Leakproof dynamic pressure type valve plate

A valve plate, dynamic pressure type technology, applied in the field of hydraulic components, can solve the problems of large overturning moment of the cylinder and large leakage, and achieve the effects of reducing friction and wear, reducing leakage and improving volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

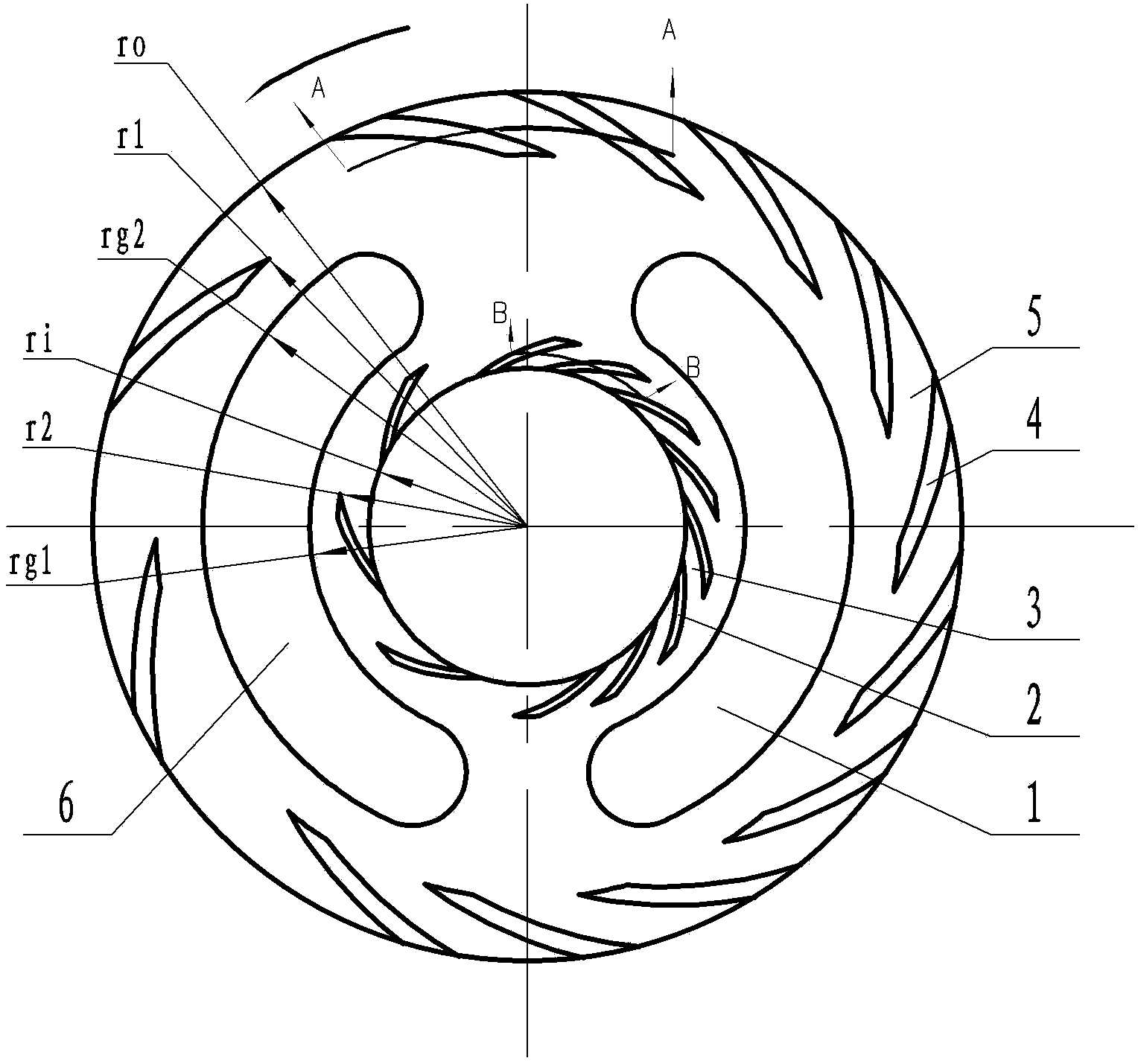

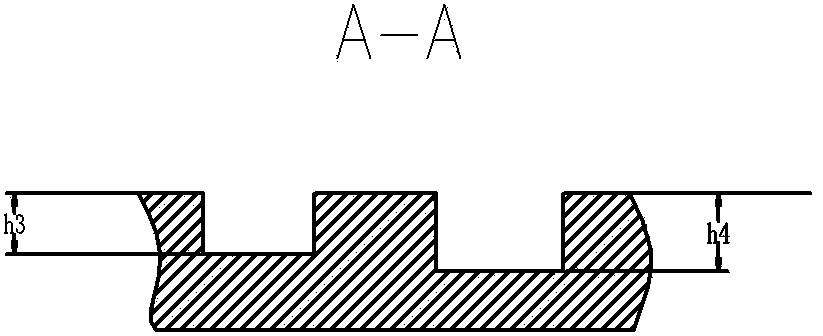

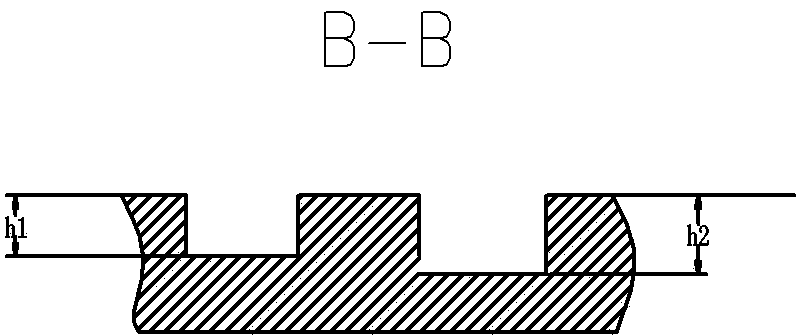

[0024] figure 1 The anti-leakage dynamic pressure distribution plate shown includes a distribution plate body with a waist-shaped distribution window, and the waist-shaped distribution window includes an oil suction port 1 in a low oil pressure area of the valve body body and an oil pressure port 6 in a high oil pressure area ; On the sealing end face of the distribution plate body, a plurality of curved first miniature grooves 2 are arranged along the inner ring surface of the inner side of the oil suction port 1 and the inner side of the oil pressure port 6, and along the outer side of the oil suction port 1 and the outer side of the oil pressure port 6 The outer ring surface is provided with a plurality of curved second micro-channels 4; the first micro-channels 2 and the second micro-channels 4 are arc grooves with one end closed and the other end open, and the first micro-channels 2 are closed. The end extends to the inner edge of the distribution plate body to form an ...

Embodiment 2

[0027]The first micro-channel and the second micro-channel of the anti-leakage dynamic pressure distribution plate of this embodiment are both spiral grooves, and the number of the first micro-channel is 5 on the side of the oil pressure port, and the groove depth is 3 