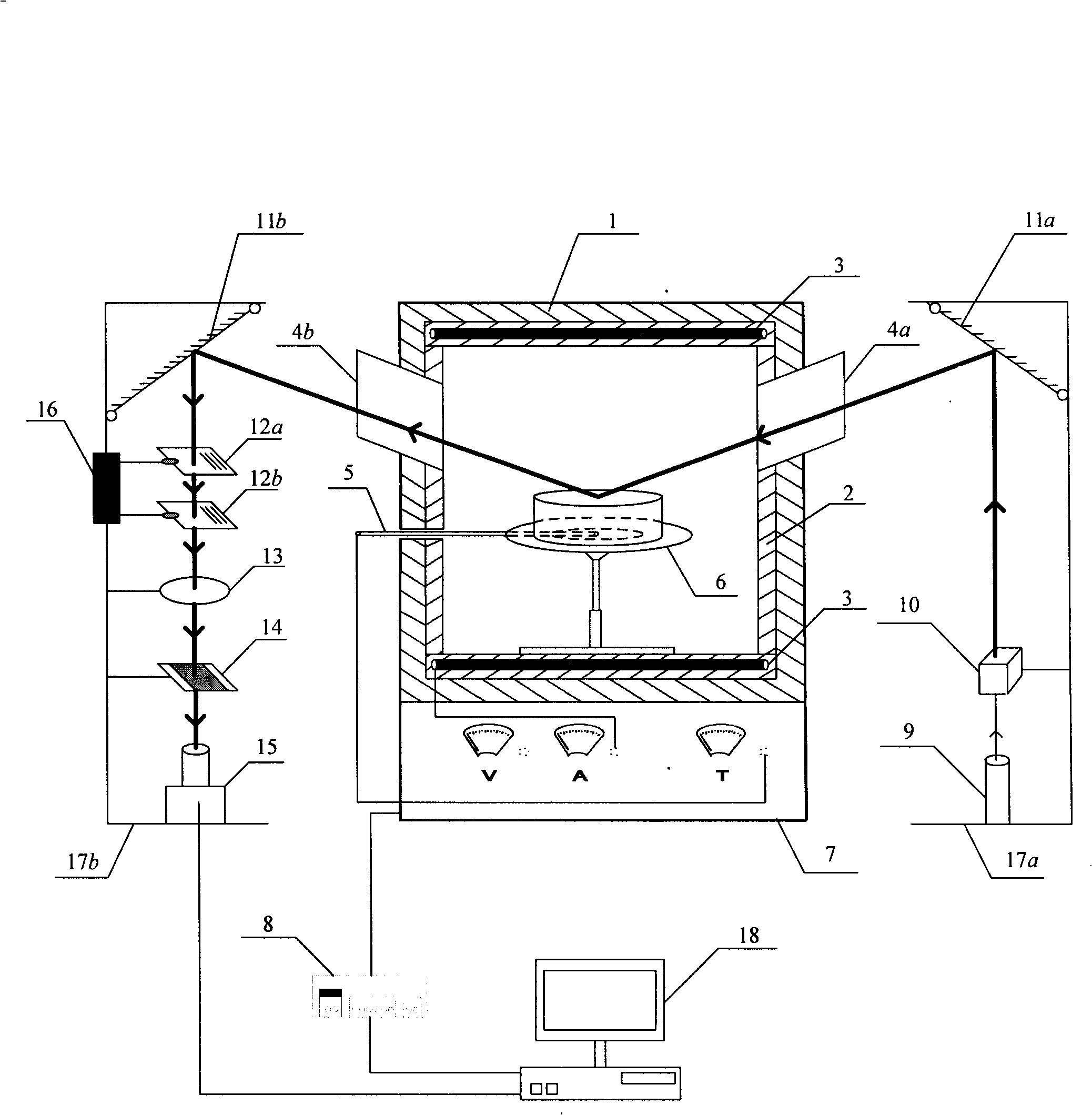

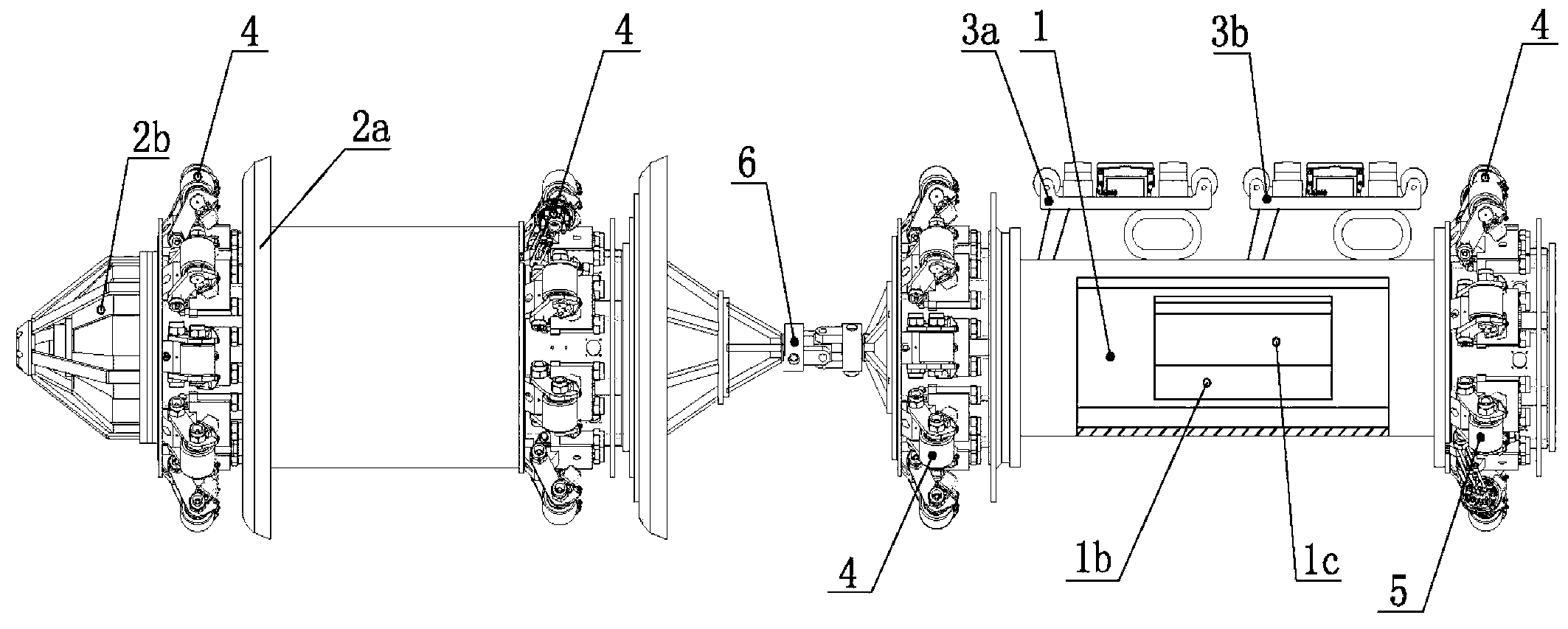

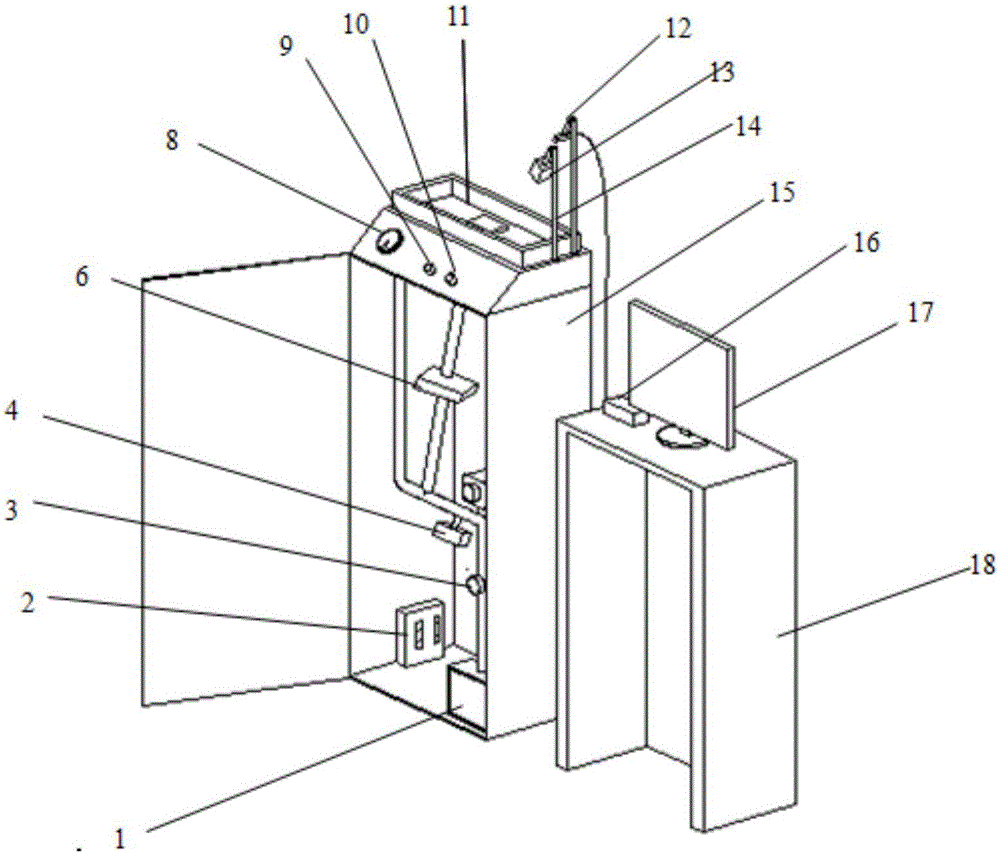

Test device for simulating and testing thermal fatigue failure of high-temperature part in real time

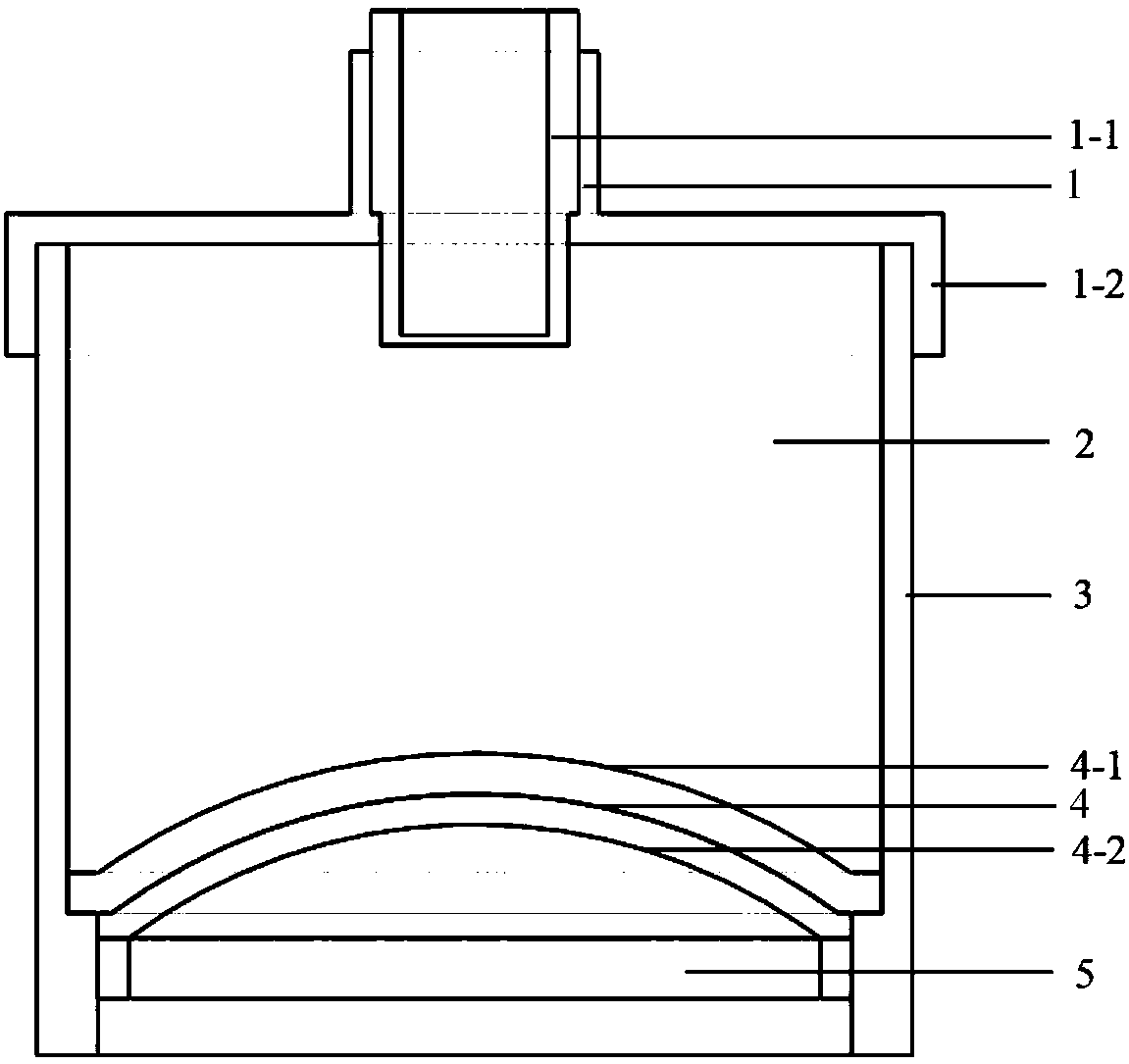

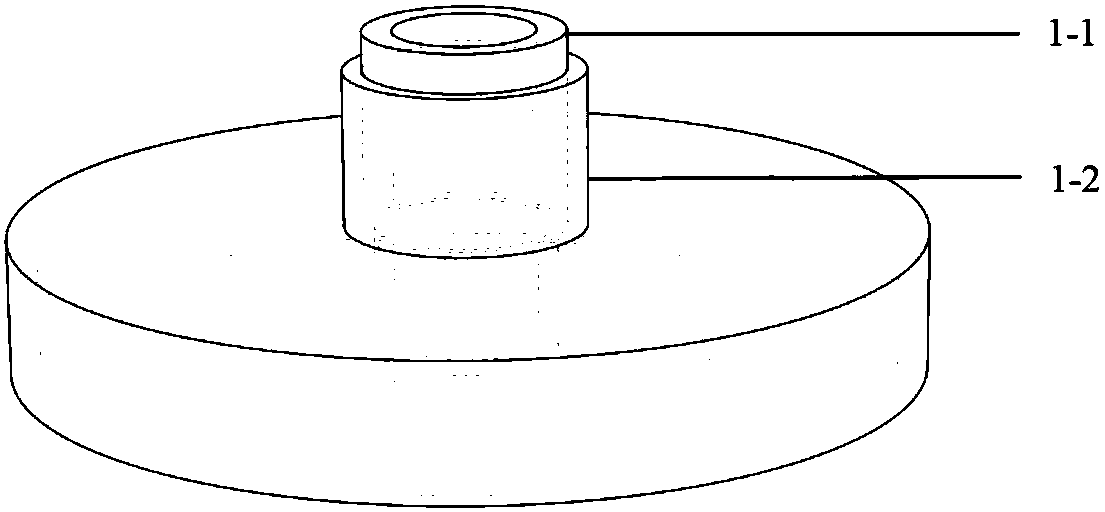

ActiveCN101762452AFast heating and cooling ratesWide temperature rangeWeather/light/corrosion resistanceHeating systemInterfacial oxide

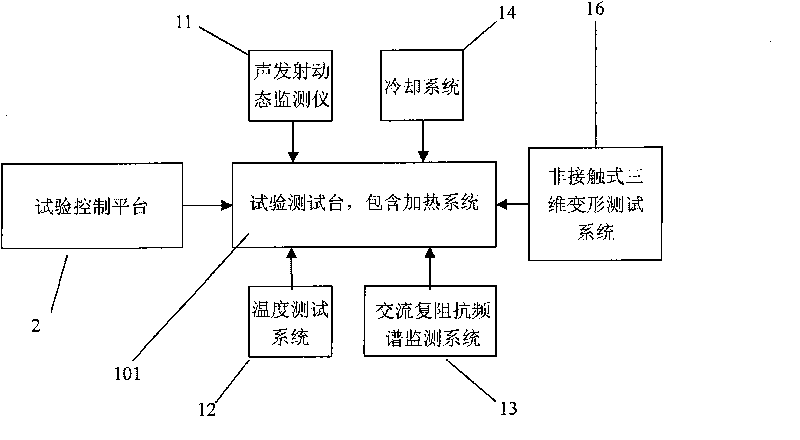

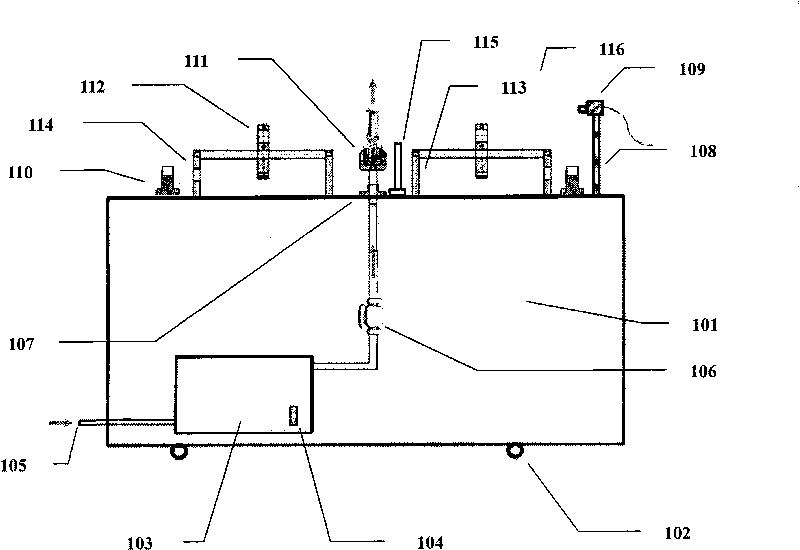

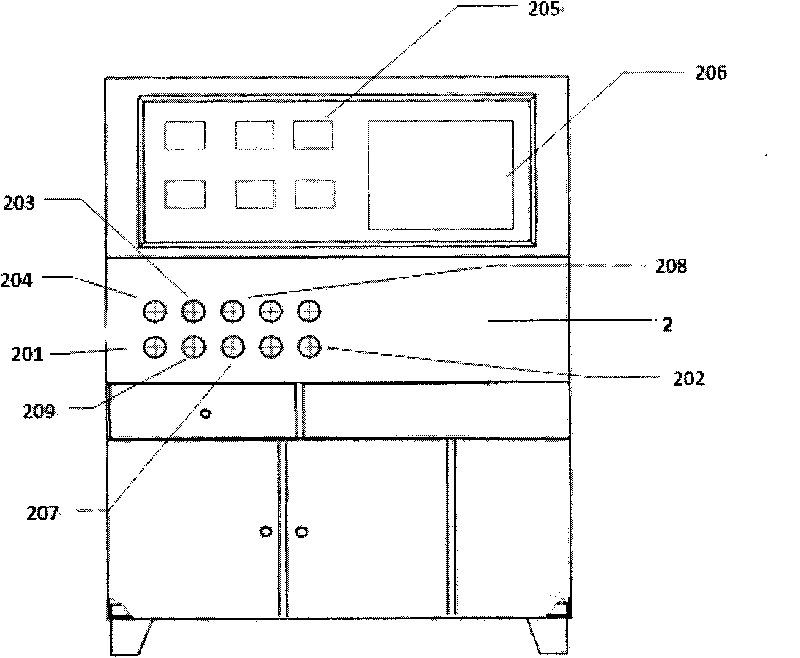

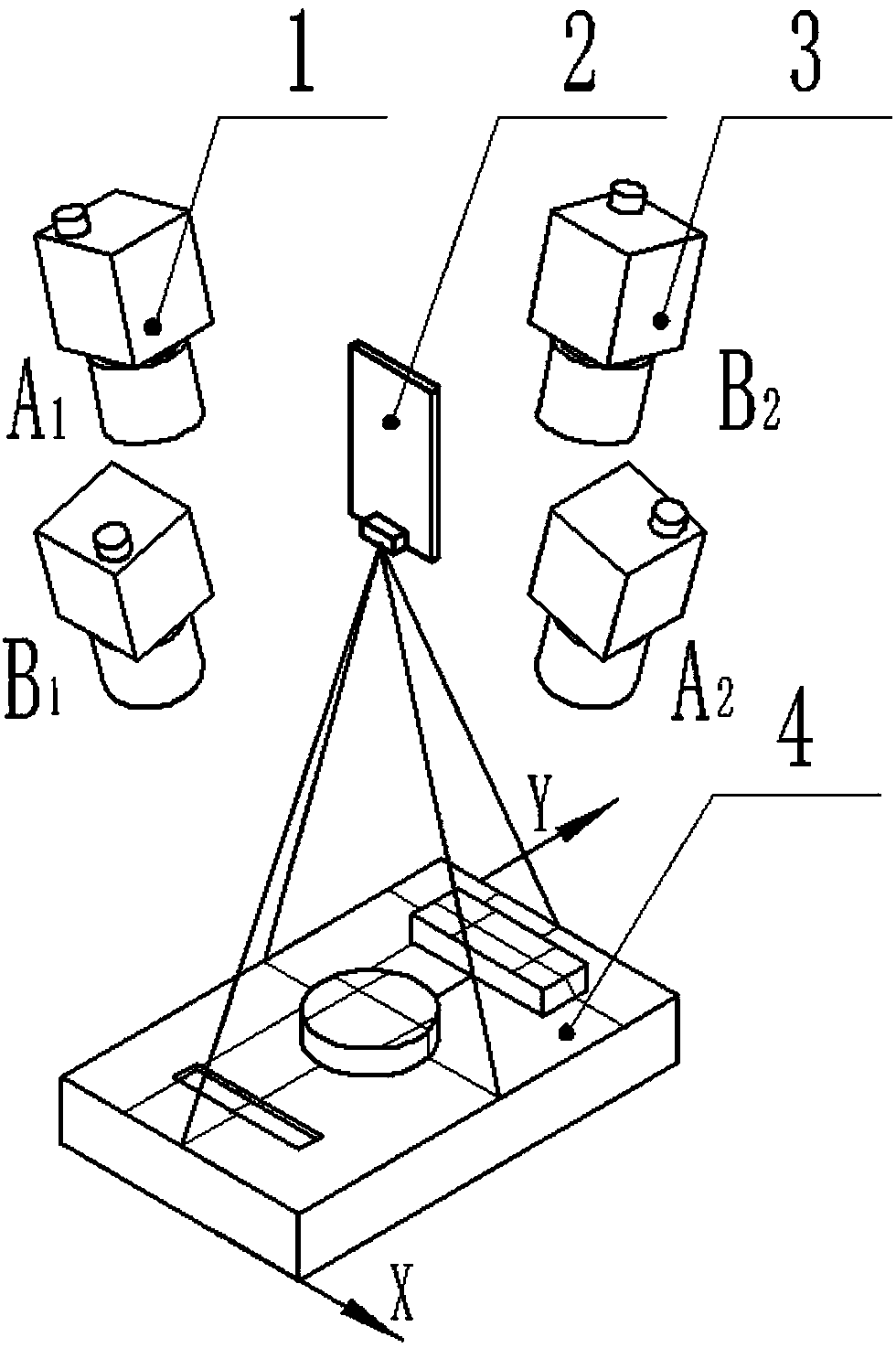

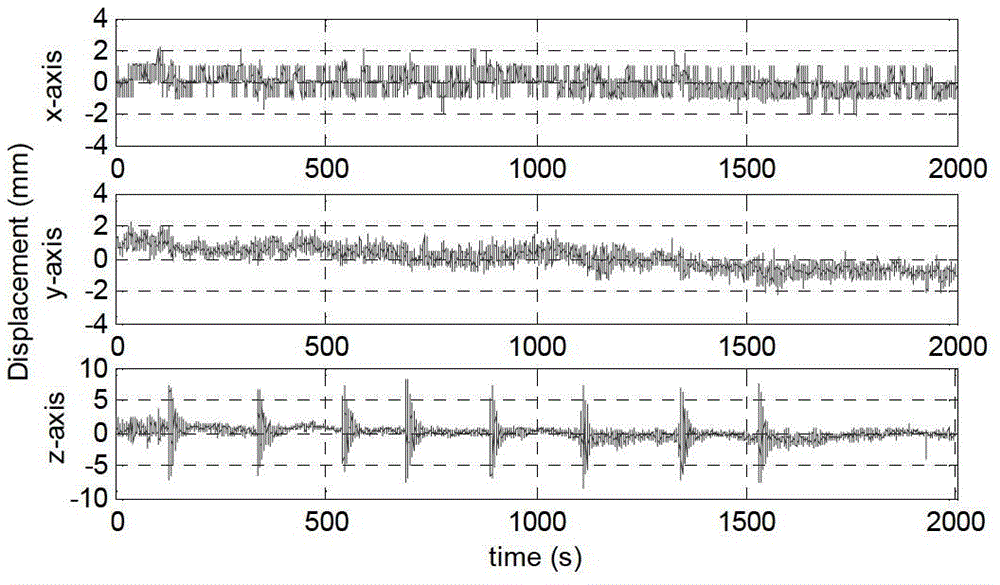

The invention belongs to the field of high-temperature part detecting equipment, in particular to a test device for simulating and testing the thermal fatigue failure of a high-temperature part in real time. The device mainly comprises a high-temperature gas two-way heating system, a real-time temperature testing and collecting system, a cooling system, an ARAMIS non-contact three-dimensional deformation test system, a PCI-2 AE non-destructive detection system, a 1260+1296-type material electric property AC impedance spectroscopy test system, a test control platform and the like. The device can simulate the thermal fatigue work environment of alternating temperature cycle in a high-performance aircraft engine, and synchronously realize the real-time testing and the analysis to the sample temperature, temperature gradient, surface morphology image evolution, three-dimensional deformation field, three-dimensional displacement field, interfacial oxide layer and thickening law, thermal fatigue crack initiation and propagation, cooling gas flow and other data. The device can provide an important experimental platform for effectively evaluating the fatigue failure process and the failure mechanism of the high-temperature part in the high-temperature thermal cycle environment.

