3D printing plant fiber composite wire with shape memory function and preparation method of 3D printing plant fiber composite wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

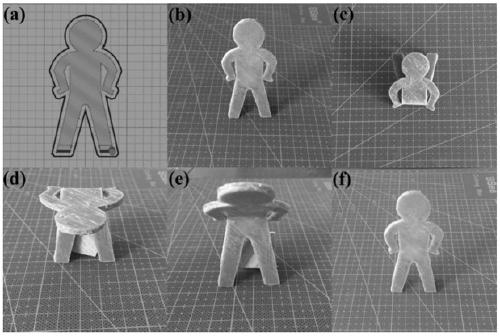

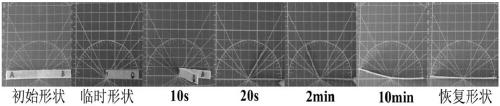

Image

Examples

Embodiment 1

[0027] A plant fiber composite wire with shape memory function for 3D printing. The composite wire includes the following components in parts by mass: 5-45 parts of plant fiber powder, 55-95 parts of TPU and 0.5-2 parts of lubricant.

Embodiment 2

[0029] A plant fiber composite wire for 3D printing with shape memory function, the composite wire includes the following components in parts by mass: 5-45 parts of plant fiber powder, 55-95 parts of TPU, 1-20 parts of modifier and 0.5 ~2 parts lubricant.

Embodiment 3

[0031] A method for preparing a plant fiber composite wire for 3D printing with shape memory function, the steps of the preparation method are as follows: 5-45 parts of plant fiber powder, 55-95 parts of TPU, 1-20 parts of modifier and 0.5- 2 parts of lubricants are fully mixed and the obtained materials are melted and extruded through a parallel twin-screw extruder in the same direction, and then crushed into pellets, which are put into a single-screw extruder, and the pellets are melted at a certain temperature. Pulling speed to obtain plant fiber composite filaments for fused deposition 3D printing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com