On-line measurement apparatus for high-temperature mechanics behavior of multi-layer film basal body structure

A high-temperature mechanics and measuring device technology, applied in the field of structural deformation and mechanical experiments, and engineering materials, it can solve problems such as film damage, cavitation, and reduce overall structural performance, and achieve the effect of avoiding the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific structure and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

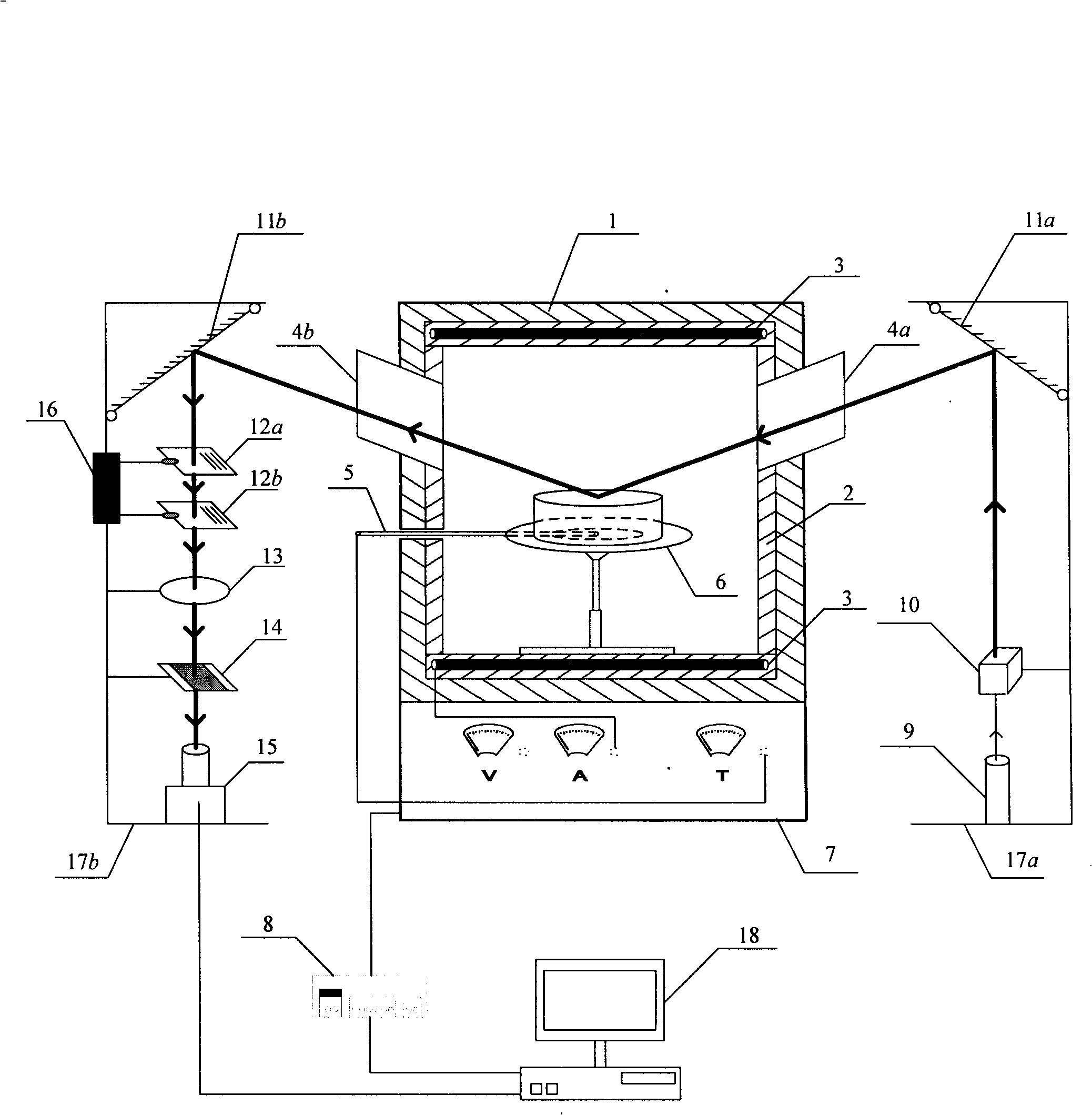

[0021] figure 1 It is a structural schematic diagram of an on-line measuring device for the high-temperature mechanical behavior of a multilayer film matrix structure provided by the present invention, the device includes a heating furnace 1 with a signal acquisition converter 8, an optical system, and a data processing and display system 18; the heating furnace 1 includes Insulation wall 2, heating rod 3, thermocouple 5 and temperature control panel 7, described heating rod 3 is respectively arranged on the top and the bottom in the heating furnace, and the specimen tray 6 is set in the described heating furnace 1, after heating The first light-through window 4a and the second light-through window 4b are symmetrically arranged on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com