Owner:XIANGTAN UNIV

Array type parallel laser projection three-dimensional scanning method

The invention discloses an array type parallel laser projection three-dimensional scanning method. The array type parallel laser projection three-dimensional scanning method comprises steps that a laser micro-vibration mirror projection device used for projecting line lasers in different directions and a plurality of array type cameras used for data acquisition are provided; laser cutter separation of each acquired image in different directions is carried out, and the laser cutter centers of the laser cutters in various directions are respectively extracted, and according to a triangle relation among the projection device and the cameras, an object surface three-dimensional coordinate of a line laser position is acquired; the projection device is used to move the line laser on the object surface by one pixel each time, and the above mentioned process of extracting the object three-dimensional coordinate on the laser cutter position is repeated until the three-dimensional coordinate of the whole object surface is acquired by the laser cutter. The laser projection device adopts MEMS scanning vibration mirror laser, and compared with a digital light and physical grating technology, field depth is large, scanning speed is fast, a size is small, and scanning precision is high; and at the same time, the system is used to distribute the cameras in an array, and then the sensitivity to complicated step edge measurement is provided, and then the non-contact, high-speed, and object edge step high precision measurement of the object is realized.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

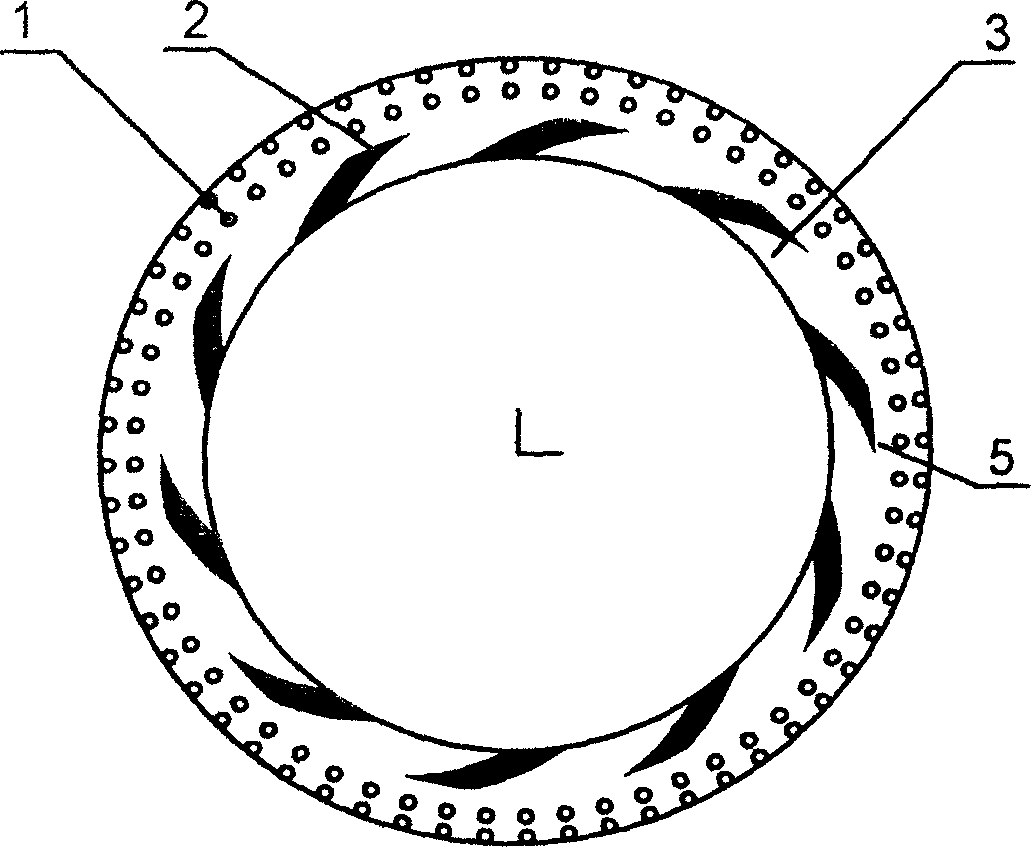

Non-contact mechanical end face sealing structure

InactiveCN1828098AImprove sealing abilityExtended service lifeEngine sealsCentre of rotationEngineering

The invention relates to a non-contact mechanical end surface sealing structure, which comprises mechanical sealed movable ring and stable ring. While the end surface of stable or movable ring has micro groove and porous zone that symmetry according to the rotational center. Wherein, said zone is at the ascending part of end surface and the micro groove is at the descending part, which has a circular sealing dam beside it. The invention can be used in variable mediums to increase the ability of solid particle, the static pressure property, fluid dynamic pressure property and the pump adsorption property, to attain better sealing effect, with long service life.

Owner:ZHEJIANG UNIV OF TECH

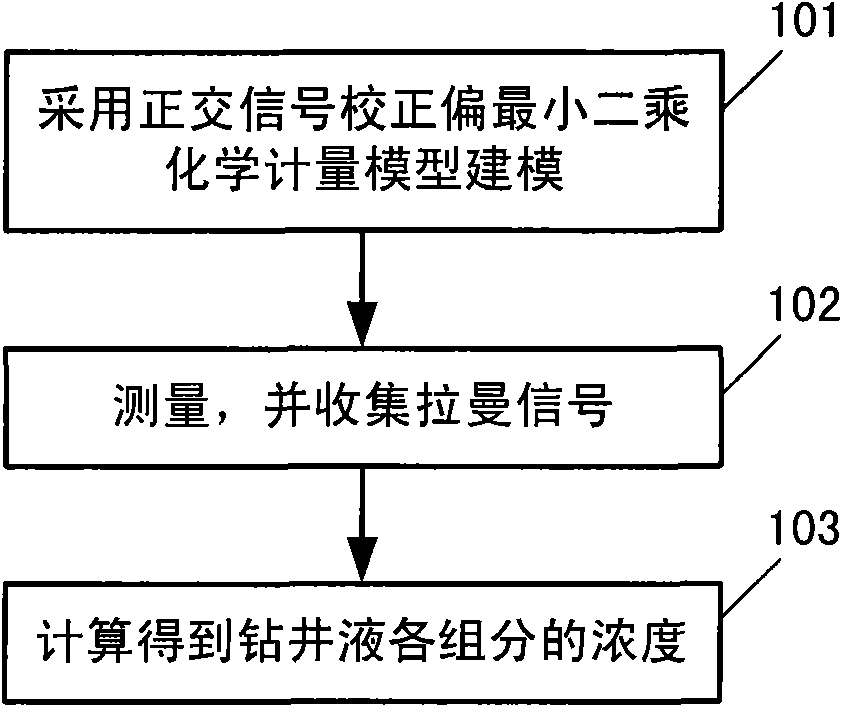

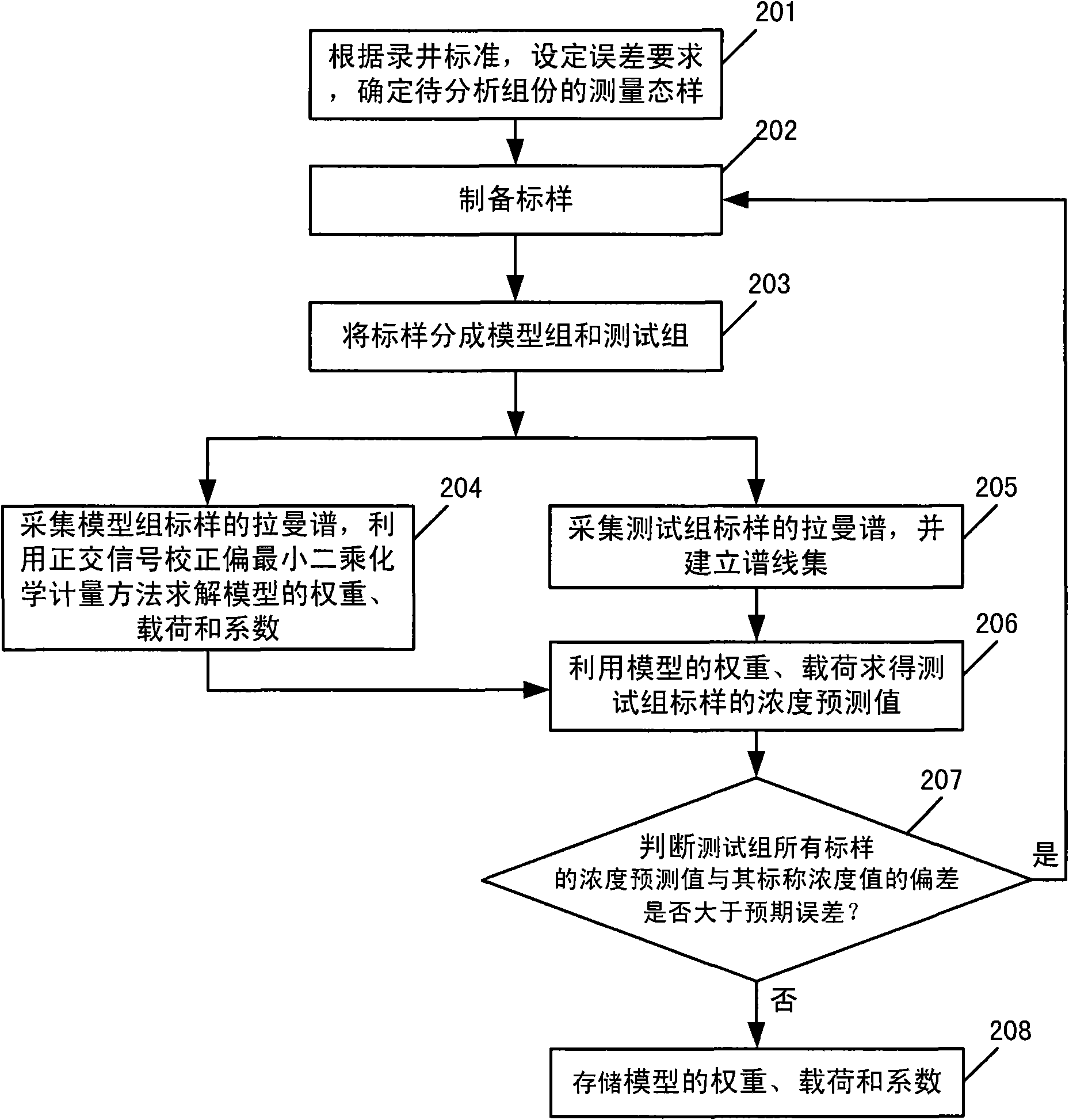

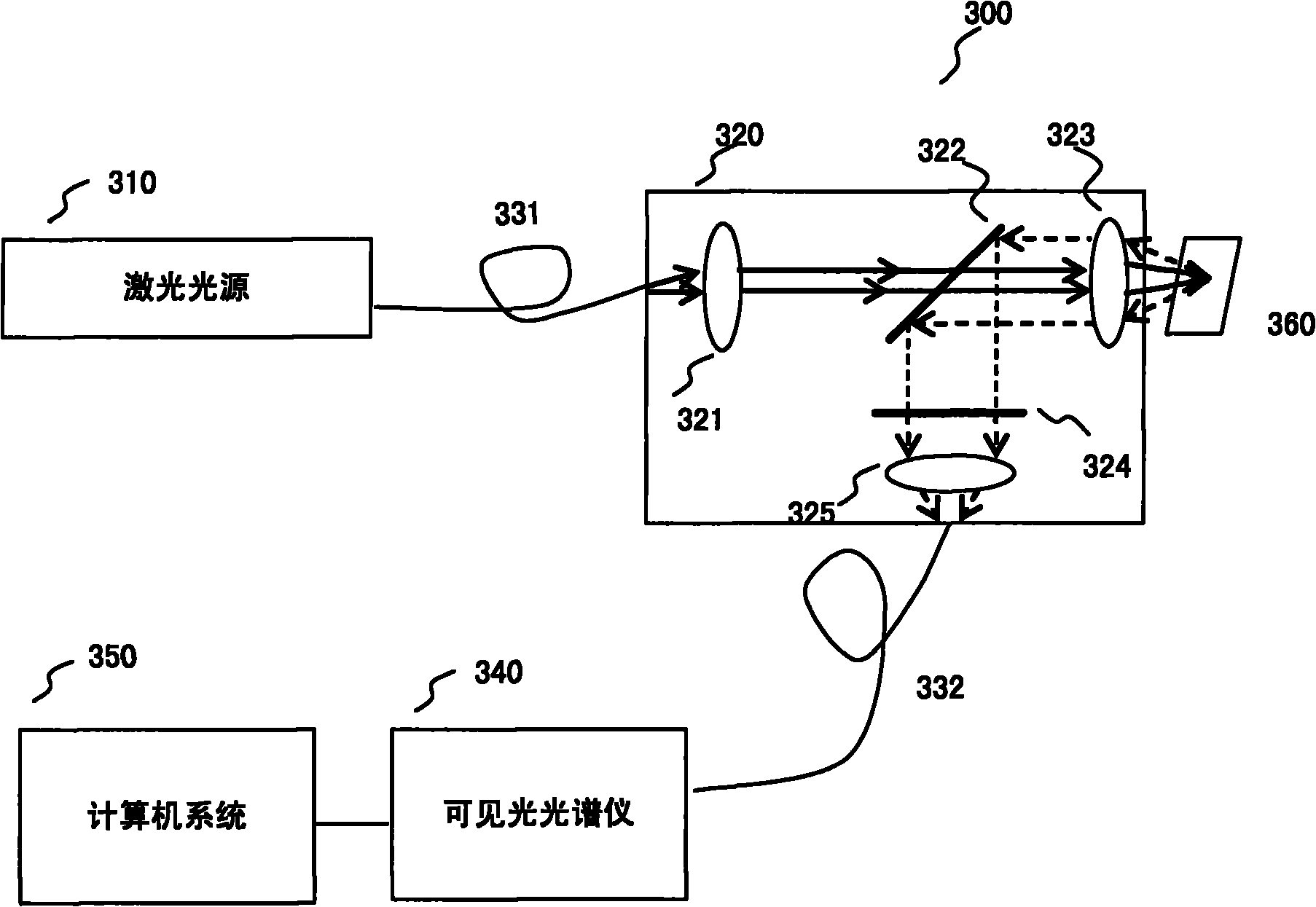

Method for performing online Raman spectral analysis on drilling fluid

The invention relates to a method for measuring all components of drilling fluid through online Raman spectra. The method comprises the following steps of: modeling by adopting an orthogonal signal to correct a partial least square stoichiometric model, and acquiring parameters which comprise coefficients, weights and loads and are pre-stored in the model; measuring and collecting Raman spectra of the drilling liquid; and establishing spectral line vectors by using the Raman spectra collected in the second step, and performing orthogonal signal correction on the spectral line vectors together with the coefficients, the weights and the loads which are acquired in the first step to acquire corrected vectors, predicated vectors and the concentration of the drilling liquid. The method for measuring all components of the drilling fluid through the online Raman spectra has the advantages of measuring on line without preprocessing the drilling liquid and extracting the drilling liquid, realizing non-contact and non-destructive measurements, shortening the analysis period, and improving the measurement sensitivity and precision, wherein the drilling liquid can be gas, liquid, emulsion, suspension or aerosol; and light hydrocarbon components, heavy hydrocarbon components and non-hydrocarbon components contained in the drilling liquid can be directly measured.

