Control system for a pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

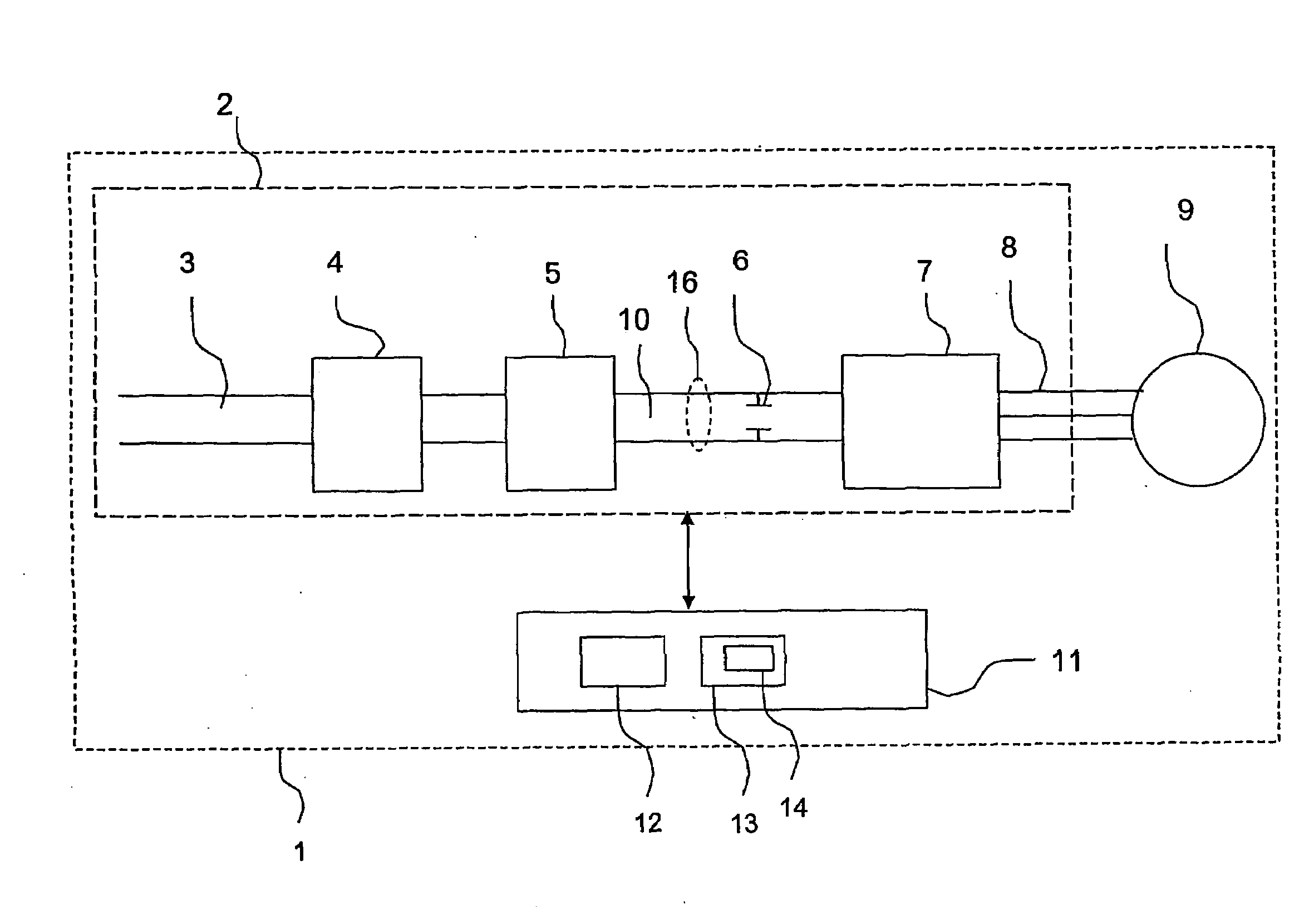

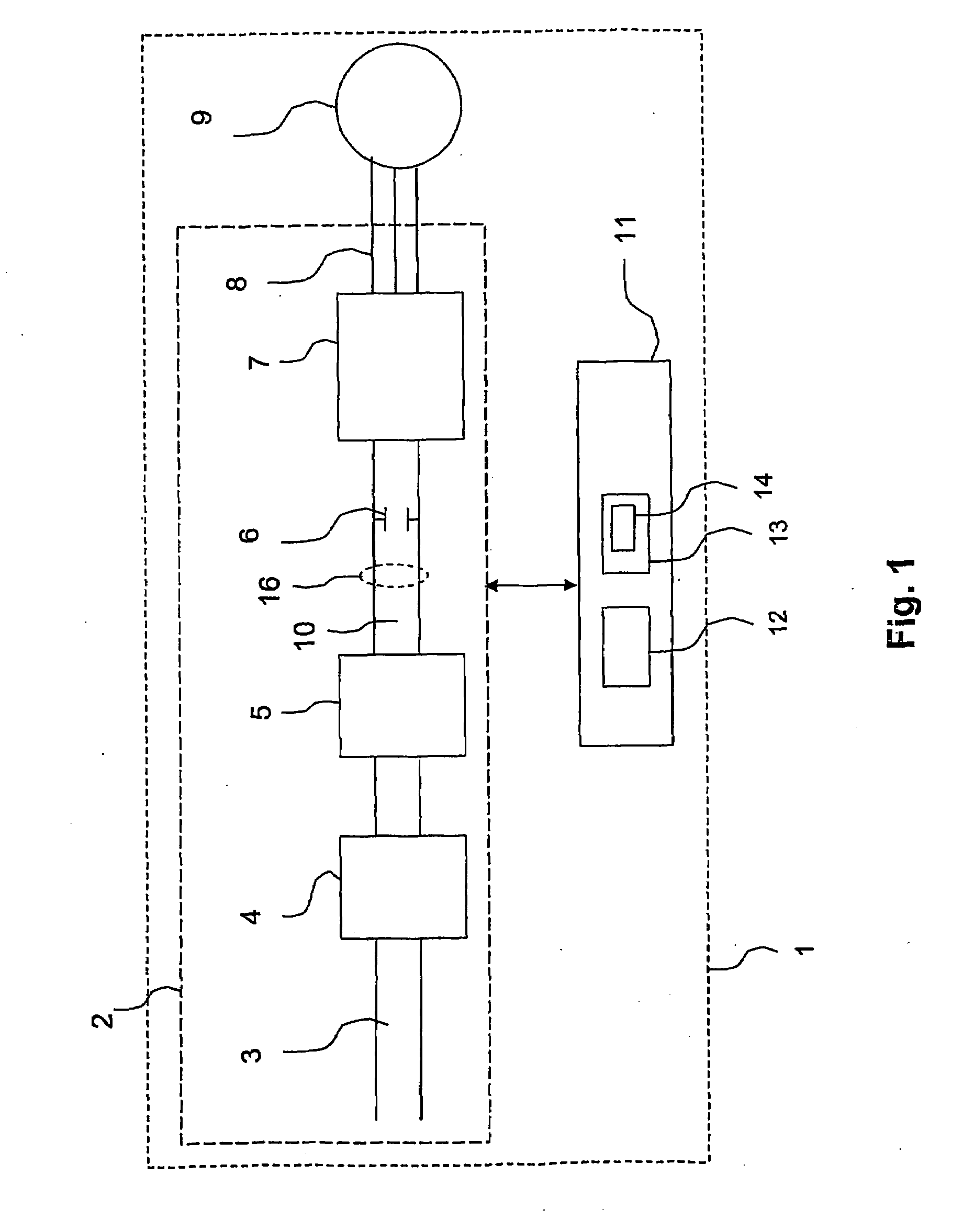

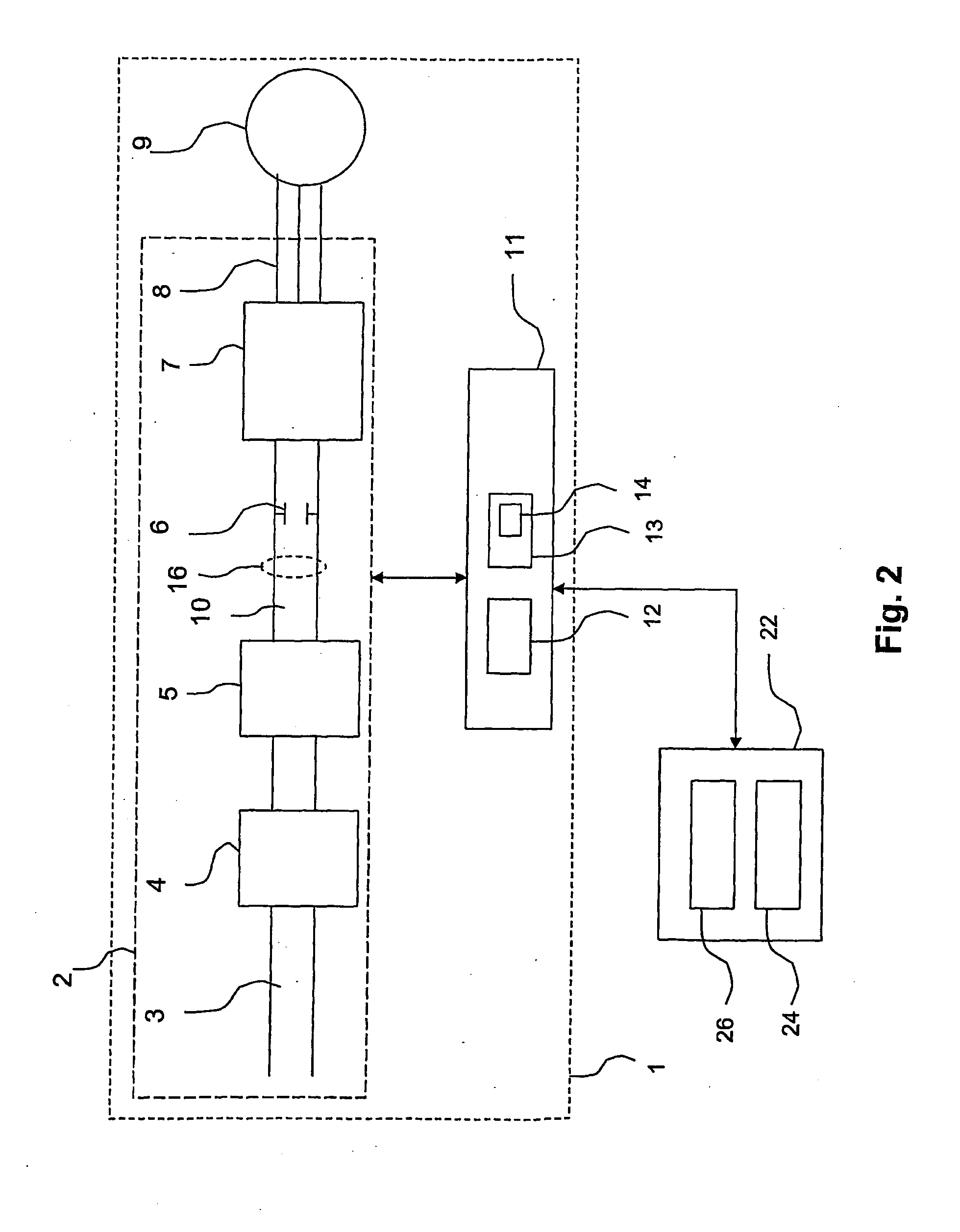

[0044]In the following, there will be disclosed preferred embodiments of a method for operating a pump and a pump system.

[0045]With reference first to FIG. 1, a first embodiment of a pump according to the present invention will be described. For purpose of illustration, the embodiments of the present invention described hereinafter are utilized in present submersible pumps comprising variable frequency drive means. But, as the skilled man within the art easily realizes, the present invention can also be utilized in other types of pumps, such as sewage pumps, drainage pumps, de-watering pumps, etc.

[0046]The submersible pump 1 of FIG. 1 comprises a variable-speed unit 2, preferably variable frequency drive means (VFD unit) connected via a connection cable 3 to a power source (not shown) delivering, for example, a single phase voltage or a three phase voltage. Unlike prior art pumps comprising a VFD unit, which are only designed to receive a power supply within the range from approxima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com