Detecting system for sealing property of aluminum foil blister package

A technology of airtightness detection and blister packaging, which is applied in the direction of testing the fluid tightness by detecting the dimensional change of the tested structural parts, and using liquid/vacuum degree to measure the liquid tightness, etc. Large error impact, waste and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

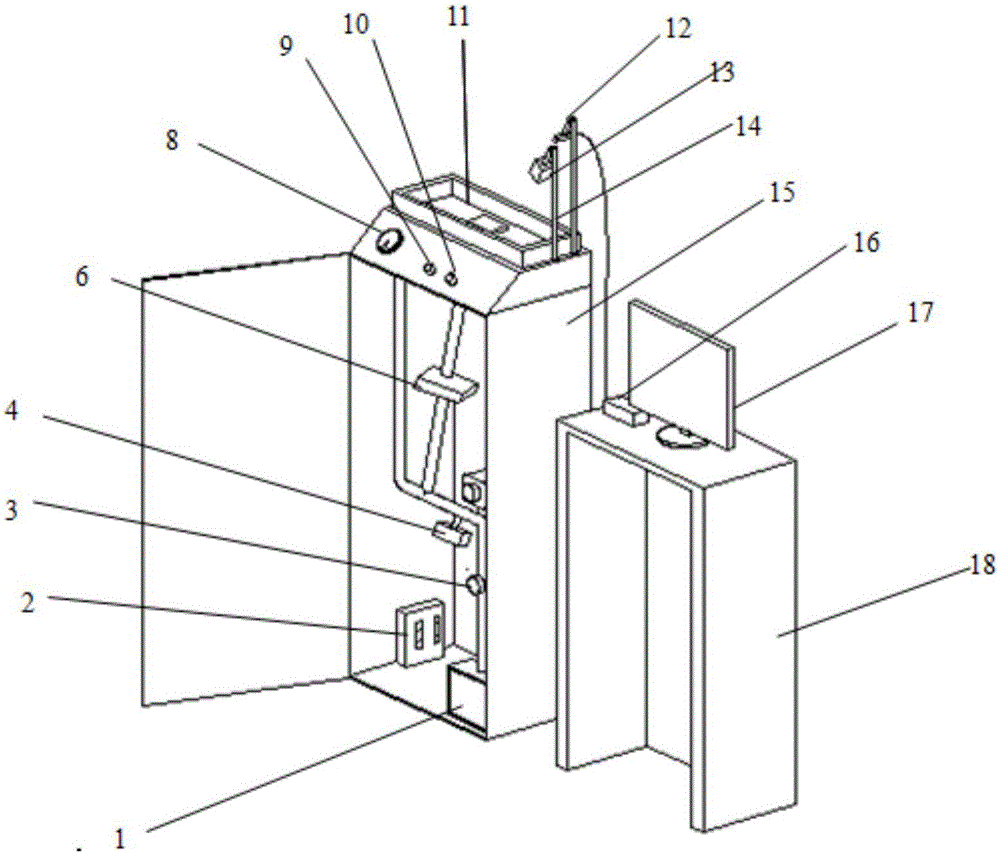

[0046] In this embodiment, the image sensor includes an image acquisition card 2 and a CCD camera 13, the image acquisition card is connected to the computer through a USB data cable, and the transparent material is glass. Install the image acquisition card, the vacuum pump 1 in the vacuum air circuit system, the pressure relief valve 4, the reversing valve 3, the pressure sensor 6 and the pipelines in the box body 15, install the sealed cavity on the upper surface of the box body, and install it in the box body. A pressure gauge 8 displaying pressure sensor pressure data, a power switch 9 and a power indicator light 10 are installed on the external surface of the body; the light source controller and the computer are installed on the console 18 close to the box body. This embodiment provides a schematic diagram of the overall structure of the aluminum-plastic blister packaging airtightness detection system as shown in figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com