Owner:SHANGHAI SHENKAI GASOLINEEUM TECH +2

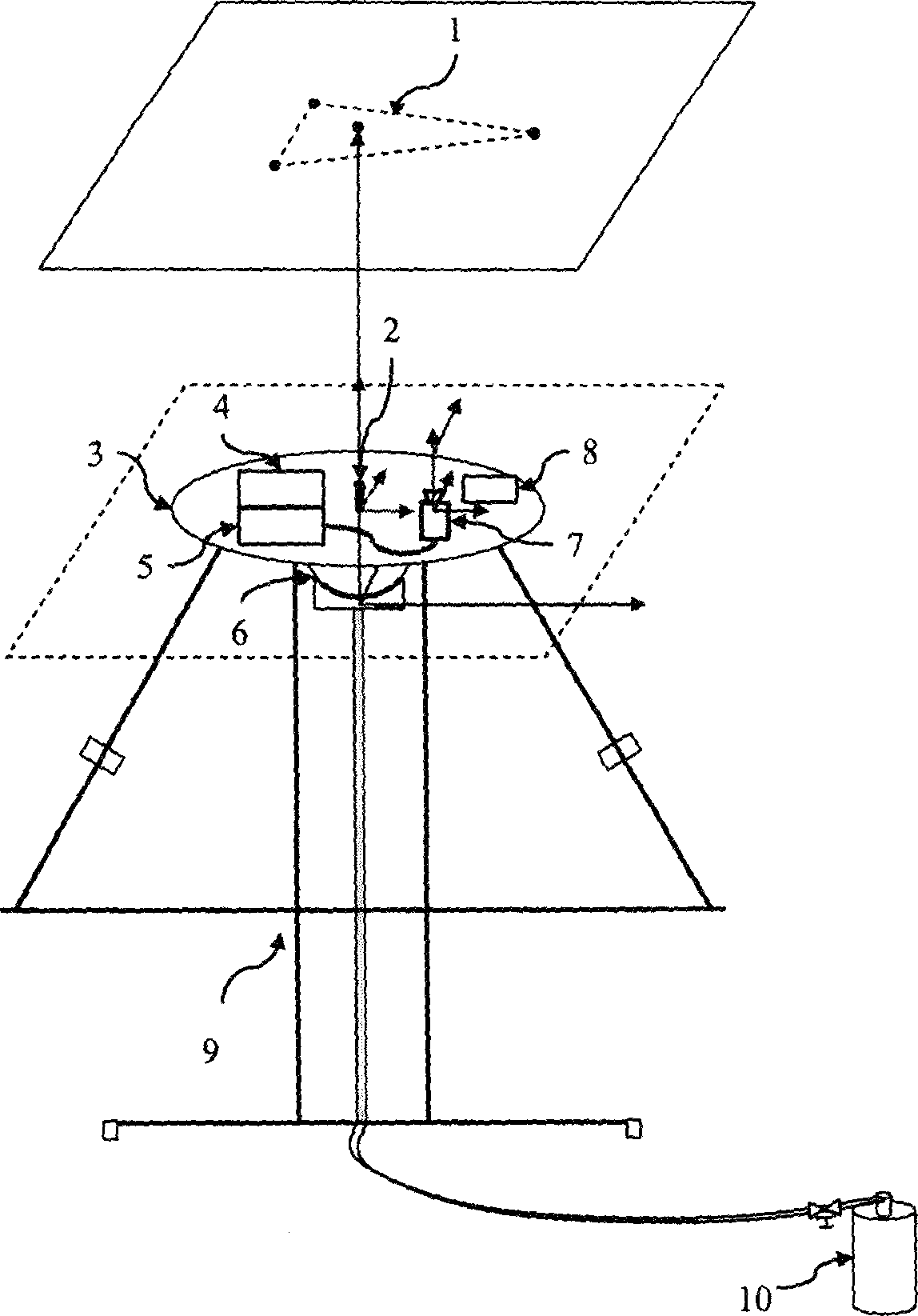

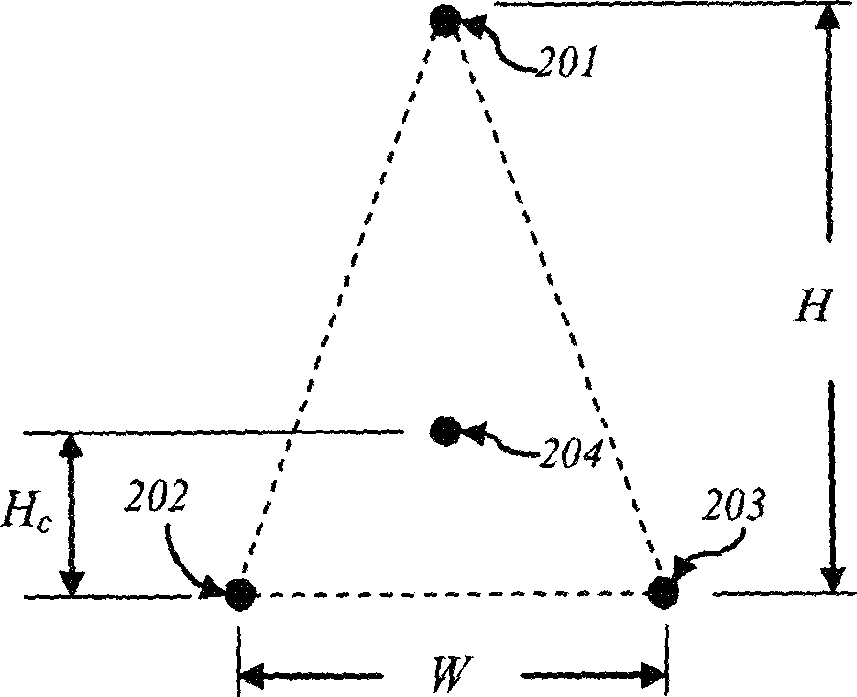

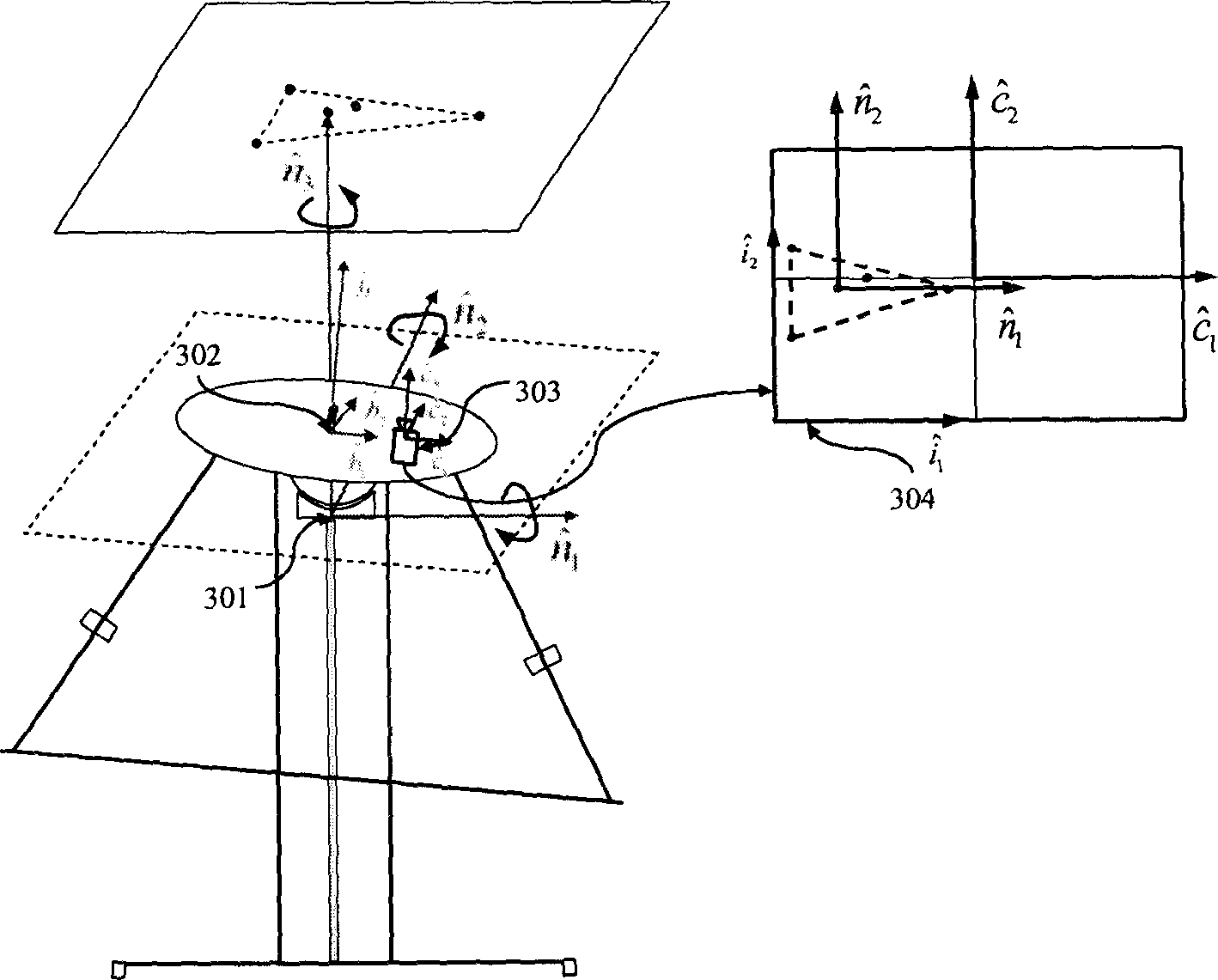

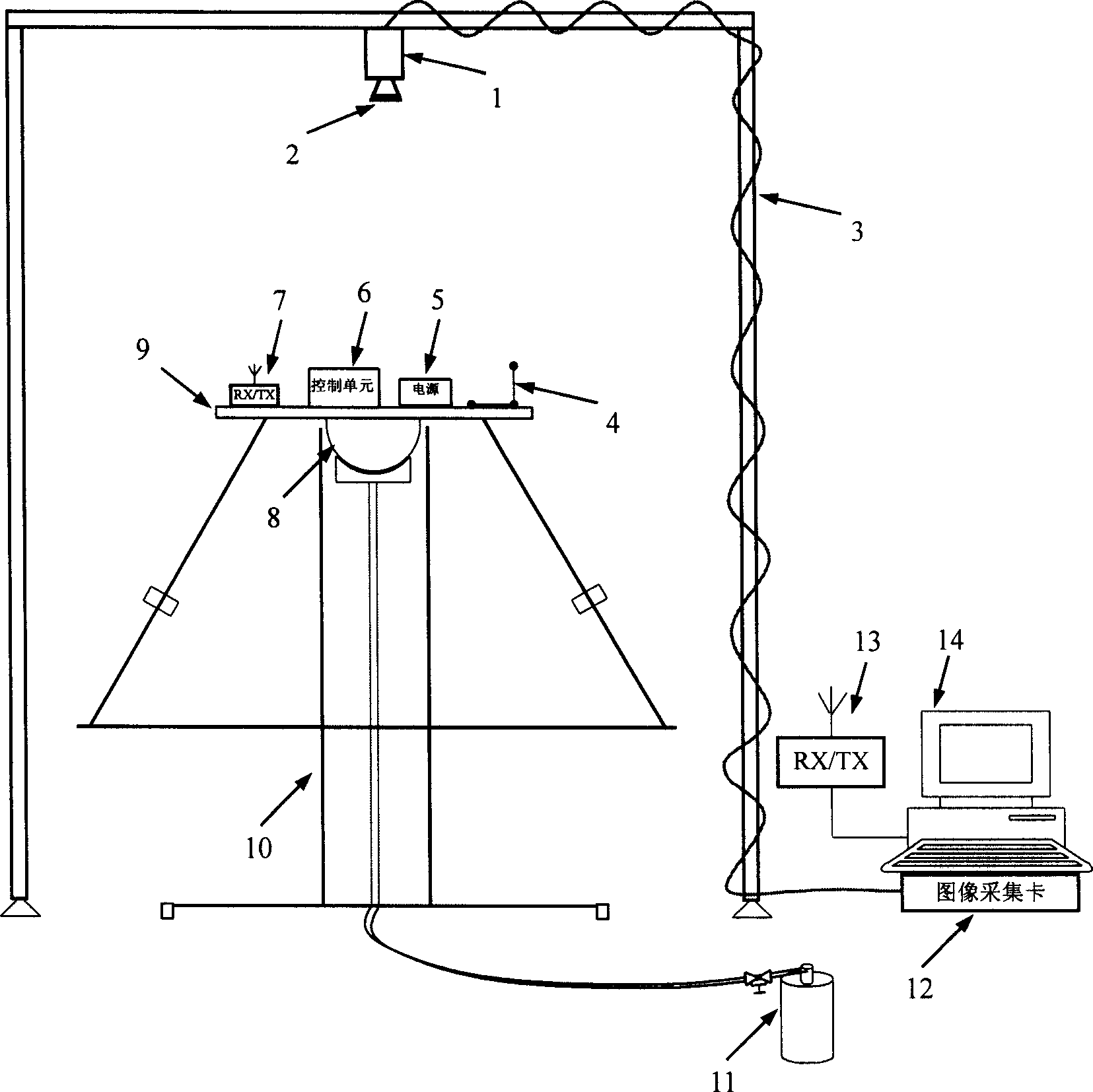

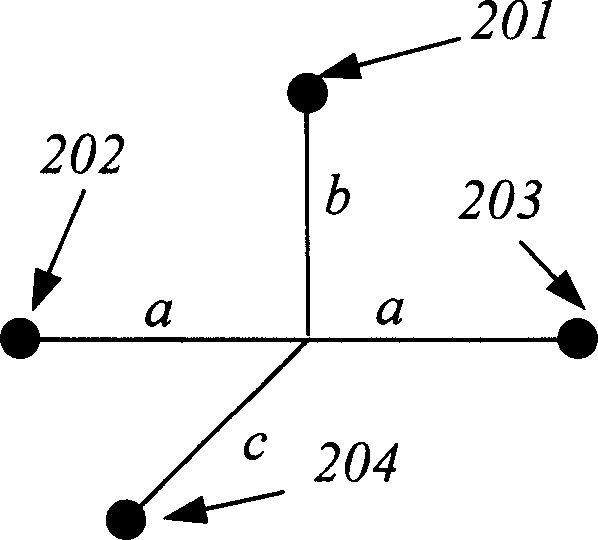

Contactless three-axle air-float stage corner measuring device and its measuring method

A method for measuring corner of gas floating table in noncontact three shafts type includes erecting green micro laser and color CCD camera on table surface (TS) connecting CCD camera to image collecting card and erecting said card in TS control unit, setting measurement target formed by four red LED and white base plate above said table, using CCD camera to collect image formed by light points made on white base plate by said LED and micro laser, calculating out rotation parameter of TS by utilizing erection information of said target and CCD camera, obtaining said image continuously for realizing corner measurement of said table.

Owner:HARBIN INST OF TECH

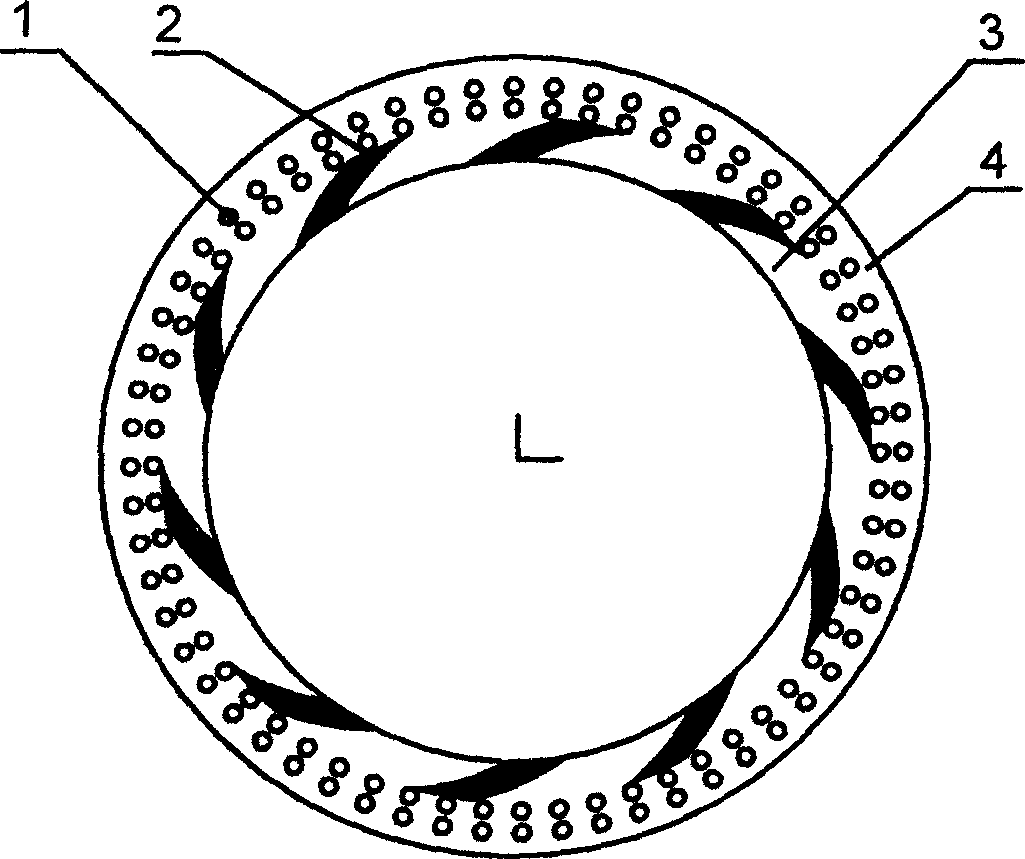

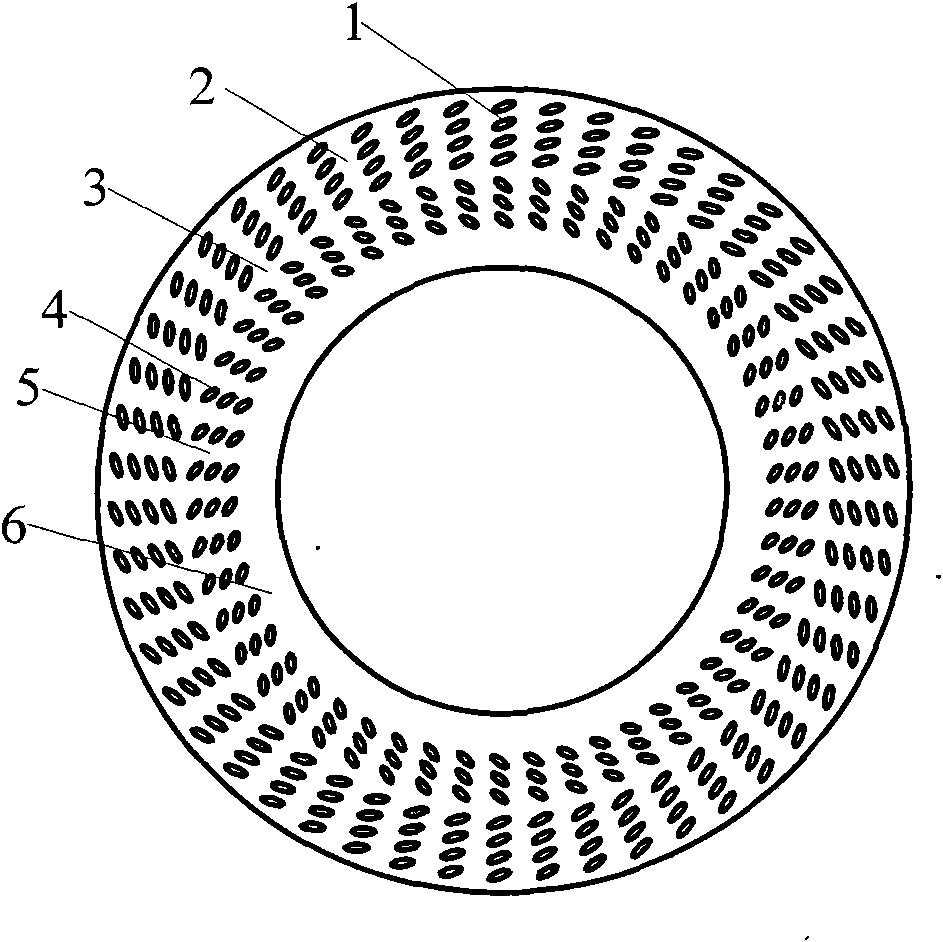

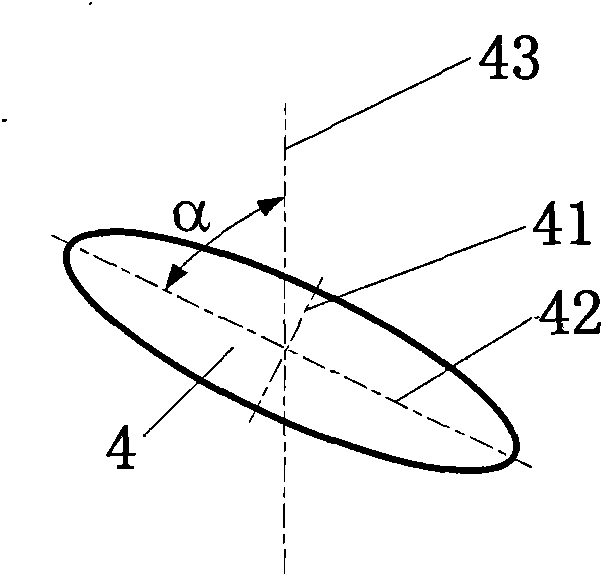

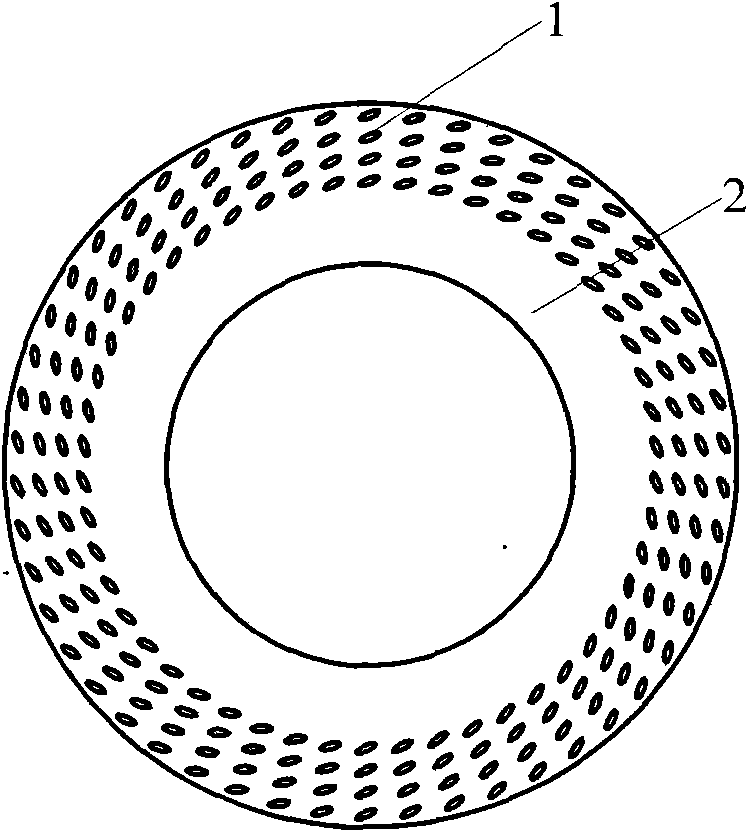

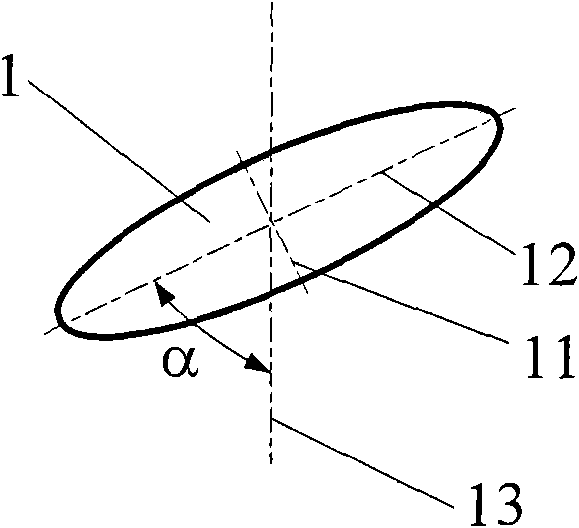

Double-row tilting directional microporous end surface no-leakage mechanical sealing structure

ActiveCN101672364AImproved hydrodynamic effect and tightnessGood start and stop effectEngine sealsDouble rowEngineering

The invention relates to a double-row tilting directional microporous end surface no-leakage mechanical sealing structure, comprising a dynamic ring and a static ring which are sealed mechanically, wherein one side of the end surface of the dynamic ring or the static ring is an high-voltage side, namely an upstream part, and the other side thereof is a low-voltage side, namely an downstream part,the end surface of the dynamic ring or the static ring is provided with an outer microporous ring belt and an inner microporous ring belt; microporous long shafts of the outer microporous ring belt and the inner microporous ring belt are opposite to the direction of a tilting angle of the diameter of the sealing end surface passing through the center of the micropore; the outer microporous ring belt and the inner microporous ring belt are respectively arranged on the upstream part and the downstream part of the end surface; and a continuous ring-shaped sealing dam are respectively arranged between the outer microporous ring belt and the inner microporous ring belt and the downstream part of the inner microporous ring belt. The mechanical sealing structure has the beneficial effects of: realizing no contact, wear resistance and no leakage of sealing, prolonging the service life and improving the sealing reliability.

Owner:ZHEJIANG UNIV OF TECH

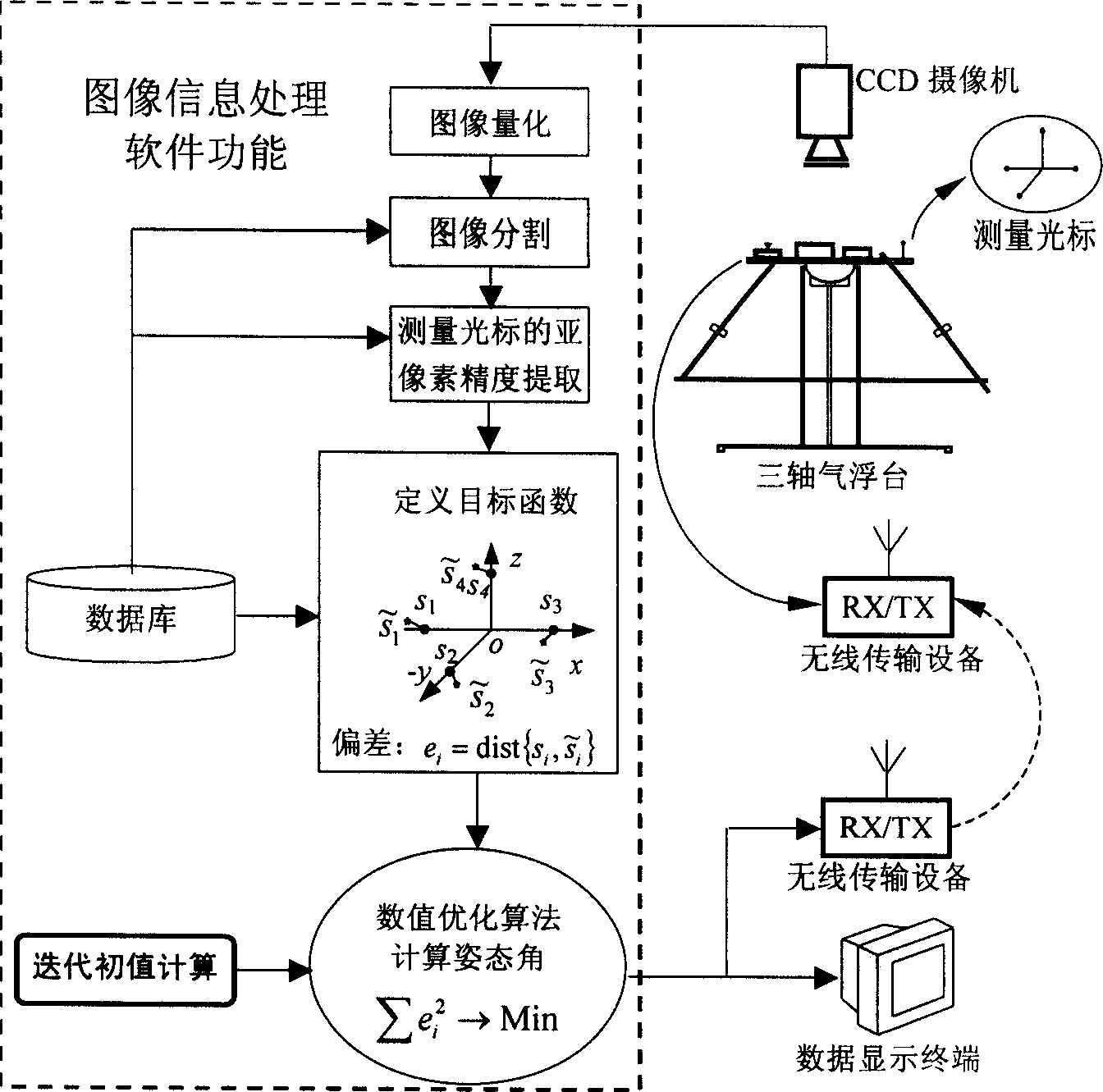

Apparatus and method for measuring attitude angle of three-axis air-bearing table

InactiveCN1877247AFilter out noiseRealize non-contactStructural/machines measurementUsing optical meansMeasurement deviceAir bearing

The invention provides a device and a method for measuring attitude angle of a three-axis air-bearing table. The three-axis air-bearing table has a cursor measuring system installed on its table-board, and has a CCD vidicon mounted with bracket above the table; the CCD vidicon is connected with an image collection card via data cable; the image collection card is installed in a computer which is equipped with a wireless transmission device. The inventive method comprises steps of employing a black-and-white CCD vidicon suite to collect images of measure cursor system composed by infrared light emitting diodes which are performed infrared filtering; employing the computer vision theory and combining with the distance information between cursor dots to be measured to calculate the relative motion parameters that the air-bearing table board relatives to the CCD vidicon; and realizing three-axis air-bearing table attitude angle measurement via continuously obtained image array without touch, disturbance and with large range and high frequency. The invention also can perform attitude angle measurement of single-axis air-bearing table or five-freedom air-bearing table.

