Patents

Literature

85results about How to "Improve startup reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

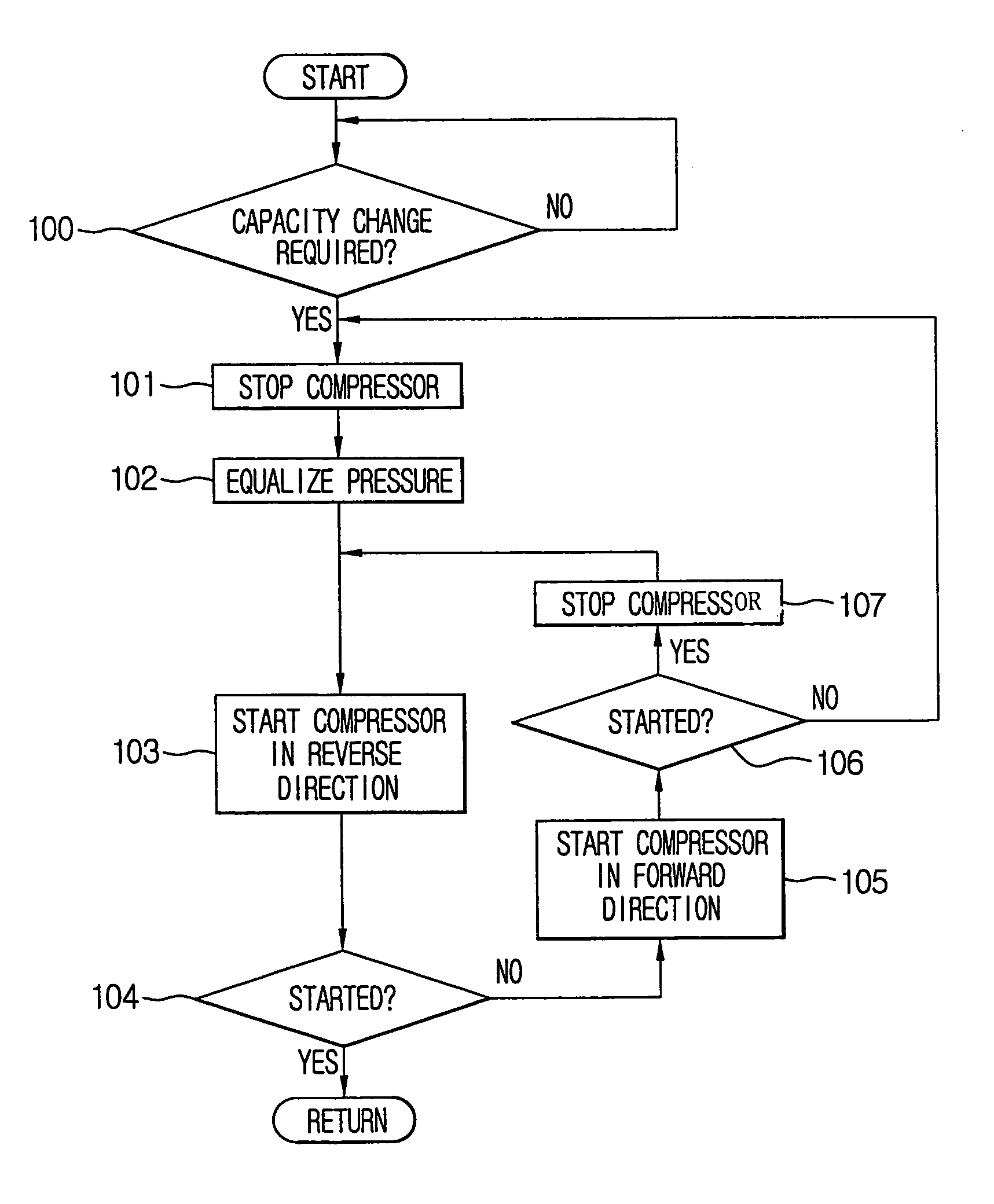

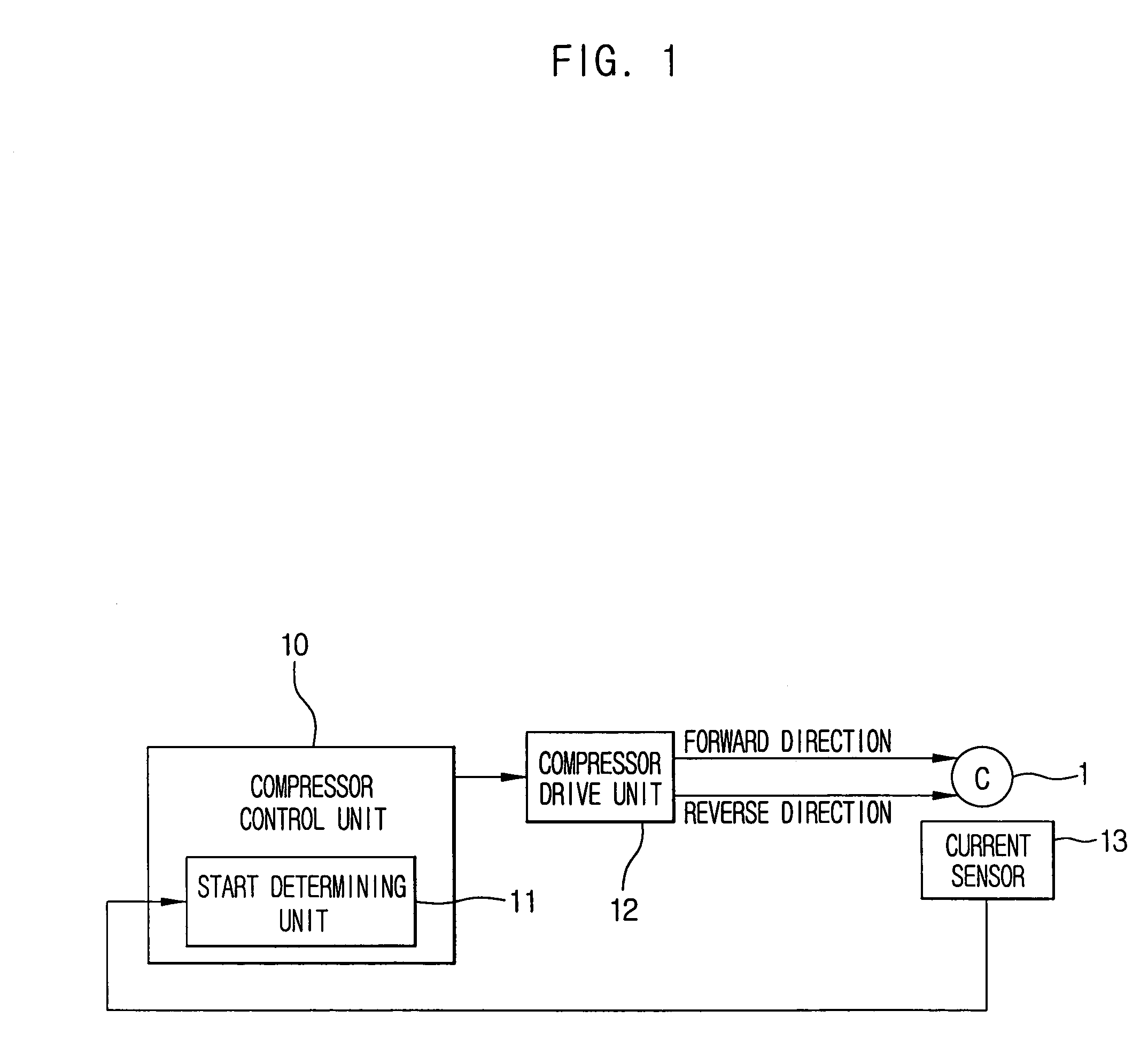

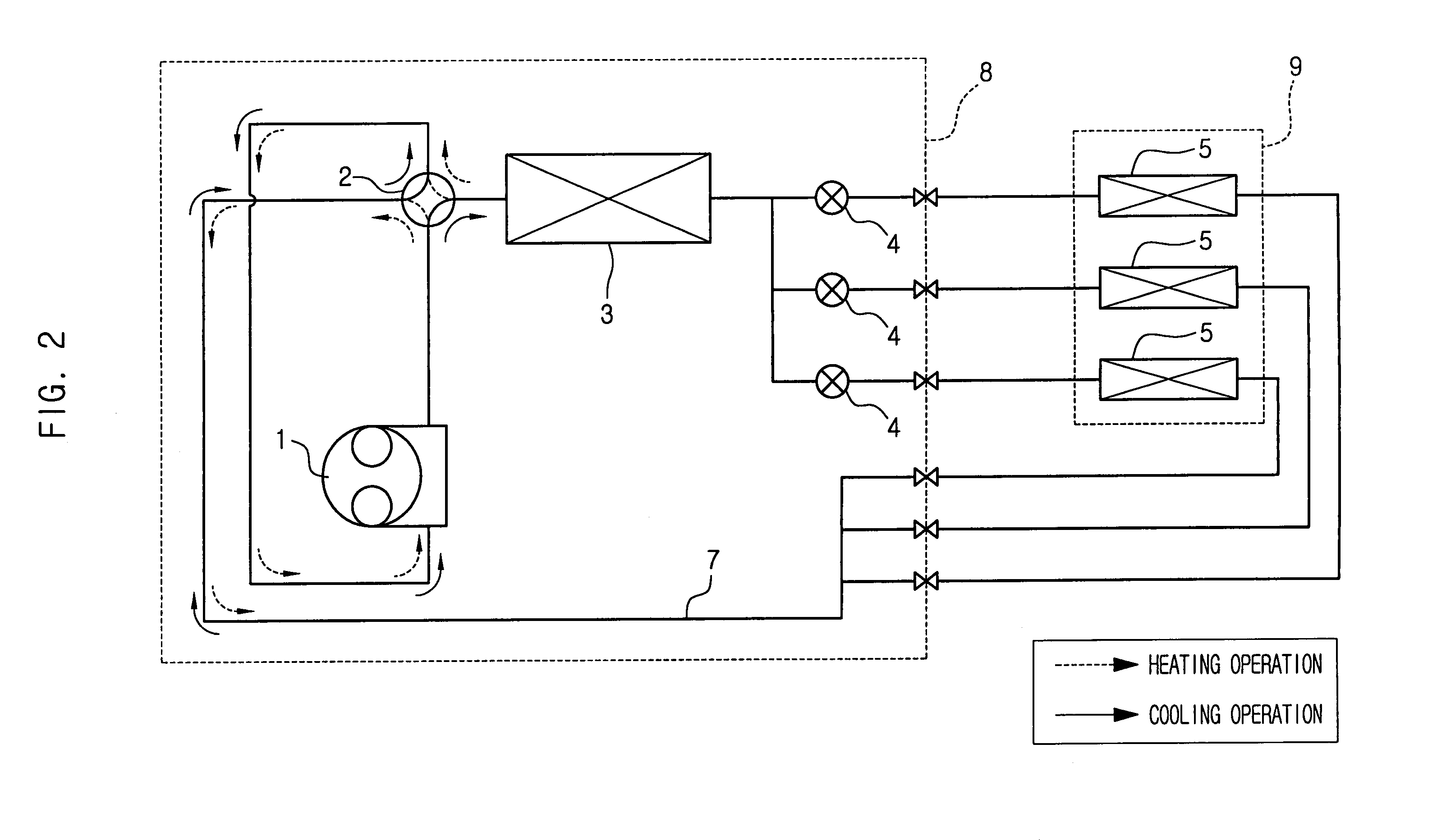

Air conditioner and method of controlling the same

InactiveUS7040107B2Smooth startImprove startup reliabilityRotary/oscillating piston combinations for elastic fluidsSpace heating and ventilation safety systemsCounter rotationVariable capacity

An air conditioner has a variable capacity rotary compressor, which allows the compressor to be smoothly re-started, thus increasing start reliability of the compressor. The air conditioner includes a compressor rotated in opposite directions. A drive unit rotates the compressor in a forward or reverse direction. A start determining unit determines whether the compressor has started to rotate in a forward direction or not. A control unit operates the drive unit so as to rotate the compressor in a direction opposite to the forward direction, and then re-start the compressor in the forward direction, when the compressor has failed to start. The air conditioner and a method of controlling the air conditioner allow the compressor to be smoothly and rapidly re-started even when the compressor has failed to re-start, thus increasing start reliability, and shortening a time required to re-start the compressor.

Owner:SAMSUNG ELECTRONICS CO LTD

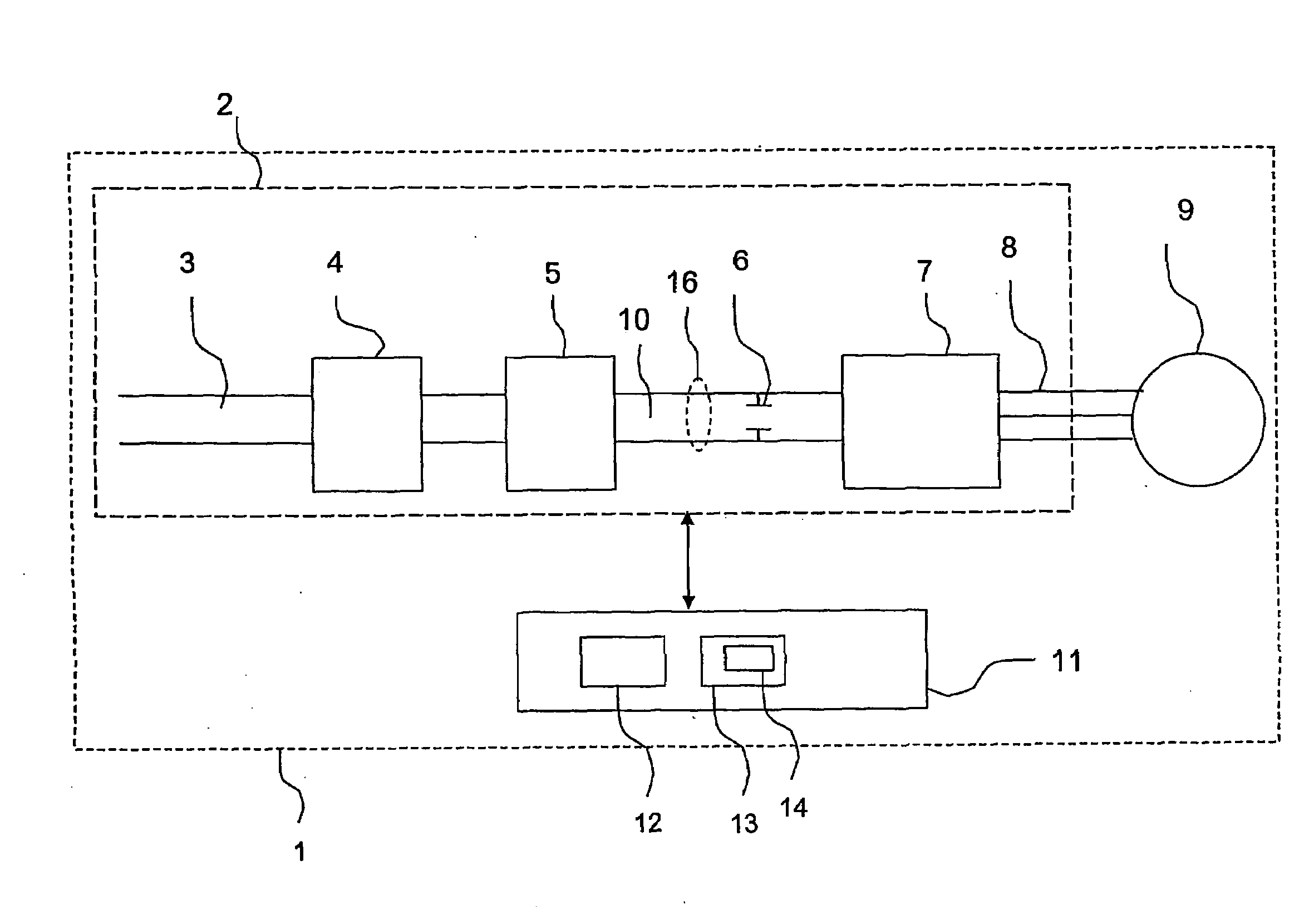

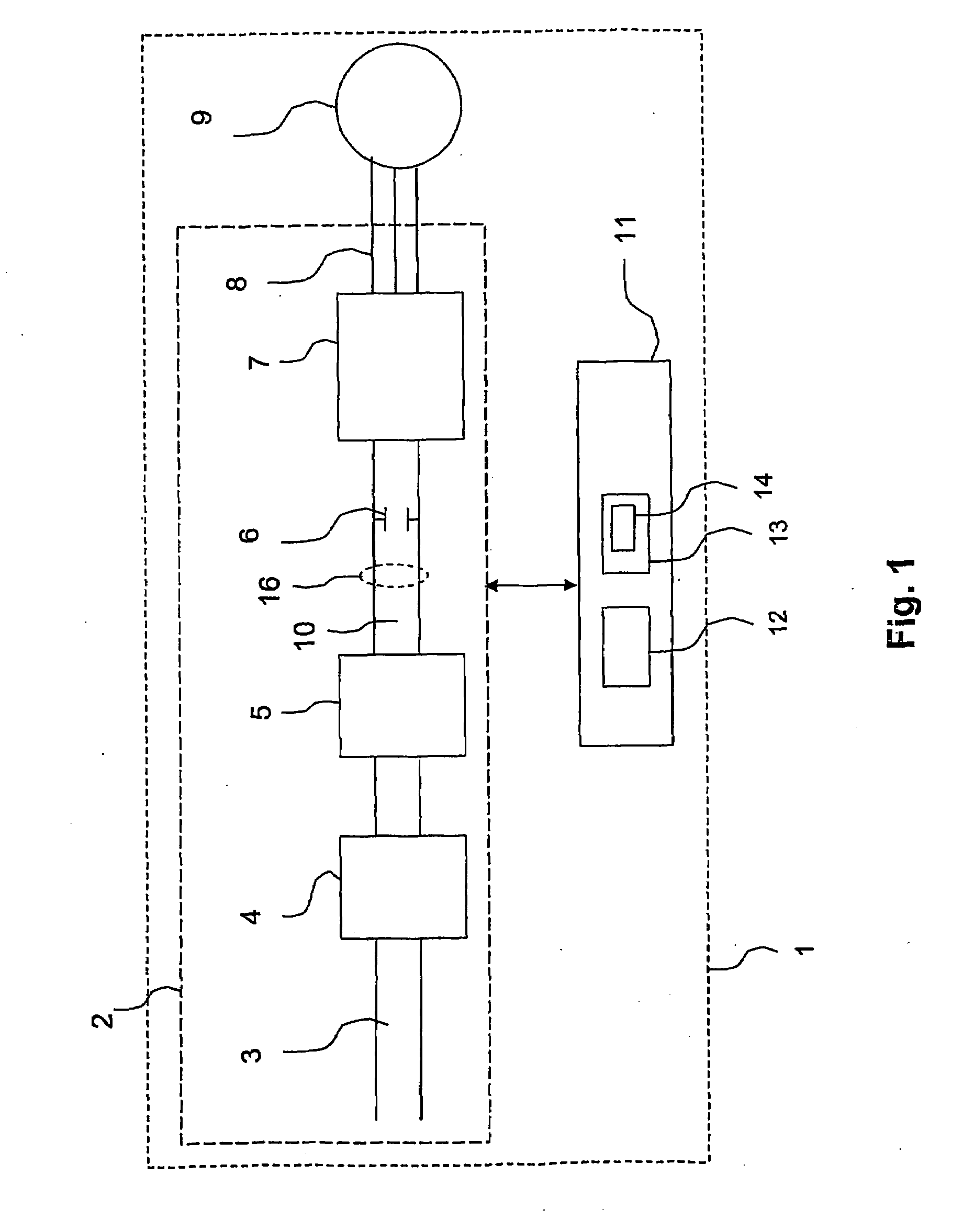

Control system for a pump

InactiveUS20100034665A1Clogging can be removedImprove startup reliabilityPump controlPositive-displacement liquid enginesSoftwareVariable-frequency drive

The present invention relates to pumps comprising variable frequency drive means and methods for operating such pumps. The inventive method for operating a pump (1) comprises the steps of obtaining values of operating parameters of the pump (1) indicating pump conditions, communicating said values of operating parameters from variable frequency drive means (2) to a control device (11), determining if a predetermined condition is fulfilled, communicating instructions from the control device (11) to the variable frequency drive means (2), based on the fulfillment of said predetermined condition. Furthermore, a computer program product loadable into a memory of a digital computer device, including software code portions for performing the inventive method, a pump (1), a pump system and a control device (11) for a pump are described.

