SPR phase measurement method for measuring thickness of nano-scale double-layer metal film

A technology of double-layer metal and thin film thickness, applied in measurement devices, optical devices, instruments, etc., can solve the problems of poor adhesion of metal materials and insufficient measurement sensitivity of SPR sensors, and achieve simple structure, easy operation, high The effect of precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

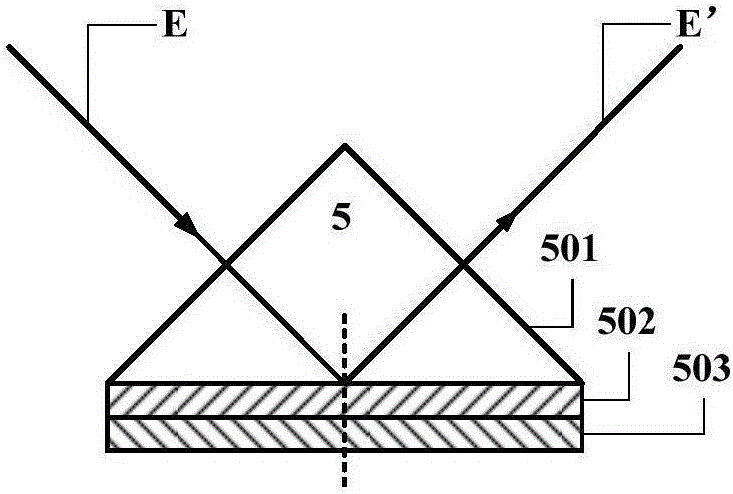

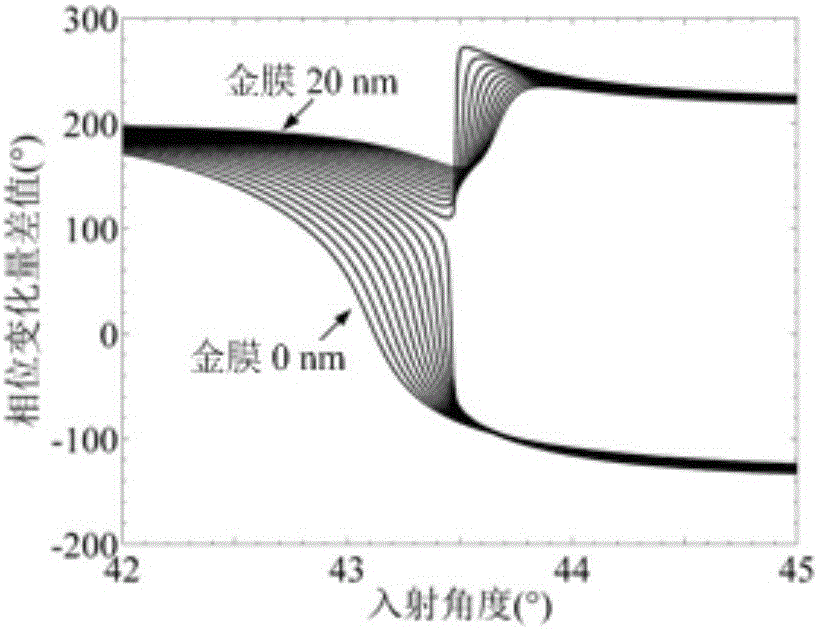

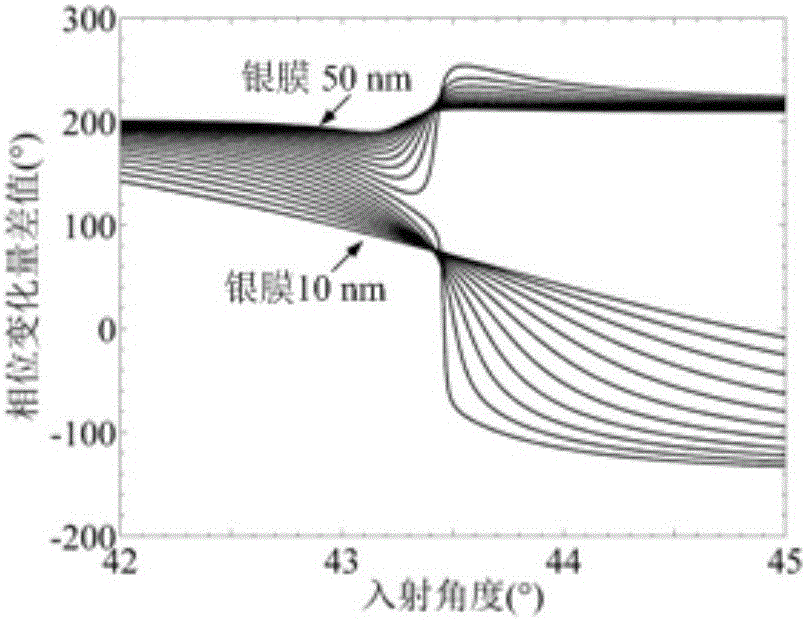

[0024] The surface plasmon resonance (Surface Plasmon Resonance, SPR) effect is a special physical optical phenomenon. The evanescent wave generated when the light wave is totally reflected at the interface between the medium and the metal can trigger the collective oscillation of the free electrons on the metal surface, thus forming a surface plasmon wave (Surface Plasmon Wave, SPW), whose magnetic field vector direction is parallel At the interface between the medium and the metal, the magnetic field intensity reaches the maximum at the interface and shows an exponential decay trend in the two media. When the wave vector of the incident light is equal to the wave vector of the surface plasmon wave, the SPR effect can be excited. At present, the modulation types of SPR sensing technology mainly include angle type, spectral type and phase type. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com