Owner:HARBIN INST OF TECH

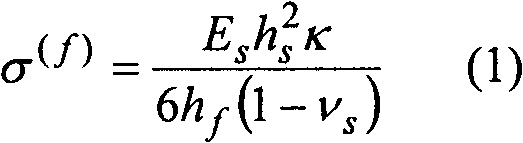

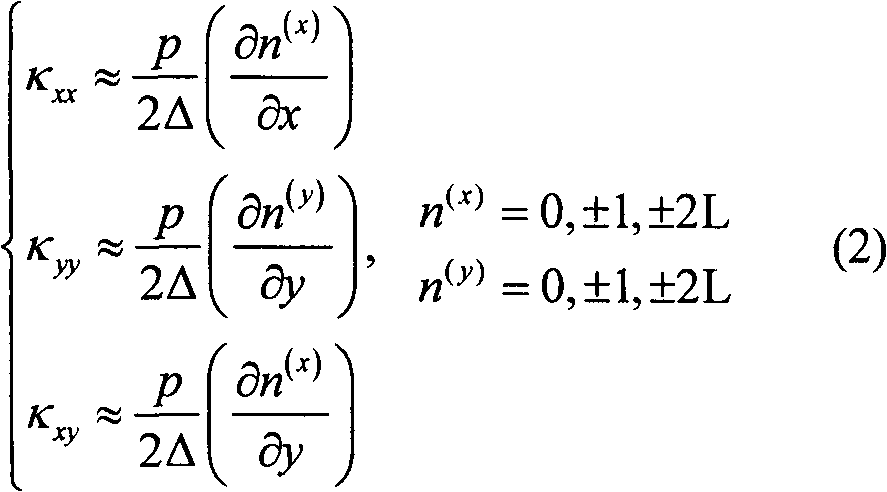

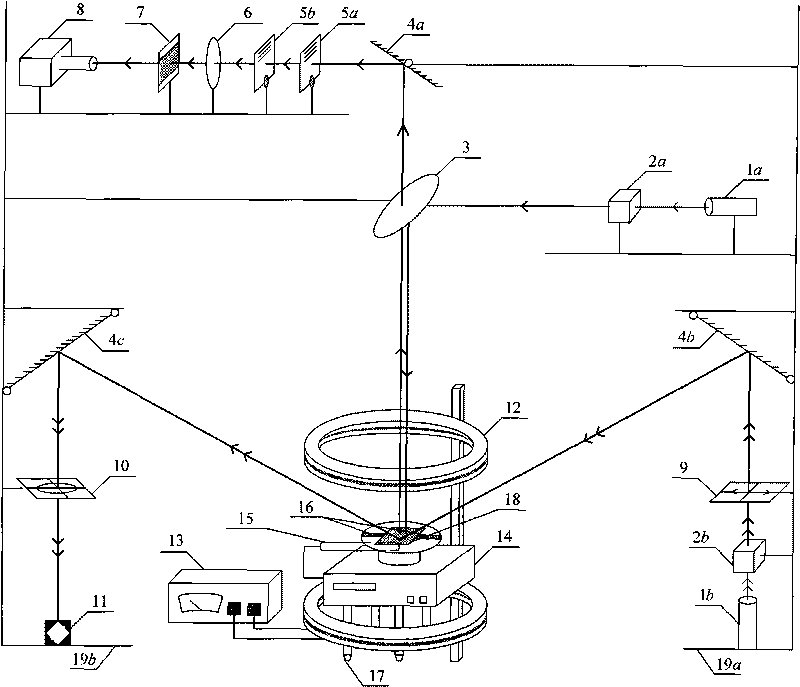

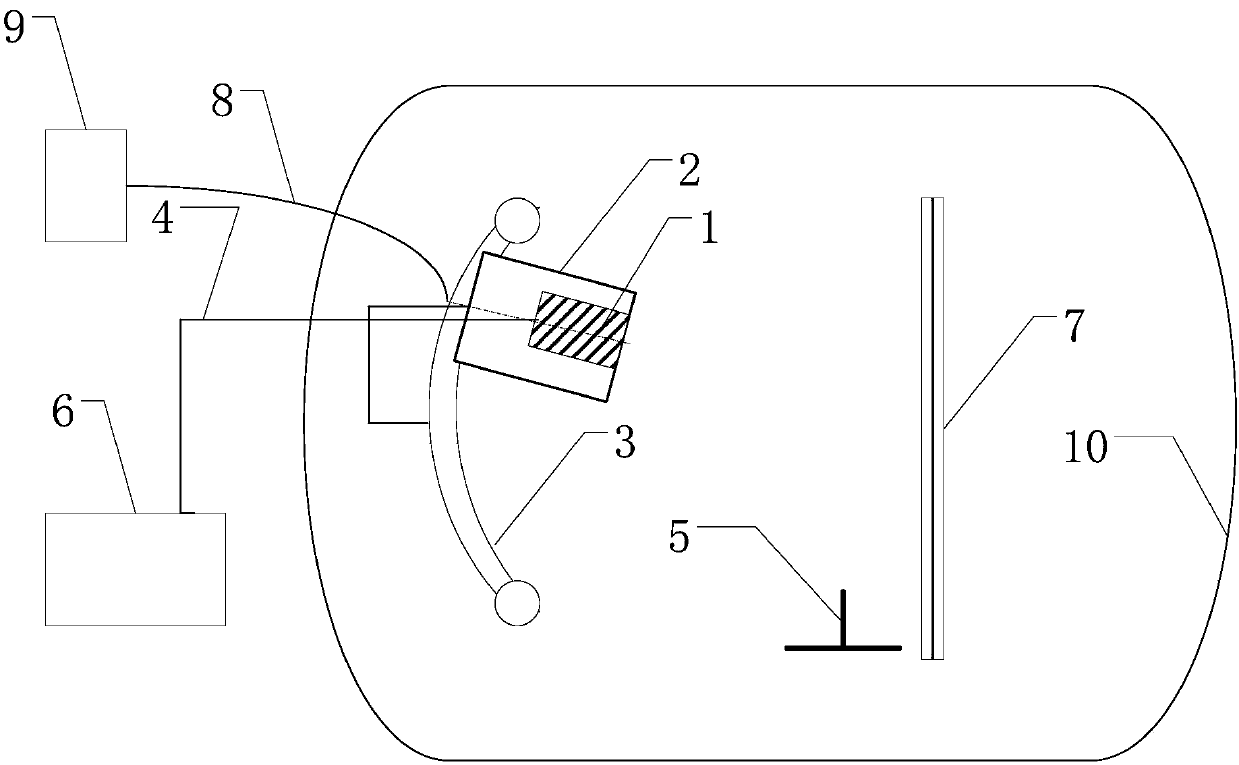

On-line measurement apparatus for high-temperature mechanics behavior of multi-layer film basal body structure

ActiveCN101355046ARealize online measurementRealize non-contactSemiconductor/solid-state device testing/measurementStructural deformationStress measurement

The invention discloses an online measuring device for the high-temperature mechanical behavior of a multilayer film matrix structure, belonging to the technical fields of engineering materials, structural deformation and mechanical experiments. The device comprises an isolated wall, an optical system and a data processing and display system, wherein the isolated wall comprises an insulated wall, a heating rod, a transmission window, a thermocouple, a specimen tray and a temperature control panel; and the optical system comprises a laser, a beam expander, an optical reflector, an optical grating, a lens, a filtering screen, a CCD camera and a piezoelectric brake. Through reconstructing the prior heating furnace, the online measuring device combines heating equipment with optical equipment so as to realize stress measurement for the multilayer film matrix structure at a high temperature. Moreover, the online measuring device has compact structure, and can realize online realtime monitoring for the mechanical property changes of the multilayer film matrix structure during heating.

Owner:TSINGHUA UNIV

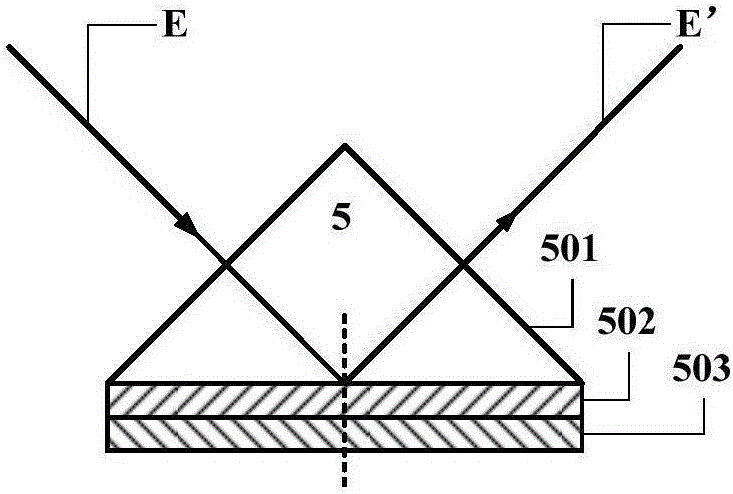

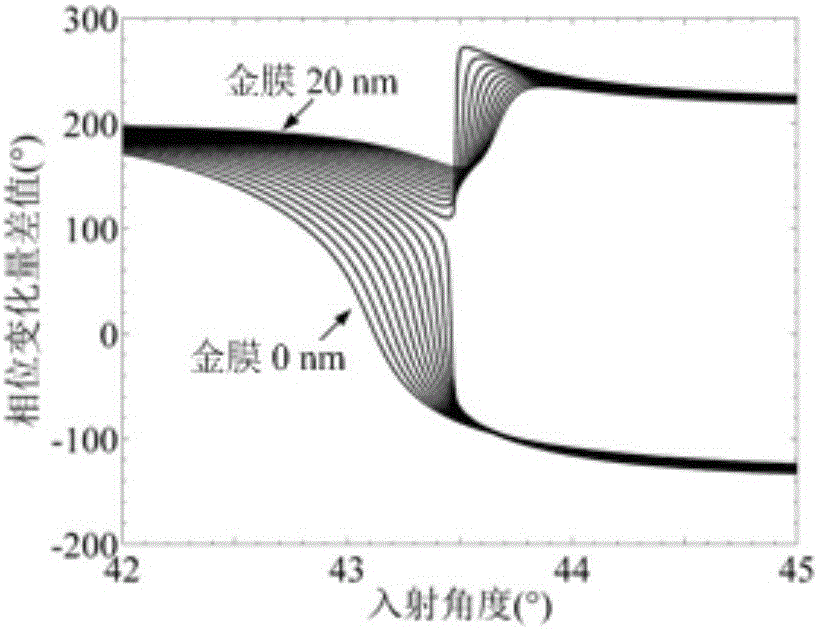

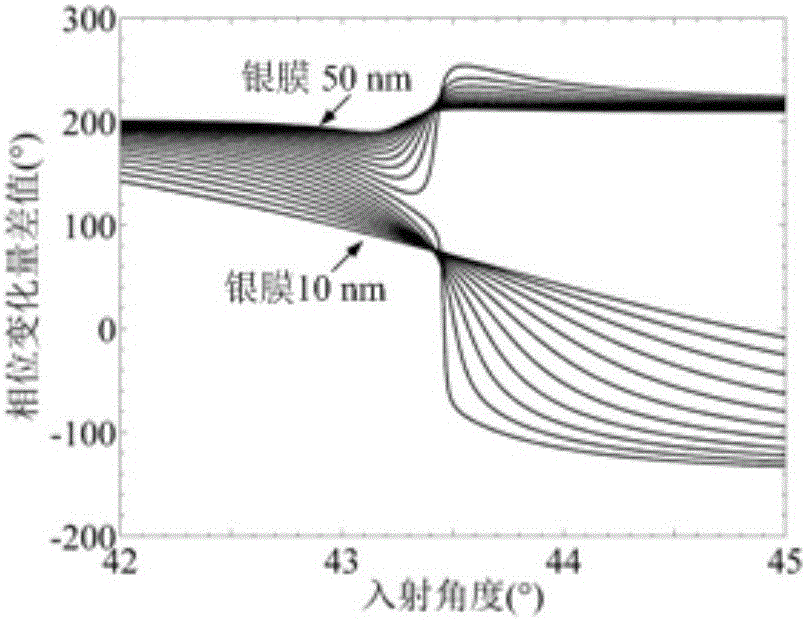

SPR phase measurement method for measuring thickness of nano-scale double-layer metal film

The invention discloses an SPR phase measurement method for measuring the thickness of a nano-scale double-layer metal film. The method comprises steps: a theoretical curve diagram for a phase change difference between TM polarized waves and TE polarized waves for the metal film layer thickness along with an incident angle change is built; a group of incident angle values with an SPR resonance angle as the center change is set; an interference fringe pattern for a prism-type SPR sensor coating region is acquired; an interference fringe pattern for a prism-type SPR sensor non coating region is acquired; a phase change difference between TM polarized waves and TE polarized waves in a coating region is calculated and obtained; the incident angle is changed sequentially starting from an initial angle, and a measurement curve diagram for the phase change difference along with the incident angle change is obtained; and according to the theoretical curve for the phase change difference along with the incident angle change and the obtained measurement curve, the thickness of the double-layer metal film coating the SPR sensor is determined. The method of the invention has the advantages of simple structure, high measurement precision and convenient operation.

Owner:TIANJIN UNIV

Method for testing water surface fine-speed flow field

ActiveCN103336144ARealize non-contactSimple methodFluid speed measurementChemical physicsCross correlation analysis

The invention relates to a method for testing a water surface fine-speed flow field. A light source is used for illuminating tracer particles, and with the cooperation of a CCD aperture, a V-shaped convergence and divergence flow field formed by tracer particles transmitted to the water surface by internal waves excited by a dragging model is photographed. The measurement of flow field speed is realized by following the speed of the tracer particles which move together with the flow field by using the above principle. The method is simple and effective, is high in application flexibility, and realizes non-contact and non-interference 'surface type' measurement of an mm / s order water surface flow field.

Owner:中国船舶重工集团公司第七〇二研究所

Device and method for detecting force thermal magnetic coupling action of ferromagnetic thin film

ActiveCN101706427ARealize onlineRealize non-contactPhase-affecting property measurementsUsing optical meansGratingHelmholtz coil

The invention relates to a device and a method for detecting a force thermal magnetic coupling action of a ferromagnetic thin film, and belongs to the technical fields of engineering materials, structure deformation and mechanical experiments. The device comprises a ferromagnetic thin film uneven stress measuring optical circuit, a film magnetic hystersis loop measuring optical circuit, a Helmholtz coil and a power supply thereof, a test piece heating table, a thermocoupler, a force loading structure and an adjusting bracket. The film uneven stress measuring optical circuit comprises a laser, a beam expander, a spectroscope, a reflector, a raster, a lens, a filtering screen and a CCD camera; and the film magnetic hystersis loop measuring optical circuit comprises a laser, a beam expander, a reflector, a polarizer, a polarization analyzer and a photodetector. The method utilizes the Helmholtz coil to provide an even magnetic field for the ferromagnetic thin film, utilizes the test piece heating table to heat the film, utilizes the force loading structure to carry out force loading on the film, utilizes shearing interference to measure uneven curvature of the surface of the film and further obtain the stress of the film through the curvature, and utilizes Kerr magnetooptical effect on the surface of the ferromagnetic thin film to measure a magnetic hystersis loop of the film.

Owner:TSINGHUA UNIV

Axial crack defect internal detector for pipe wall based on magnetostrictive effect

InactiveCN102798666ARealize non-contactNo coupling detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorUniversal joint

The invention discloses an axial crack defect internal detector for pipe wall based on the magnetostrictive effect. The axial crack defect internal detector runs forward under the driving of media in a pipeline, and detects axial crack defects of the pipe wall during the running process. The internal detector comprises an electric sealed cabin, a plurality of ultrasonic sensors based on magnetostrictive effect and a driver, wherein the electric sealed cabin is internally provided with a data collecting part, a signal processing part and a data storage part; two ends of the electric sealed cabin are respectively provided with a set of support wheels which are ranked circumferentially; the plurality of ultrasonic sensors based on the magnetostrictive effect are connected out of the electric sealed cabin in a circumferential arrangement mode, and are tightly close to the inner wall of a pipeline; each ultrasonic sensor comprises a permanent magnet, an ultrasonic coil and a spring support; the ultrasonic coil is positioned between the pole N and pole S of the permanent magnet; the spring support is connected between the permanent magnet and the ultrasonic coil; the driver is connected with the electric sealed cabin through a universal joint; and two ends of the driver are respectively provided with a set of support wheels which are arranged circumferentially, and a plurality of staggered mileage wheels are arranged one set of the two sets of support wheels which are arranged circumferentially.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

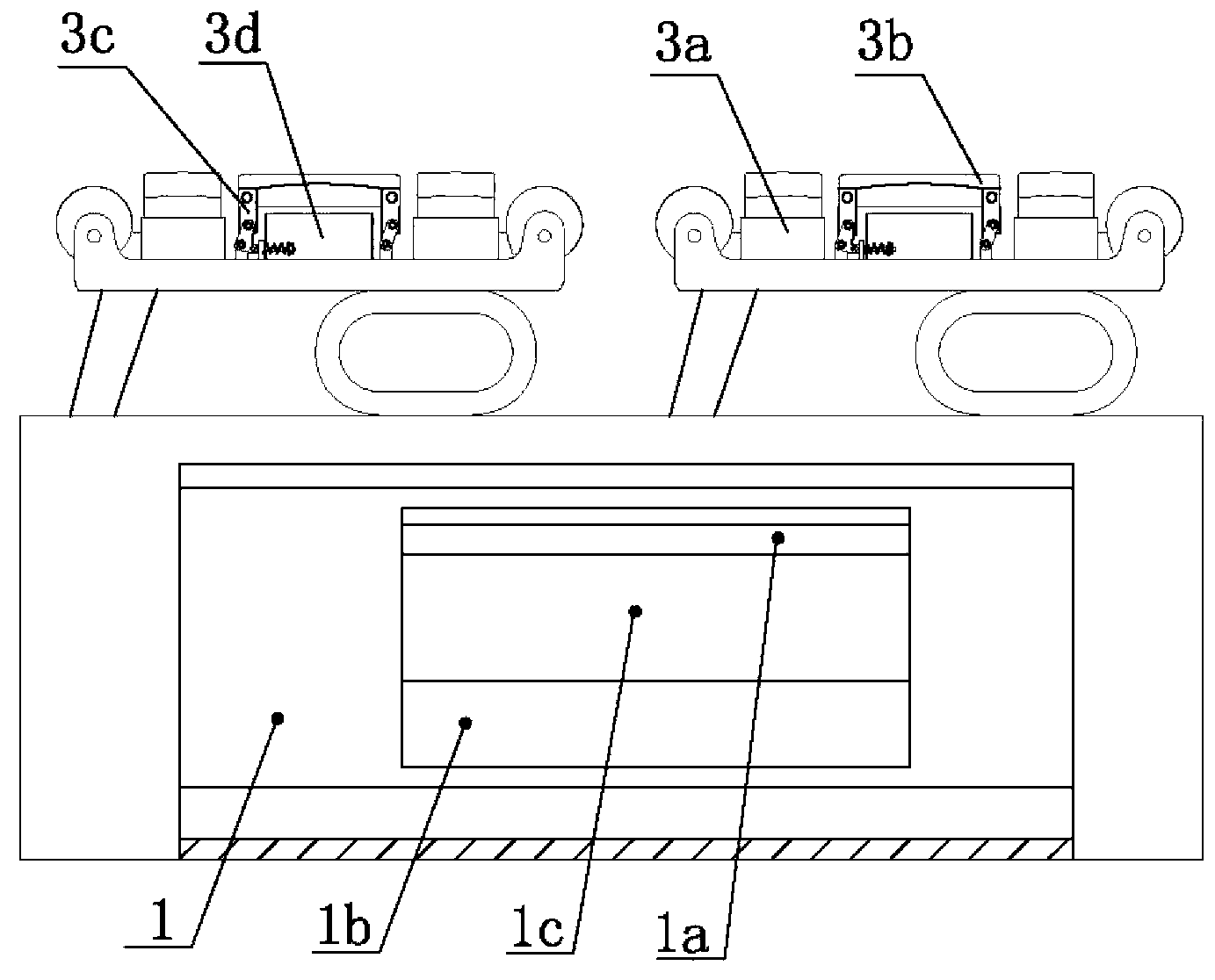

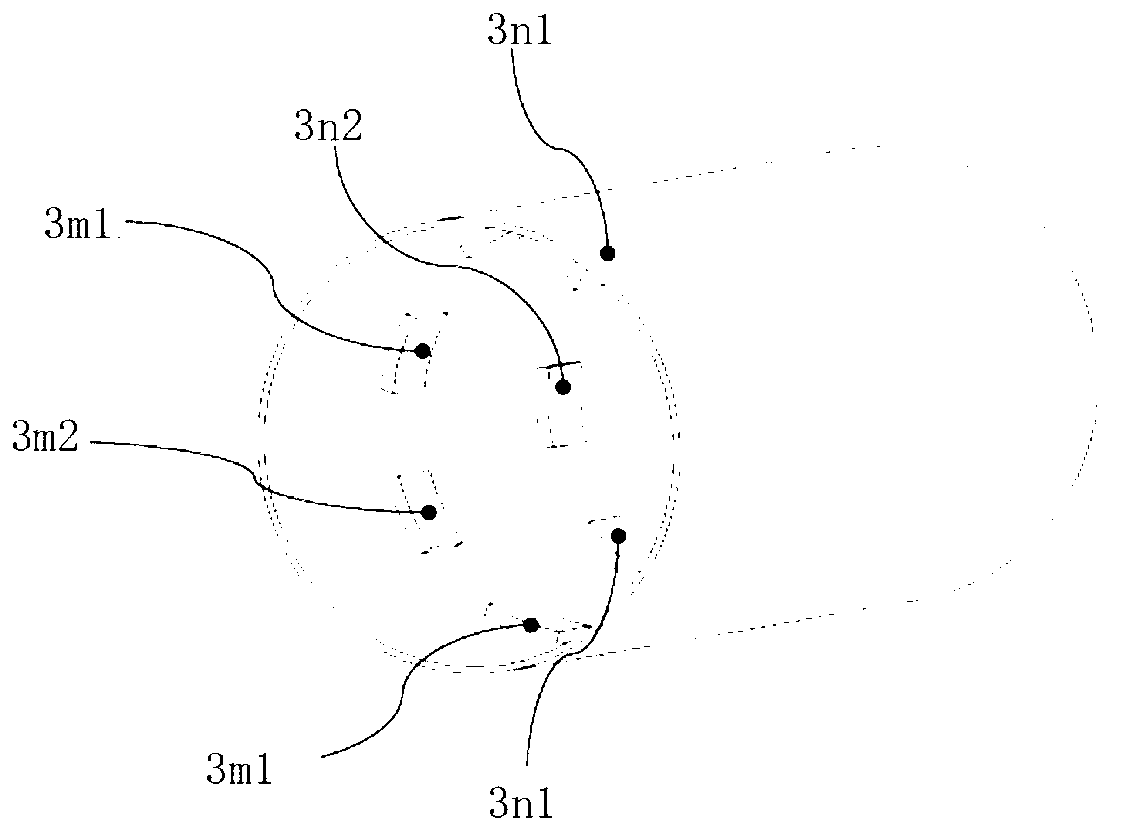

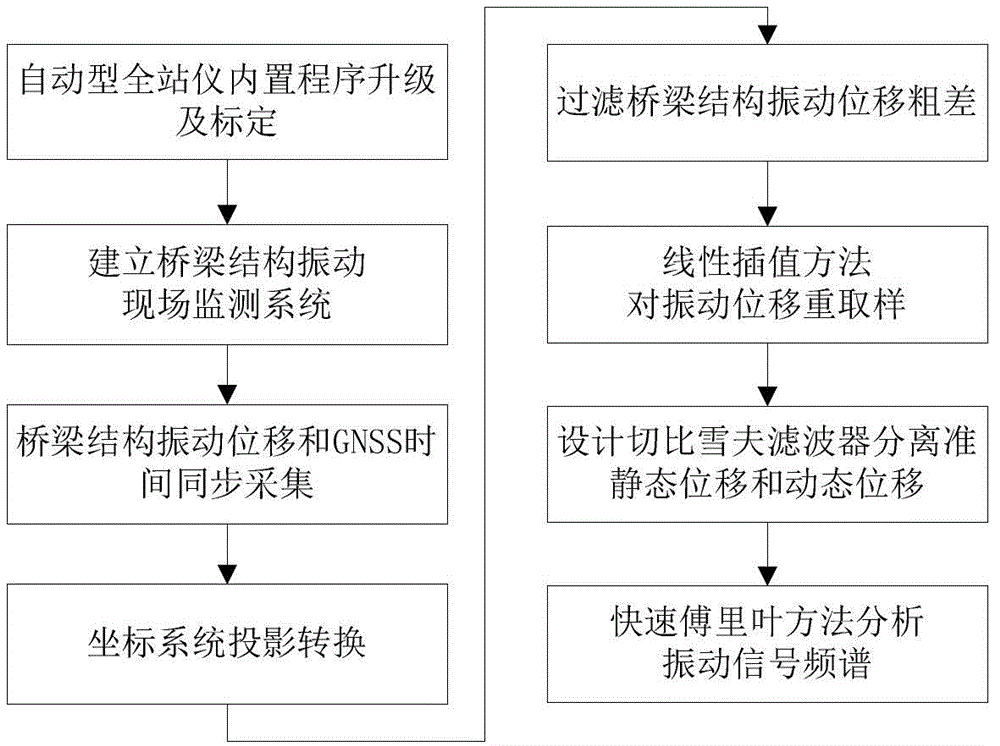

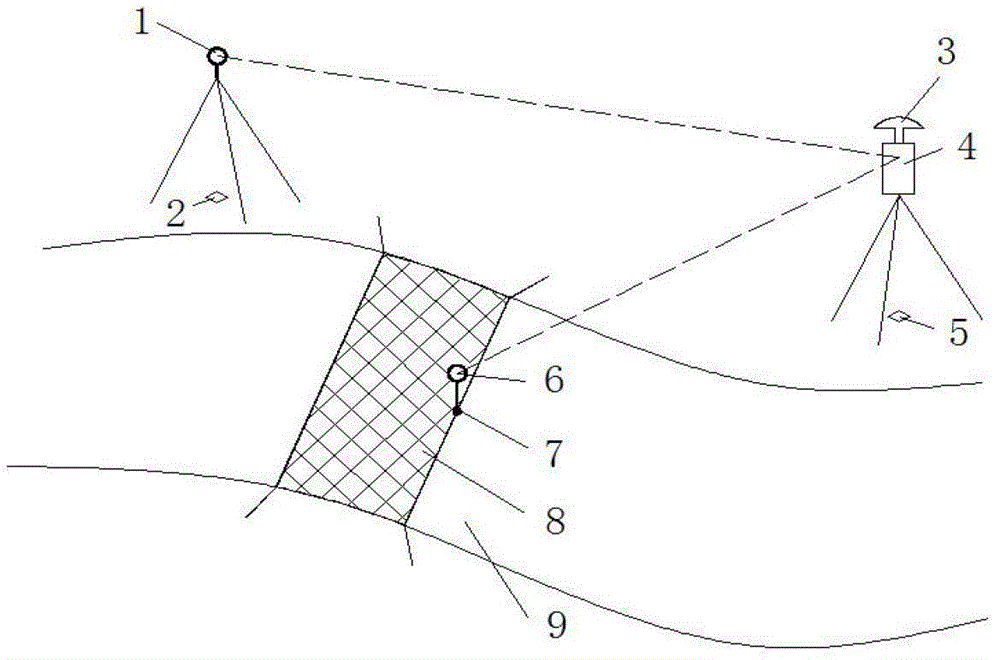

Method for measuring bridge structure dynamic displacement and vibration frequency