Owner:XYLEM IP HLDG

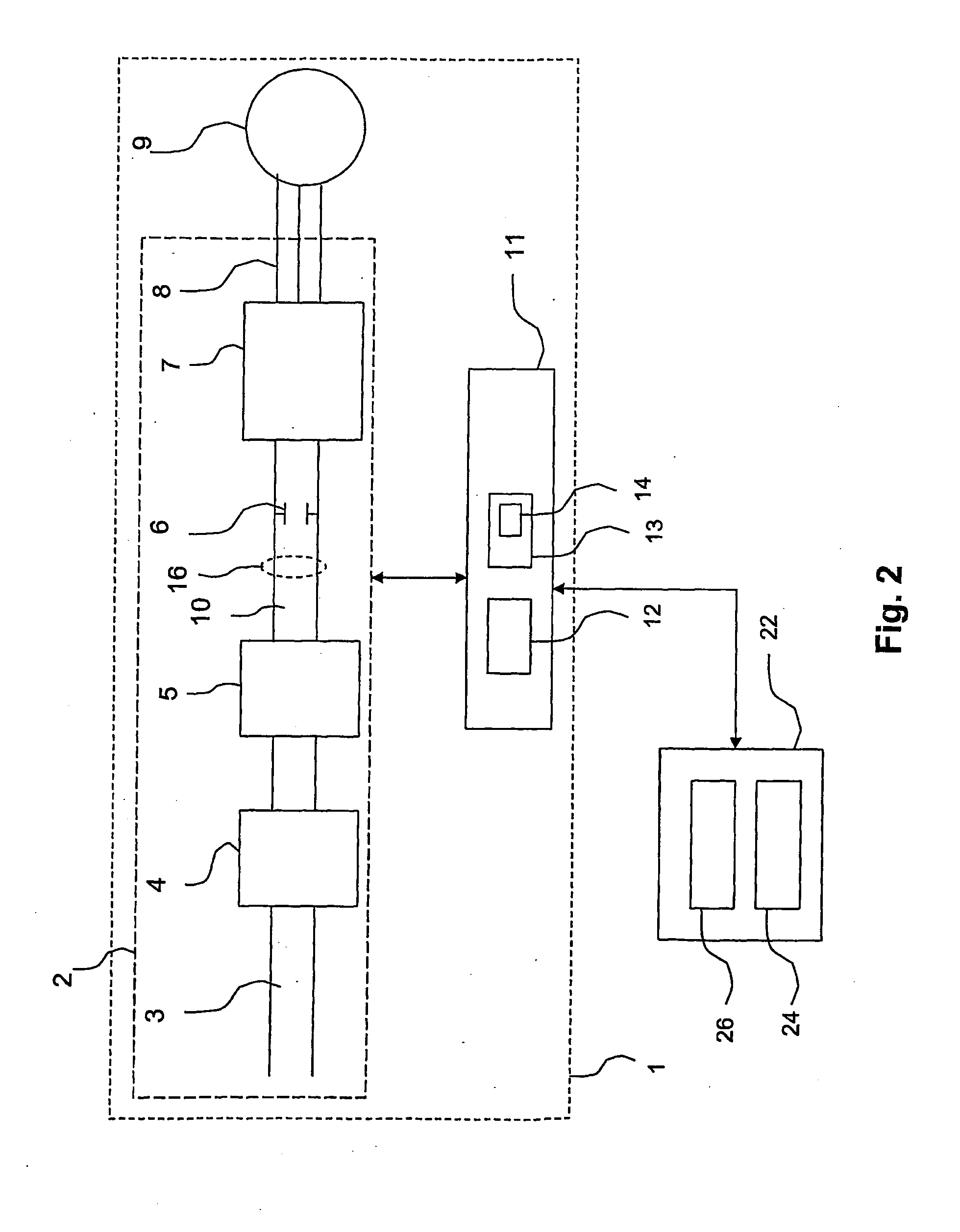

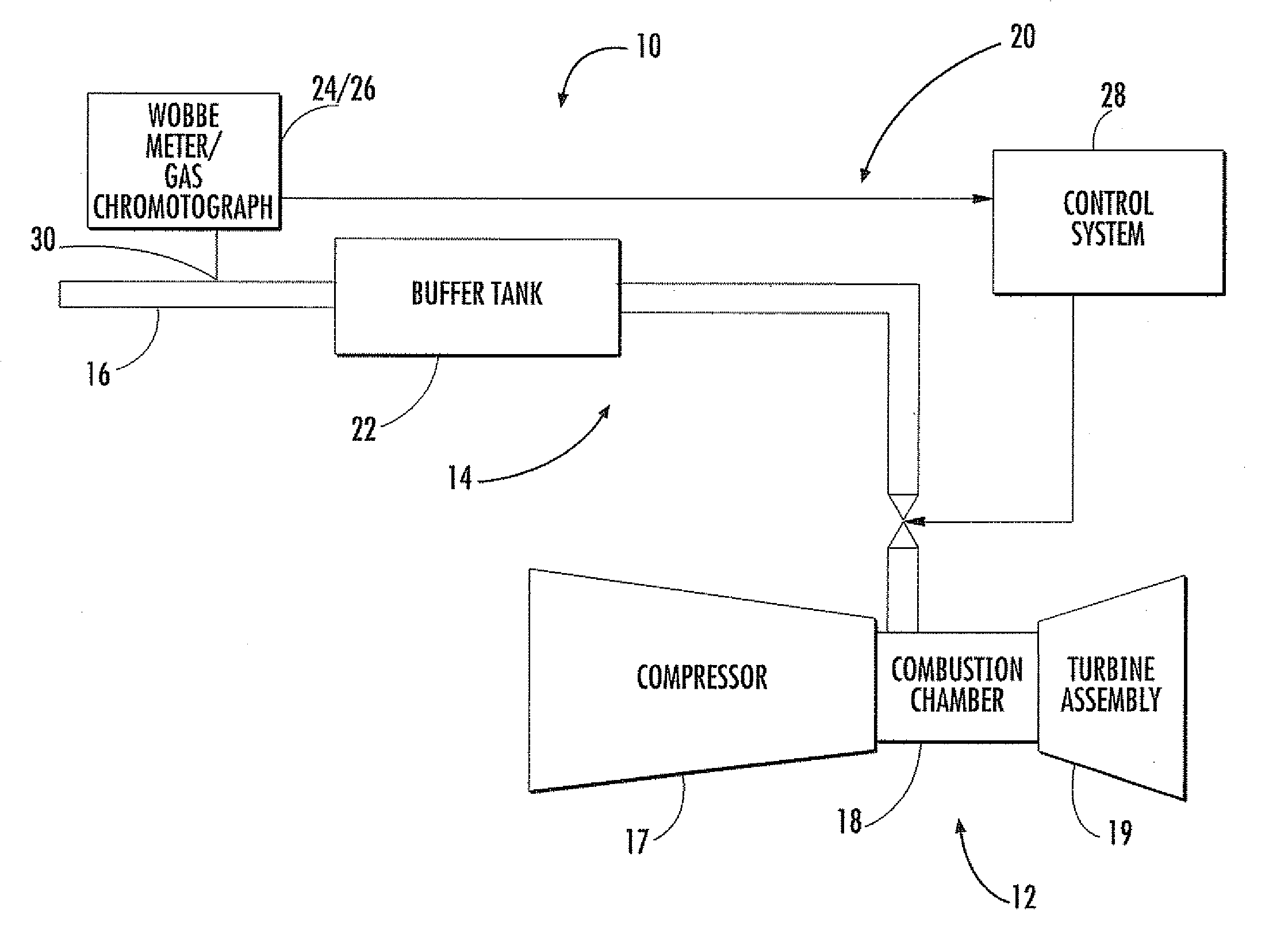

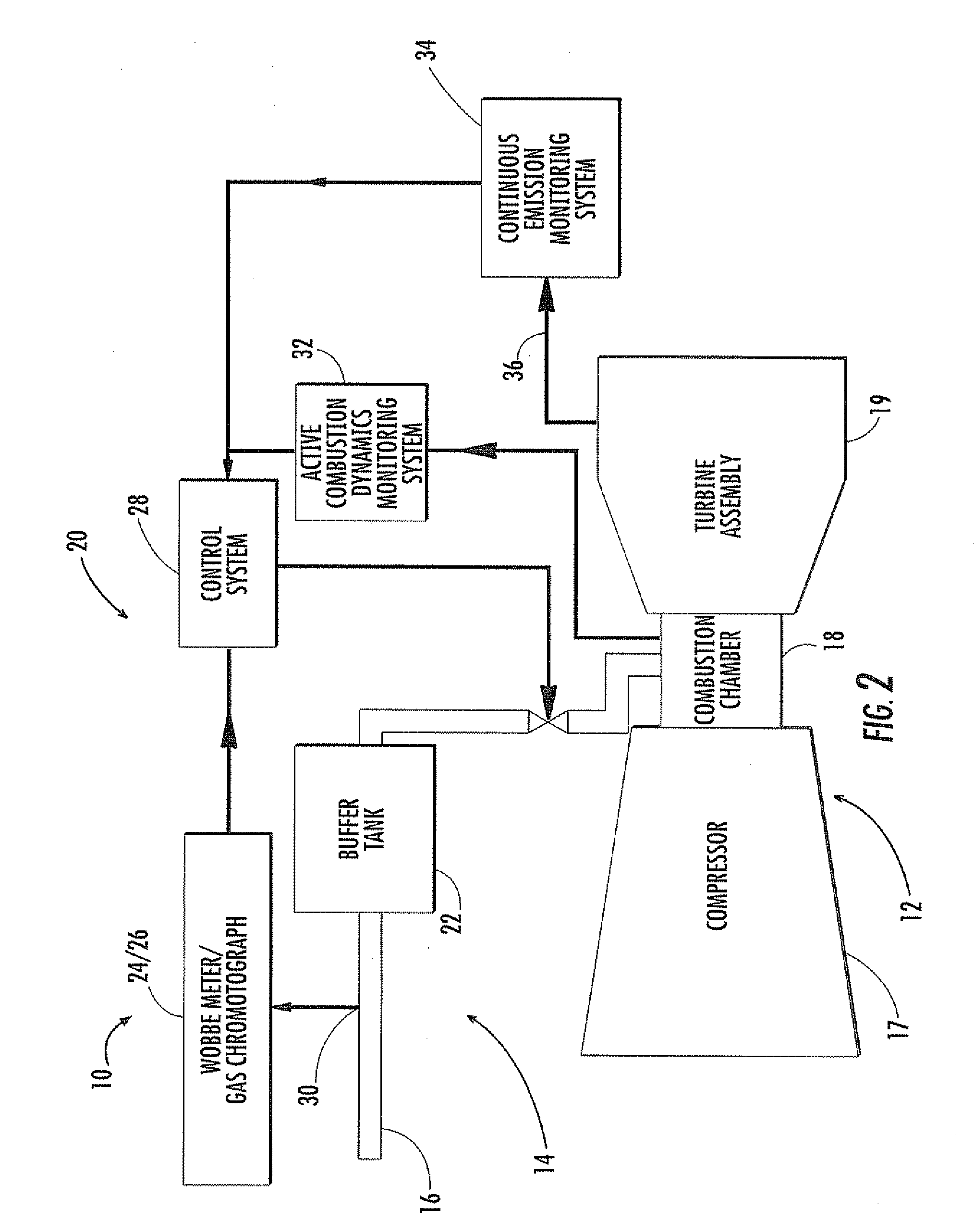

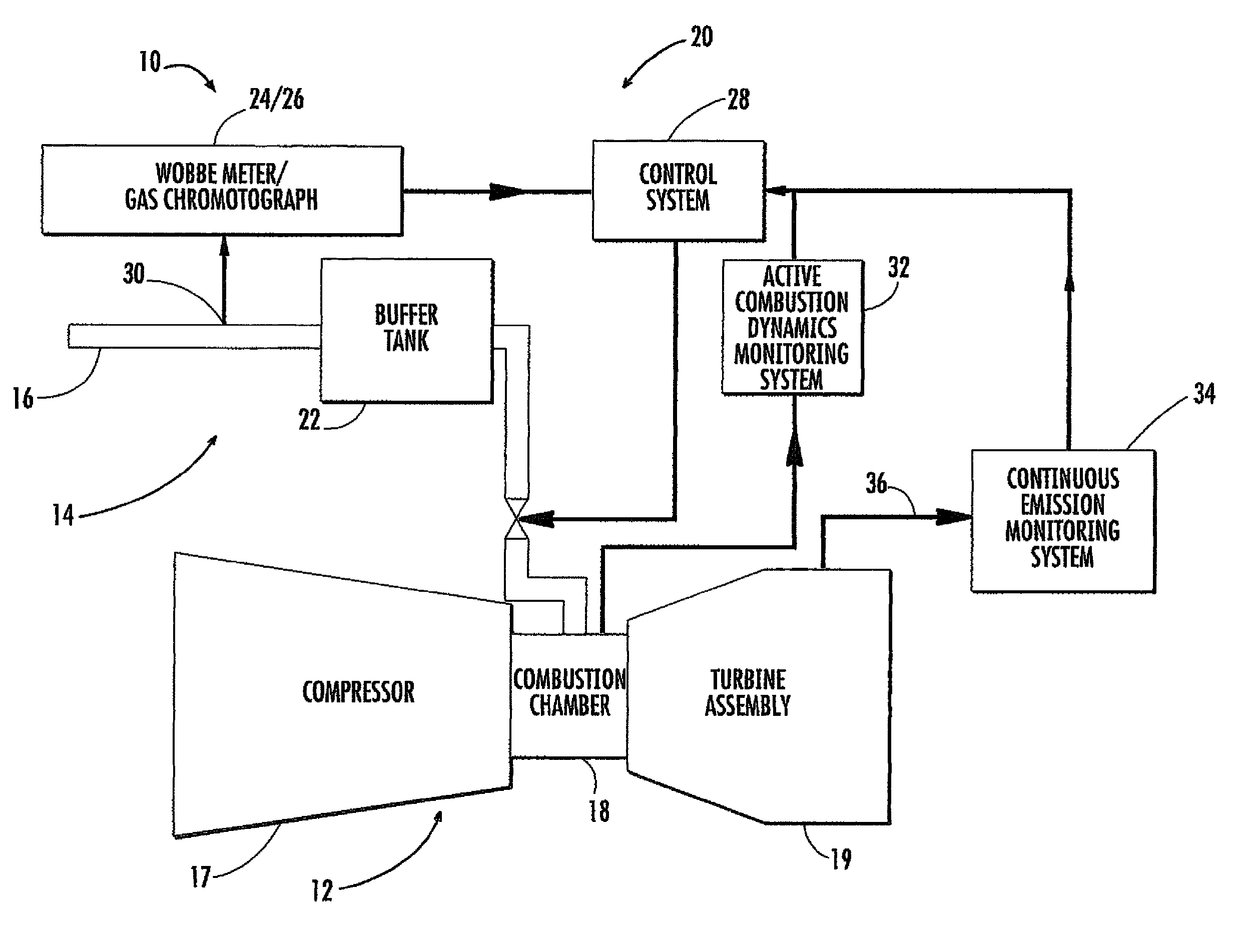

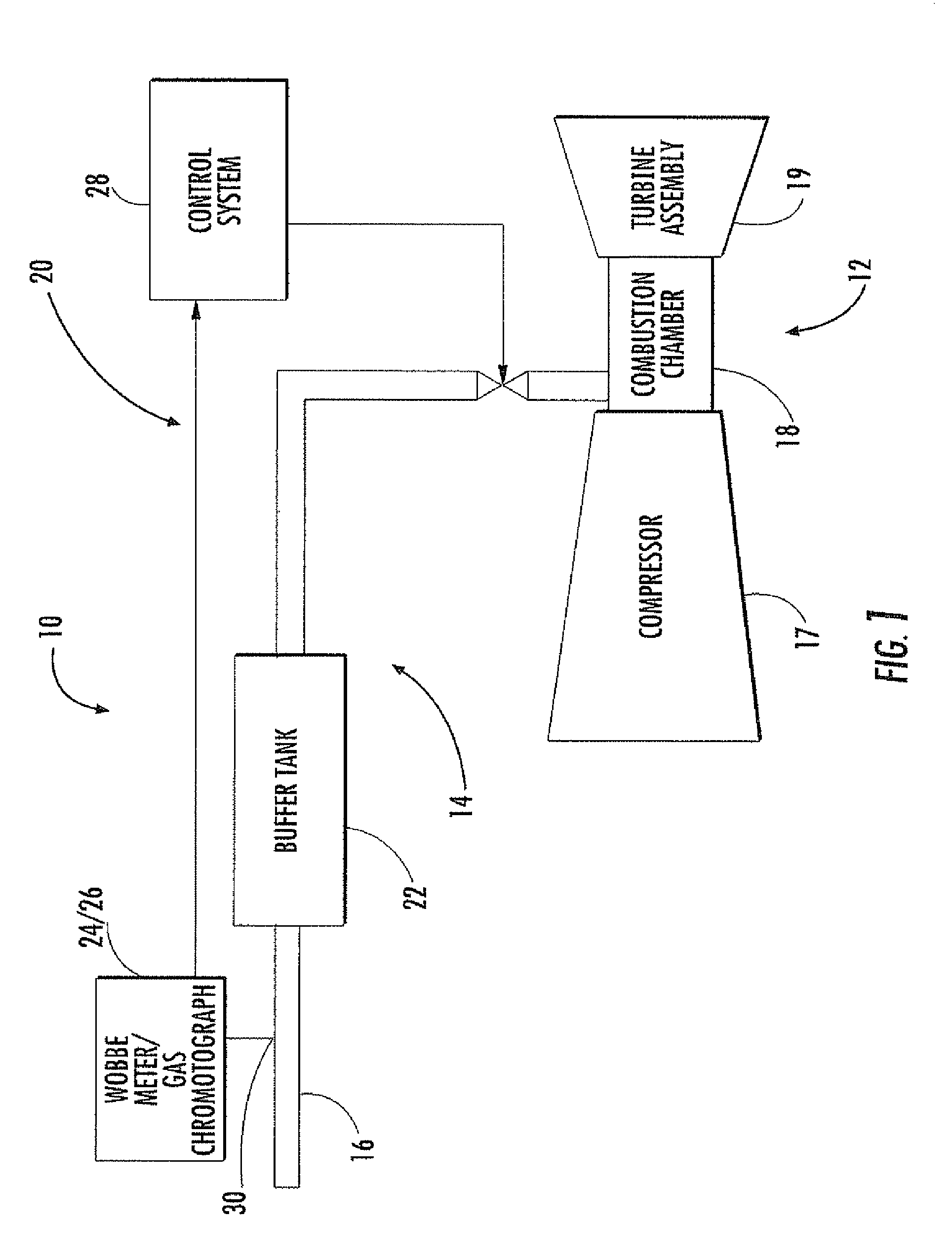

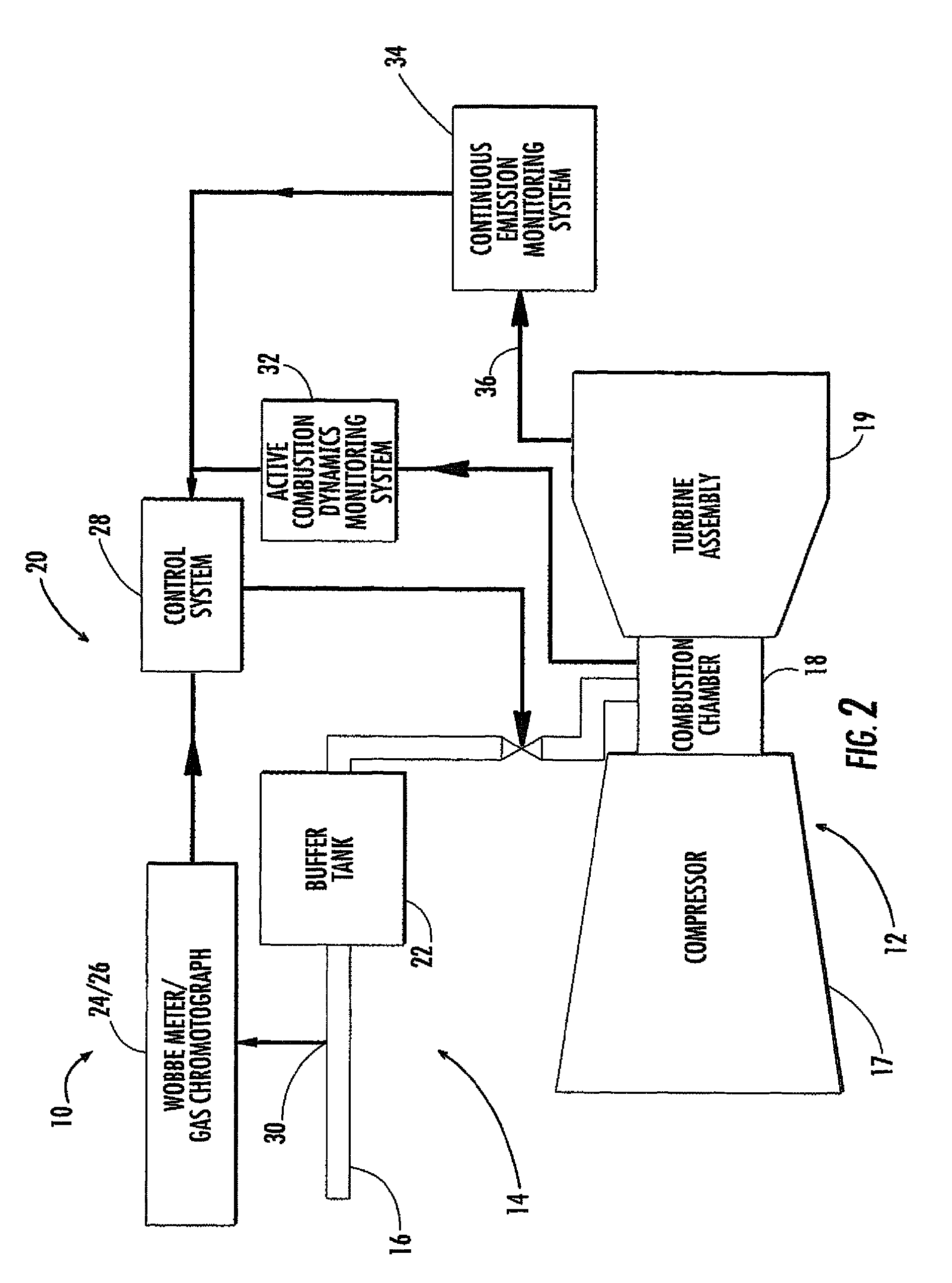

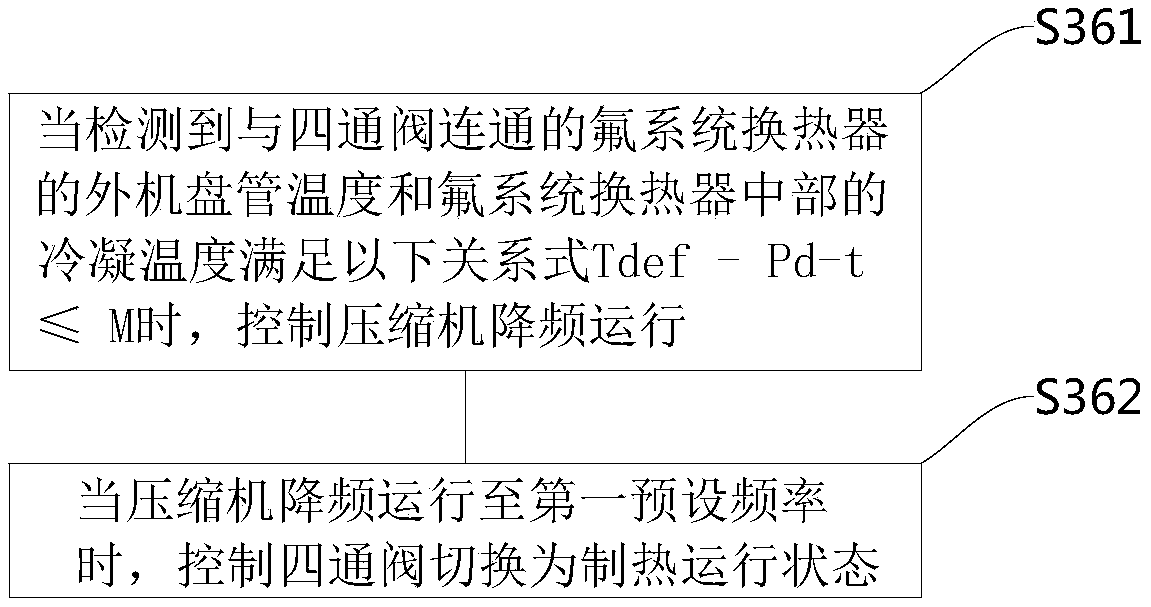

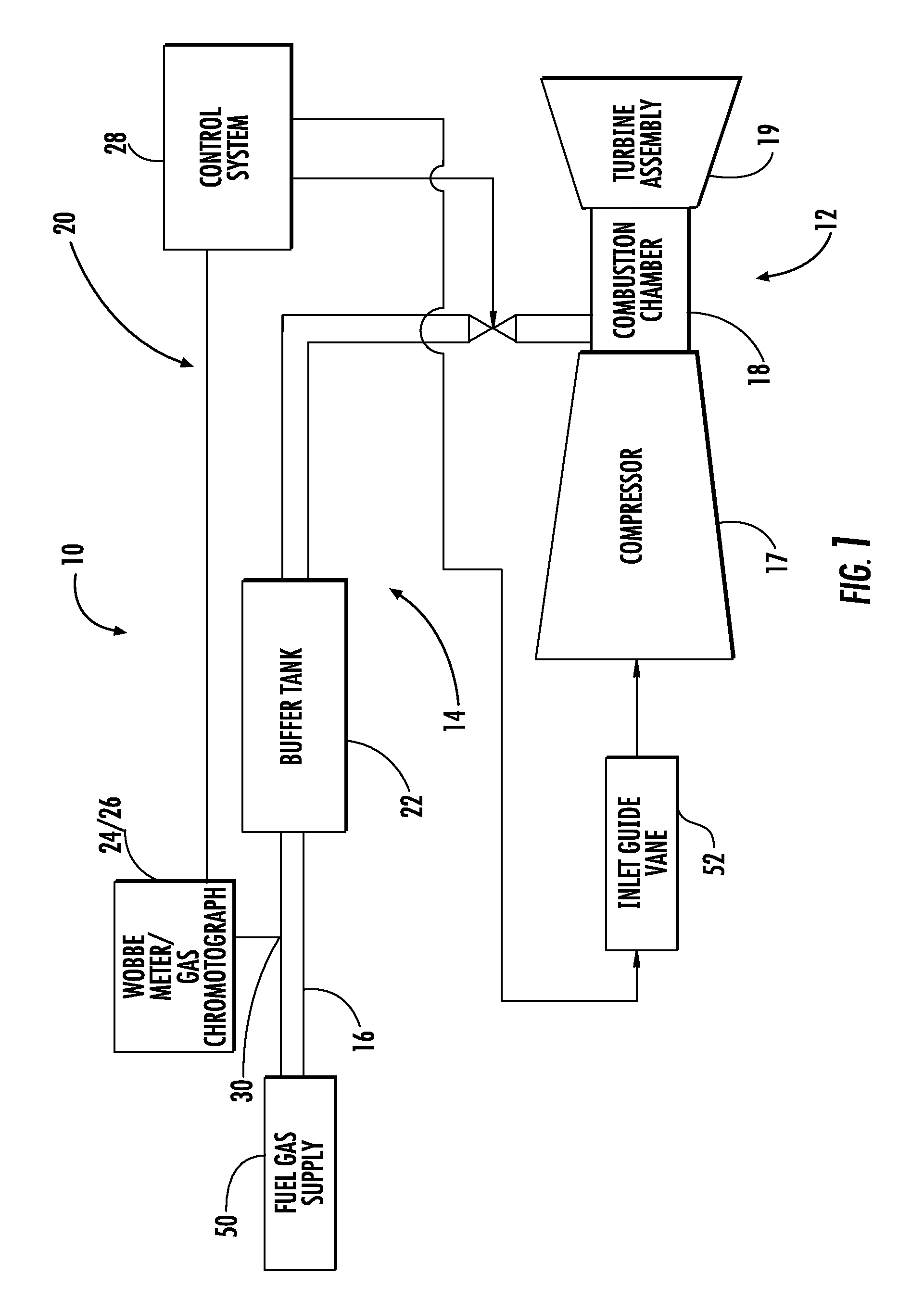

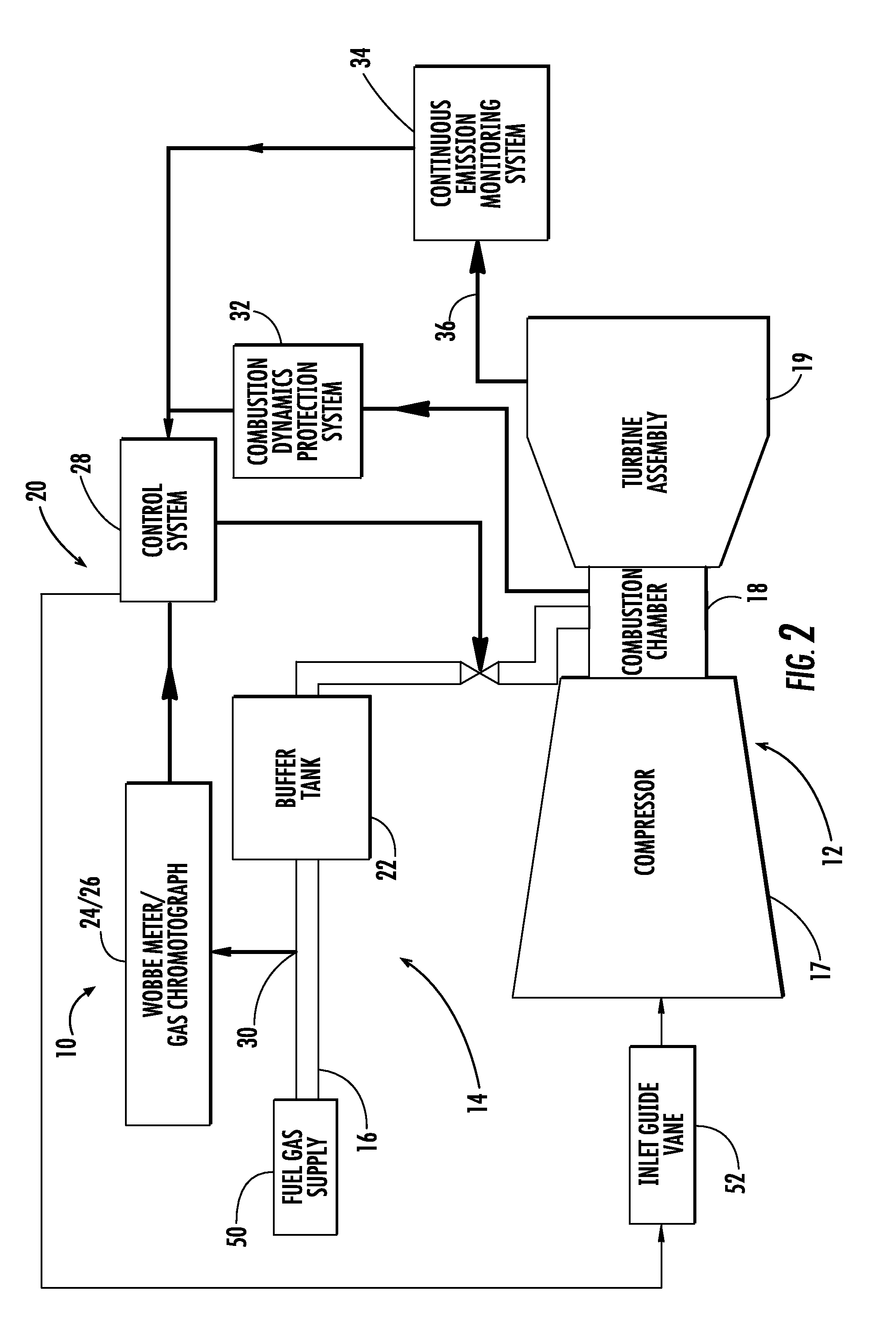

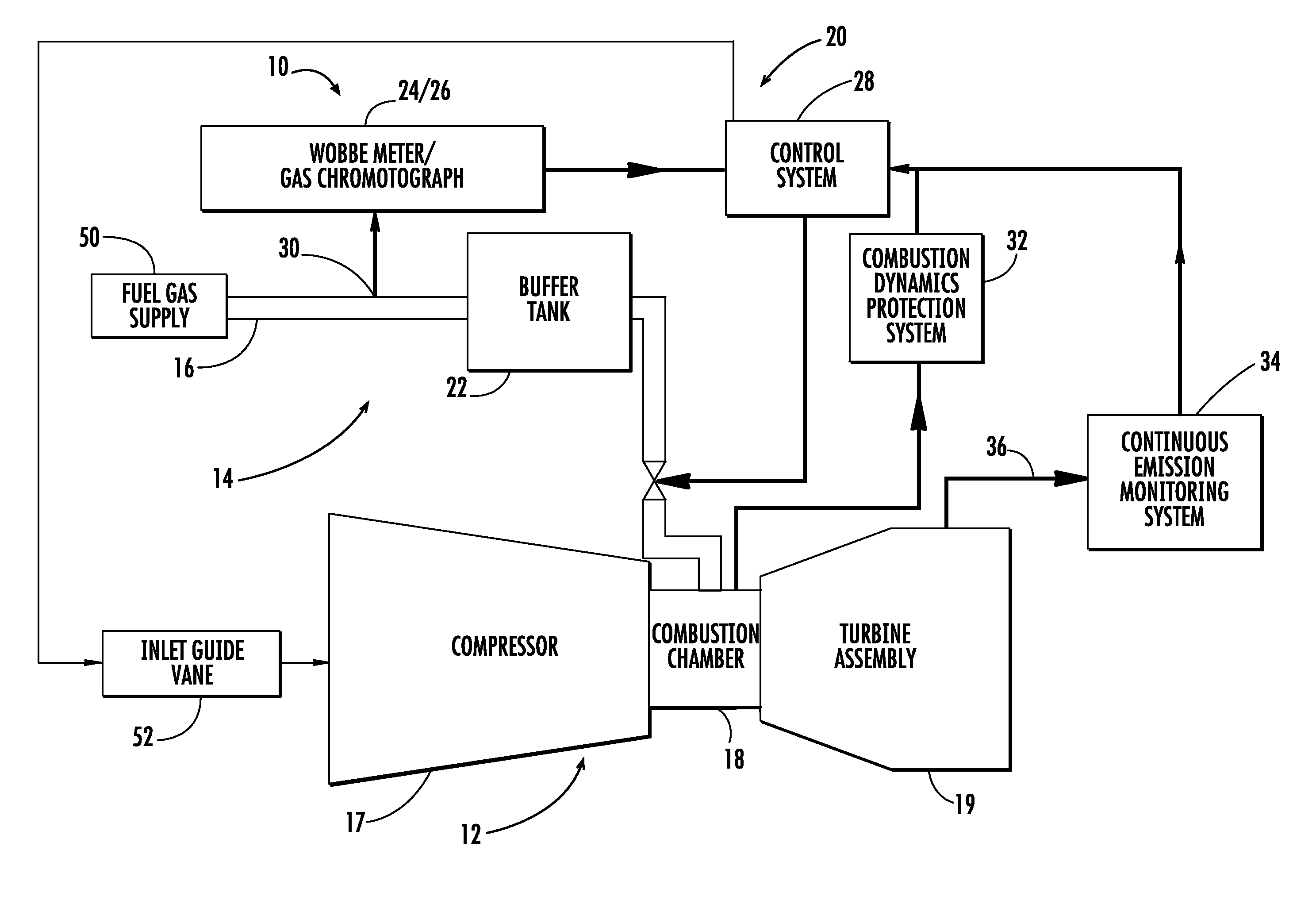

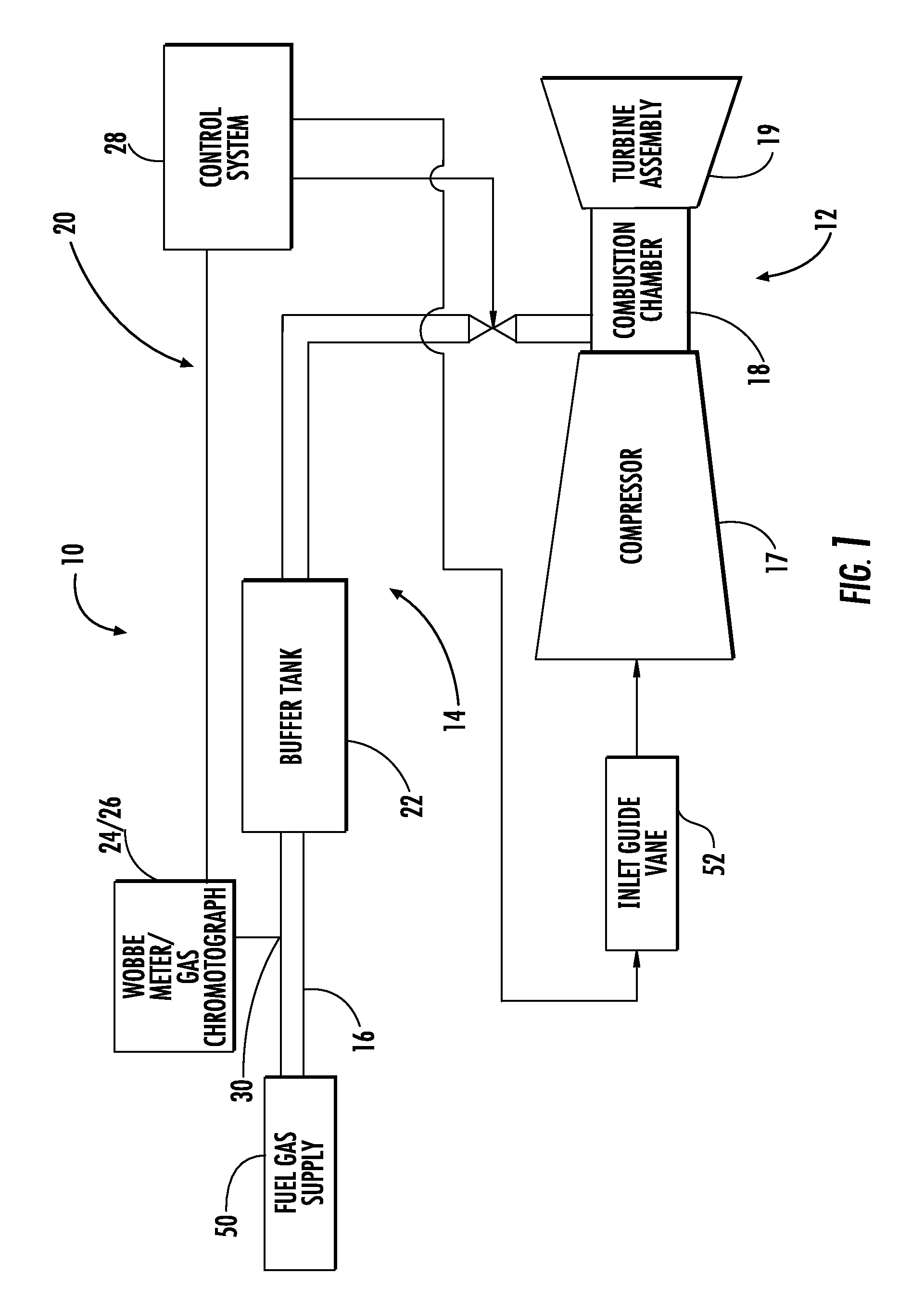

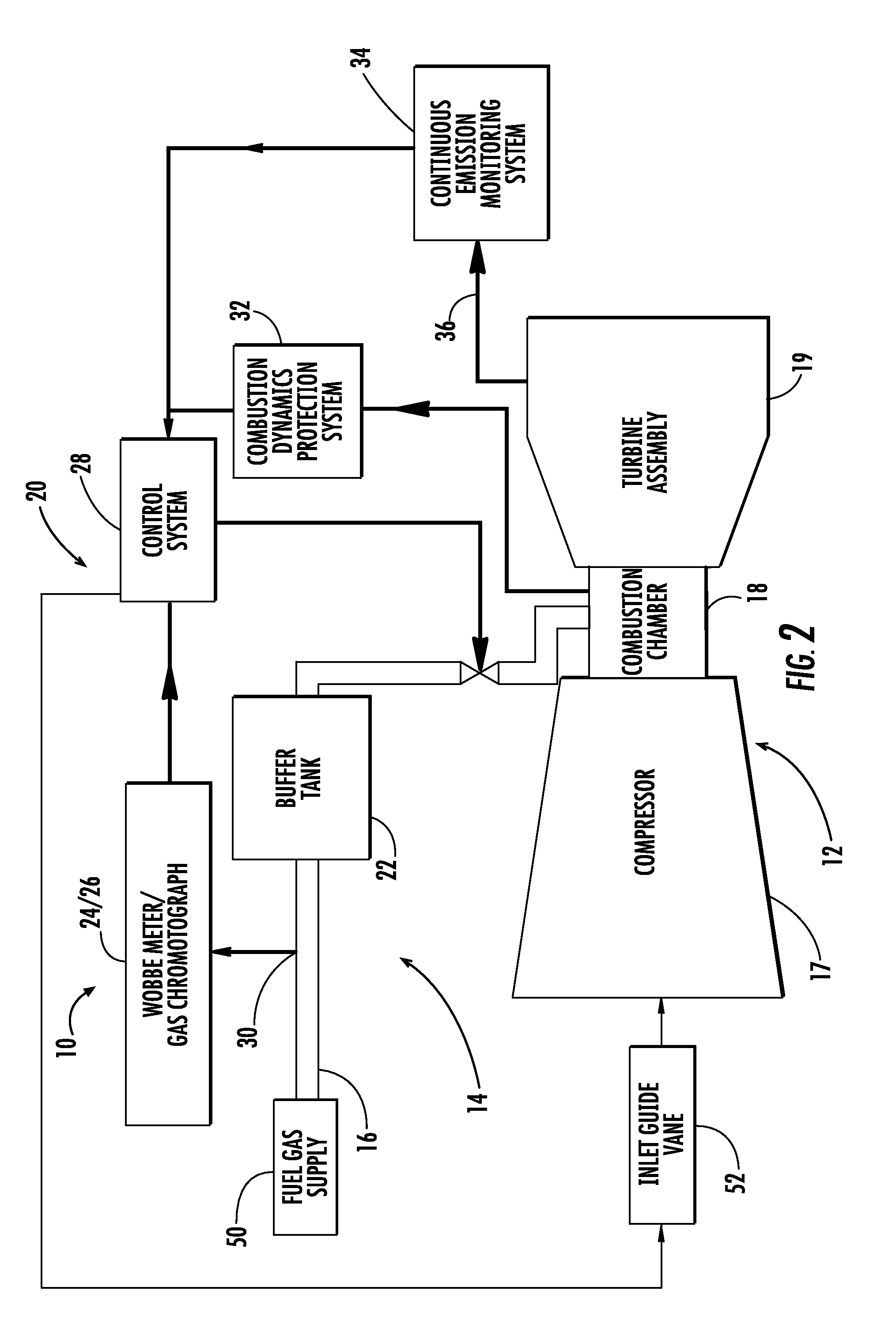

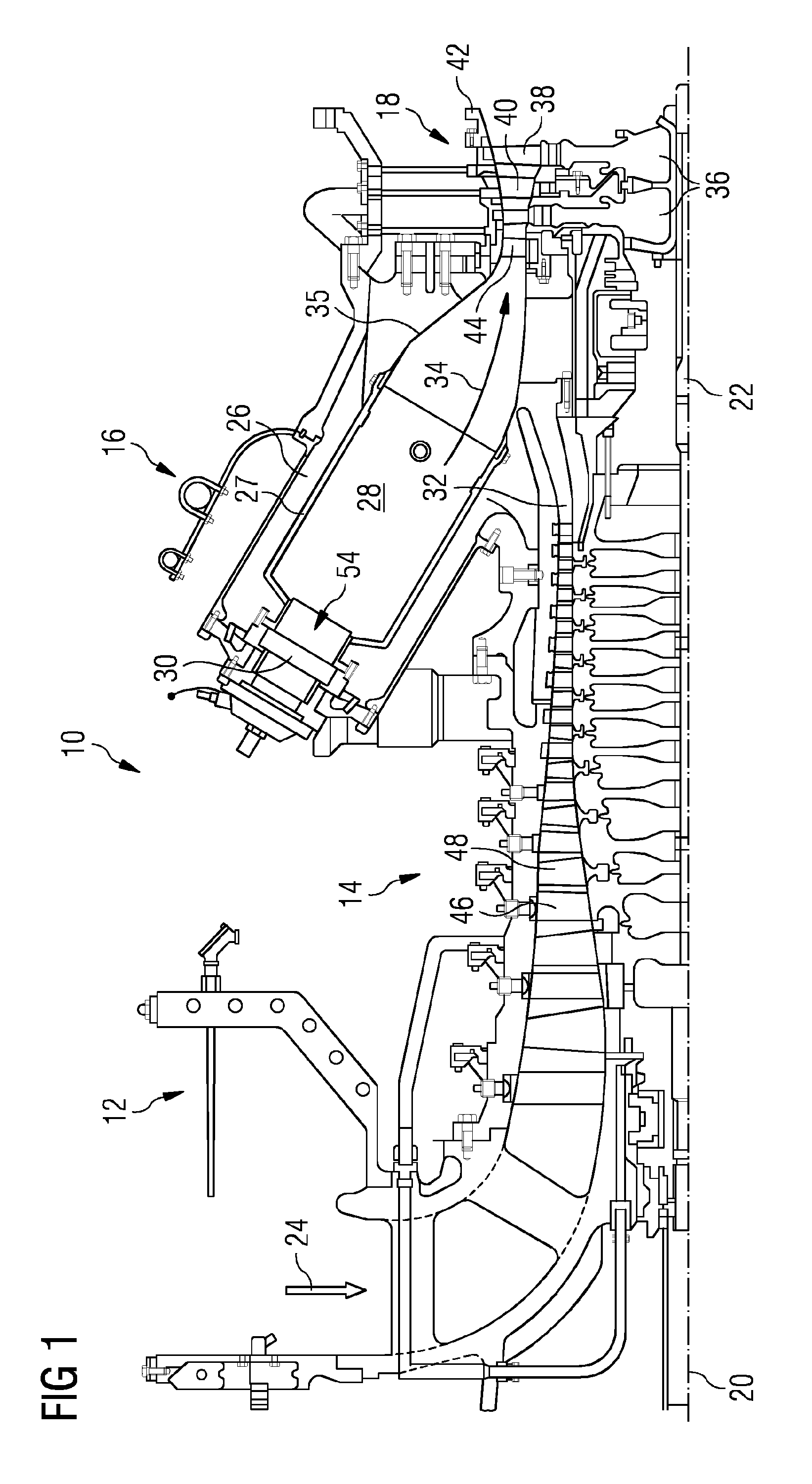

Integrated Fuel Gas Characterization System

InactiveUS20080115482A1Reduce temperature peaksAccelerate emissionsGas turbine plantsTurbine/propulsion fuel controlBuffer tankEngineering

A gas turbine engine that includes a compressor, a combustion stage, a turbine assembly, a fuel gas feed system for supplying fuel gas to a combustion stage of the gas turbine, and an integrated fuel gas characterization system. The integrated fuel gas feed system can include a buffer tank. The integrated fuel gas characterization system for determining the amount of energy provided by the fuel prior to combustion of the fuel in the combustion stage. The integrated fuel gas characterization system minimizes megawatt swings by adjusting the operating parameters of the gas turbine engine based on the rate of change in fuel gas energy content. The integrated fuel gas characterization system also provides improved turbine engine start-up reliability by tuning the turbine engine operating parameters using fuel gas energy content measurements obtained prior to actual start-up.

