Manufacturing method for printed matter anti-counterfeit mark of combination splicing of grating and image carrier

A technology of anti-counterfeiting marks and image carriers, which is applied to the printing, printing, and printing processes of producing special varieties of printed matter. It can solve the problems of increasing anti-counterfeiting application, being easy to be imitated, and being unable to be recognized by ordinary consumers, so as to increase interest and add value. Value, the effect of improving anti-counterfeiting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] Now, the production and operation process of the present invention will be described in detail by taking the hidden information divided into the blue plate and the corresponding display and hidden grating as an example.

[0036] 1. Create a background color block, create a workspace with an image size of 5cm×5cm in Photoshop, a resolution of 2400dpi, and a color mode of CMYK. Fill foreground color C, M, Y, K dot area rate is 20% respectively. Separate four color channels, perform bitmap processing, output resolution 2400dpi, set halftone screen, frequency to 175LPI, shape to be circular, and screen angles of C, M, Y, and K channels to be 15°, 75°, respectively. °, 90°, 45°. After the setting is completed, it is converted to grayscale mode, and the conversion ratio is 1, forming a color version of four colors of yellow, magenta, cyan and black.

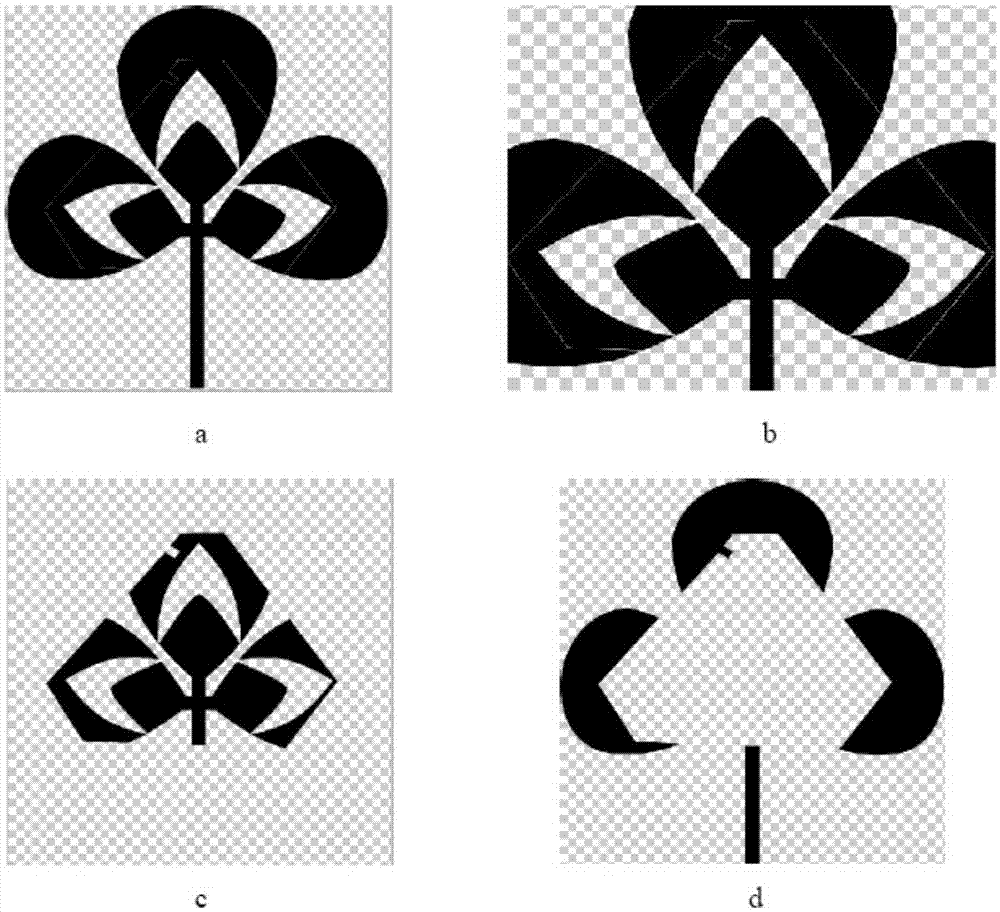

[0037] 2. To make graphic information to be hidden, first draw hidden information graphics in CorelDraw software, and the im...

Embodiment 2

[0043] Now, the production and operation process of the present invention will be described in detail by taking the example that the hidden information is divided into the yellow plate and the corresponding display and hidden grating respectively.

[0044] 1. Create a background color block, create a workspace with an image size of 3cm×3cm in Photoshop, a resolution of 310dpi, and a color mode of CMYK. Fill foreground color C, M, Y, K dot area rate is 30% respectively. Separate four color channels, perform bitmap processing, output resolution 310dpi, set halftone screen, frequency to 172LPI, shape to be circular, C, M, Y, K four channel screen angles are 20°, 80° respectively °, 90°, 40°. After the setting is completed, it is converted to grayscale mode, and the conversion ratio is 1, forming a color version of four colors of yellow, magenta, cyan and black.

[0045] 2. To make the graphic information to be hidden, first draw the hidden information graphics in CorelDraw soft...

Embodiment 3

[0051] Now, the production and operation process of the present invention will be described in detail by taking the hidden information divided into the blue plate and the corresponding display and hidden grating as an example.

[0052] 1. Create a background color block, and create a workspace with an image size of 21cm×21cm in Photoshop, a resolution of 2400dpi, and a color mode of CMYK. Fill foreground color C, M, Y, K dot area rate is 18% respectively. Separate four color channels, perform bitmap processing, output resolution 2400dpi, set halftone screen, frequency is 175LPI, shape is circular, and the screen angles of C, M, Y, and K channels are 18°, 77°, respectively. °, 90°, 43°. After the setting is completed, it is converted to grayscale mode, and the conversion ratio is 1, forming a color version of four colors of yellow, magenta, cyan and black.

[0053] 2. To make the graphic information to be hidden, first draw the hidden information graphics in CorelDraw softwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com