InactiveCN103335858ASolve the difficulties that are difficult to monitor simultaneouslyHigh measurement accuracySubsonic/sonic/ultrasonic wave measurementStructural/machines measurementField monitoringStructural vibration

A method for measuring bridge structure dynamic displacement and vibration frequency is provided. The method includes the following steps of: (1) establishing a bridge structure vibration field monitoring system so as to synchronously acquire vibration displacement and global navigation satellite system (GNSS) time; (2) performing coordinate system projection conversion which comprises the steps of calculating projection parameters between a local coordinate system and a bridge independent coordinate system and transforming measured structure vibration coordinate projection into the bridge independent coordinate system; (3) filtering bridge structure vibration displacement gross errors; (4) re-sampling vibration displacement through using a linear interpolation method; (5) separating quasi-static parts from dynamic parts in displacement by using a Chebyshev filter; and (6) analyzing vibration signal frequency spectrums through using a fast Fourier method. The method of the invention has the advantages of non-contact property, high precision, high reliability, high automation and the like.

Owner:HUNAN UNIV

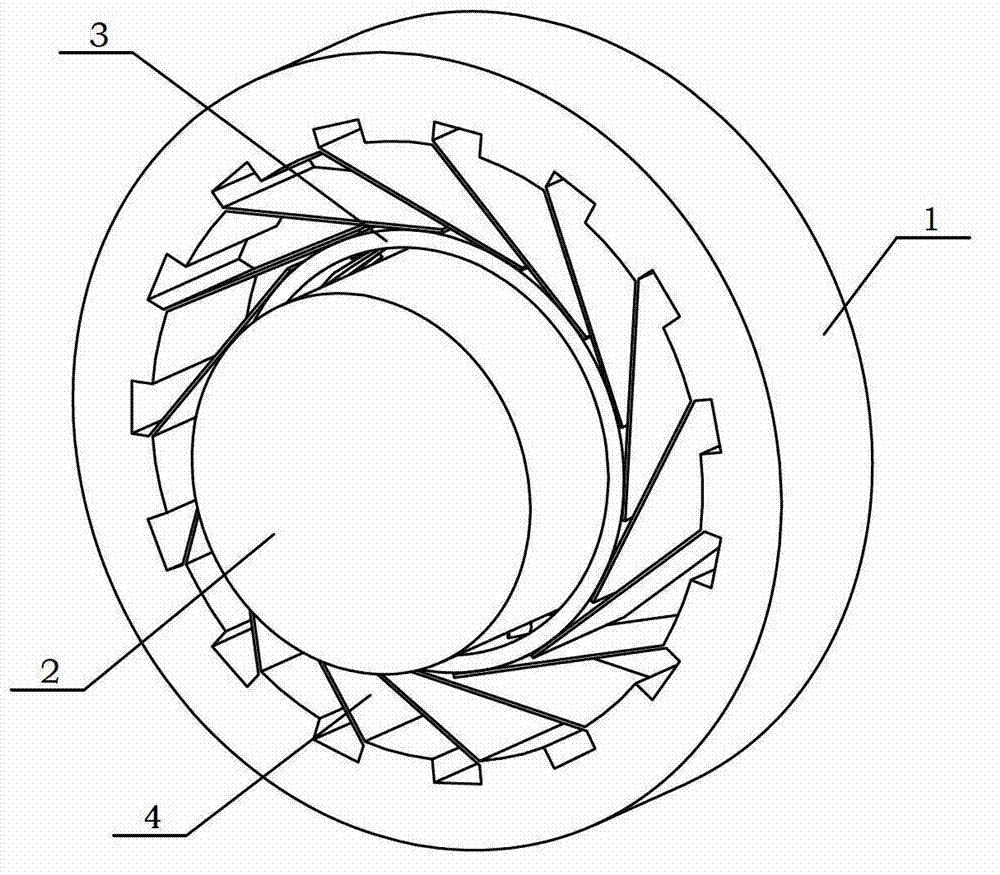

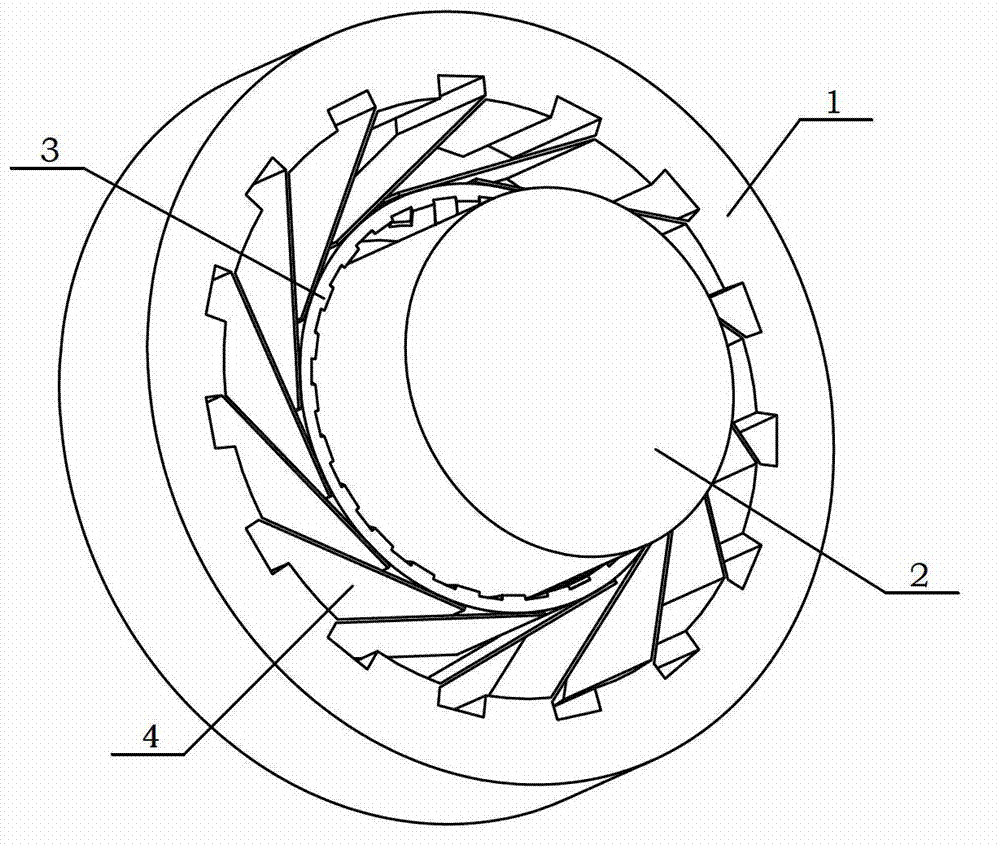

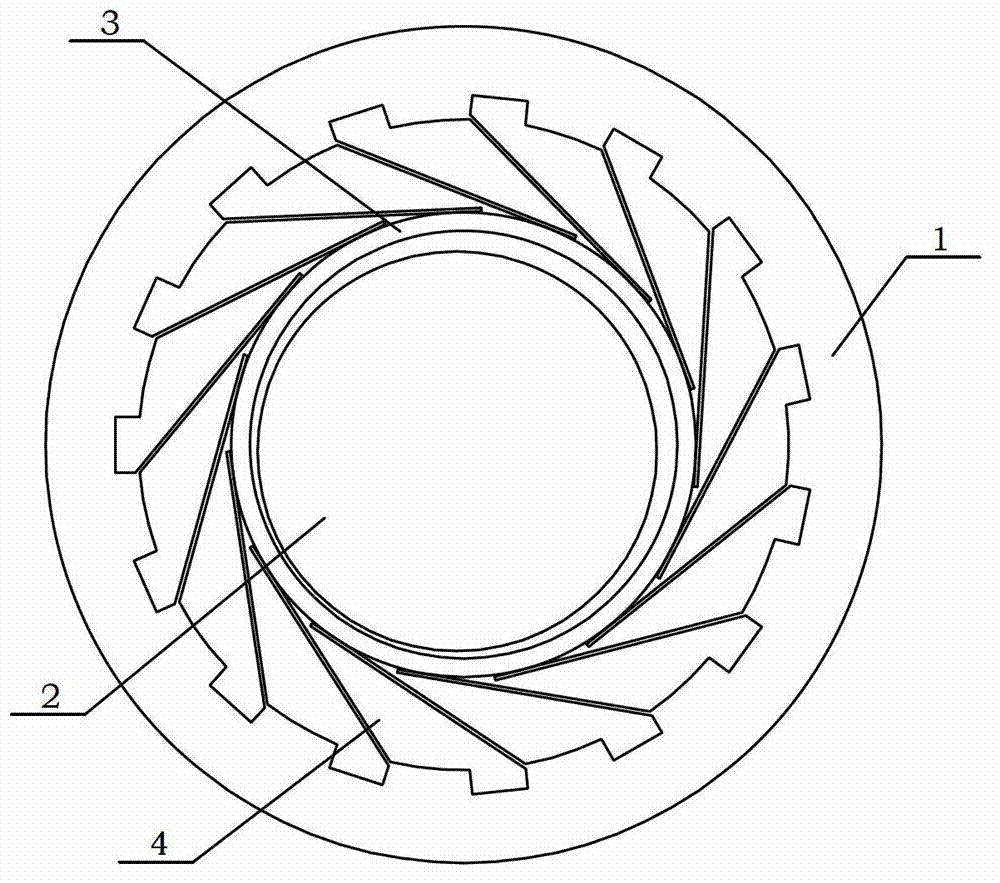

Gas cylinder surface sealing device with cantilever support and spiral chute

InactiveCN102758918AAchieving deformation adaptabilityAvoid or reduce contact wearEngine sealsHigh-pressure areaGas cylinder

The invention discloses a gas cylinder surface sealing device with a cantilever support and a spiral chute. The device comprises a sealing retainer, a rotor journal, a floating sealing ring and a cantilever supporting plate, wherein a dynamic pressure cylindrical sealing area is formed between the cylindrical sealing interface of the floating sealing ring and the cylindrical surface of the rotor journal, a high-pressure area and a low-pressure area are respectively arranged on two sides of the floating sealing ring, and the rotor journal and the floating sealing ring rotate relatively; and the floating sealing ring is supported by a plurality of cantilever sheets which are distributed circumferentially, and the cantilever sheets are fixed by the sealing retainer. The cylindrical surface gas film sealing device realizes non-contact and small-leakage sealing while adapting to the deformation in position sealing work process through the flexibility of the support and a dynamic pressure gas film, and is adaptive to the installation space requirement on non-shaft end position sealing through the cylindrical surface structure.

Owner:BEIHANG UNIV

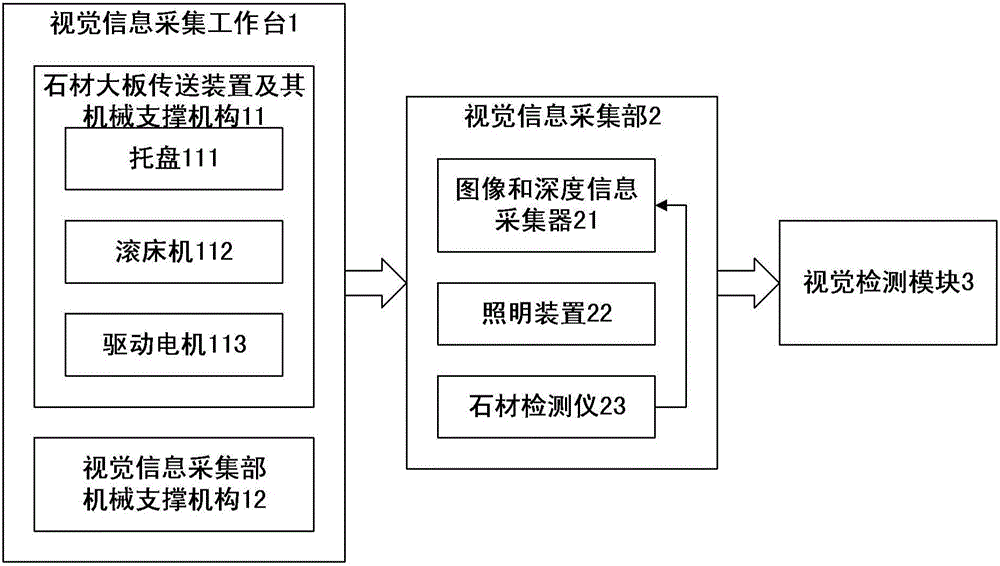

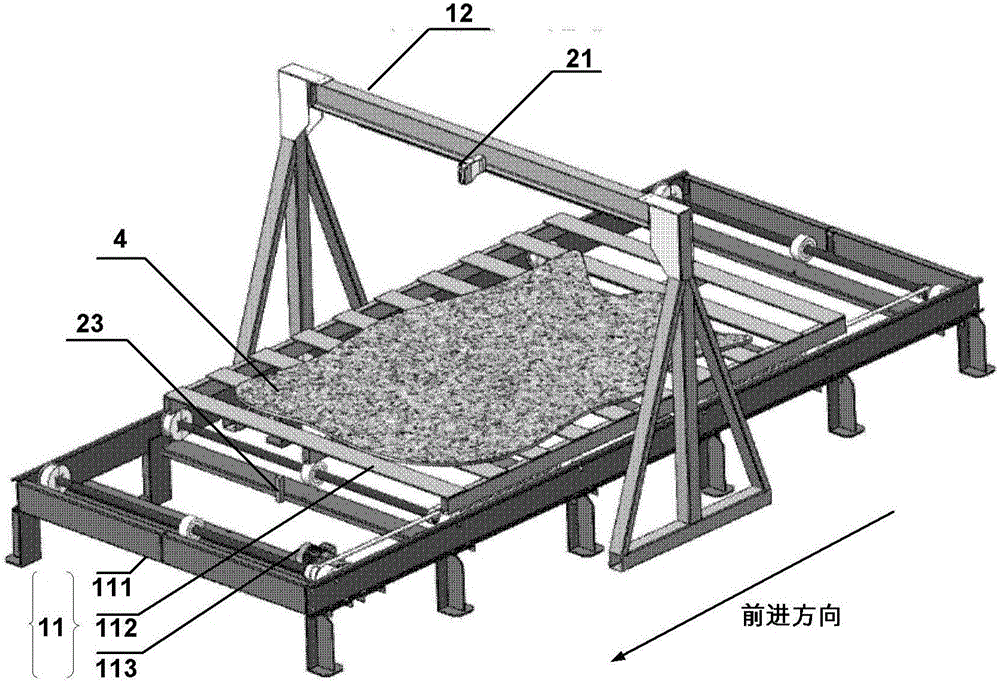

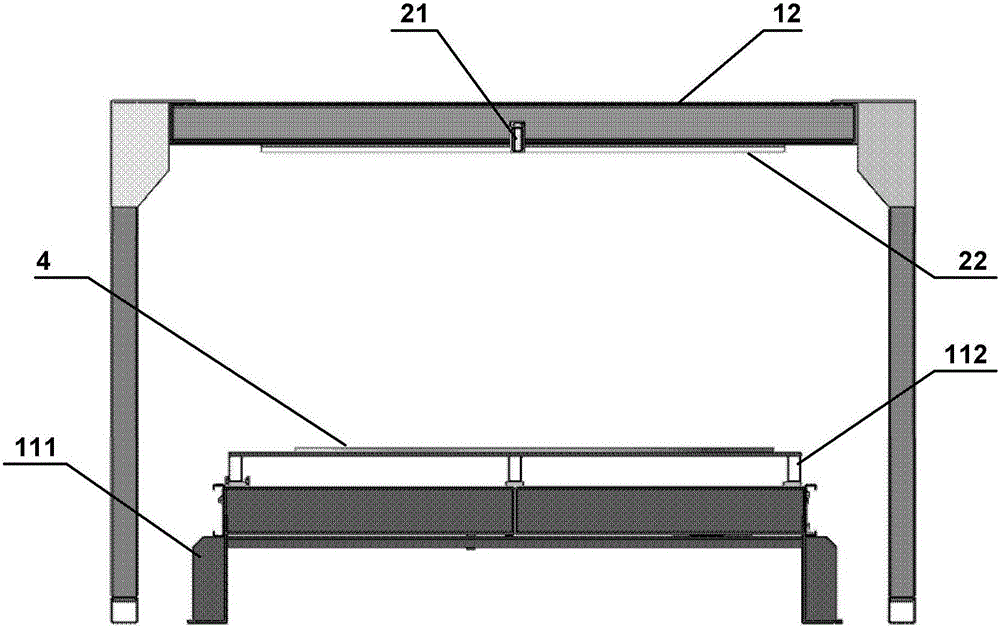

Stone big board surface contour dimension obtaining system and method based on machine vision

The present invention discloses a stone big board surface contour dimension obtaining system and method based on the machine vision. The system comprises a vision information collection work bench, a vision information collection portion and a vision detection module; the vision information collection work bench is provided with the vision information collection portion; the vision information collection portion collects the color images and the depth information of the stone big board in an online and non-contact mode; and the vision detection module is configured to perform feature analysis and target detection of the color images and depth information obtained by the vision information collection portion, identify the target area of the stone big board, extract the surface contour of the stone big board, and further combine imaging parameters to collect the length-width information of the maximum inscribing rectangular of the surface contour of the stone big board. The stone big board surface contour dimension obtaining system and method based on the machine vision can automatically extract the surface contour and the size of the stone big board through comprehensive adoption of the collected images and the depth information of the stone big board aiming at a stone block big board with the irregular shape.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Coiled tubing ovality testing method

ActiveCN103063126AAchieve losslessRealize non-contactElectric/magnetic contours/curvatures measurementsContinuous measurementStraight tube

The invention relates to the technical field of coiled tubing testing, and discloses a coiled tubing ovality testing method. Lift-off heights of eight points of the same circumference of a certain position of coiled tubing are detected by means of the adoption of a displacement sensor, and then ovality of the coiled tubing on the position is calculated. Compared with a magnetic flux leakage testing method and an ultrasonic testing method, the coiled tubing ovality testing method can achieve undamaged, contactless and continuous measurement, cannot be subjected to influences of non-electrical-conductivity sundries of the surface of the coiled tubing, and is suitable for coiled tubing in various specifications or straight pipes and bent pipes made of other materials.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