Owner:SIEMENS ENERGY INC

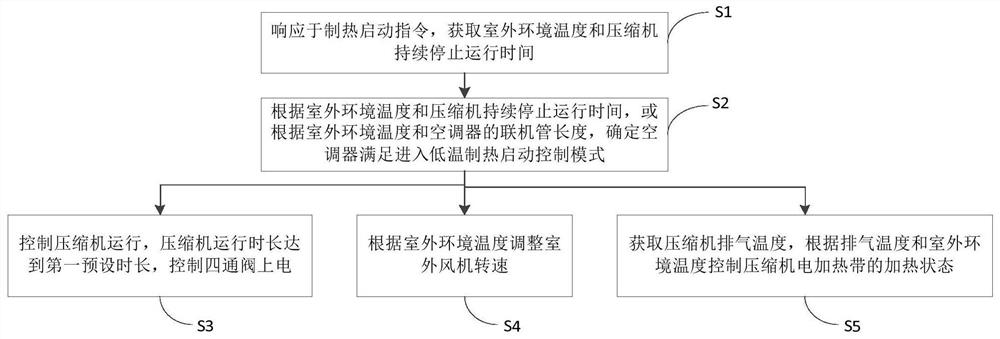

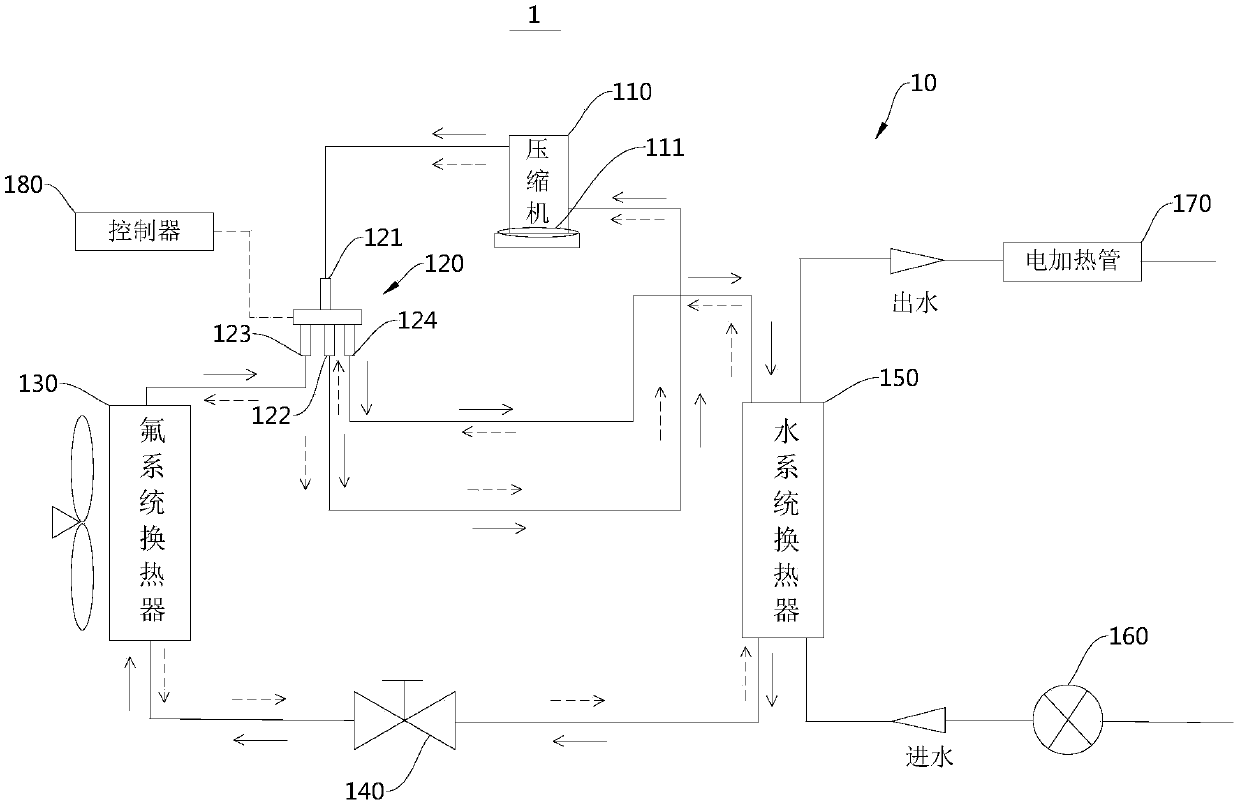

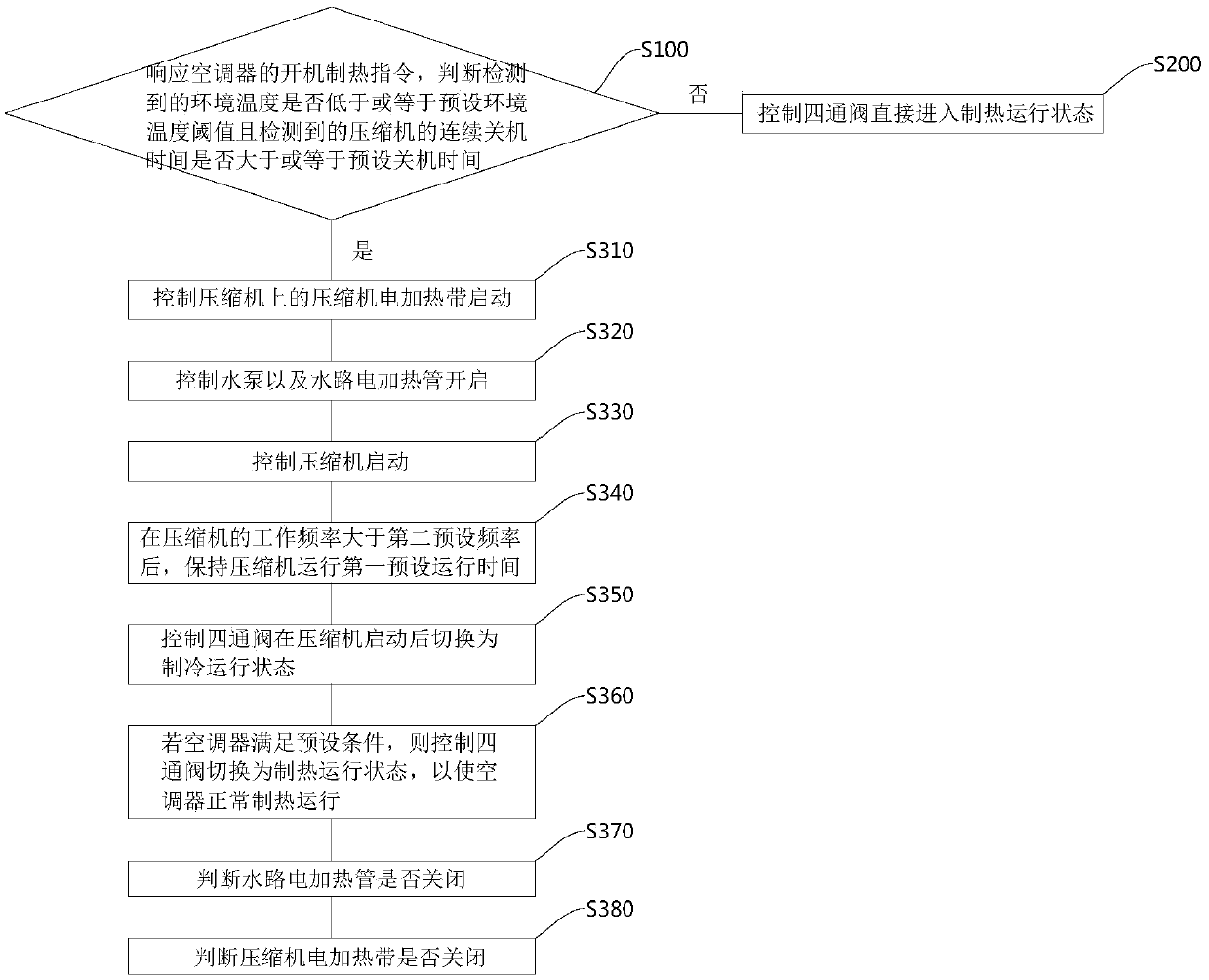

Method for controlling low-temperature heating start of air conditioner as well as air conditioner and storage medium

InactiveCN111765606AGuaranteed uptimeAvoid hard-to-start situationsMechanical apparatusSpace heating and ventilation safety systemsTemperature controlFour-way valve

The invention discloses a method for controlling low-temperature heating start of an air conditioner as well as the air conditioner and a storage medium. The method for controlling low-temperature heating start of the air conditioner comprises the following steps: responding to a heating start instruction, and obtaining outdoor environment temperature and compressor duration time of stopping operation; according to the outdoor environment temperature and the compressor duration time of stopping operation or according to the outdoor environment temperature and length of a connected tube of theair conditioner, determining that the air conditioner meets a condition of entering a low-temperature heating start control mode; performing at least one of the following: controlling compressor operation, and controlling a four-way valve to electrify while operation time length of the compressor reaches first preset time length; regulating rotation speed of an outdoor fan according to the outdoorenvironment temperature; and obtaining a compressor gas exhaust temperature, and controlling a heating state of an electric heating belt of the compressor according to the gas exhaust temperature andthe outdoor environment temperature. The method can increase gas suction pressure, under a low-temperature environment, of the compressor, and strengthens use reliability of the compressor.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

