Dynamic-static pressure combined type asymmetrical waviness end face fluid mechanical sealing structure

A fluid machinery and sealing structure technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of reducing the bearing capacity and stability of the sealing system, weakening the hydrostatic pressure capacity, increasing the risk of failure, etc. Work efficiency, improve hydrodynamic pressure effect, prevent accumulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with accompanying drawings and examples.

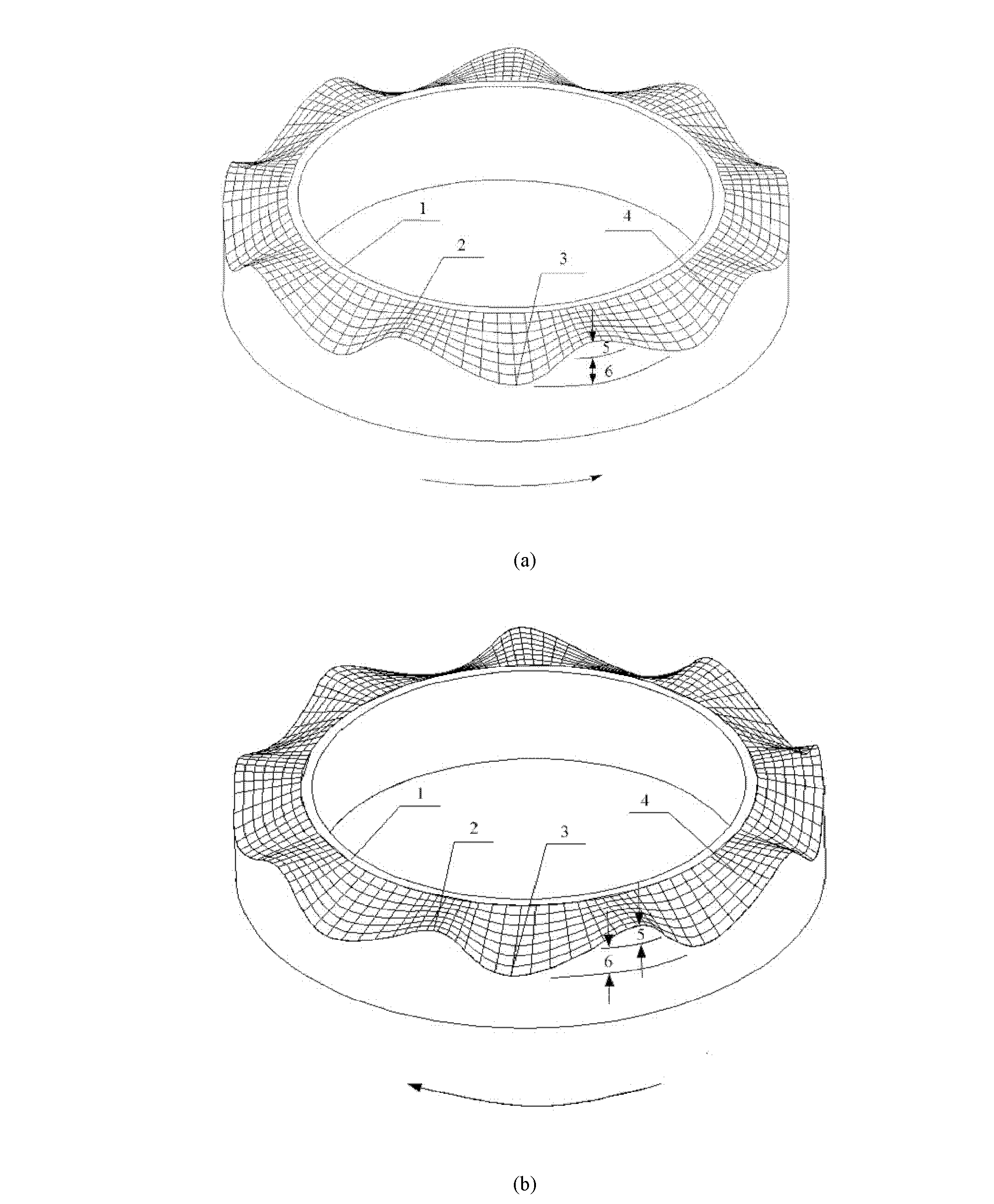

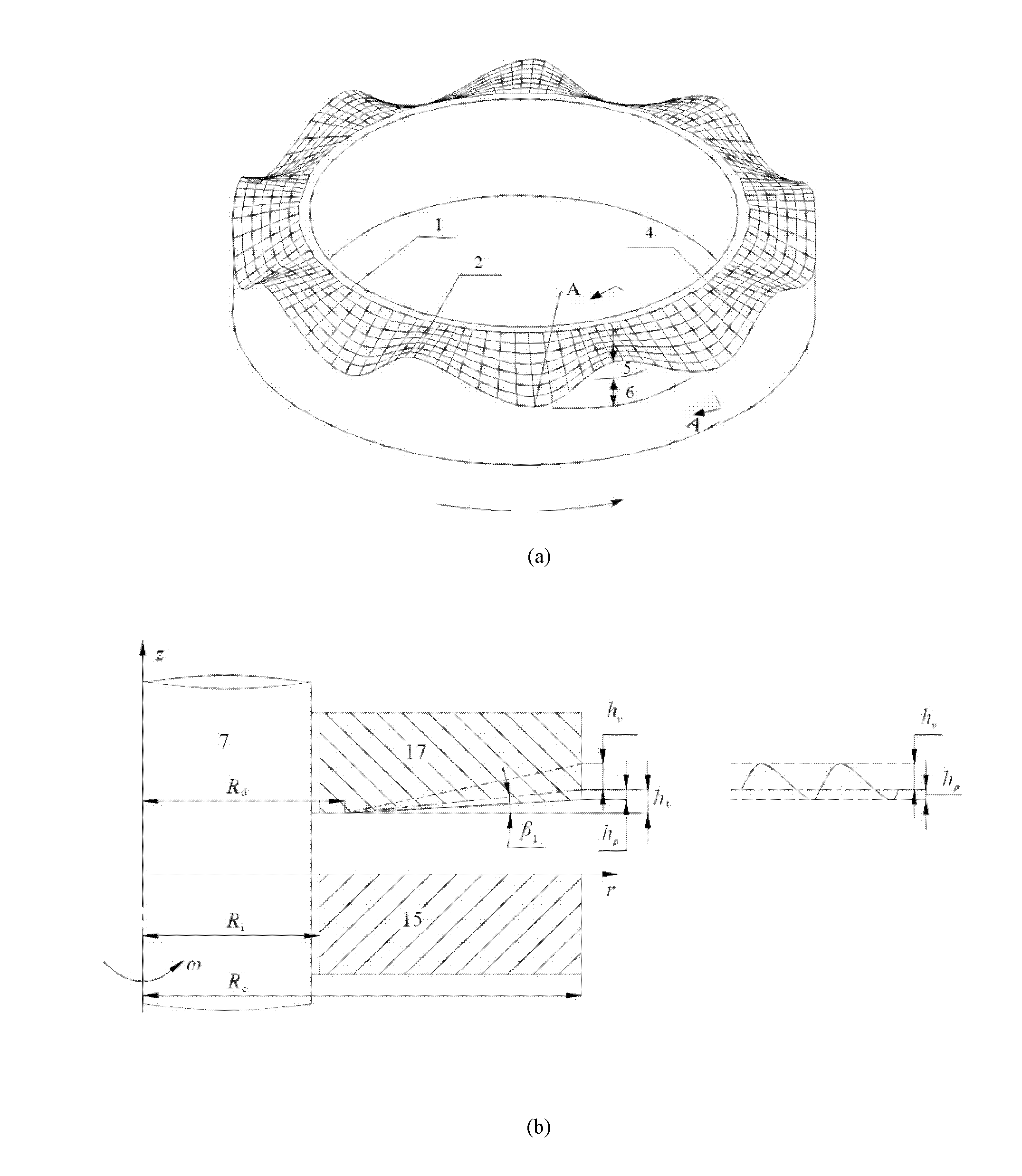

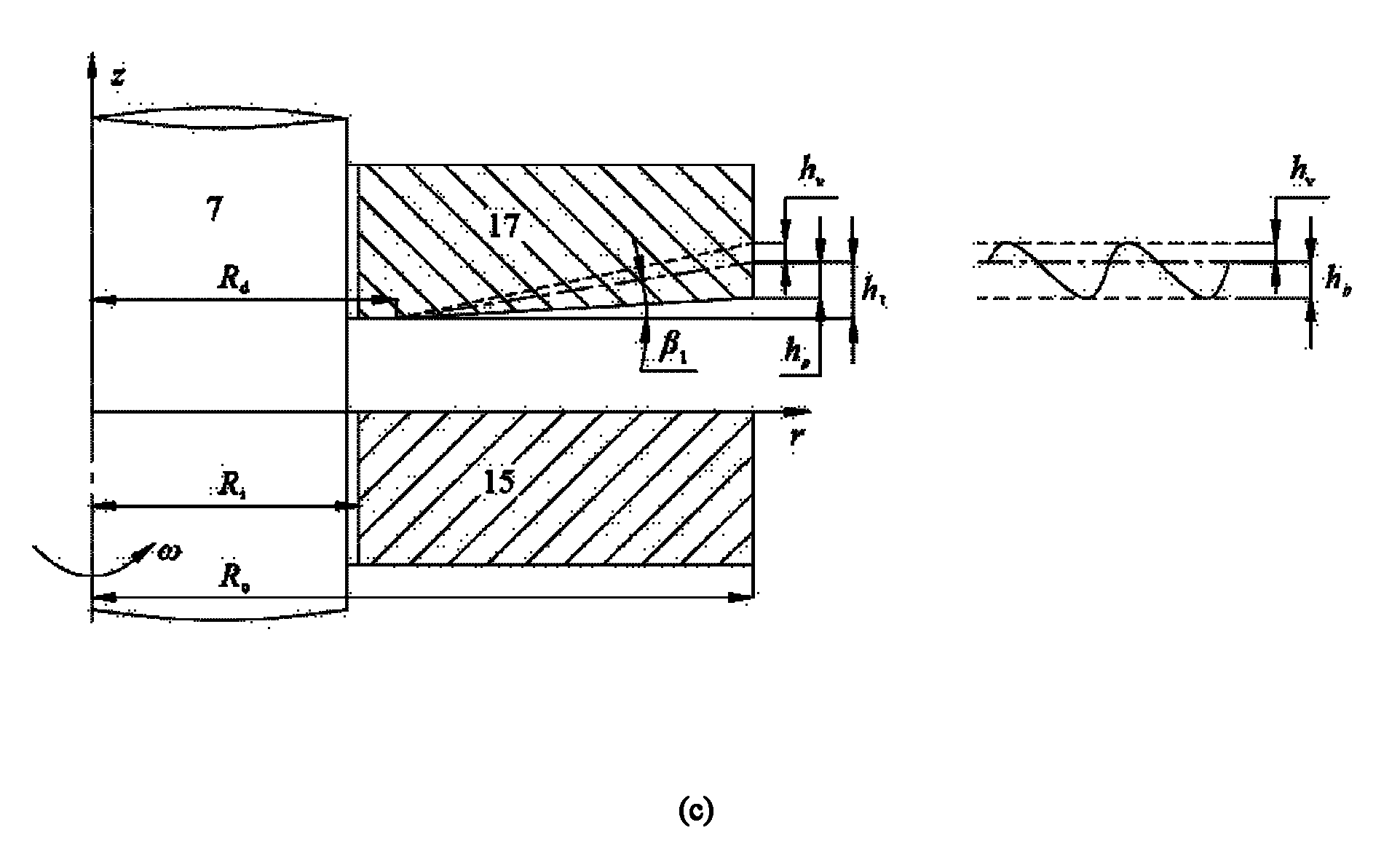

[0027] refer to figure 1 (a), figure 1 (b), figure 2 (a), figure 2 (b) and figure 2 (c), a combination of dynamic and static pressure type asymmetric waviness end face liquid mechanical seal structure, including the main shaft 7, the moving ring 15 and the static ring 17 of the mechanical seal, the end faces of the moving ring 15 and the static ring 17 are the high pressure side, That is, the upstream, and the other side is the low-pressure side, that is, the downstream. At least one sealing end surface of the moving ring 15 and the static ring 17 has more than two three-dimensional asymmetric waviness shapes, and the asymmetric waviness is periodic on the sealing end surface. Arrangement, the asymmetric waviness sealing end face includes dam area 1, cone surface 4, wave crest 2, wave trough 3 and the formed wave peak height 5 and wave trough depth 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com