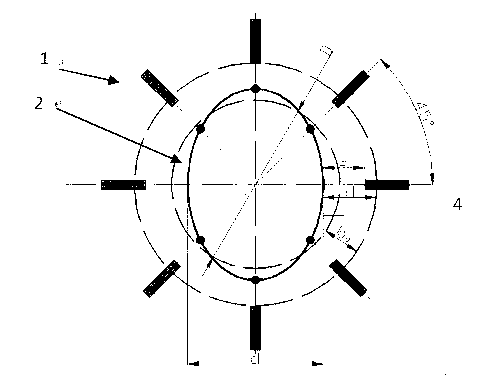

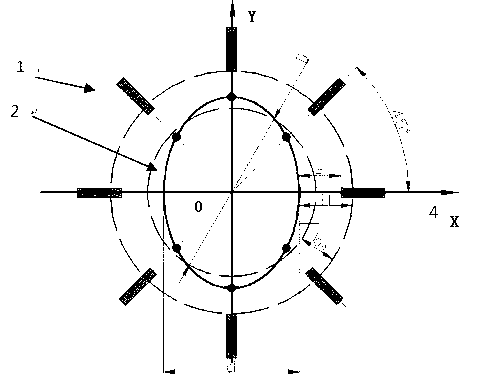

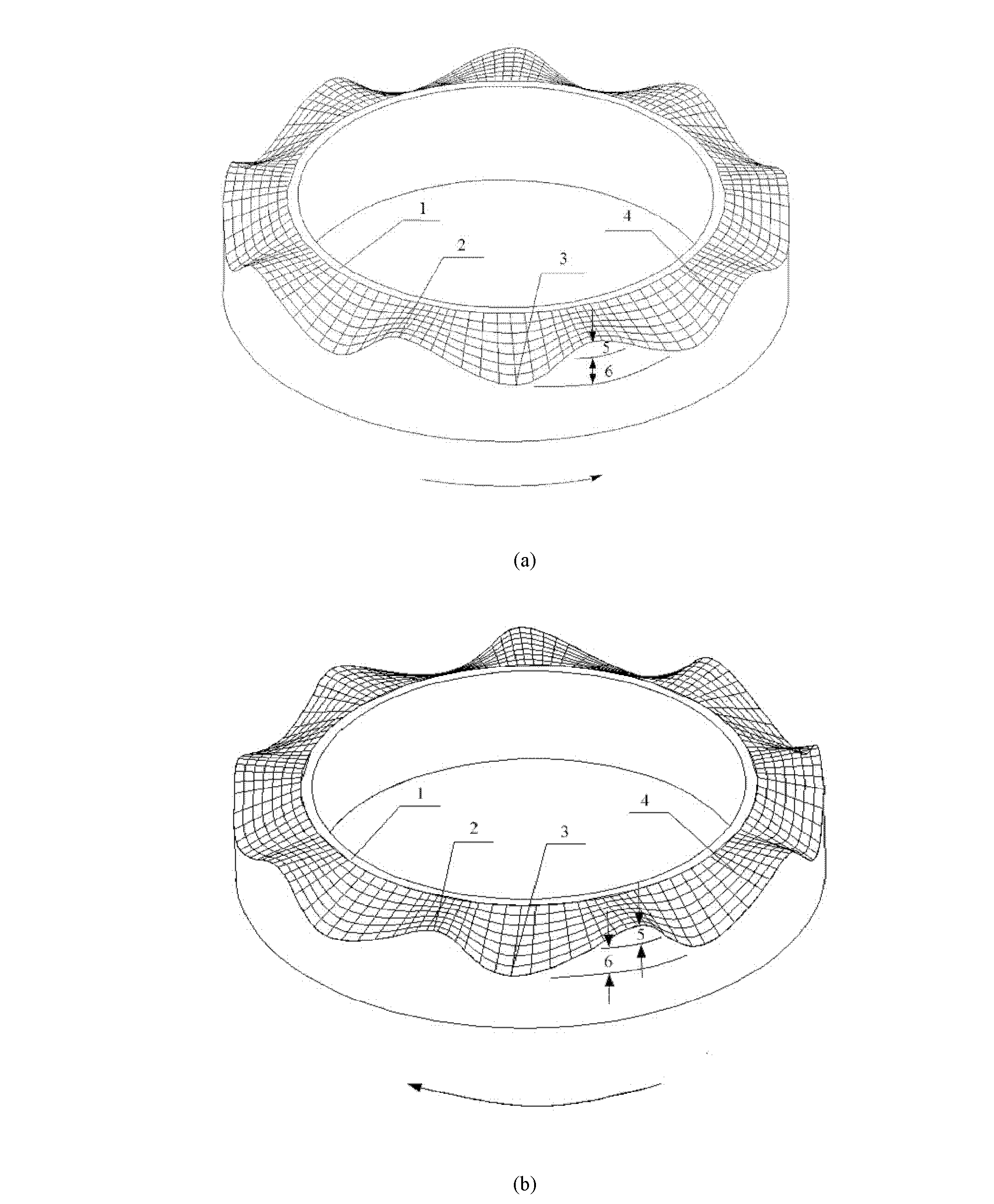

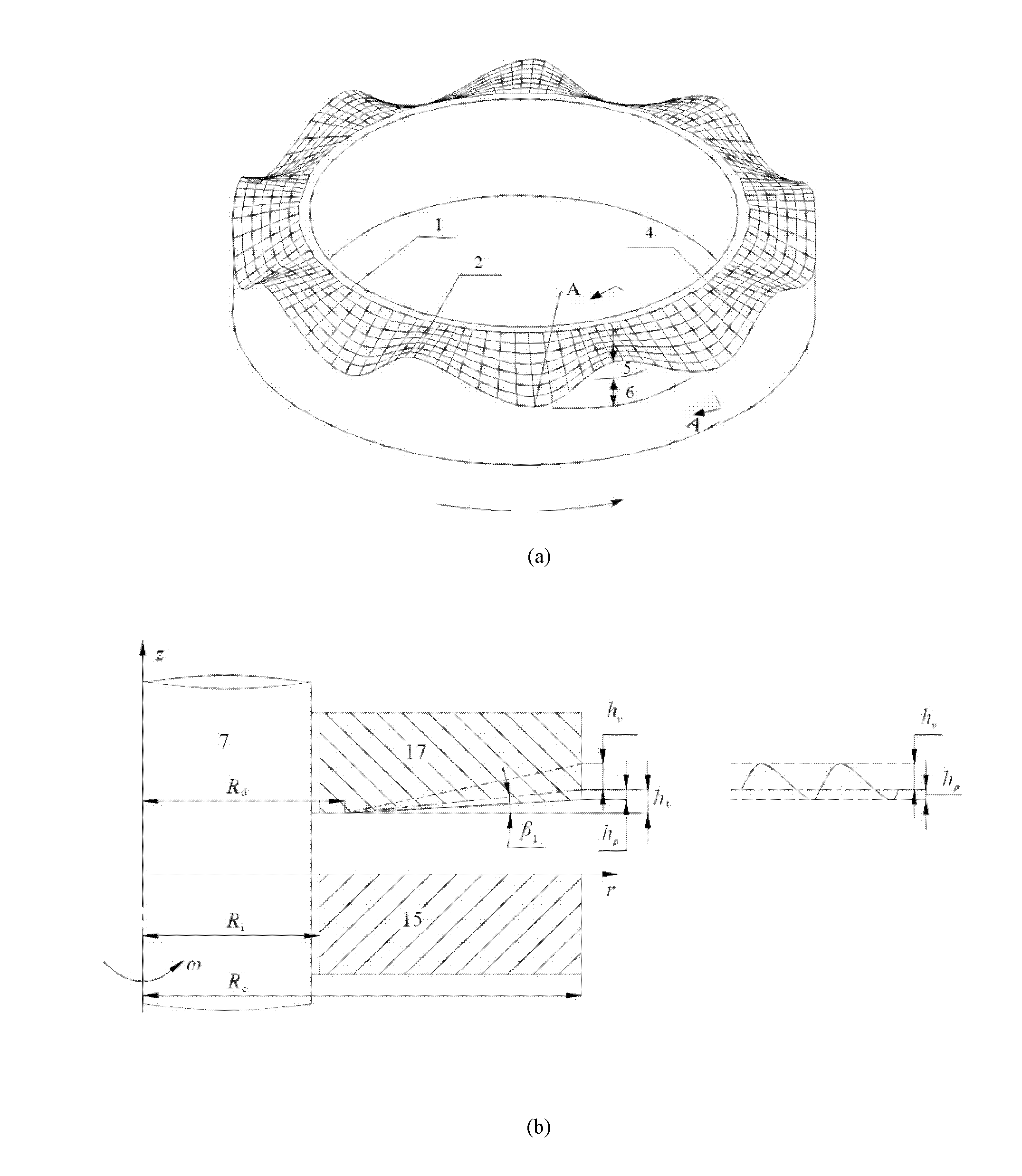

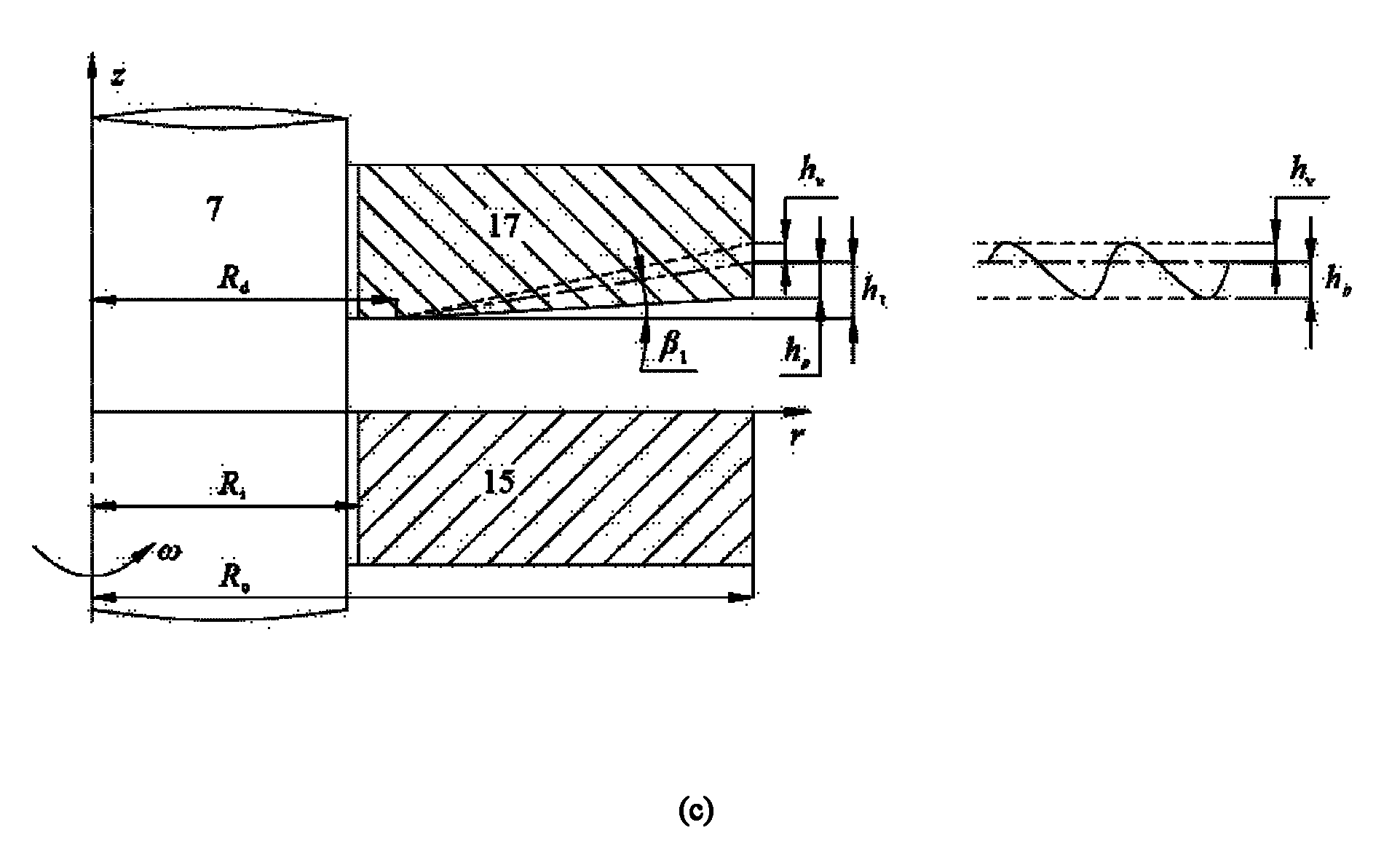

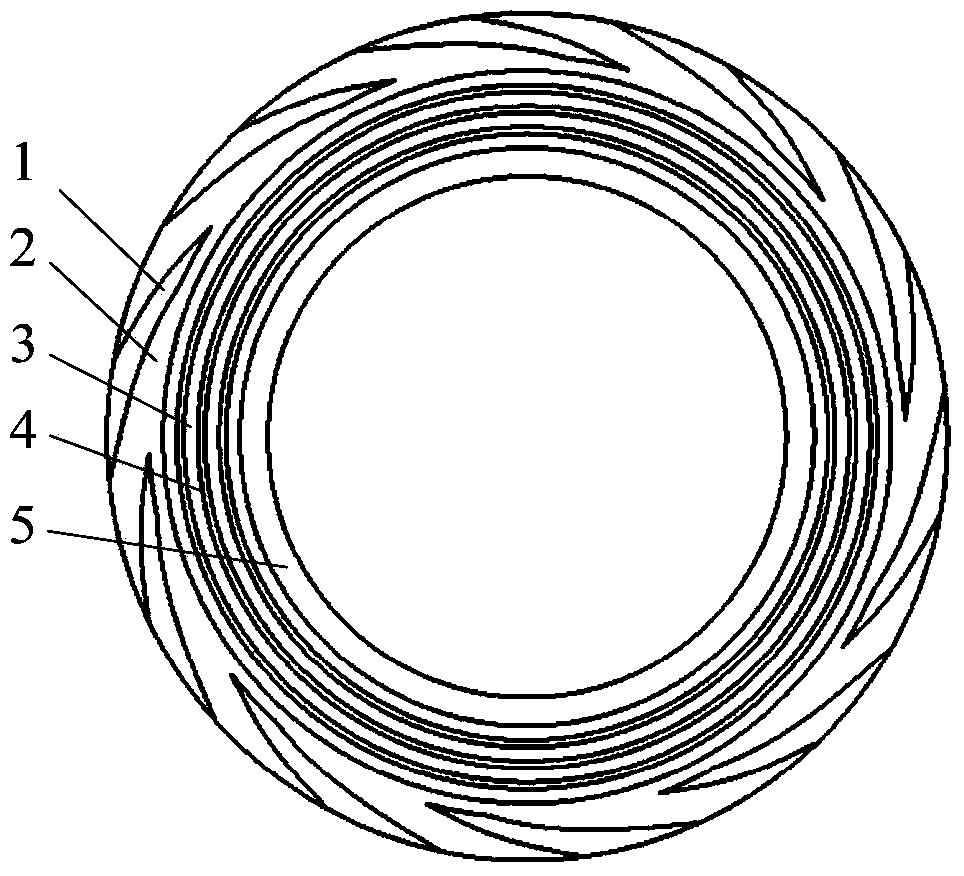

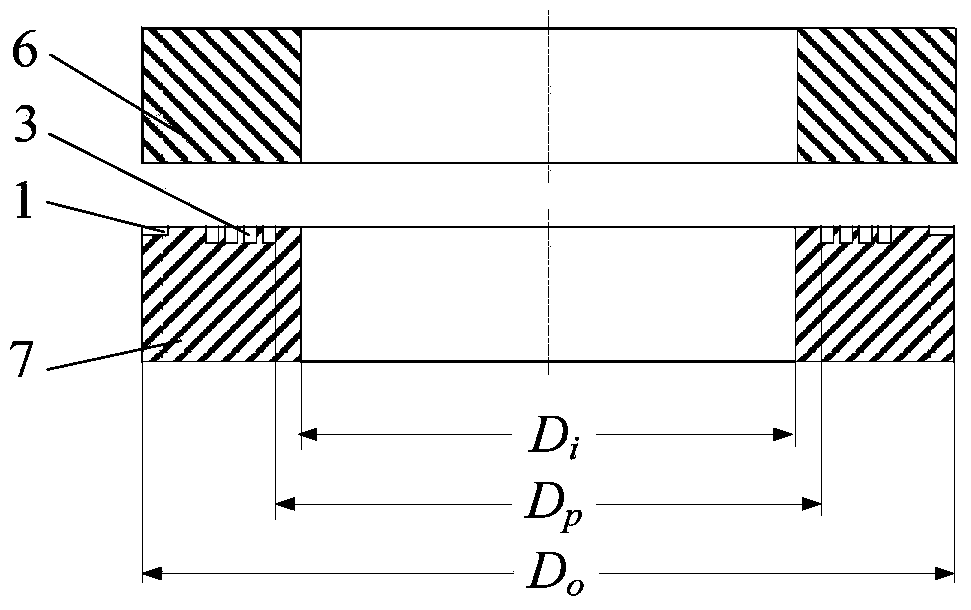

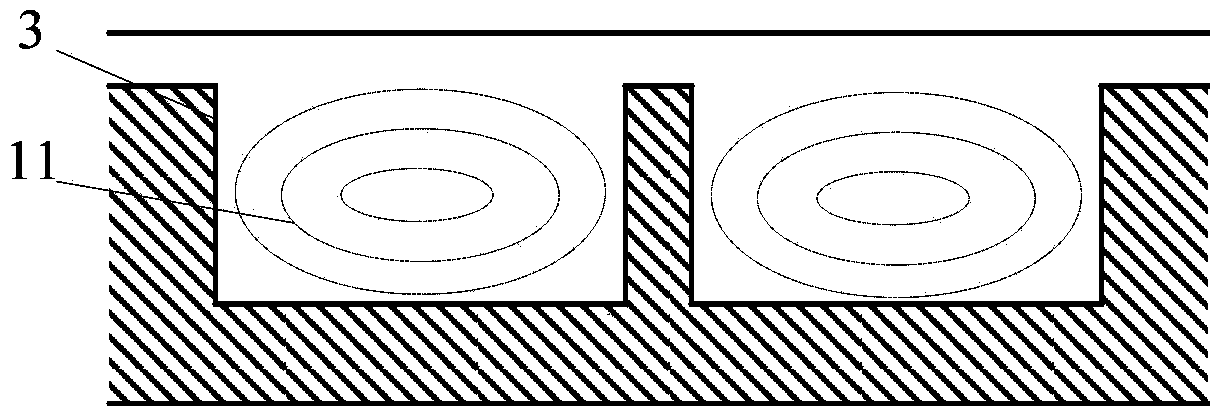

Dynamic-static pressure combined type asymmetrical waviness end face fluid mechanical sealing structure

ActiveCN102322528AEnhance the dynamic pressure effectImprove work performanceEngine sealsNon symmetricEngineering

The invention provides a dynamic-static pressure combined type asymmetrical waviness end face fluid mechanical sealing structure. At least one sealing end face on a moving ring and a stationary seal ring is provided with more than two three-dimensional asymmetrical waviness appearances, the asymmetrical waviness is in a periodical arrangement on the at least one sealing end face, the asymmetrical waviness sealing end face comprises a dam area, a conical surface and a wave crest and a wave trough of the asymmetrical waviness, the dam area is a groove-less parallel annular sealing dam arranged at the low-pressure side, the wave crest and the wave trough are connected through the conical surface, the conical surface is a linear convergence cone formed from the high-pressure side to a low-pressure side and is connected with the dam area, the conical surface can realize sealed non-contact static pressure effect; the conical degree combines with the asymmetrical waviness so that the sealing reliability can be improved, an asymmetrical waviness smooth transition curve can prevent the particles in the sealing fluid from being cumulated, and the dam area can realize static sealing when the axle is stationary. The structure provided by the invention has strong pressure resistance and antijamming capability, the leakage rate is lower at the conditions of high parameters, the fluid has good dynamic pressure effect in the process of start and stop and the fluid bearing capacity is sufficient in the normal operation.

Owner:TSINGHUA UNIV

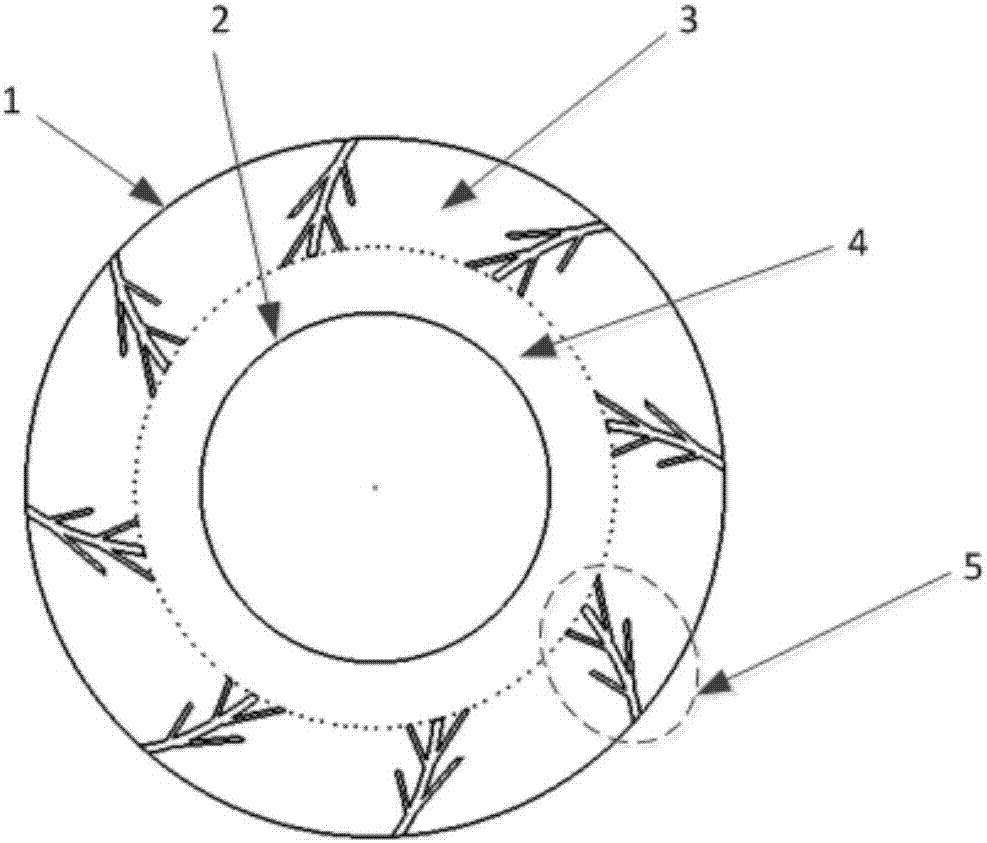

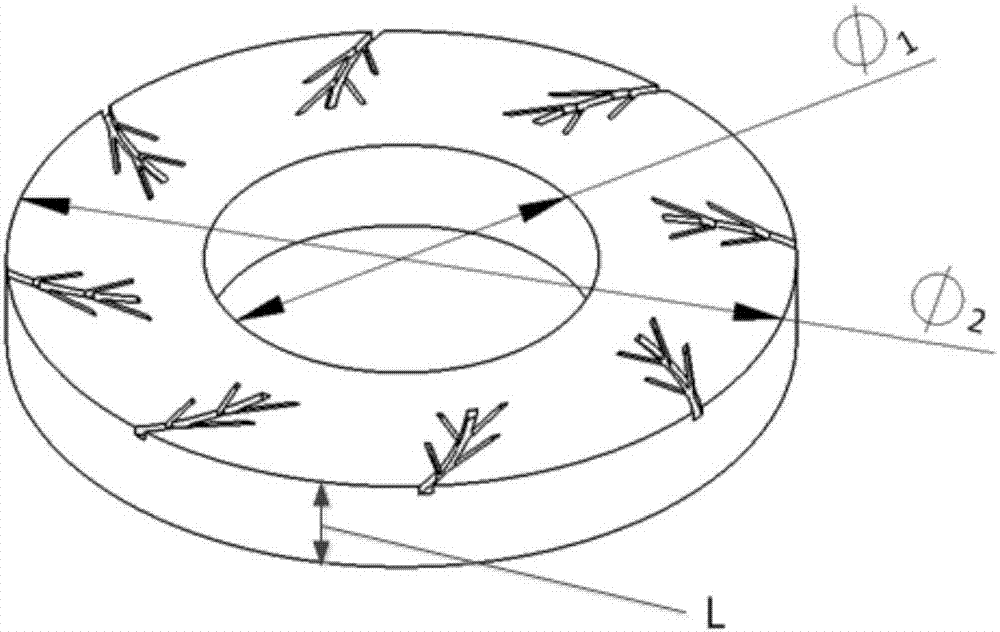

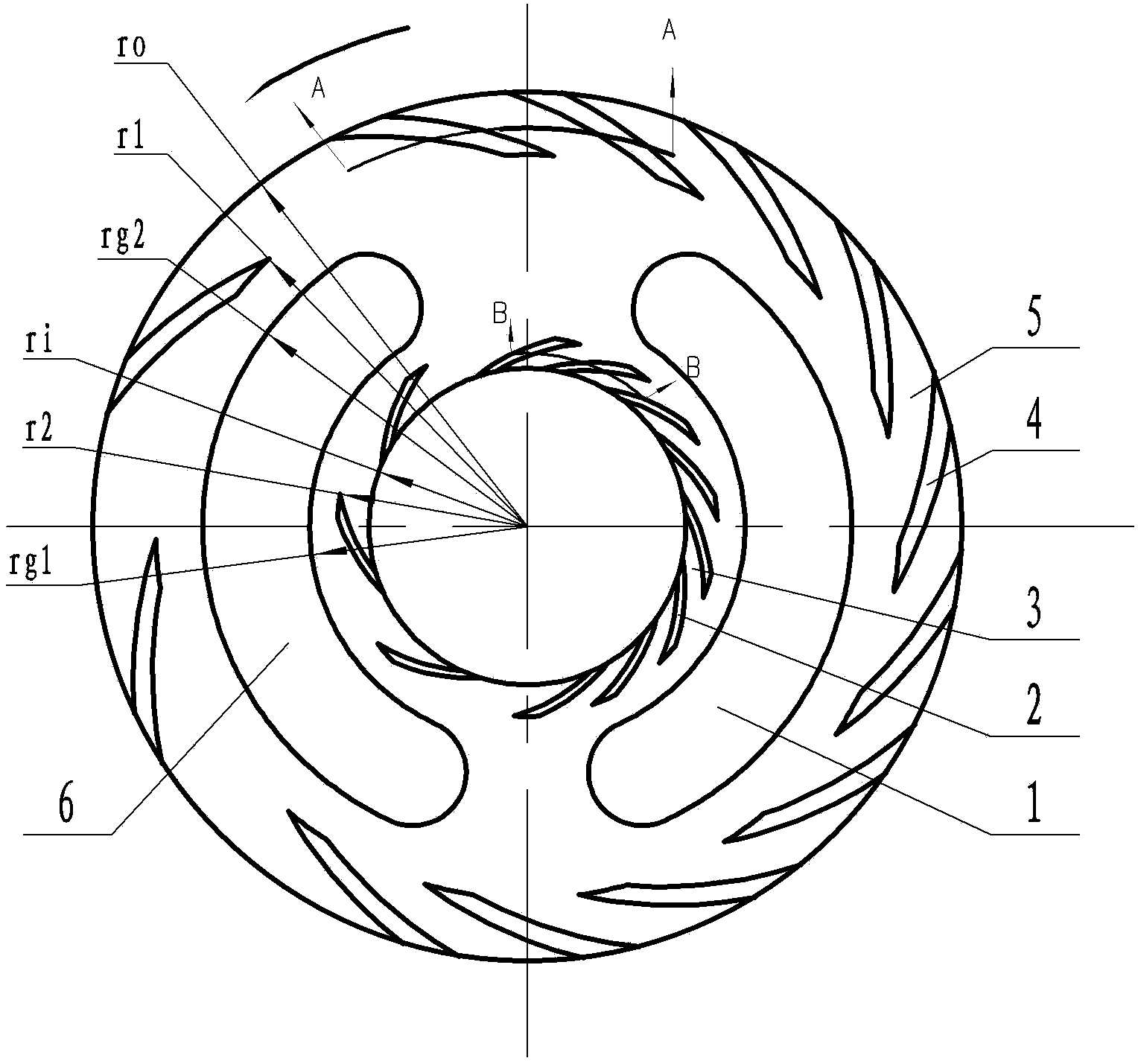

Mechanical sealing structure with end face being provided with vein-shaped grooves

ActiveCN107218396AEnhance the dynamic pressure effectImprove work performanceEngine sealsVeinPressure difference

Owner:BEIHANG UNIV

Multipurpose unexploded ordnance energy-gathering destroyer

PendingCN107677169AApplicable to non-contactApplicable to weak explosion destructionBlastingDetonatorArchitectural engineering

The invention discloses a multipurpose unexploded ordnance energy-gathering destroyer. The multipurpose unexploded ordnance energy-gathering destroyer comprises an end cover, main charge, a housing, an ammunition type cover and a baffle ring, wherein the end cover is positioned on the top of the housing and is in threaded connection with the housing; the baffle ring is arranged on the bottom of the housing; the ammunition type cover is arranged above the baffle ring; the baffle ring is used for limiting and fixing the ammunition type cover to the bottom of the housing; the main charge is arranged in the housing; a detonator is inserted into the main charge through a central hole of the end cover; and the bottom of the main charge is in contact with the top of the ammunition type cover. Themultipurpose unexploded ordnance energy-gathering destroyer disclosed by the invention can be selectively combined for use, and adopts a non-contact mode to perform in-place destroying on unexplodedordnance of different types, so that an operator does not need to touch, move or perform any mechanical treatment on the unexploded ordnance, reduces touching, carrying and transporting risks, and reduces treatment risk.