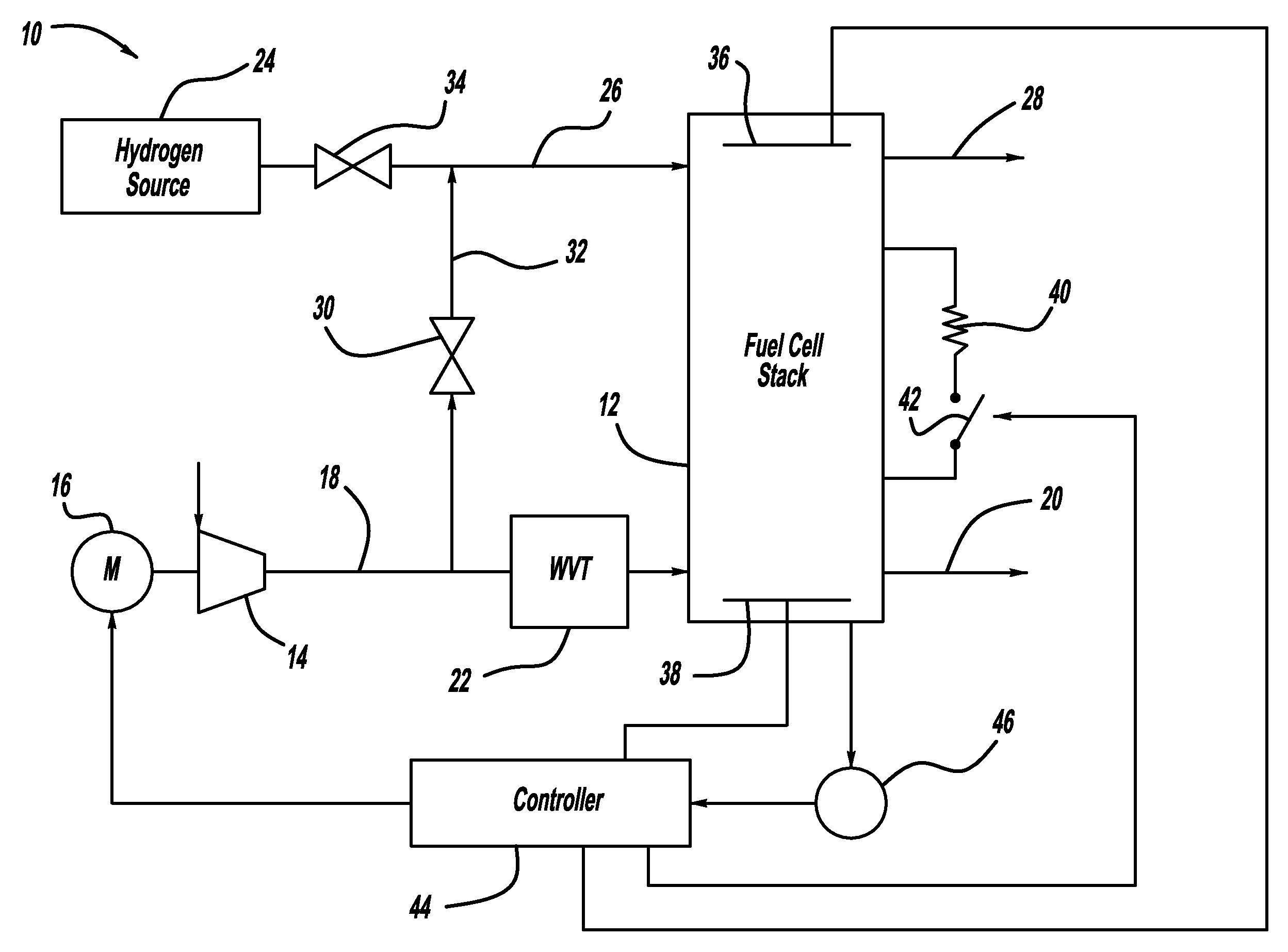

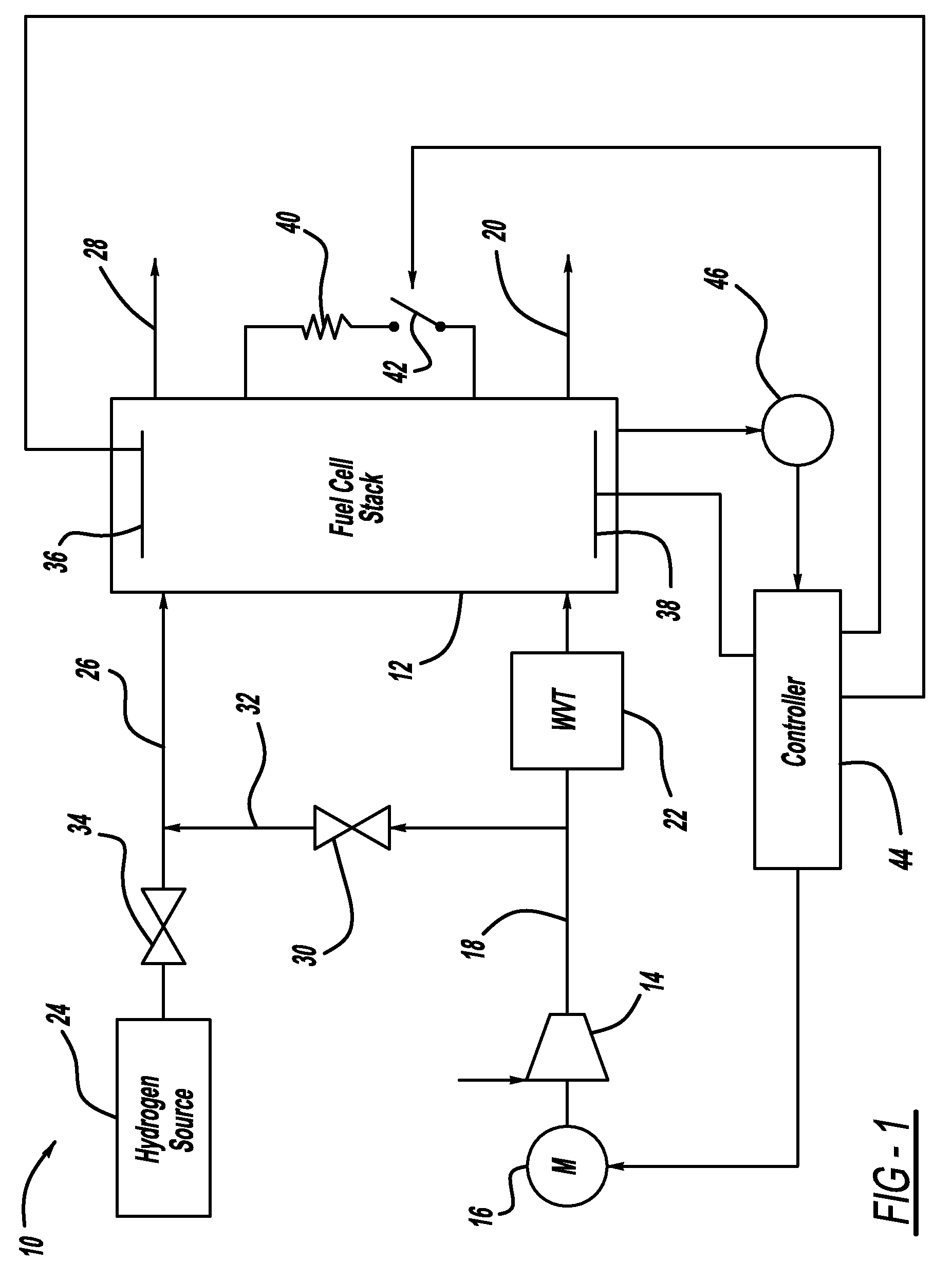

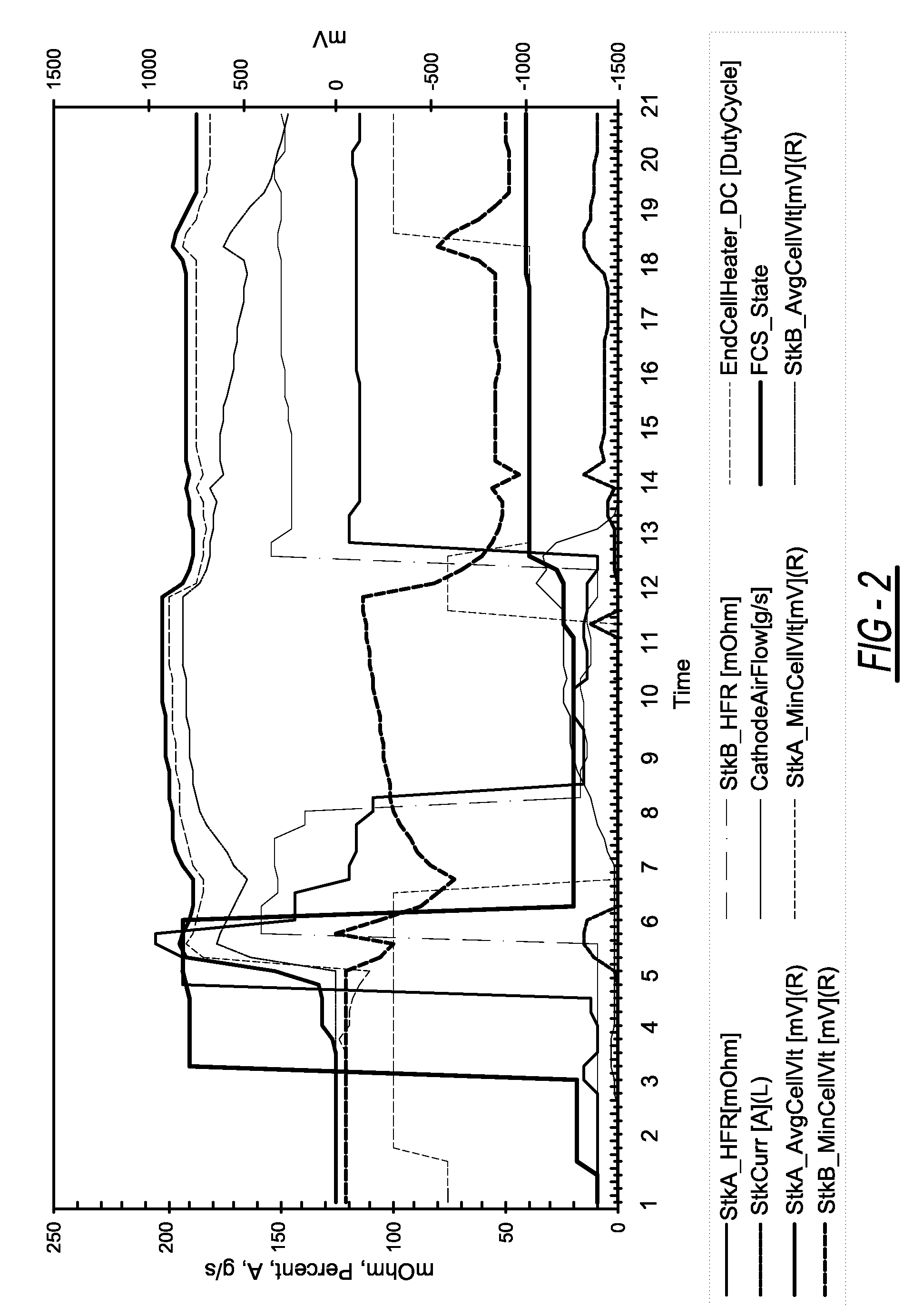

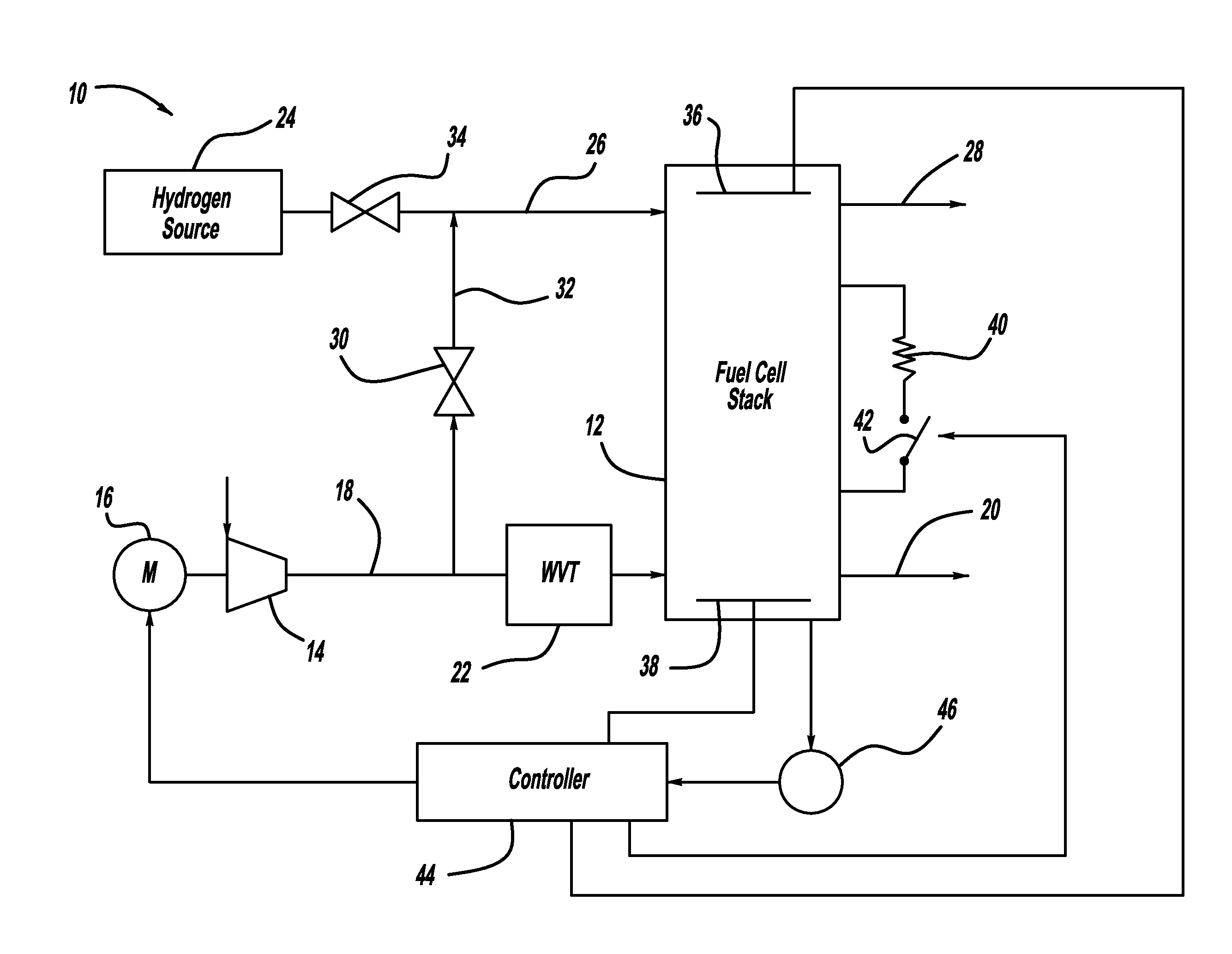

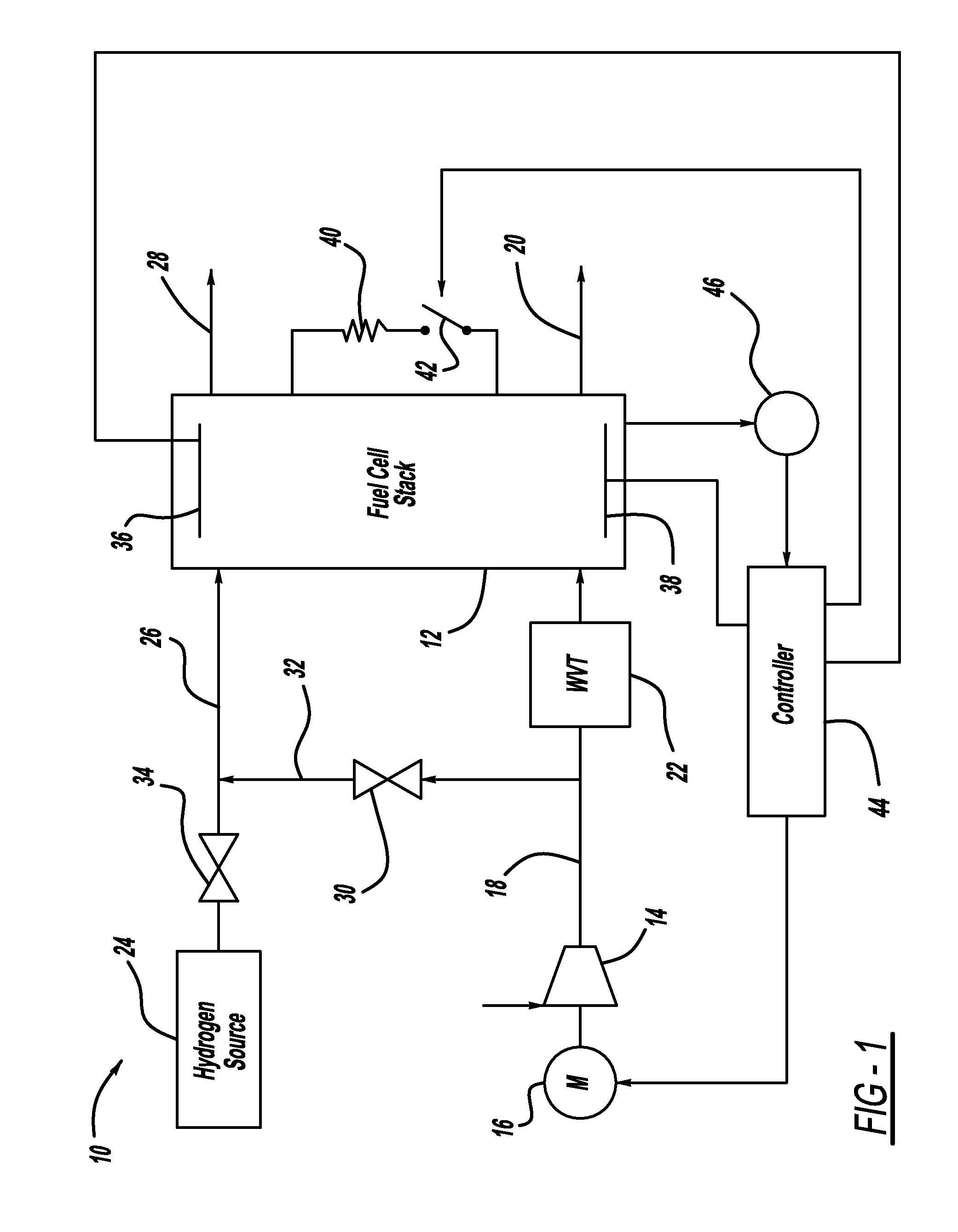

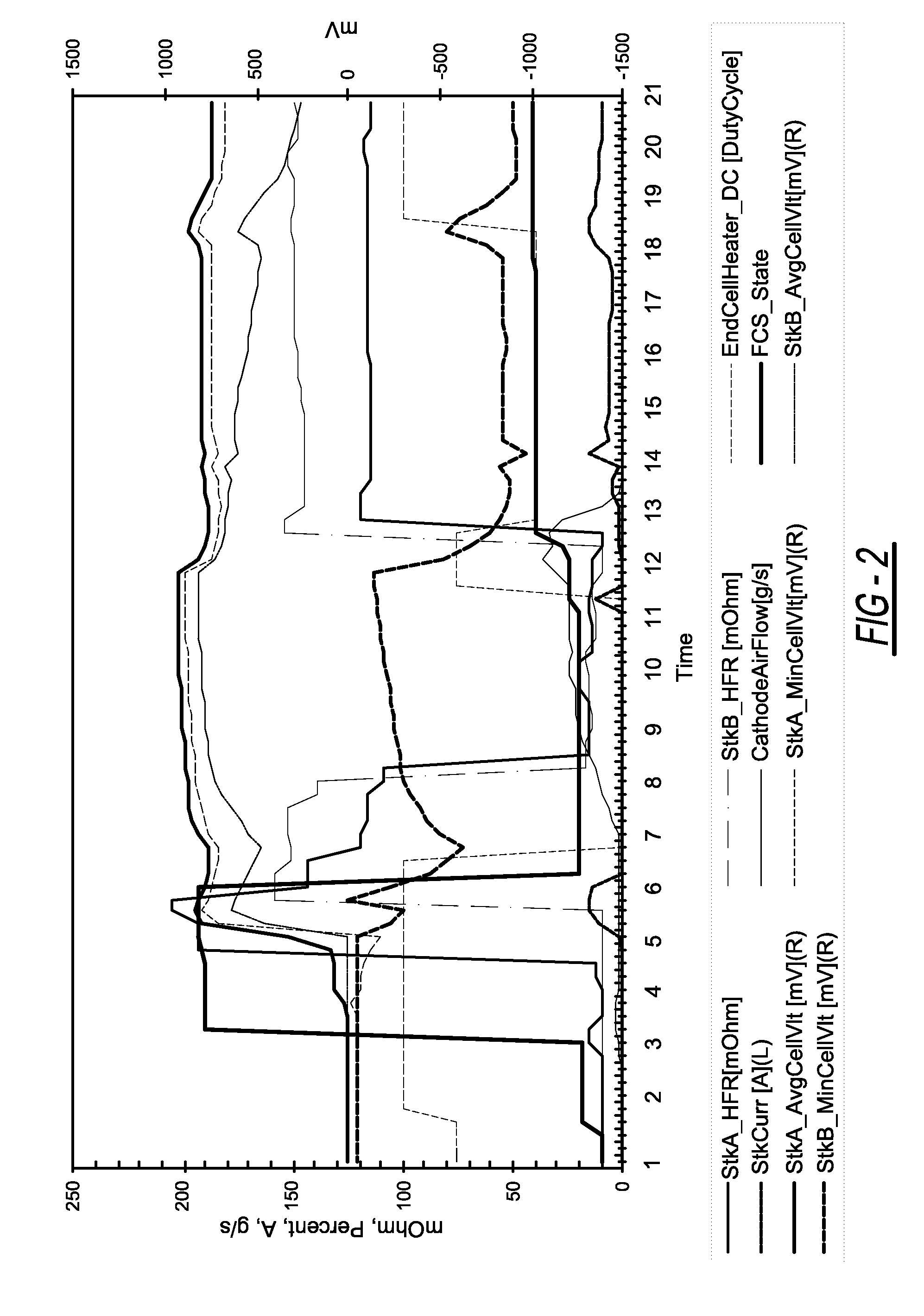

Startup reliability using hfr measurement

ActiveUS20090305099A1Improve start-up reliabilityReduces system reliabilityFuel cells groupingFuel cell auxillariesRemedial actionAirflow

A system and method for improving fuel cell system start-up reliability. The method includes determining if the resistance of the membranes in a fuel cell stack is too high, where the reliability of system start-up will be reduced, and if so, providing one or more remedial actions to help ensure that the start-up is more reliable. In one embodiment, the system and method determine that the fuel cell membranes are to dry based on whether a high frequency measurement of the fuel cell stack exceeds a predetermined HFR threshold. If the HFR threshold has been exceeded, a special start-up procedure is used that increases the reliability that the start-up will be successful using the remedial actions, such as reducing cathode airflow and turning on stack end cell heaters.

Owner:GM GLOBAL TECH OPERATIONS LLC

Integrated fuel gas characterization system

InactiveUS7854110B2Reduce riskAccelerate emissionsGas turbine plantsTurbine/propulsion fuel controlBuffer tankEngineering

A gas turbine engine that includes a compressor, a combustion stage, a turbine assembly, a fuel gas feed system for supplying fuel gas to a combustion stage of the gas turbine, and an integrated fuel gas characterization system. The integrated fuel gas feed system can include a buffer tank. The integrated fuel gas characterization system for determining the amount of energy provided by the fuel prior to combustion of the fuel in the combustion stage. The integrated fuel gas characterization system minimizes megawatt swings by adjusting the operating parameters of the gas turbine engine based on the rate of change in fuel gas energy content. The integrated fuel gas characterization system also provides improved turbine engine start-up reliability by tuning the turbine engine operating parameters using fuel gas energy content measurements obtained prior to actual start-up.

Owner:SIEMENS ENERGY INC

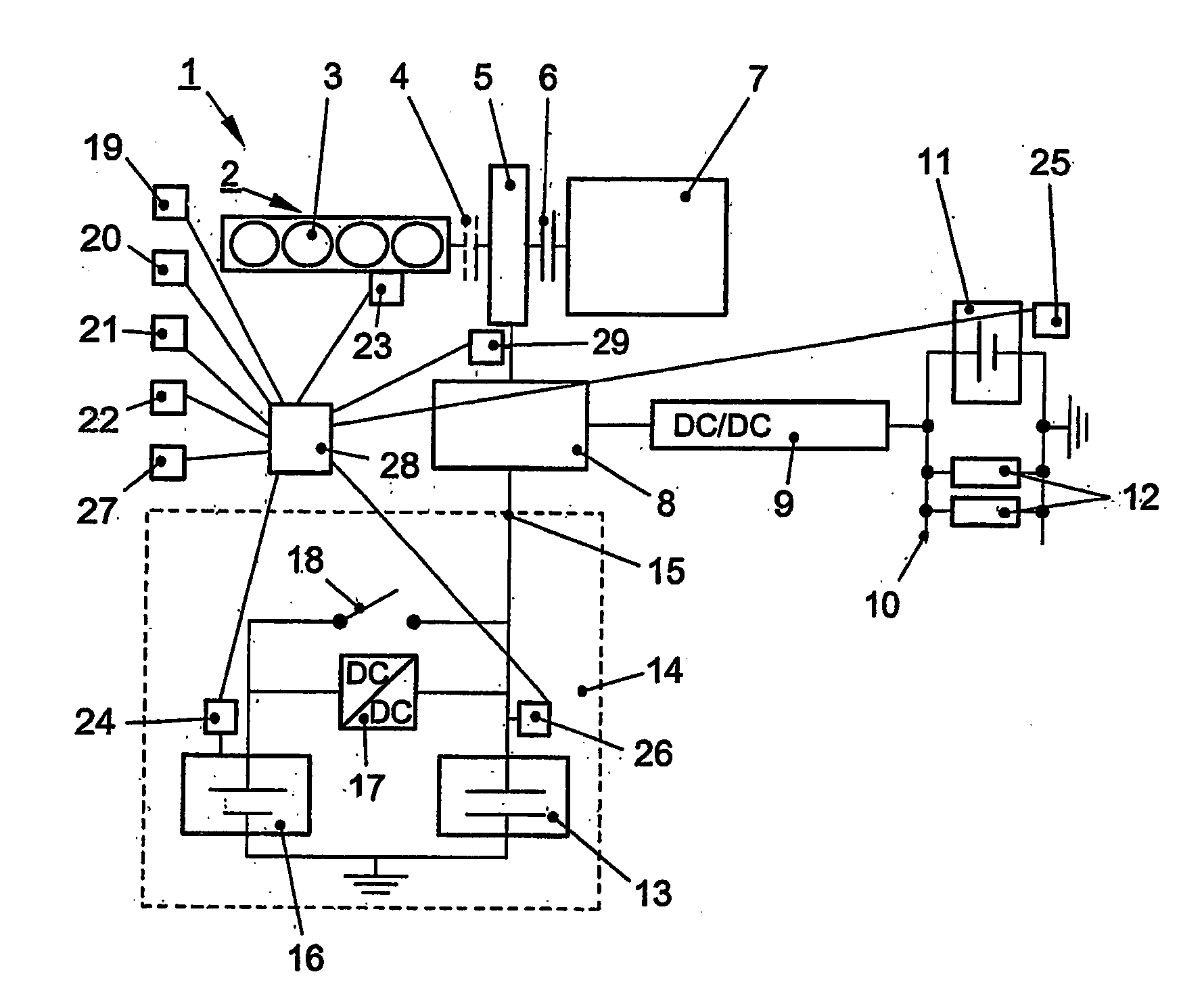

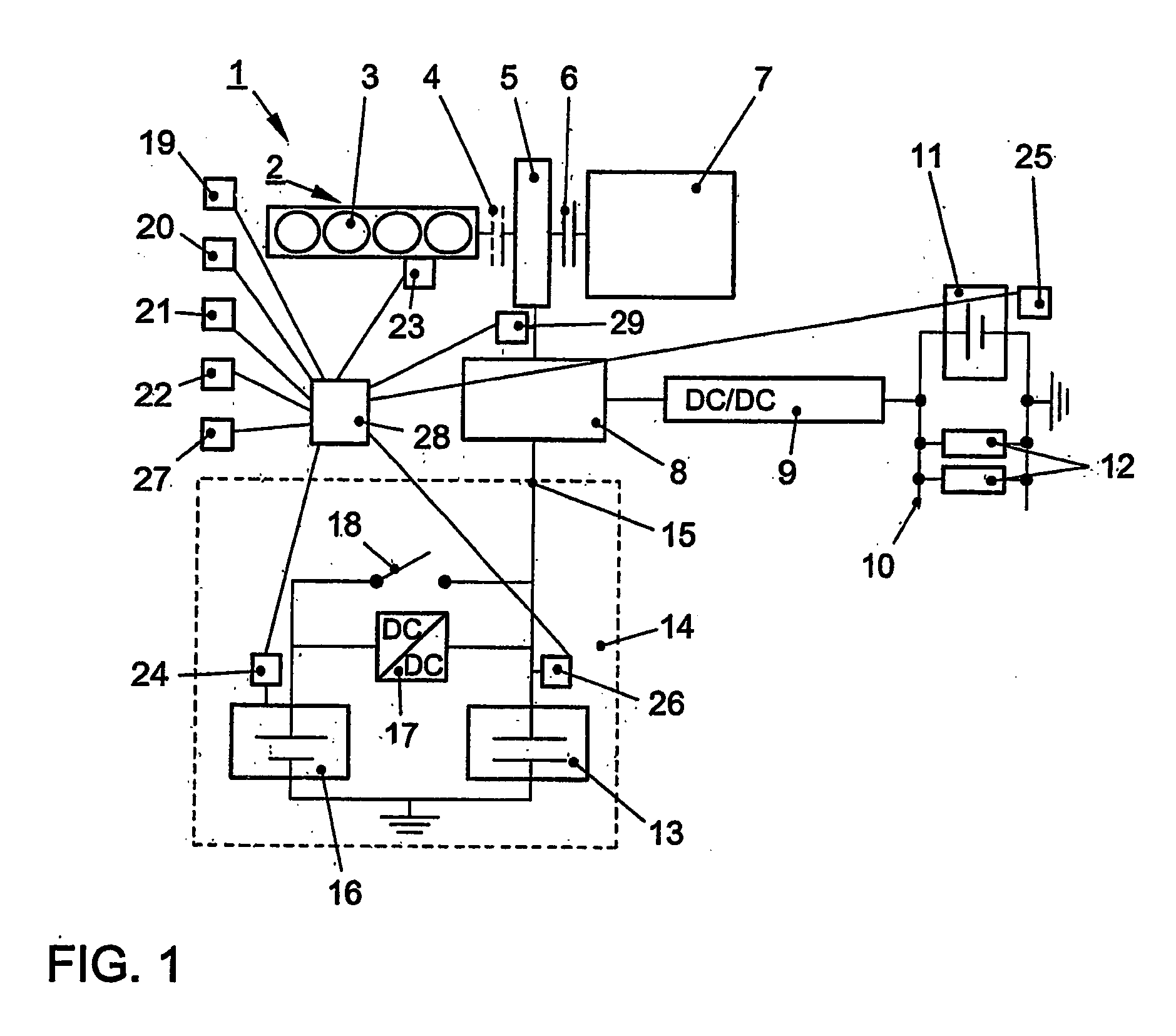

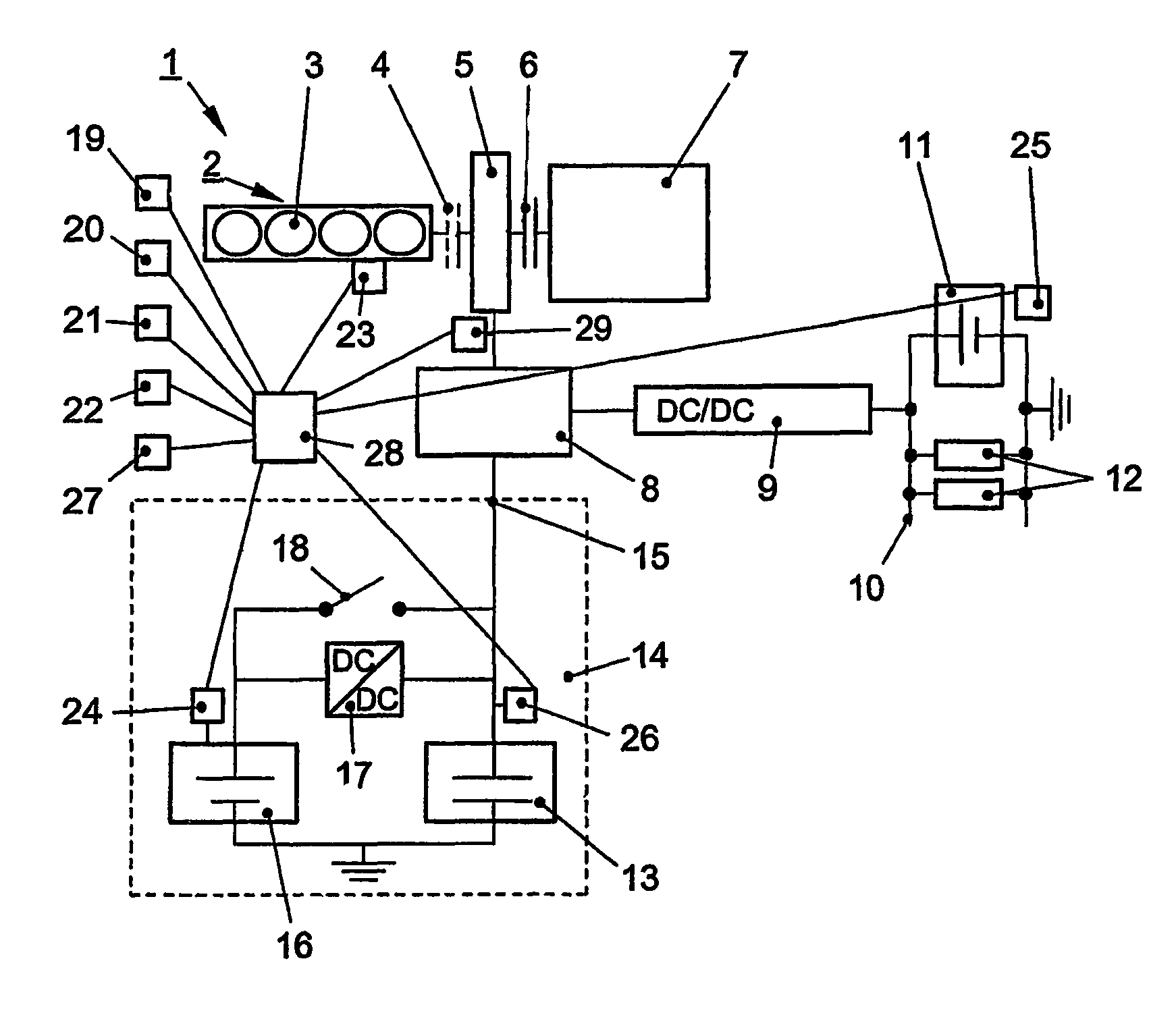

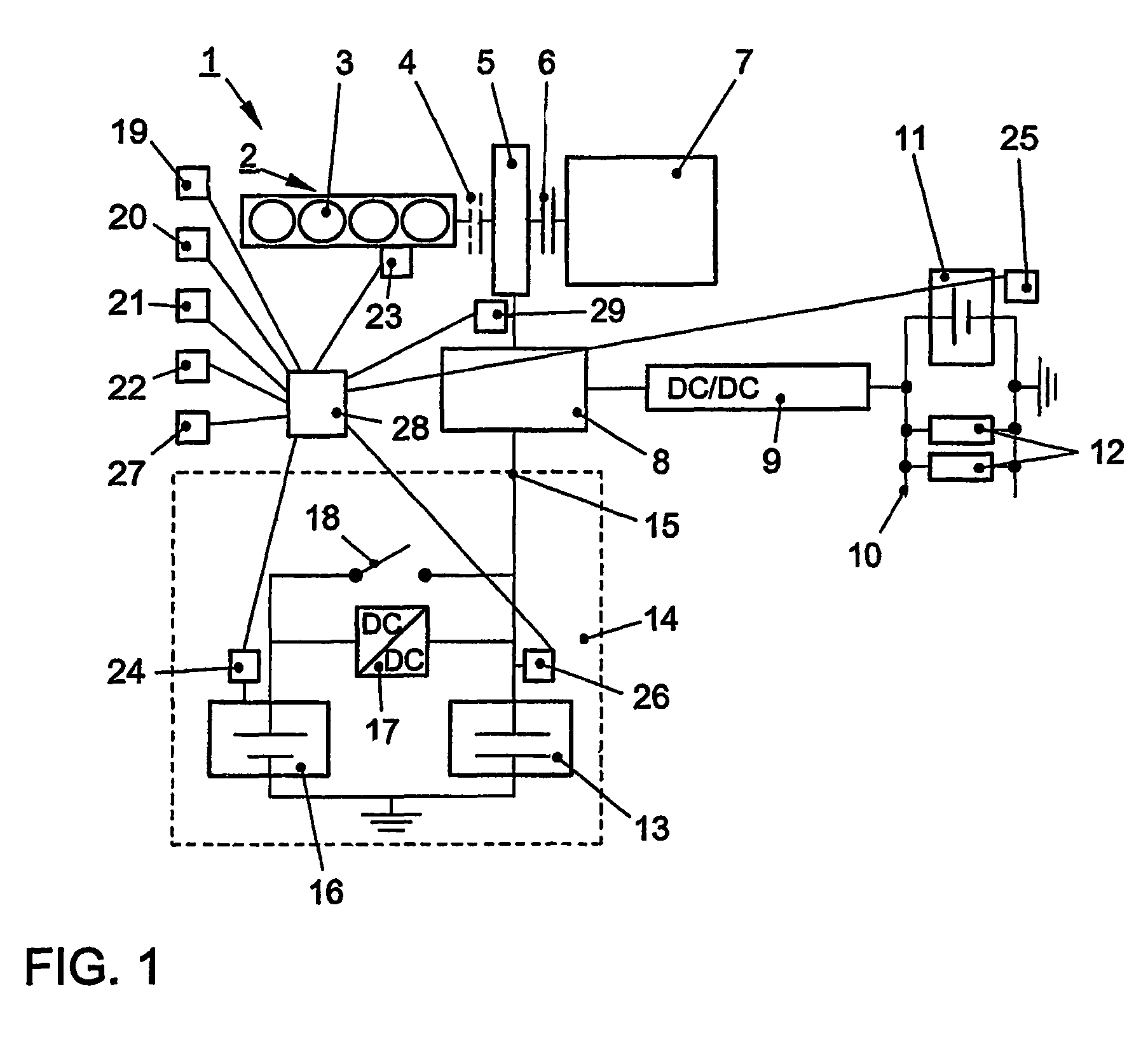

Method and Device for the Optimized Starting of an Internal Combustion Engine

ActiveUS20100108009A1Improve startup reliabilityIncrease loadPower operated startersGas pressure propulsion mountingConvertersElectrical battery

A method and a device are for the optimized starting of an internal combustion engine using a starter, which is connected to a capacitor store, the capacitor store being connected via a DC / DC converter to a vehicle electrical system of a vehicle, and the vehicle electrical system including an energy store for supplying electrical energy having a nominal voltage, and the starter consuming a starting energy for starting the internal combustion engine, which is a function of a temperature of the internal combustion engine, the temperature of the internal combustion engine being measured by at least one temperature sensor and the capacitor store being charged to a setpoint voltage with the aid of a battery via another DC / DC converter, which connects the battery in parallel to the capacitor store parallel to a switch, the setpoint voltage being set by a control unit such that the electrical energy stored in the capacitor store charged to the setpoint voltage is greater than the starting energy ascertained on the basis of the measured temperature.

Owner:VOLKSWAGEN AG

Method and a system for reliably starting a turbine engine

ActiveUS20170002744A1Improve startup reliabilityRobust ignitionEngine fuctionsTurbine/propulsion engine ignitionDc dc converterElectrical battery

There is provided a starting system for reliably starting a turbine engine, the system including first and second circuits connected in parallel and arranged between a battery of the engine and a DC starter of the engine, the first circuit including a DC-DC converter connected in series with a first switch and the second circuit including a second switch; a sensor configured to sense a speed of rotation of a compressor of the engine; a sensor configured to sense a temperature at an inlet to a free turbine of the engine; and a control circuit configured to control the first and second switches as a function of information supplied by the sensor configured to sense the speed of rotation of the compressor and by the sensor configured to sense the inlet temperature of the free turbine.