microns. The number of grooves on the side of the oil suction port is 9, the groove depth is 5 microns, the ratio of the total cross-sectional area of the first micro channel to the total area of the first sealing weir is 0.4:1, and the radius ri of the inner edge of the valve plate body is 20 mm, the closed ends of all the first micro channels are on the same circle, the radius r2 of this circle is 23.5 mm, the radius rg1 inside the oil pressure port is 27 mm, and the inner edge of the valve plate body reaches the first The ratio of the radial distance of the closed end of the micro-channel to the radial distance inside the oil pressure port is (r2-ri): (rg1-ri)=(23.5-20): (27-20)=0.5:1 ; The second miniatu...

Embodiment 3

[0029] The first micro-channel and the second micro-channel of the anti-leakage dynamic pressure distribution plate of this embodiment are both spiral grooves, and the number of the first micro-channel is 55 on the side of the oil pressure port, and the groove depth is 2 microns. The number of grooves on the side of the oil suction port is 45, the groove depth is 1 micron, the ratio of the total cross-sectional area of the first micro channel to the total area of the first sealing weir is 10:1, and the radius ri of the inner edge of the valve plate body is 20 mm, the closed ends of all the first micro channels are on the same circle, the radius r2 of this circle is 22 mm, the radius rg1 inside the oil pressure port is 40 mm, and the inner edge of the valve plate body reaches the first The ratio of the radial distance of the closed end of the micro channel to the radial distance inside the oil pressure port is (r2-ri): (rg1-ri)=(22-20): (40-20)=0.1:1 ; The second micro chan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com