Owner:ARMY ENG UNIV OF PLA

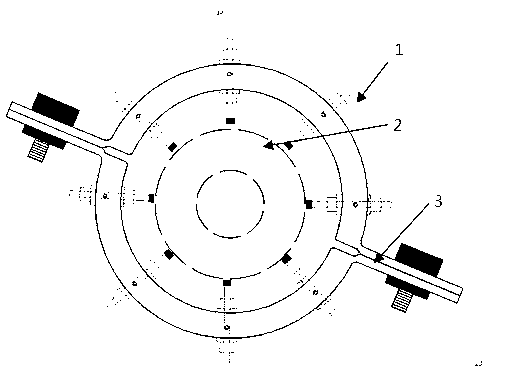

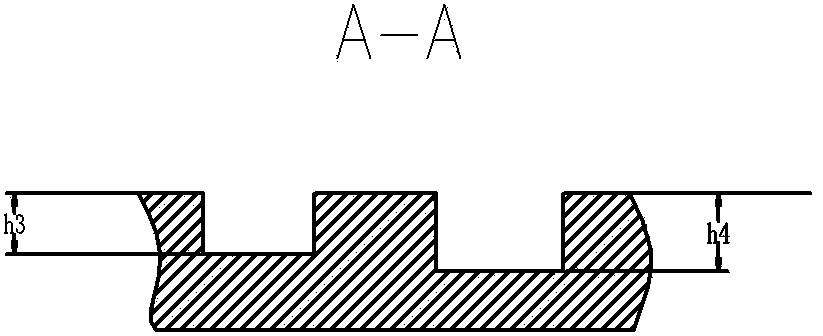

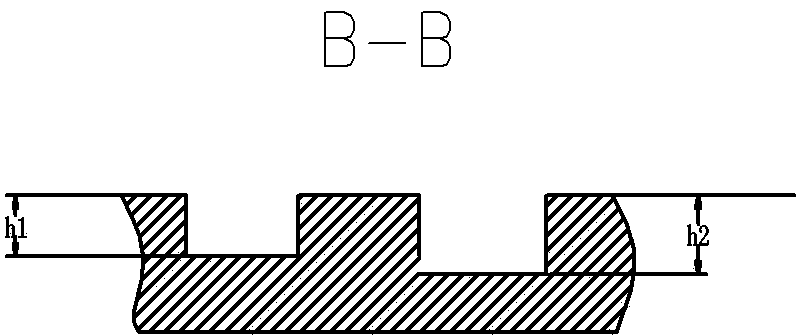

Deep groove belt dynamic pressure type end face mechanical sealing structure

ActiveCN104019237AIncrease end face dampingReduce leakageEngine sealsEnd face mechanical sealEngineering

A deep groove belt dynamic pressure type end face mechanical sealing structure comprises a dynamic ring and a static ring, wherein the dynamic ring and the static ring are sealed in a mechanical mode, one side of the end face of the dynamic ring and one side of the end face of the static ring are high-pressure sides, namely upstream portions, the other side of the end face of the dynamic ring and the other side of the end face of the static ring are low-pressure sides, namely downstream portions, one end face of the dynamic ring or the static ring is provided with a dynamic pressure groove and a groove ring throttling groove, the dynamic pressure groove and the groove ring throttling groove are symmetrically distributed according to the rotation center, the dynamic pressure groove is arranged in the upstream portion of the end face, the deep ring throttling groove is formed in the tail end of the downstream portion of the dynamic pressure groove, the deep ring throttling groove is formed due to concentrically and intensively distribution of two or more annular deep grooves in the radial direction, a first annular sealing dam with a smooth plane is arranged between the dynamic pressure groove and the deep ring throttling groove, and a second annular sealing dam with a smooth plane is arranged between the inner diameter of the deep ring throttling groove and the inner diameter of the sealing ring.

Owner:自贡市川密机械密封件有限公司

Leakproof dynamic pressure type valve plate

InactiveCN104019024AReduce leakageImprove volumetric efficiencyPositive displacement pump componentsLiquid fuel engine componentsPlunger pumpCylinder block

The invention discloses a leakproof dynamic pressure type valve plate, and relates to the technical field of engineering machines. The leakproof dynamic pressure type valve plate comprises a valve plate body with an oil suction opening and an oil pressing opening, a plurality of bending first micro type channels are arranged on the sealed end face of the valve plate body along the inner ring face of the inner side of the oil suction opening and the inner ring face of the inner side of the oil pressing opening, and a plurality of bending second micro type channels are arranged on the sealed end face of the valve plate body along the outer ring face of the outer side of the oil suction opening and the outer ring face of the outer side of the oil pressing opening. One ends of the first micro type channels are sealed, and the sealed ends extend towards the inner edge of the valve plate body to form openings. One ends of the second micro type channels are sealed, and the sealed ends extend towards the outer edge of the valve plate body to form openings. The rotating direction of the second micro type channels is the same as the counterrotating direction of the valve plate body, and the rotating direction of the first micro type channels is opposite to that of the second micro type channels. According to the valve plate, the problems that the amount of leakage between an existing dynamic pressure type valve plate and a plunger pump cylinder body is large, and the overturning moment of the cylinder body is large are solved, the volume efficiency of the valve plate is improved, and the service life is prolonged.

Owner:LIUZHOU LIUGONG HYDRAULIC COMPONENTS +1

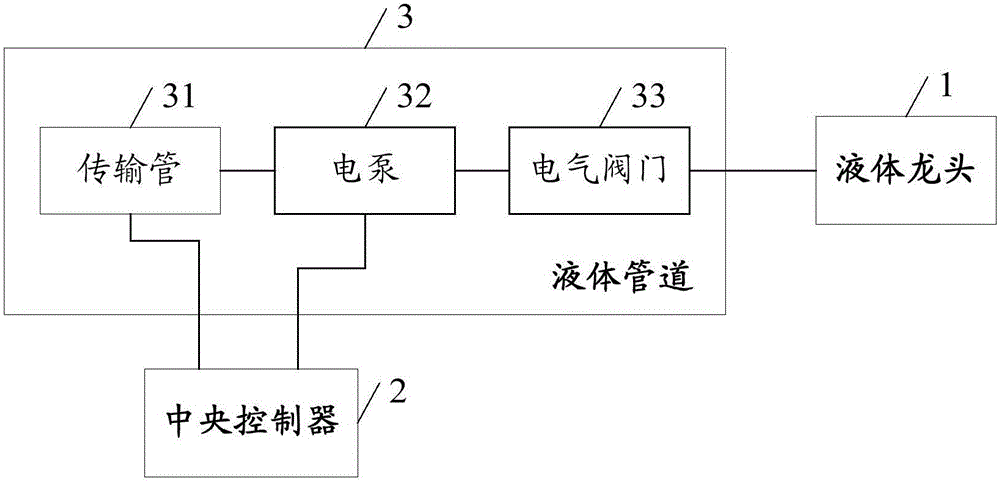

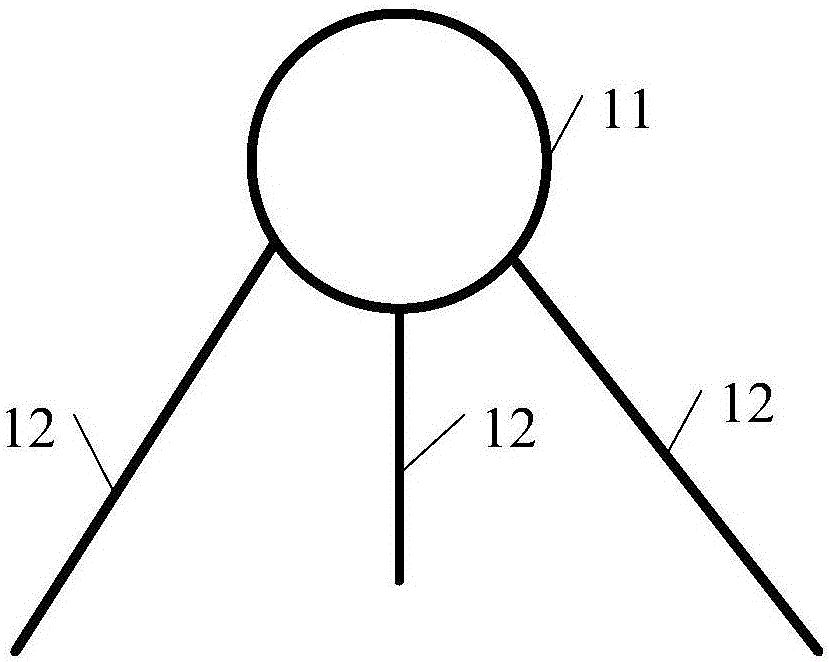

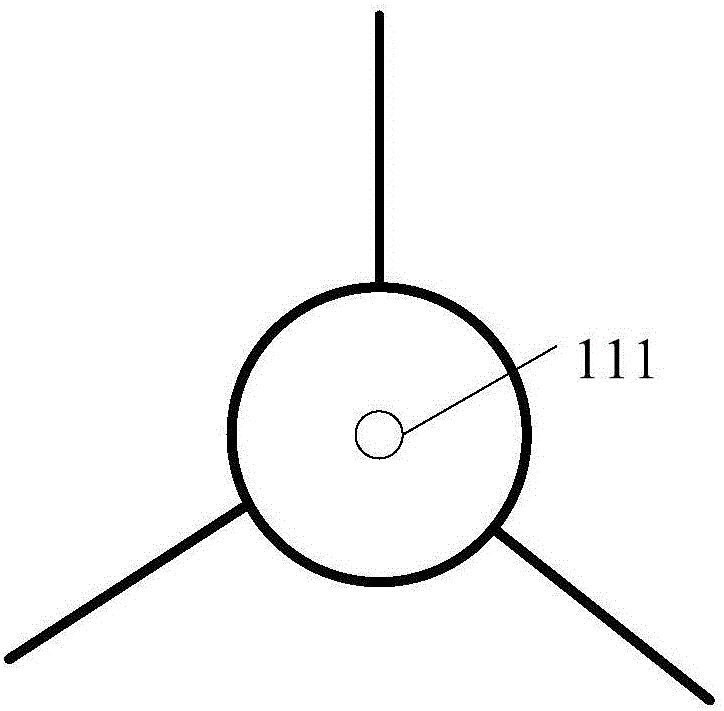

Liquid supply device

ActiveCN105736946ARealize automatic controlRealize non-contactOperating means/releasing devices for valvesFlexible member pumpsControl mannerElectrical and Electronics engineering

The invention discloses a liquid supply device. The device comprises a liquid faucet, a central controller and a liquid pipeline. The liquid faucet comprises a main part and a support. The main part is provided with a liquid outlet. The support is provided with a guide pipe communicating with the liquid outlet. The liquid pipeline comprises a transmission pipe, an electric pump and an electrical valve. The transmission pipe is connected to the guide pipe of the support of the liquid faucet. The electric pump and the electrical valve are arranged on the transmission pipe. The electric pump provides liquid transmission power for the liquid pipeline, and the electrical valve serves as a switch of the liquid pipeline. The central controller controls the electric pump and the electrical valve on the liquid pipeline according to a user instruction, and liquid outputting or liquid outputting stopping is achieved. Compared with the prior art, in the technical scheme, quantitative liquid outputting, automatic residual liquid recycling, automatic cleaning and other multifunctional effects can be achieved, the liquid supply device can be matched with a mobile control terminal as well to achieve non-contact and long-distance control over the liquid supply device, and a control manner is more convenient and flexible.

Owner:BUBBLE LAB CO LTD

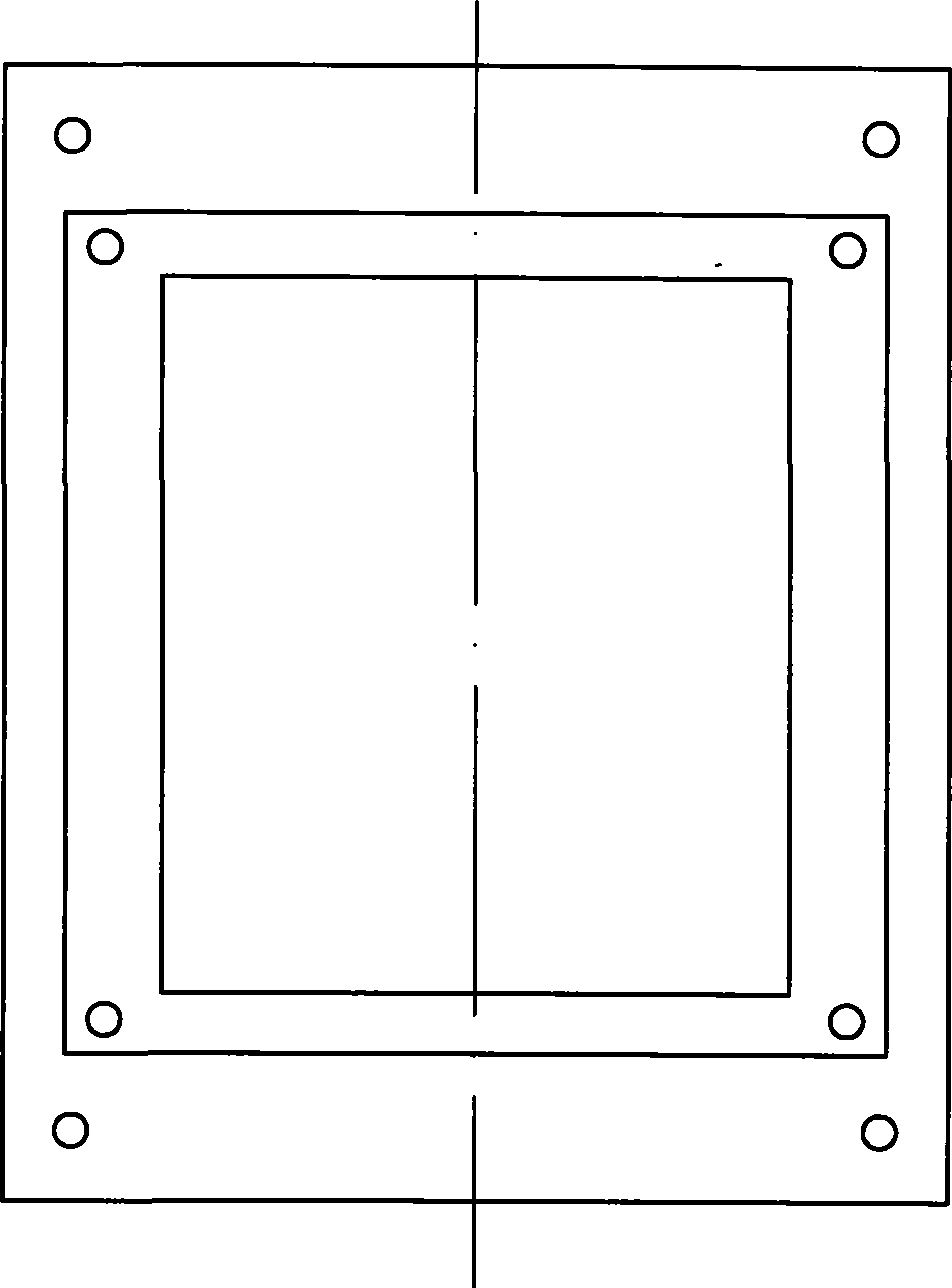

Detecting system for sealing property of aluminum foil blister package

ActiveCN105910777AFully automatedAutomation hasFluid-tightness measurement by detecting dimension changeOptical measurementsData treatment

The invention relates to a detecting system for sealing property of an aluminum foil blister package. The detecting system comprises a vacuum air path system, an optical measuring system and a data collecting processing system, wherein the vacuum air path system comprises a sealing cavity, a vacuum pump, a pressure-relieving valve, a reversing valve and a pressure sensor; the reversing valve is respectively connected with the sealing cavity, the vacuum pump and the pressure-relieving valve through the pipelines; the pressure sensor is also mounted on a pipeline which is directly communicated with the sealing cavity; the bottom in the sealing cavity is used for loading a to-be-detected aluminum plastic bubble cap; the top surface of the sealing cavity is provided with a window sealed with a transparent material; the optical measuring system comprises a light source, a light source controller, an image sensor and a bracket; the light source and the image sensor are mounted on the same side of the sealing cavity through the bracket; included angles between the irradiating direction of the light source as well as the shooting direction of the image sensor and the inner bottom of the sealing cavity are 45-60 degrees; the light source controller is connected with the light source and is used for controlling the luminance of the light source; a data processing system comprises a computer connected with the image sensor.

Owner:天津河北工业大学科技园发展有限公司

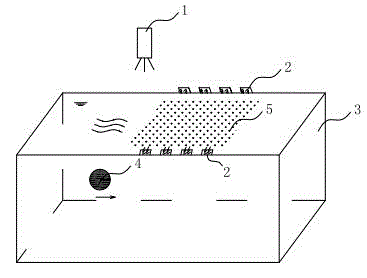

Antenna area array thermal deformation non-contact measurement system under thermal vacuum environment

InactiveCN107941161ASolve protection problemsSolving Self-Calibration Accuracy ProblemsUsing optical meansData acquisitionThermal deformation

The invention discloses an antenna area array thermal deformation non-contact measurement system under a thermal vacuum environment. The system comprises a control terminal internally equipped with thermal deformation measurement control and analysis software, a measuring camera and a protection device for the measuring camera under the thermal vacuum environment. The control terminal is arrangedoutside a vacuum tank, and is connected with the measuring camera arranged in the vacuum tank through a motion control and data collection cable; the measuring camera is arranged in the protection device for the measuring camera under the thermal vacuum environment through a fixture; and the vacuum tank is also equipped with a measuring camera two-dimensional motion device, an antenna area array and a zero-expansion microcrystalline glass reference scale. The system can realize thermal deformation measurement of the antenna area array under the thermal vacuum environment by enabling one measuring camera to finish two-dimensional motion in the thermal vacuum environment and carry out image acquisition on an object to be measured at different positions, and carrying out calculation through the corresponding measurement control and analysis software; and the system has the advantages of non-contact, high precision and high degree of automation.