Owner:SAFRAN HELICOPTER ENGINES

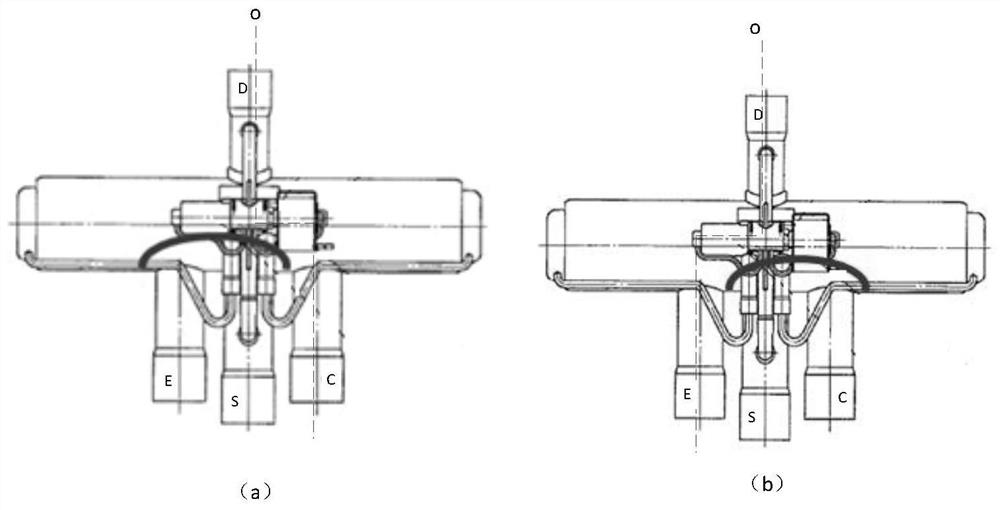

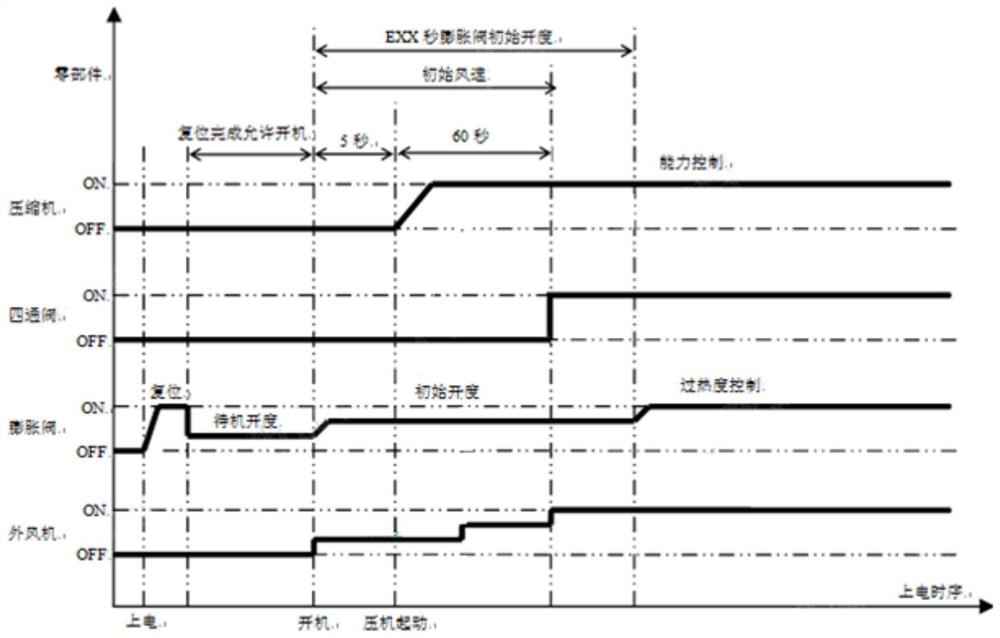

Control method for low temperature start-up of air conditioner of air-source heat pump system, and air conditioner

ActiveCN109556308AImprove startup reliabilityLow viscosityMechanical apparatusFluid circulation arrangementFour-way valveEngineering

The invention provides a control method for low temperature start-up of an air conditioner of an air-source heat pump system, and the air conditioner, and relates to the technical field of air conditioners. The control method comprises the steps that in response to a start-up heating instruction of the air conditioner, whether the detected ambient temperature is lower than or equal to a preset ambient temperature threshold or nor is judged, and the detected continuous shutdown time of a compressor is greater than or equal to the preset shutdown time is judged; and if the ambient temperature islower than or equal to the preset ambient temperature threshold, and the continuous shutdown time is greater than or equal to the preset shutdown time, so that a four-way valve of the air-source heatpump system is controlled to be switched to be in a refrigeration operation state after the compressor is started up. If the air conditioner meets the preset conditions, the four-way valve is controlled to be switched to be in a heating operation state to enable the air conditioner to conduct normal heating operation. According to the control method for low temperature start-up of the air conditioner of the air-source heat pump system, liquid impact of the compressor can be effectively avoided, thus the start-up reliability of the compressor and the system operation reliability are improved,and the service life of the compressor is prolonged.

Owner:NINGBO AUX ELECTRIC +1

Integrated fuel gas characterization system

ActiveUS20100050641A1Improve startup reliabilityTurbine/propulsion engine ignitionTurbine/propulsion engine startersCombustorBuffer tank

A gas turbine engine that includes a compressor, a combustion stage, a turbine assembly, a fuel gas feed system for supplying fuel gas to a combustion stage of the gas turbine, an integrated fuel gas characterization system, and a buffer tank is disclosed. The integrated fuel gas characterization system may determine the heating value of the fuel and adjust either the airflow to the compressor or the fuel gas flow to the combustor to maintain a design fuel-to-air ratio.

Owner:SIEMENS ENERGY INC

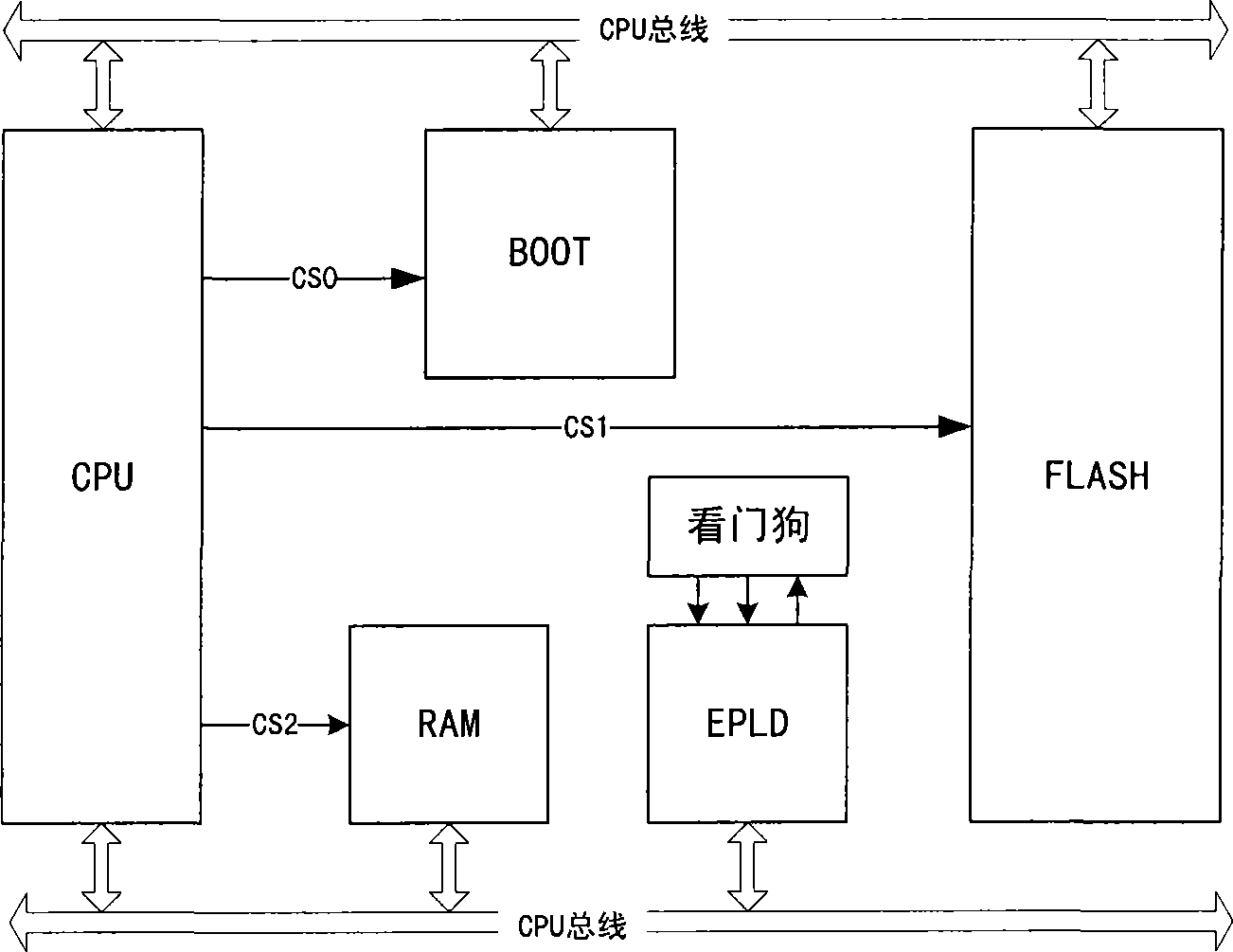

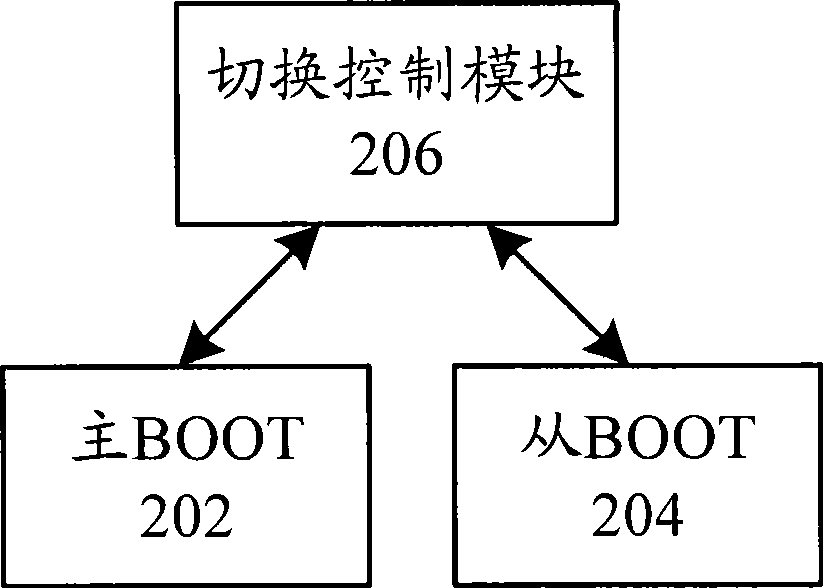

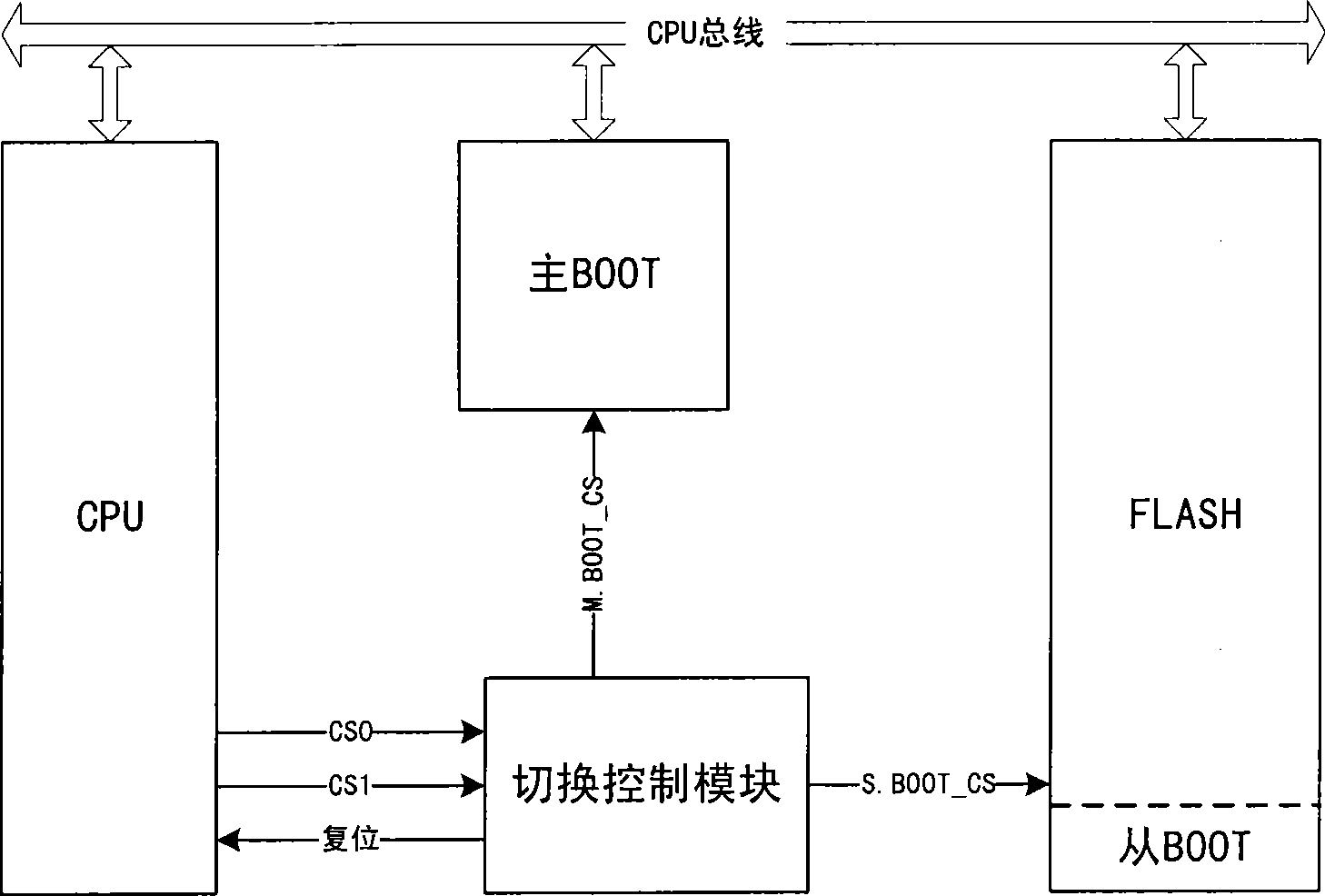

Single board starting system and method

ActiveCN101499909AReduce version upgrade riskLow costData switching detailsProgram loading/initiatingSingle plateOperating system

The invention provides a single-plate startup system, which comprises a first startup booting chip which is connected with a single plate by a chip socket and used for CPU startup; a second startup booting chip which is arranged on a program storage, stores version information of the first startup booting chip and is used for starting a CPU with the version information; and a switch control module which is used for taking the other one from the first startup booting chip and the second startup booting chip as the secondary startup booting chip to start the CPU under the situation that CPU startup of the main startup booting chip which is the first startup booting chip or the second startup booting chip fails. The invention further discloses a single-plate startup method. The single-plate startup system and the single-plate startup method can flexibly realize version update and maintenance of the main and secondary BOOT after the CPU runs normally, thus lowering version update risks and improving system startup reliability; furthermore, the single-plate startup system and the single-plate startup method have simple implementation, and do not need additional devices, thus lowering system cost.

Owner:ZTE CORP

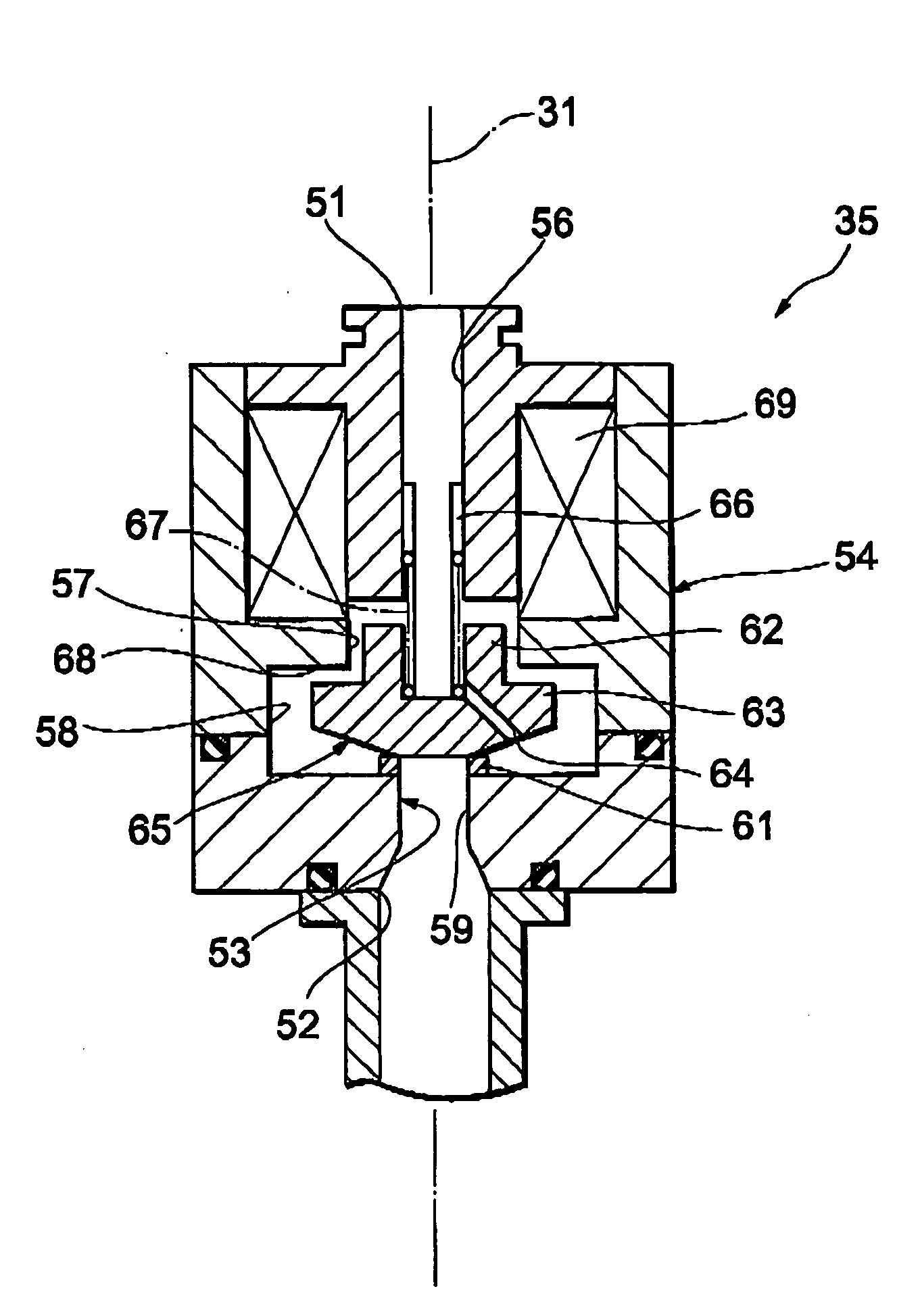

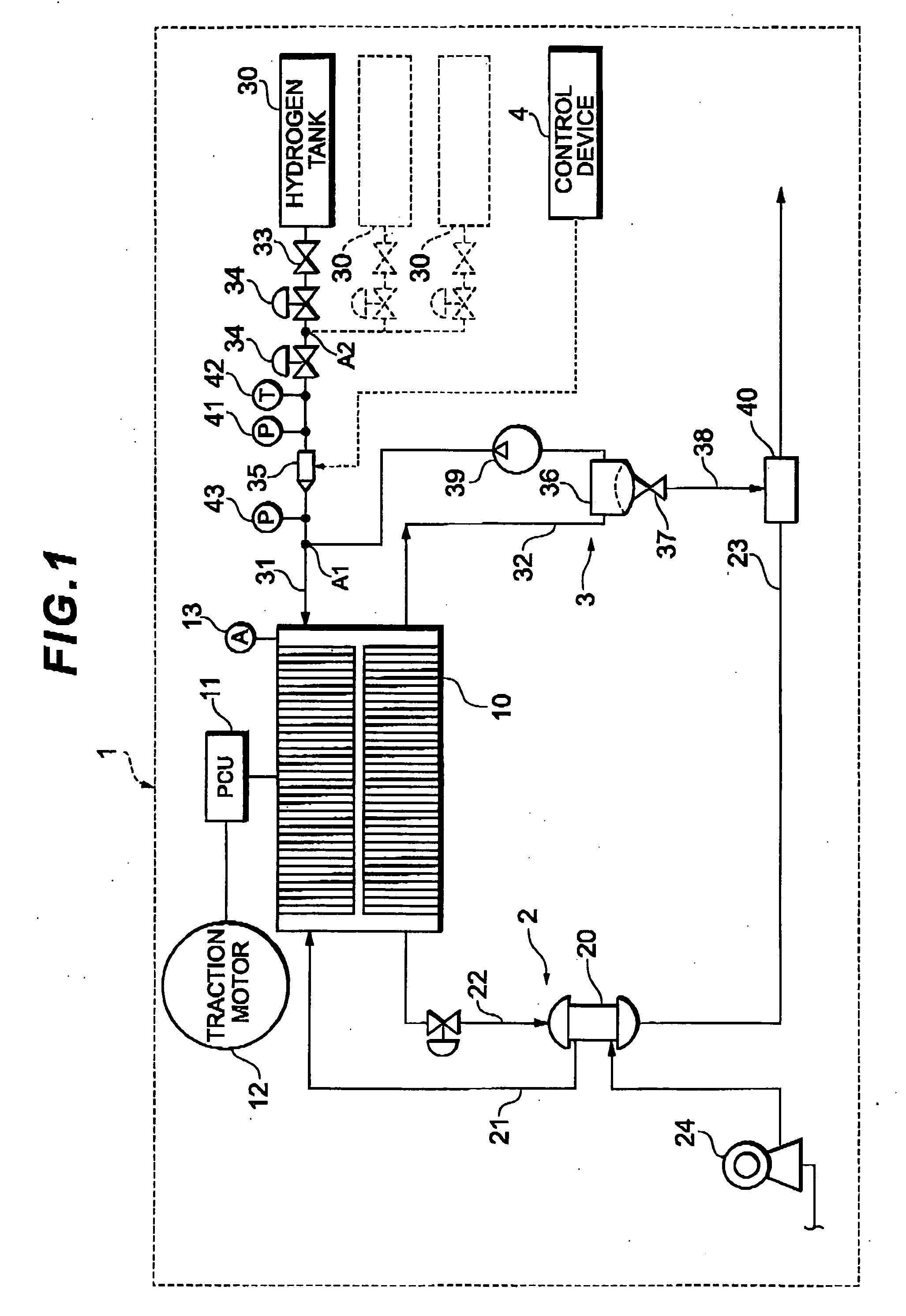

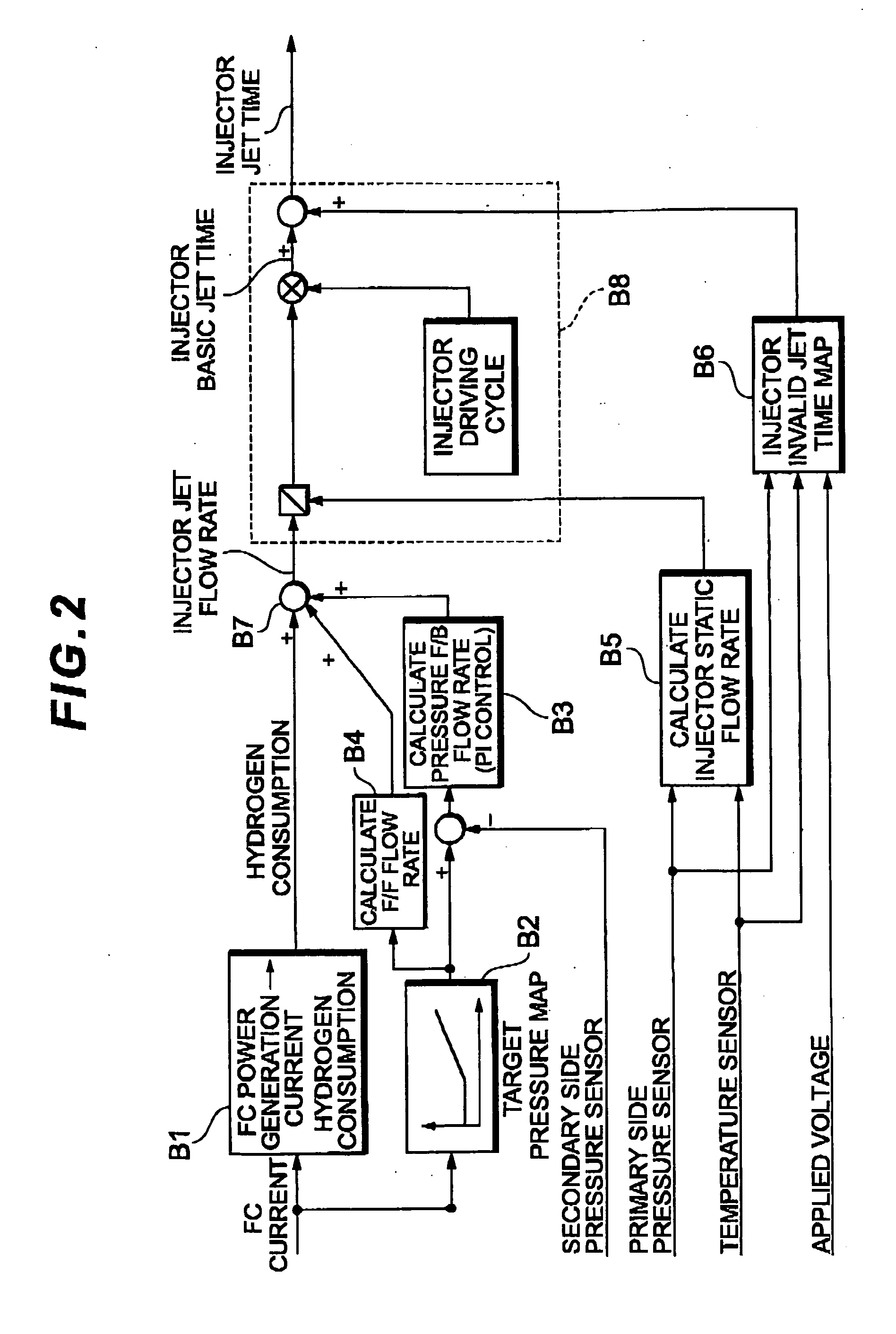

Fuel Cell System and Its Operation Stop Method

ActiveUS20090252997A1Avoid misuseImprove startup reliabilityOperating means/releasing devices for valvesReactant parameters controlFuel cellsHydrogen

The present invention provides a fuel cell system including a fuel cell, a hydrogen gas pipe system for supplying a fuel gas to the fuel cell, and an injector for adjusting a pressure of the upstream side of the hydrogen gas pipe system to supply the hydrogen gas to the downstream side, wherein the injector includes an internal channel for communicating the upstream side of the injector with the downstream side of the injector, and a valve body movably arranged in the internal channel for switching a channel opening area in multiple stages corresponding to a movement position of the valve body, and wherein water at least around the valve body of the injector is reduced when the system stops.

