Method and apparatus for laser shock wave three dimensional highly false proof nondestructive marking

A shock wave and laser technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of poor anti-counterfeiting performance, unevenness, complicated operation, etc., and achieve the effect of non-destructive and high anti-counterfeiting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

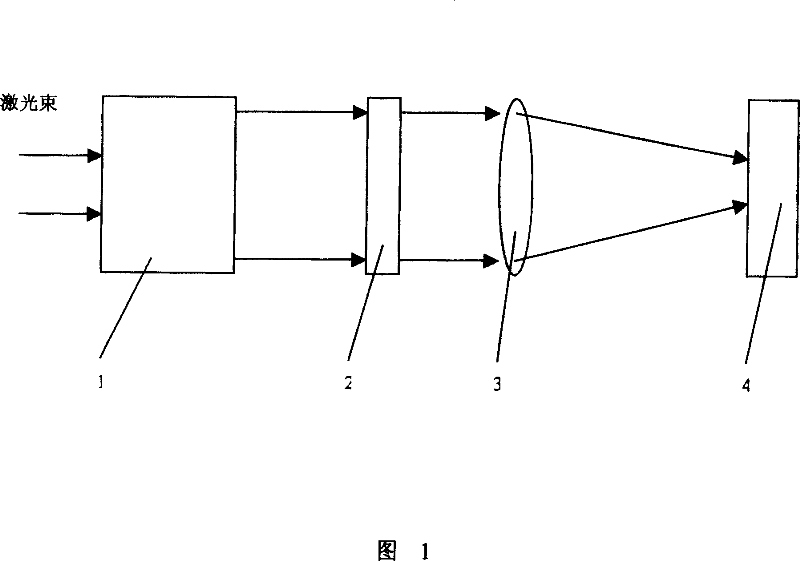

[0020] The details and working conditions of the specific device proposed by the present invention will be described in detail below with reference to FIG. 1 .

[0021] The device comprises a laser generator, a beam spatial modulator (1), a liquid crystal mask (2), a lens (3), a part (4), and a control system. The laser beam spatial modulator consists of a concave lens, a convex lens and a homogenizer.

[0022] According to the size and material of the marked area of the part, select a flexible film and stick the flexible film on the surface of the part; according to the requirements of the logo, draw a pattern with grayscale, display the pattern on the LCD screen to form a liquid crystal mask, and The liquid crystal mask is controlled by the computer to realize fast pattern transformation; the laser generator generates laser pulses with an energy of 10-100 joules and a duration of 8-80 nanoseconds. The light spot mode can be fundamental mode, multi-mode and other modes. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com