Coiled tubing ovality testing method

A detection method and ellipticity technology, applied in the field of ellipticity detection, can solve the problems of low sensitivity, bulky instruments, difficult ultrasonic detection methods, etc., and achieve the effects of simple detection methods, accurate results, and good measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

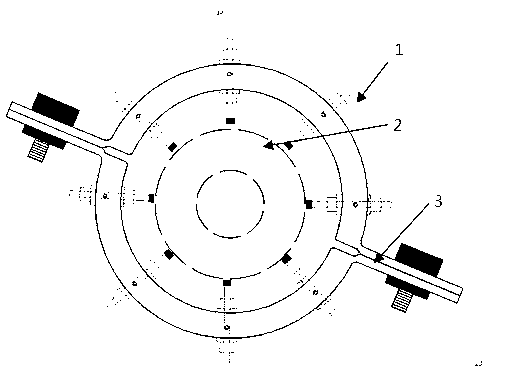

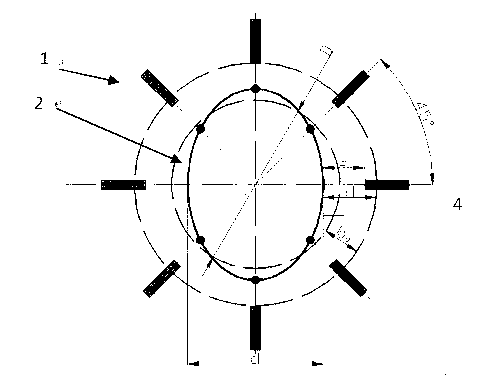

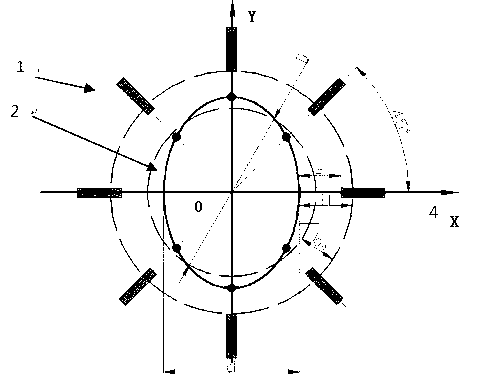

[0044] As a preferred embodiment of the present invention, the present invention discloses a method for detecting the ellipticity of coiled tubing, which uses a displacement sensor to measure the lift-off heights of 8 points on the same circumference of a certain position of the coiled tubing, and then calculates the coiled tubing at this position ellipticity. The lift-off height refers to the vertical distance between the front end of the displacement sensor probe and the surface of the coiled tubing.

Embodiment approach

[0047] The invention uses an eddy current displacement sensor (hereinafter referred to as displacement sensor) to measure the lift-off height of 8 points on the same circumference of a certain position of the coiled tubing (that is, the vertical distance between the front end of the probe and the surface of the coiled tubing), and calculates the ellipticity of the coiled tubing at this position.

[0048] The specific operation includes the following steps:

[0049]Step 1, fix the mounting bracket. Put the coiled tubing into the mounting frame, tighten the bolts of the mounting frame; adjust the position and angle of the mounting frame so that the tubing is concentric with the mounting frame and perpendicular to the circular surface of the mounting frame, and then fix the mounting frame on the pipe rack.

[0050] Step 2, install the sensor. The displacement sensor extends into 8 through holes evenly distributed along the circumference, and is fixed on the mounting frame by scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com