Owner:TOYOTA JIDOSHA KK

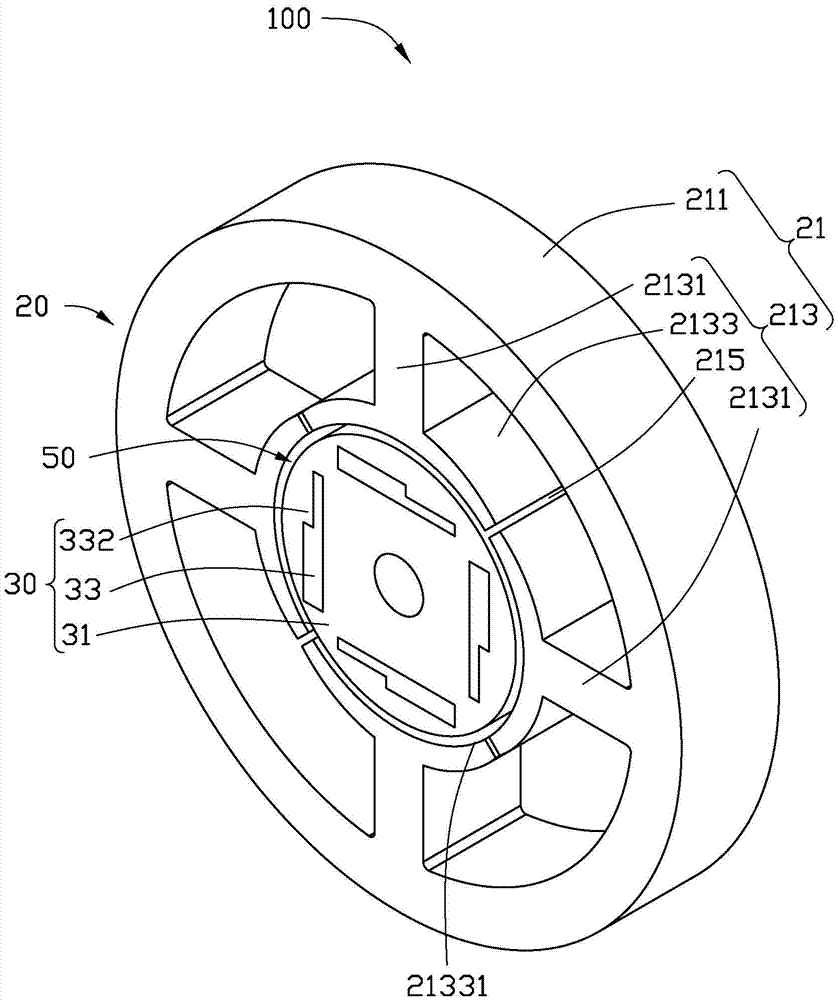

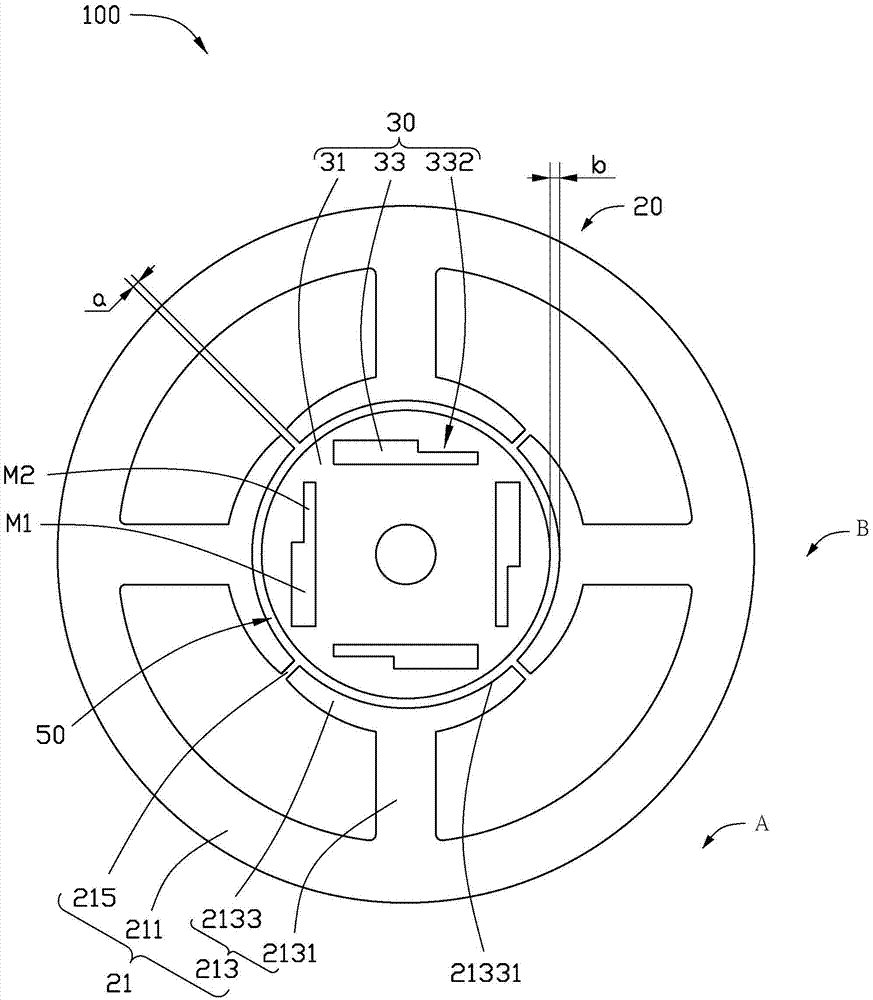

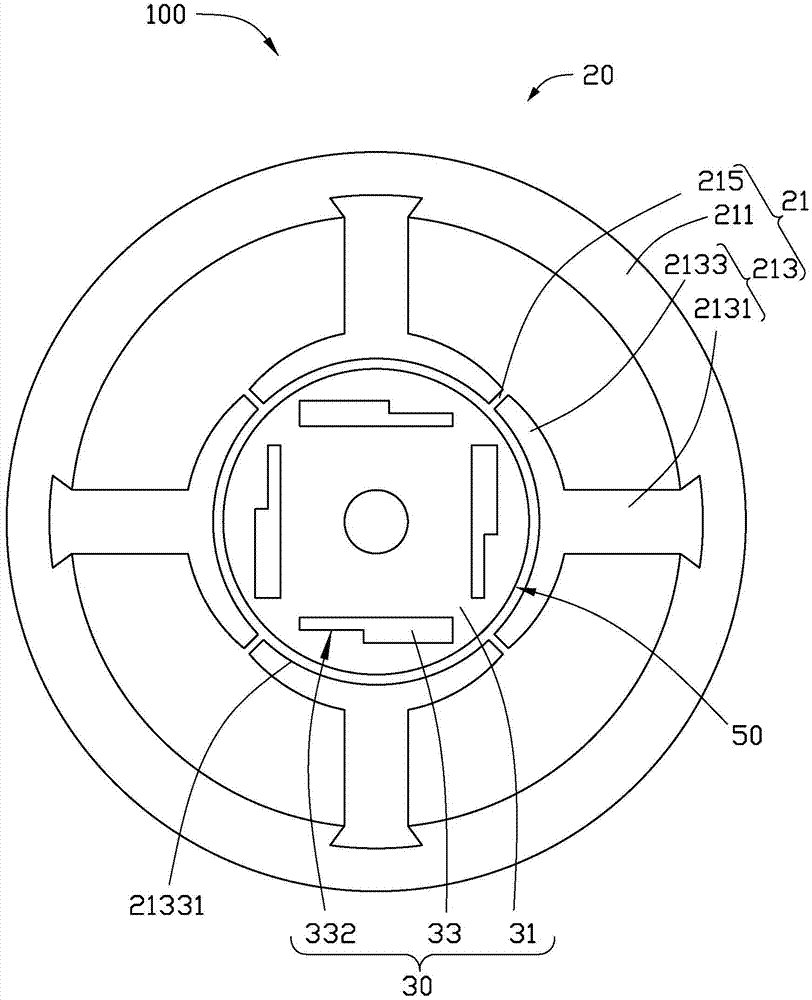

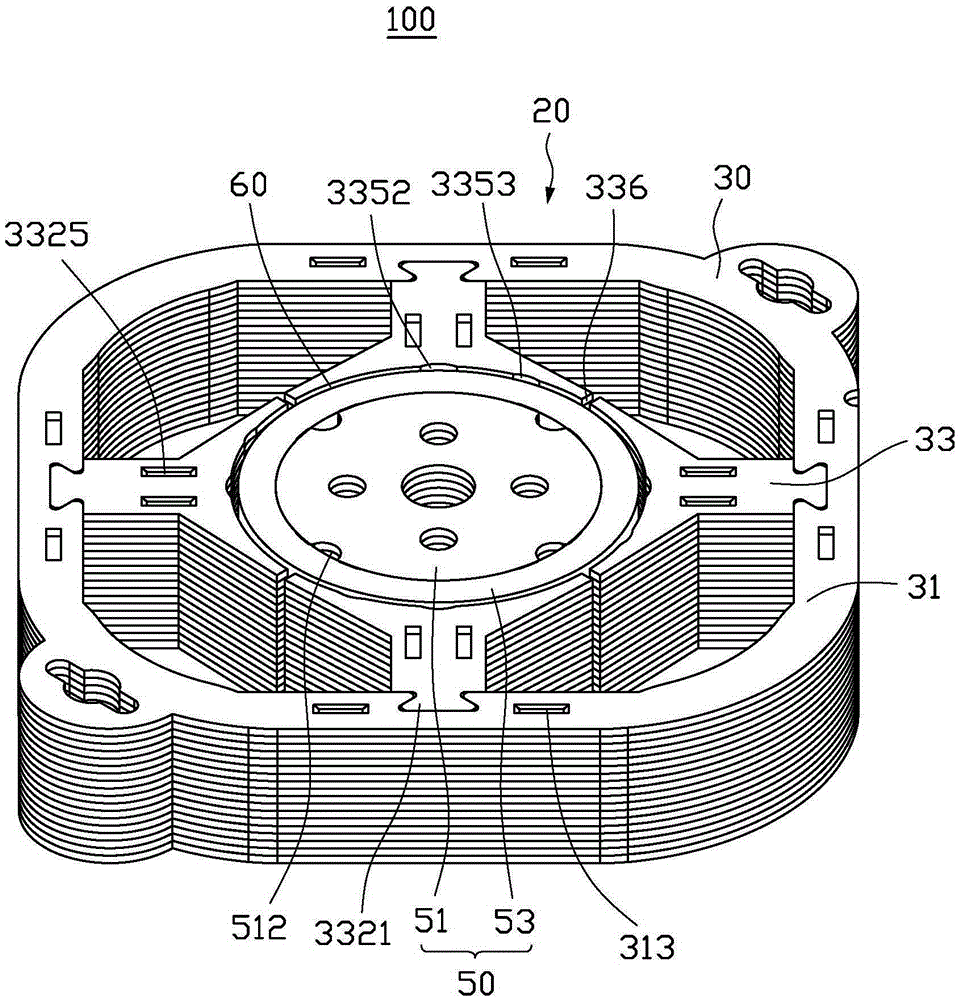

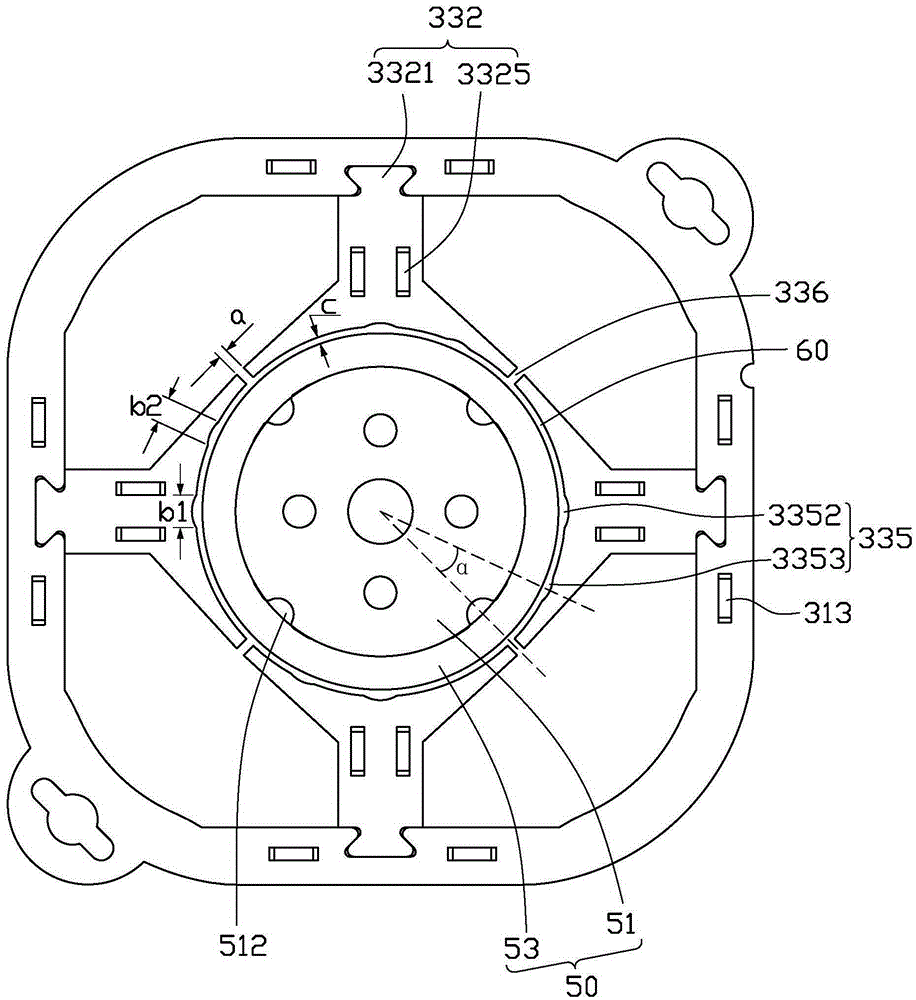

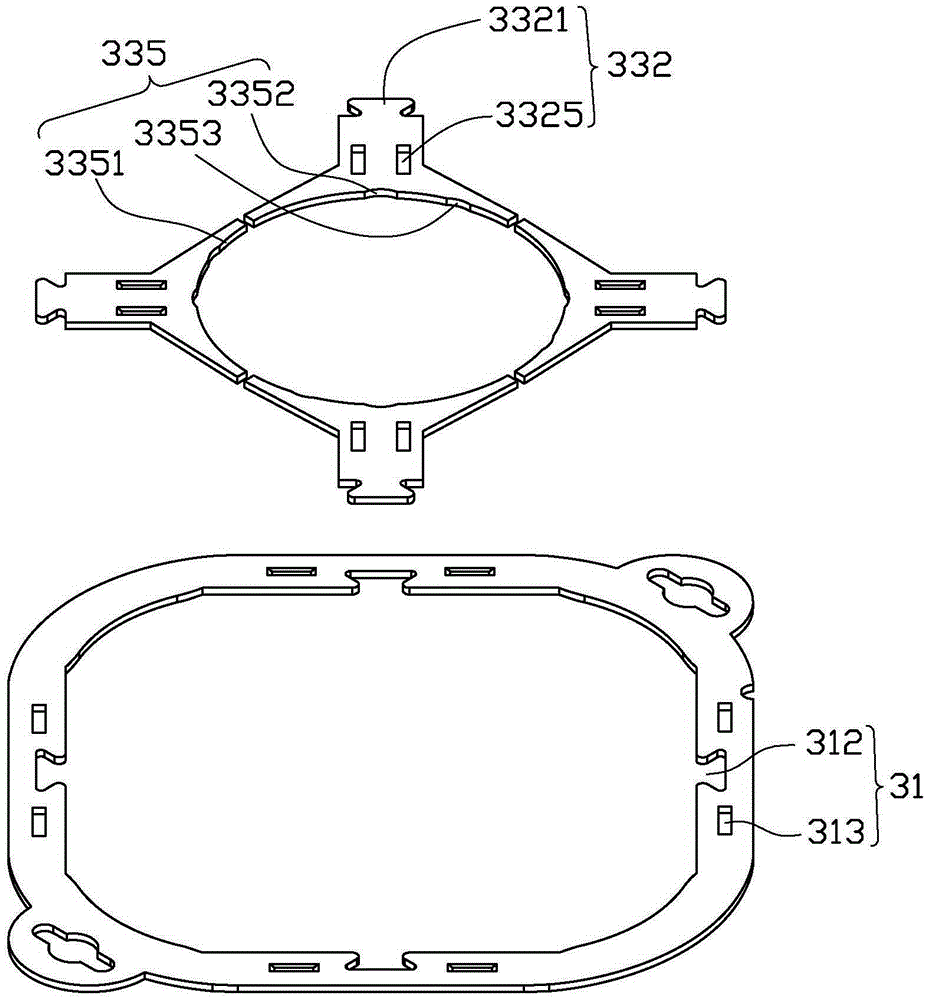

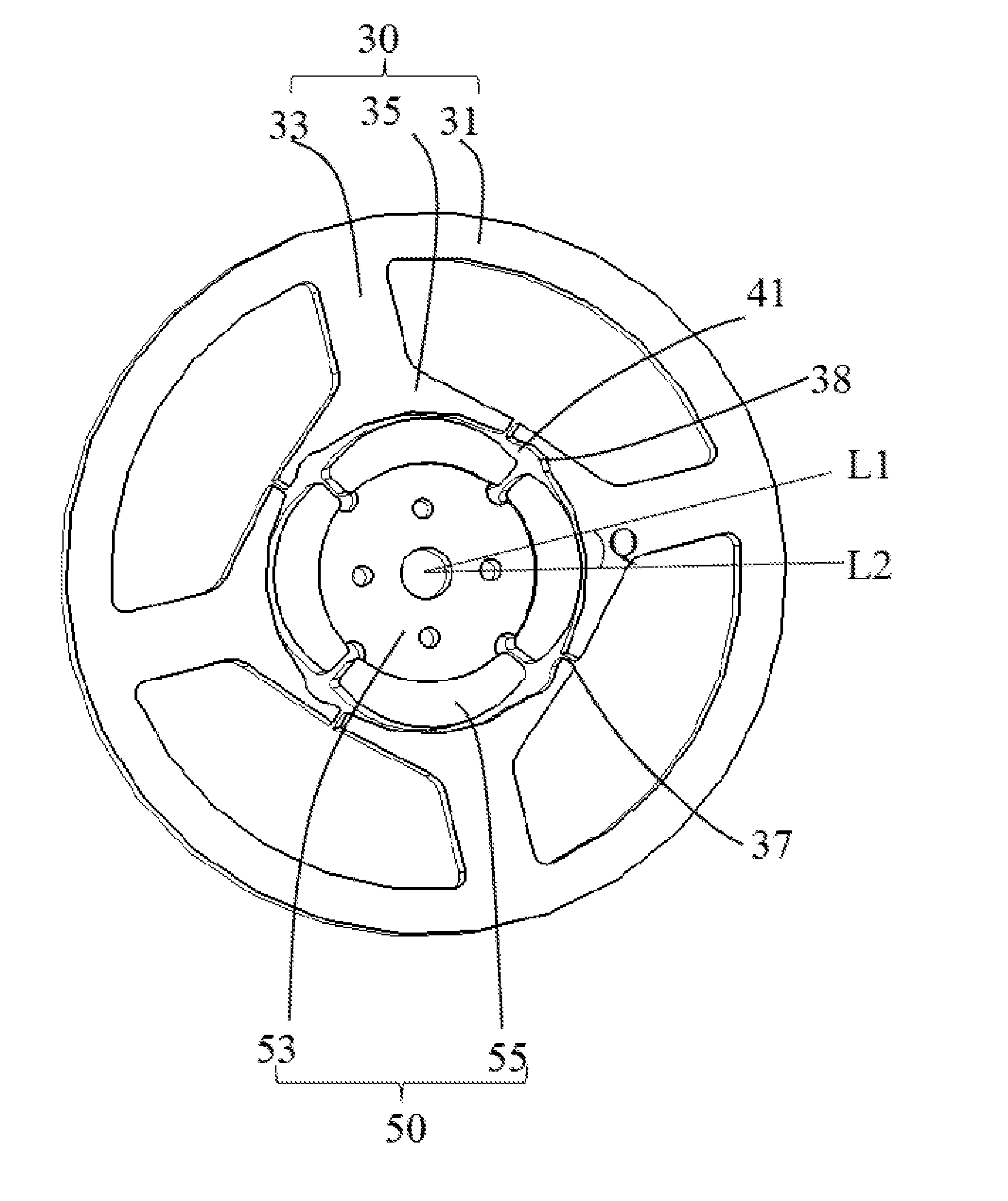

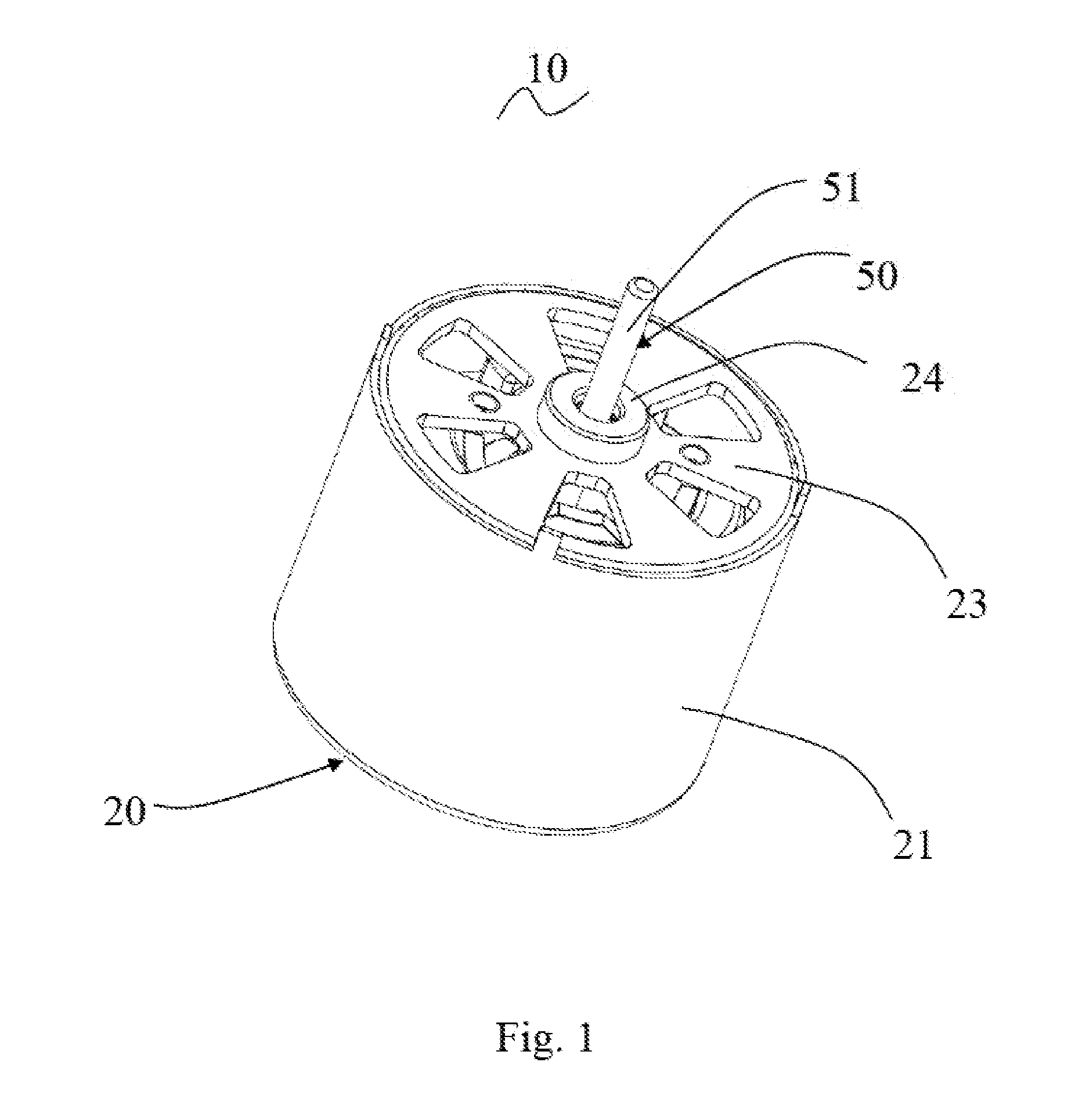