Owner:SHANGHAI INST OF SATELLITE EQUIP

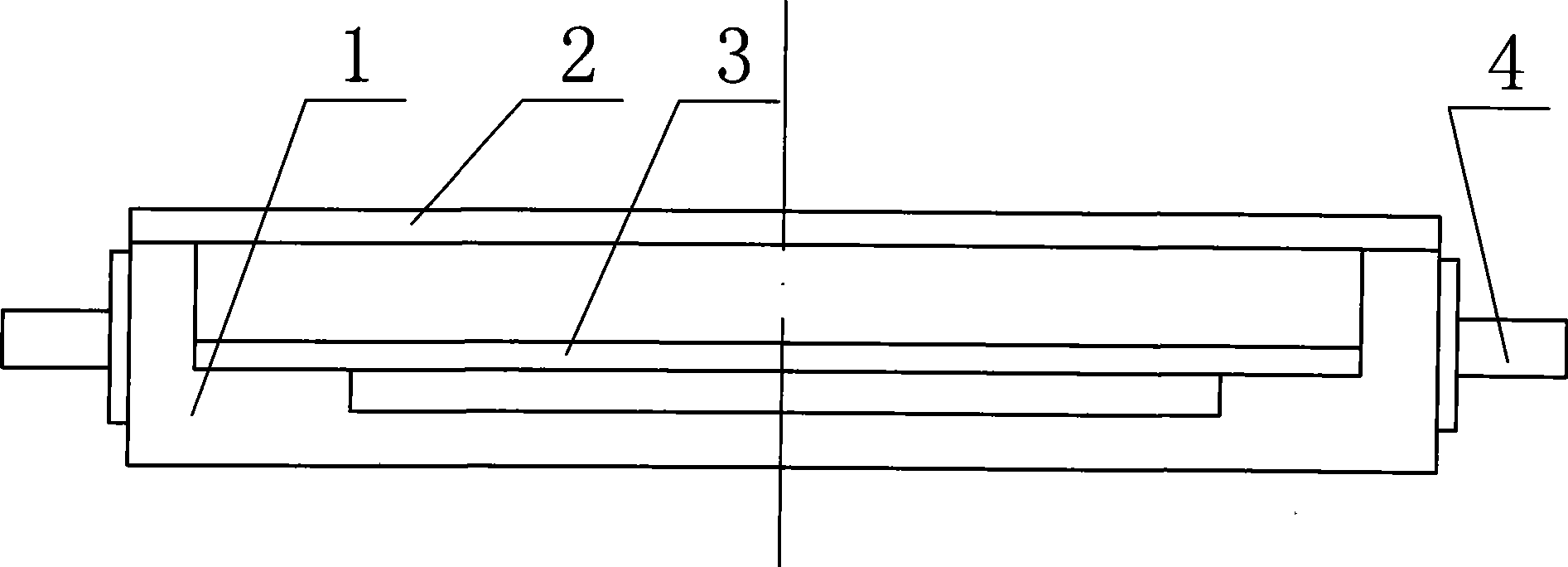

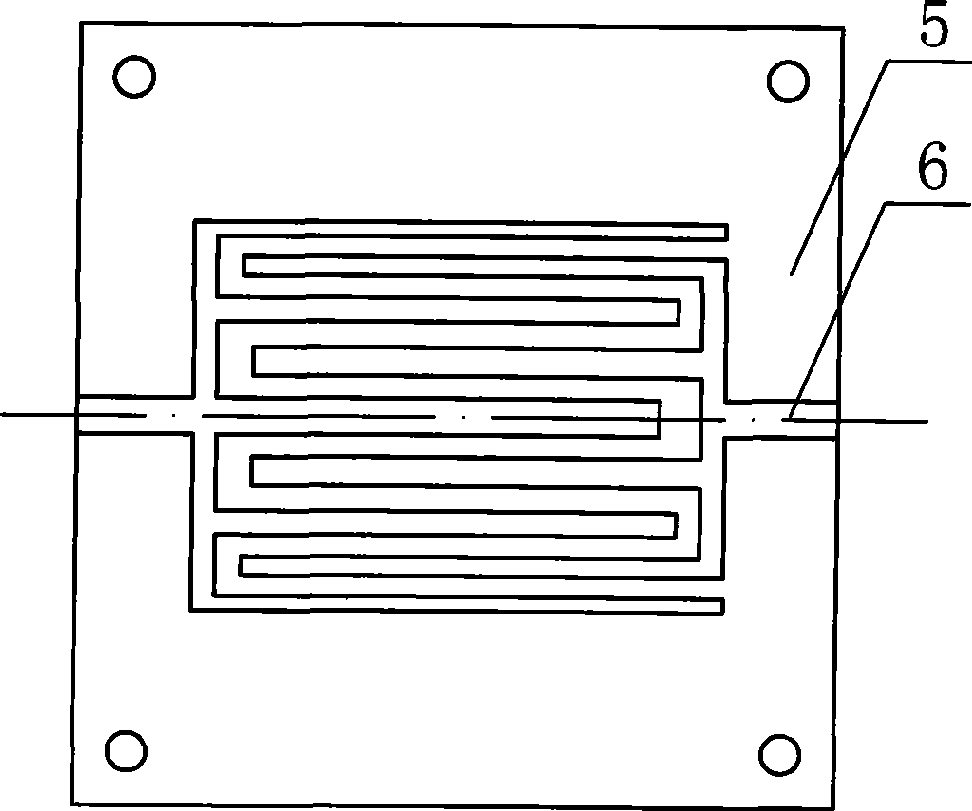

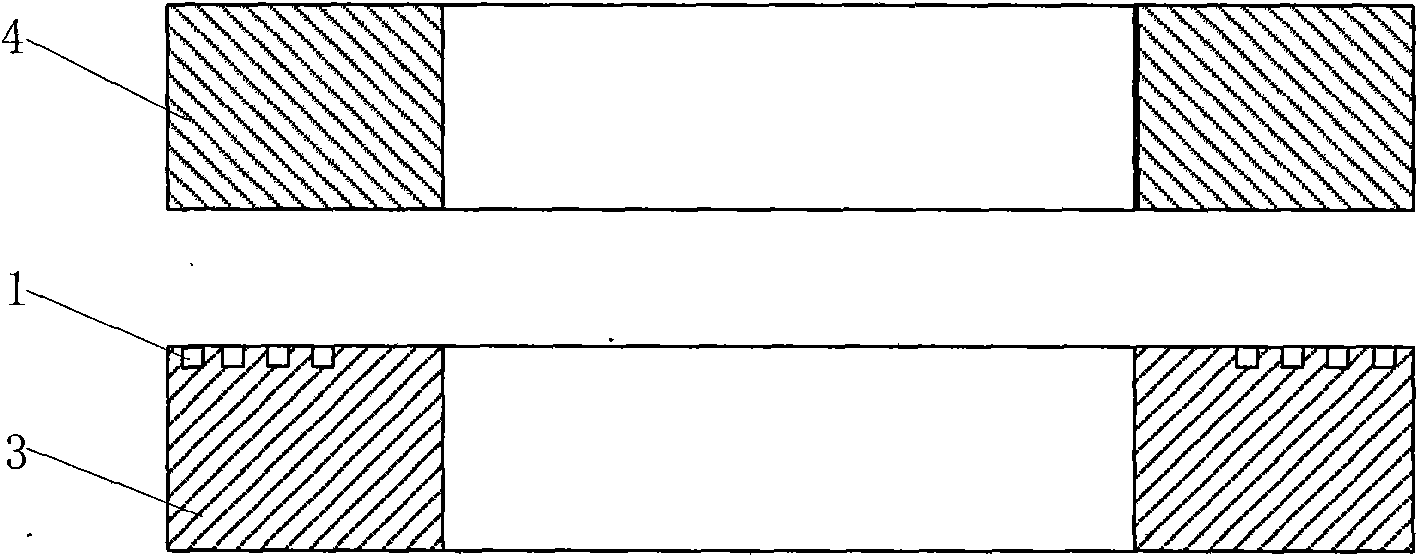

Interdigital capacitor sensor for cereal moisture percentage

InactiveCN101498679ARealize non-contactSimple structureMaterial capacitanceCapacitanceCopper coating

The invention discloses an interdigital capacitance grain water content sensor aiming at overcoming the defects that the prior grain water content sensor uses infrared spectrum to irradiate grain, can not measure the grain water content and is easy to disturb in the grain water content measurement process. The interdigital capacitance grain water content sensor comprises a pedestal (1) which is connected with a cover plate (2) and a circuit board (3); two ends of the pedestal (1) are connected with SMA connectors (4); the circuit board (3) is a polyfluortetraethylene baseplate (5) with the specific inductive capacity being 2.2; the upper surface and the lower surface of the polyfluortetraethylene baseplate (5) are coated with copper coatings with the thicknesses of 0.017 mm; the copper coated on the upper surface is provided with an interdigital capacitor (6), and the copper coated on the lower surface unevenly protrudes from the polyfluortetraethylene baseplate (5) from inside to outside to form a square shape (8). The invention is used for measuring the grain water content.

Owner:南通艾林电子科技有限公司

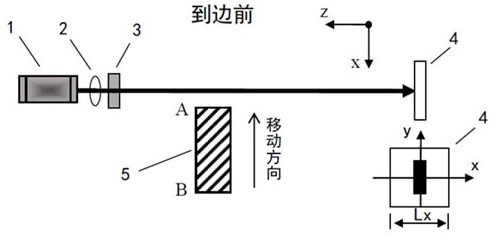

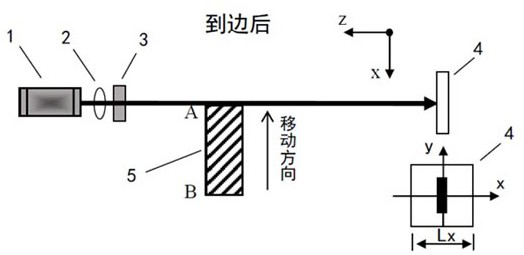

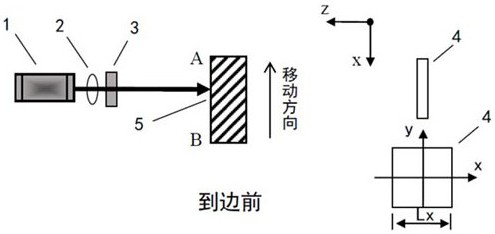

Photoelectric edge detection system and detection method thereof

ActiveCN111721235ARealize non-contactRealize high-precision detectionUsing optical meansPhotovoltaic detectorsOptical property

The invention provides a photoelectric edge detection system and a detection method thereof. The system comprises a light source, which is matched with a diaphragm through a collimator, wherein the diaphragm is matched with a position sensitive photoelectric detector, the light source, the collimator, the diaphragm and the position sensitive photoelectric detector are located on the same side or two sides of a to-be-detected object according to different optical properties of the material of the to-be-detected object, and the position sensitive photoelectric detector is connected with a signalprocessing unit. According to the invention, object edge detection is converted into measurement light beam light spot intensity center position change detection, so that non-contact and high-precision detection of the object edge is achieved, corresponding shaping can be conducted on the measurement light beam through the specific diaphragm according to the edge characteristics of different to-be-detected objects, and the sensitivity and stability of object edge detection are greatly improved; and the system is simple and flexible in overall structure, can be adjusted according to materialswith different optical properties, and facilitates the on-site measurement.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

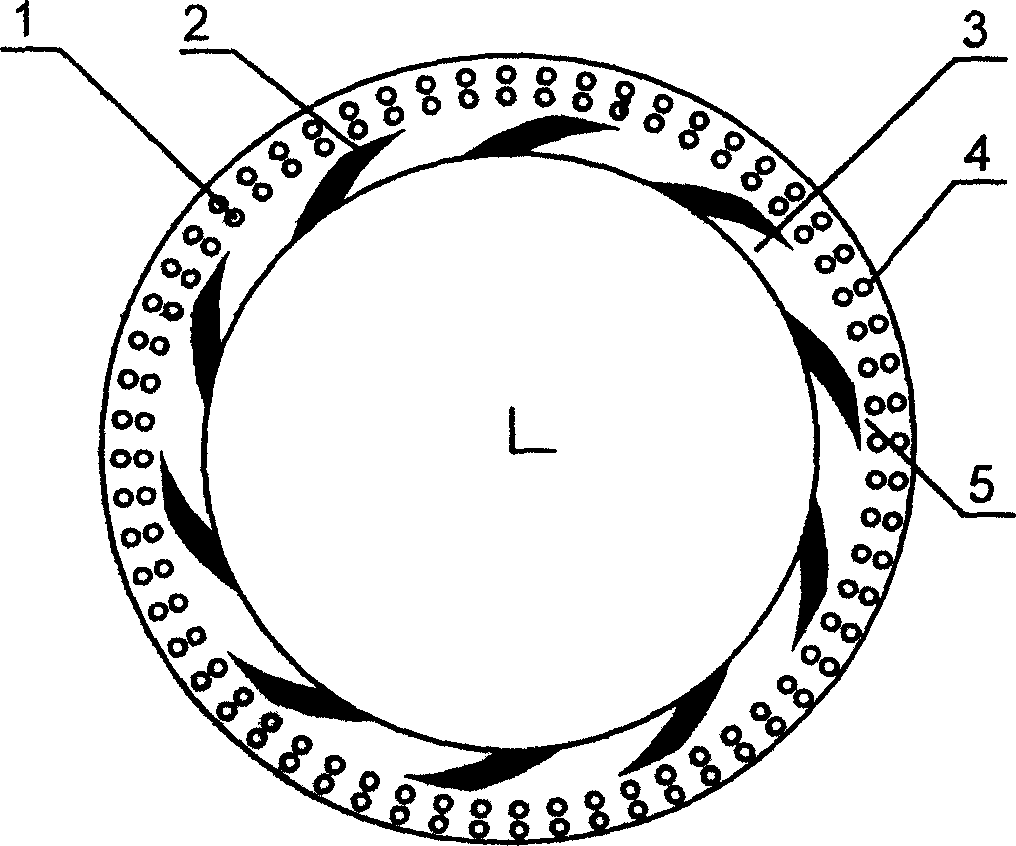

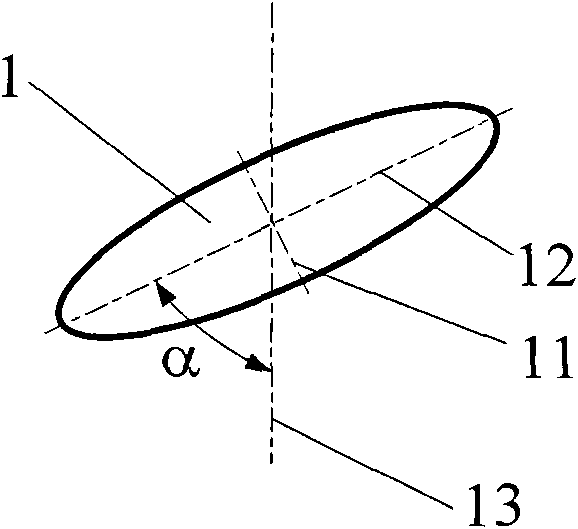

Tilting directional microporous end surface mechanical sealing structure

ActiveCN101672366AImprove reliabilityEnhanced hydrodynamic effectEngine sealsStart stopLiquid medium

The invention relates to a tilting directional microporous end surface mechanical sealing structure comprising a dynamic ring and a static ring which are sealed mechanically, one side of the end surface of the dynamic ring and the static ring is a high-voltage side, namely, an upstream part, and the other side thereof is a low-voltage side, namely, a downstream part; the end surface of the dynamicring or the static ring is provided with a microporous ring belt which is arranged on the upstream part of the end surface; the downstream part of the microporous ring belt is provided with a continuous ring-shaped sealing dam; and a long shaft of the micropore forms a tilting angle with the diameter of the sealing end surface passing through the center of the micropore. The tilting directional micropore end surface mechanical sealing structure has the beneficial effects of: greatly improving hydrodynamic effect of the microporous end surface, leading the sealing to have good starting-stopping effect under low-voltage condition, being capable of being applied in a liquid medium and a gas medium by setting the depth of the micropore, being capable of fully exerting the capabilities and advantages of microporous solid particles, realizing no contact, wear resistance and no leakage of sealing, prolonging the service life and improving the sealing reliability.

Owner:ZHEJIANG UNIV OF TECH

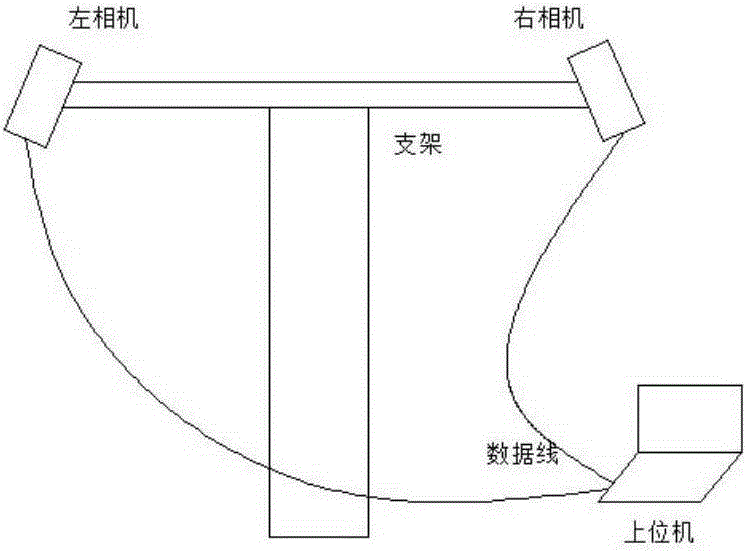

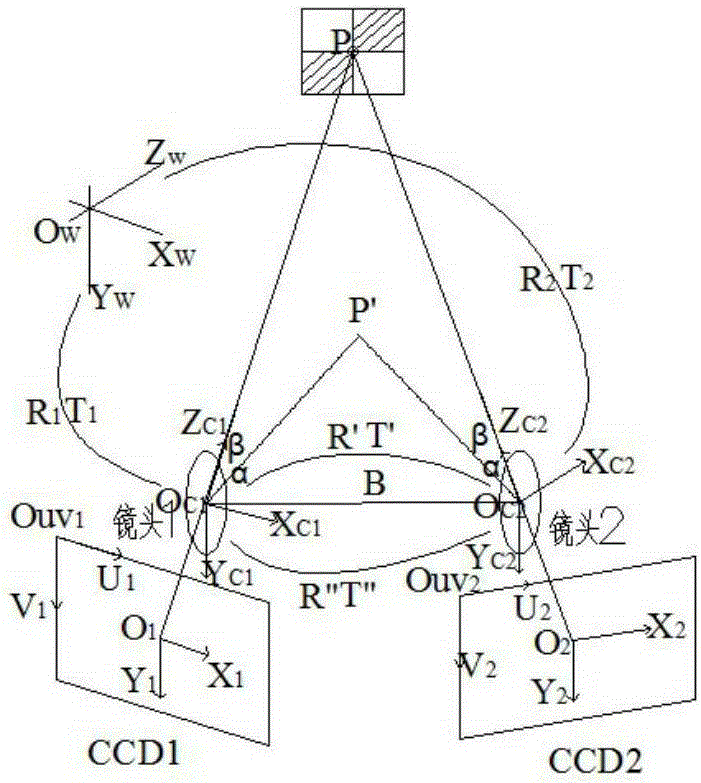

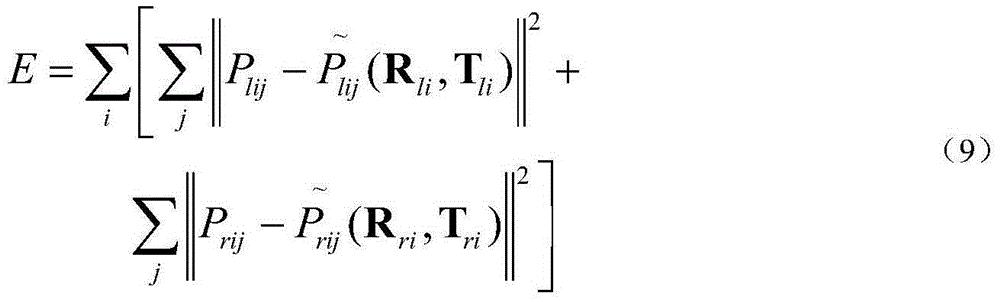

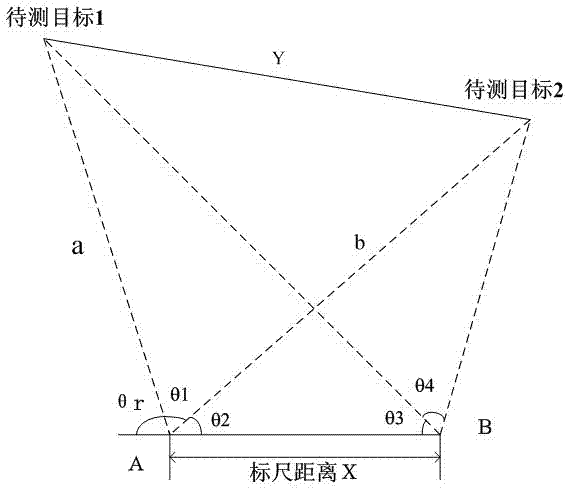

Wire ice-shedding skip trajectory binocular measurement method

InactiveCN105181109AReal-time measurementAccurate measurementSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansMeasurement deviceStereo matching

The invention relates to a wire ice-shedding skip trajectory binocular measurement method, which comprises the steps of (1) system calibration: erecting a binocular measurement device at a location parallel to a to-be-measured lead, connecting the measurement device with a host computer to form a measurement system in the two-camera-based measurement manner, and acquiring the internal parameters and the structural parameters of the measurement system through the computation of the host computer; (2) picture shooting: continuously shooting a ice-shedding lead by means of the measurement device in the look-up gesture; (3) data processing: conducting the data processing operation by means of the host computer, completing the stereo matching process of the two cameras with lead picture matching points and calculating the three-dimensional coordinates of the matching points; (4) trajectory displaying: conducting the coordinate transformation for the calculation result of the data processing operation, and displaying the lateral motion trajectory, the longitudinal motion trajectory and the axis motion trajectory of the ice-shedding lead. According to the technical scheme of the invention, the method integrates the binocular vision technology, the digital image processing technology, the computer software technology and the like, thus being advanced in technology.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

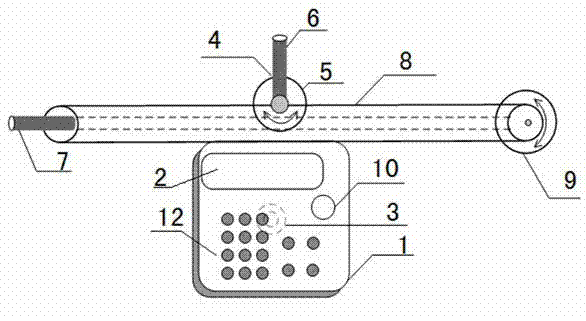

Laser distance measuring and height measuring device

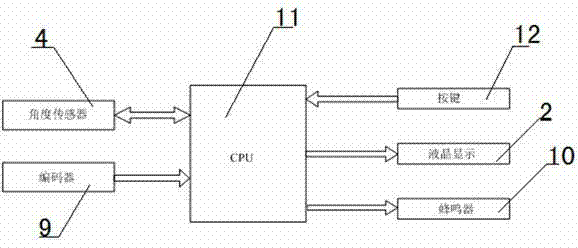

InactiveCN102445184ARealize non-contactRealize long-distance measurementOptical rangefindersLaser rangingLiquid-crystal display

The invention discloses a laser distance measuring and height measuring device. An angle sensor consists of a stepping motor, a laser lamp A and a laser lamp B, wherein the laser lamp B is fixed on a bracket; the laser lamp A is fixed on the stepping motor; a singlechip control circuit and a sliding track are fixed on a triangular bracket; the sliding track is provided with an encoder and an angle sensor; a CPU (Central Processing Unit) is arranged in the singlechip control circuit, and is connected with the angle sensor, the encoder, a key, a buzzer and a liquid phase display; a fixed laser beam is aligned with a target A to be detected to obtain a reference line of an angle; the stepping motor is moved to a leftmost end; a keyboard rotating key is rotated till a laser beam controlled by the stepping motor is emitted onto a target B to be detected; the laser beam points the direction of a track gauge; the stepping motor is moved to the other end of the sliding track; the stopping motor is used for driving the encoder to record a moving distance; an LCD (Liquid Crystal Display) is used for displaying results; and if height is required to be measured, a height measuring mode is switched to. The laser distance measuring and height measuring device has the characteristics of convenience for carrying, accurate measurement and convenience for operating.

Owner:SHAANXI UNIV OF SCI & TECH

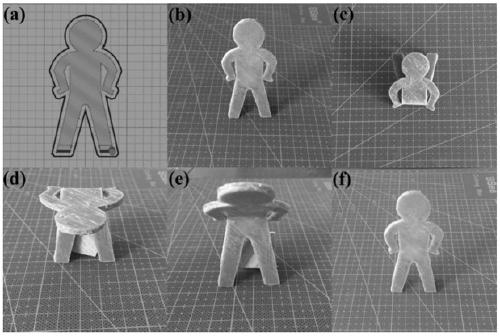

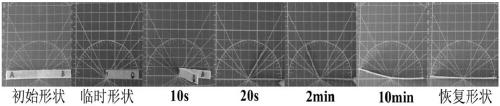

3D printing plant fiber composite wire with shape memory function and preparation method of 3D printing plant fiber composite wire

ActiveCN109371501AReduce material costsIncrease profitAdditive manufacturing apparatusConjugated synthetic polymer artificial filamentsMemory functionsFiber

The invention belongs to the technical field of 3D printing and in particular relates to a 3D printing plant fiber composite wire with a shape memory function and a preparation method of the 3D printing plant fiber composite wire. The plant fiber composite wire comprises raw materials: plant fiber powder, TPU, a modifier and a lubricant. The preparation method comprises the preparation steps as follows: carrying out melt extrusion on a material obtained by sufficiently mixing the plant fiber powder, TPU, the modifier and the lubricant by using a parallel double-screw extruder, then, smashing the material to form aggregates; placing the aggregates into a single-screw extruder, melting the aggregates at a certain temperature, and dragging the molten aggregates at a certain speed to obtain the melted deposition type 3D printing plant fiber composite wire. By using the 3D printing plant fiber composite wire, the problem of relatively high cost caused by adopting a thermoplastic polyurethane elastomer as a 3D printing material is solved, not only is the material cost reduced, but also the interfacial compatibility between TPU and the plant fiber powder is improved by modifying TPU and the plant fiber powder, so that the prepared composite wire has relatively strong toughness and shape memory restorability.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com