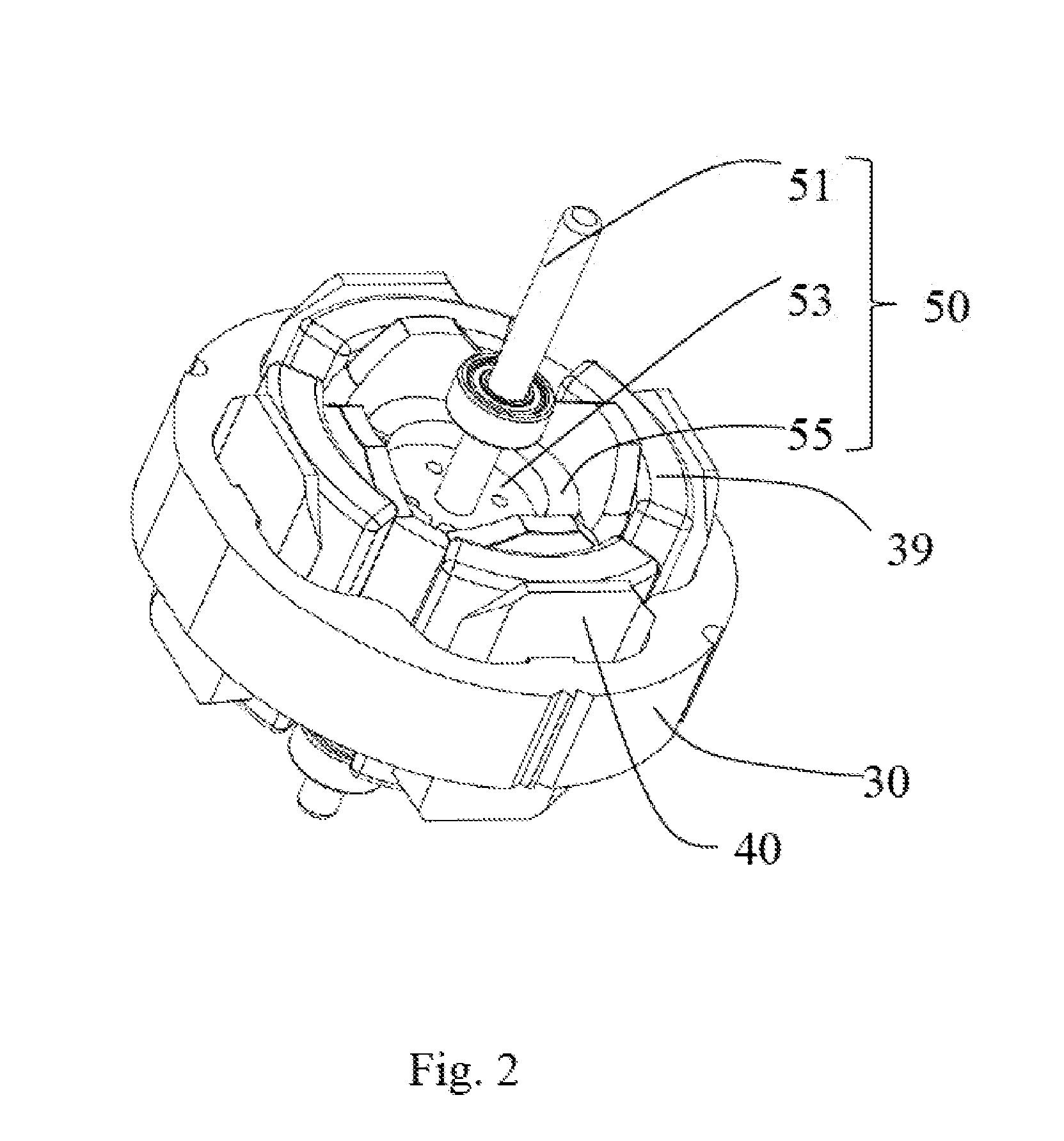

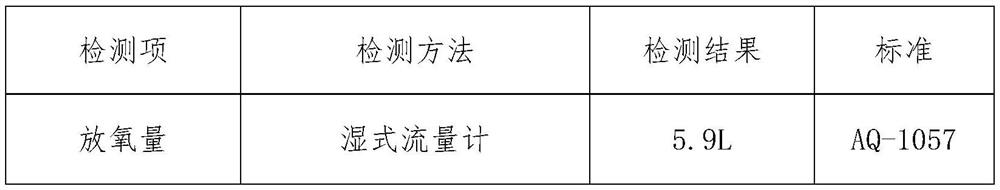

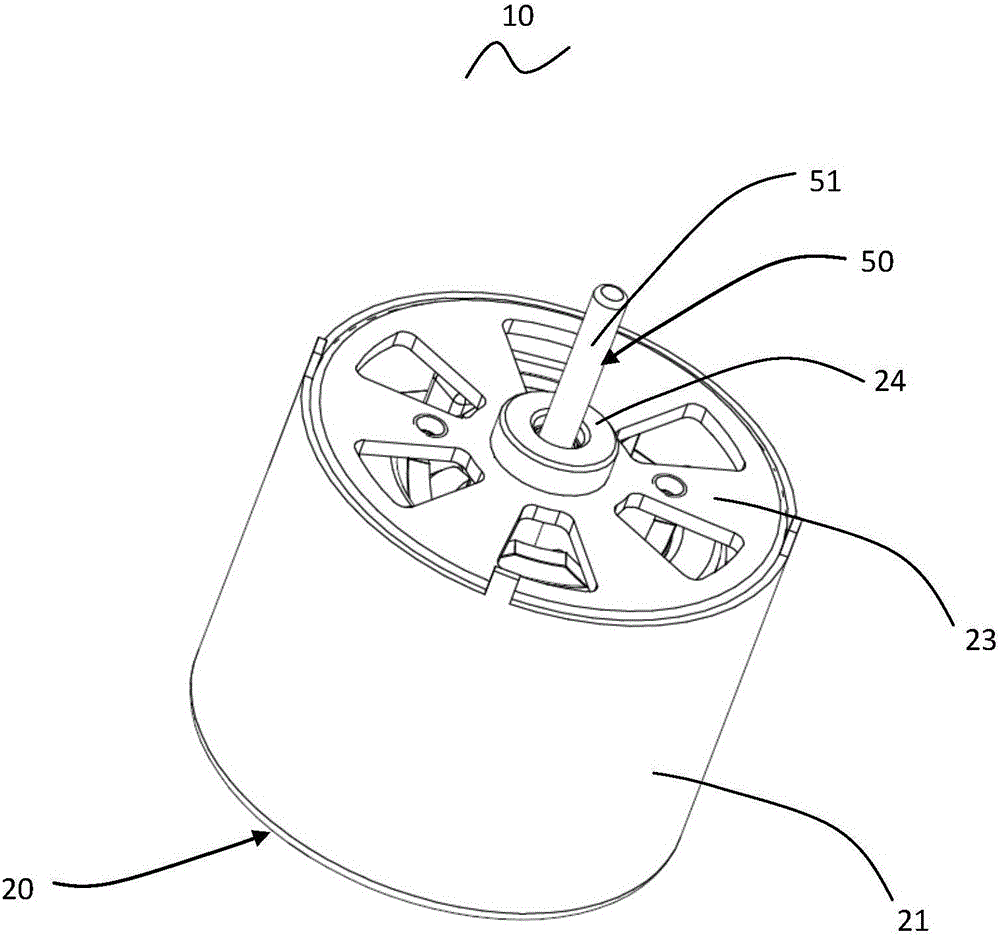

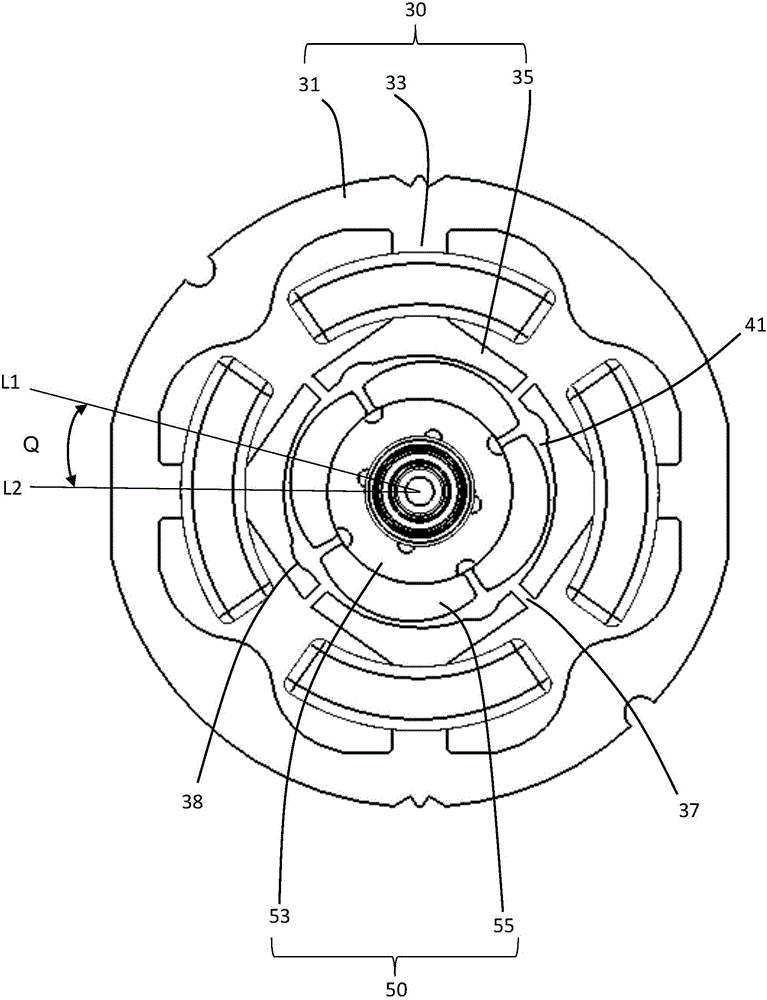

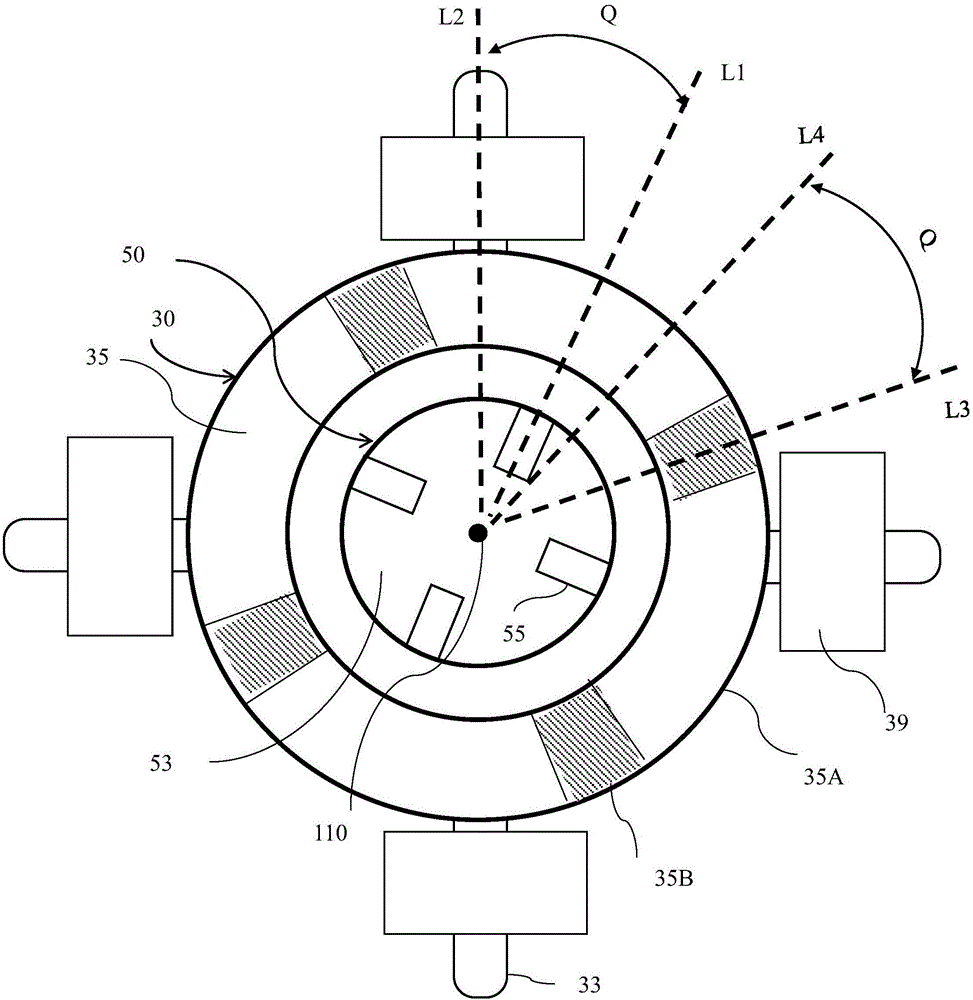

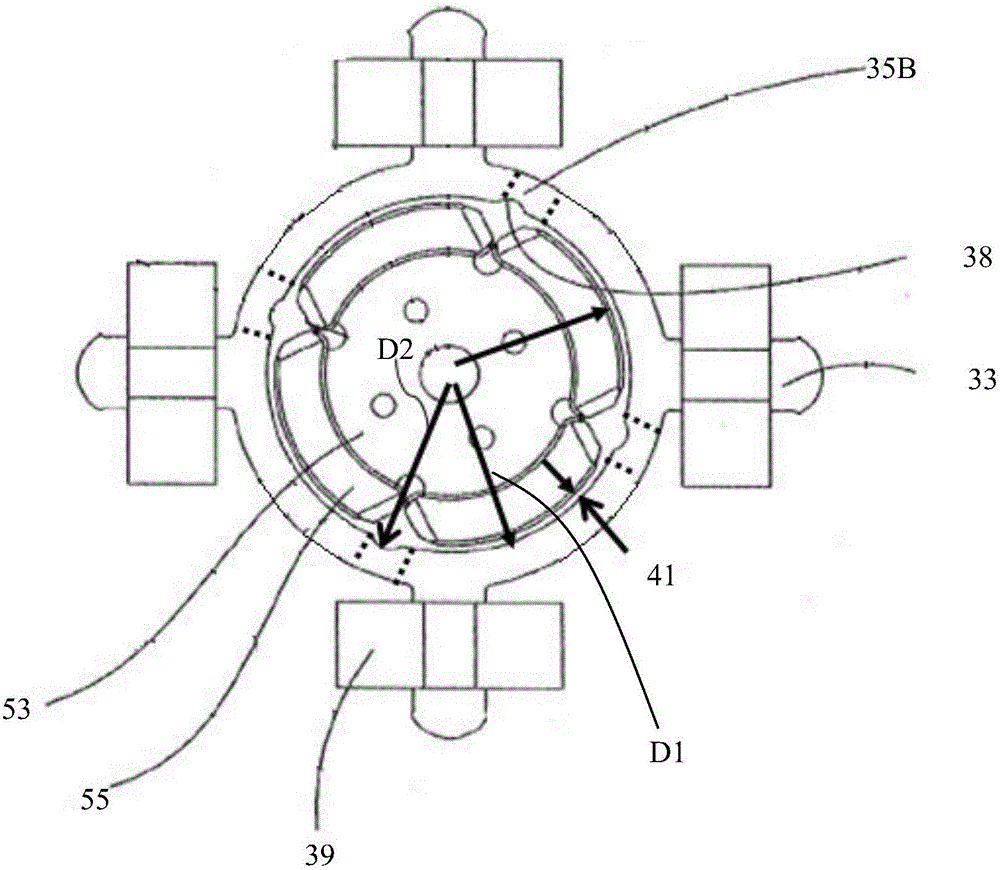

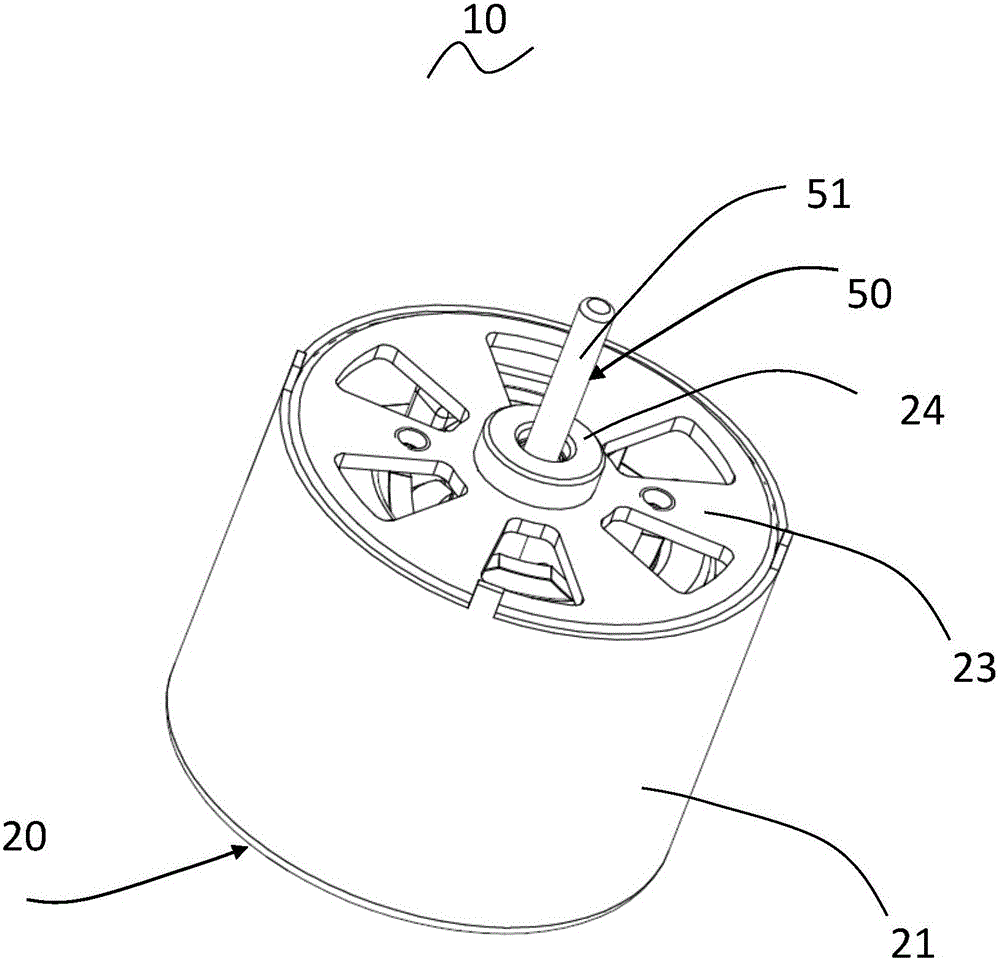

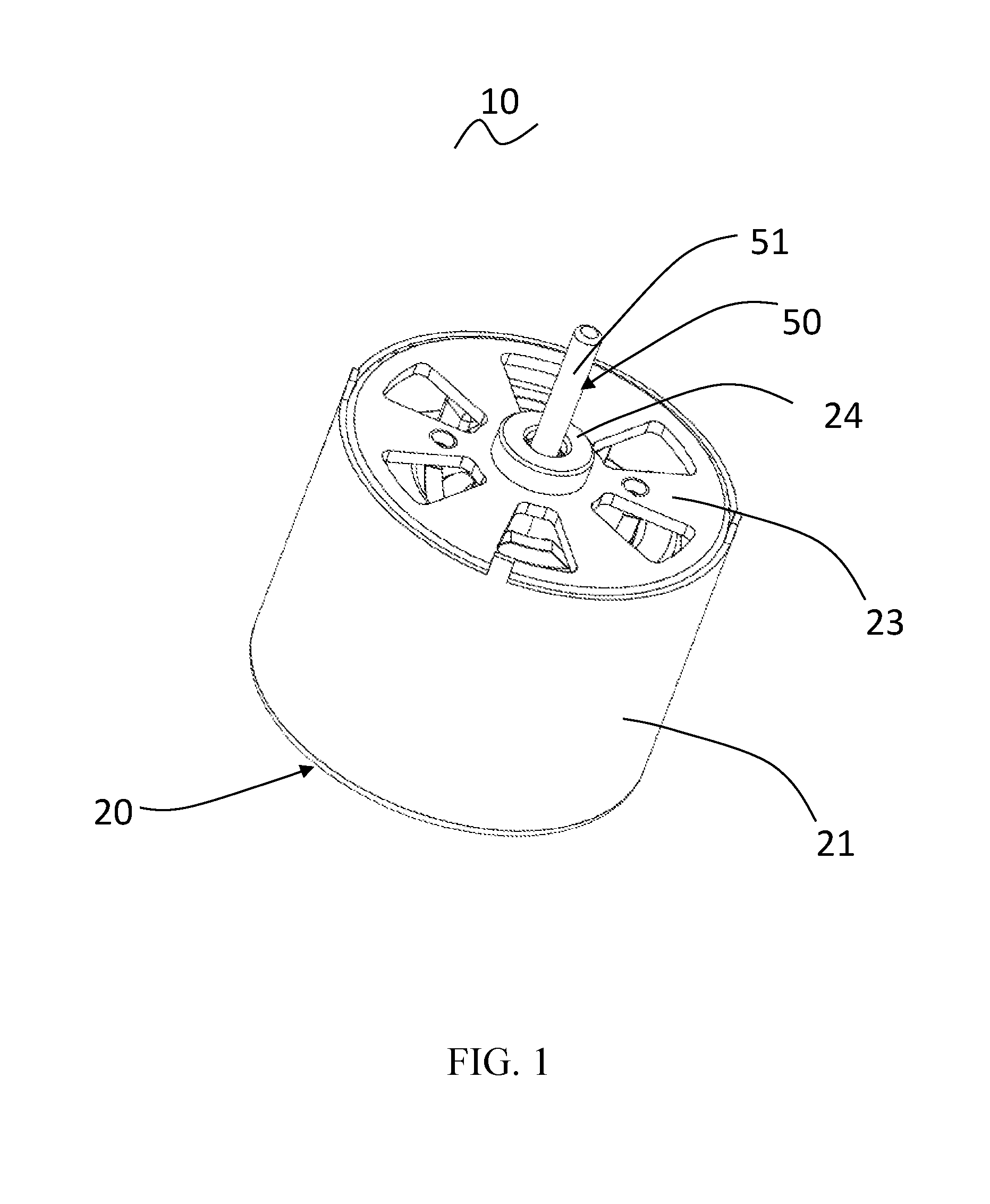

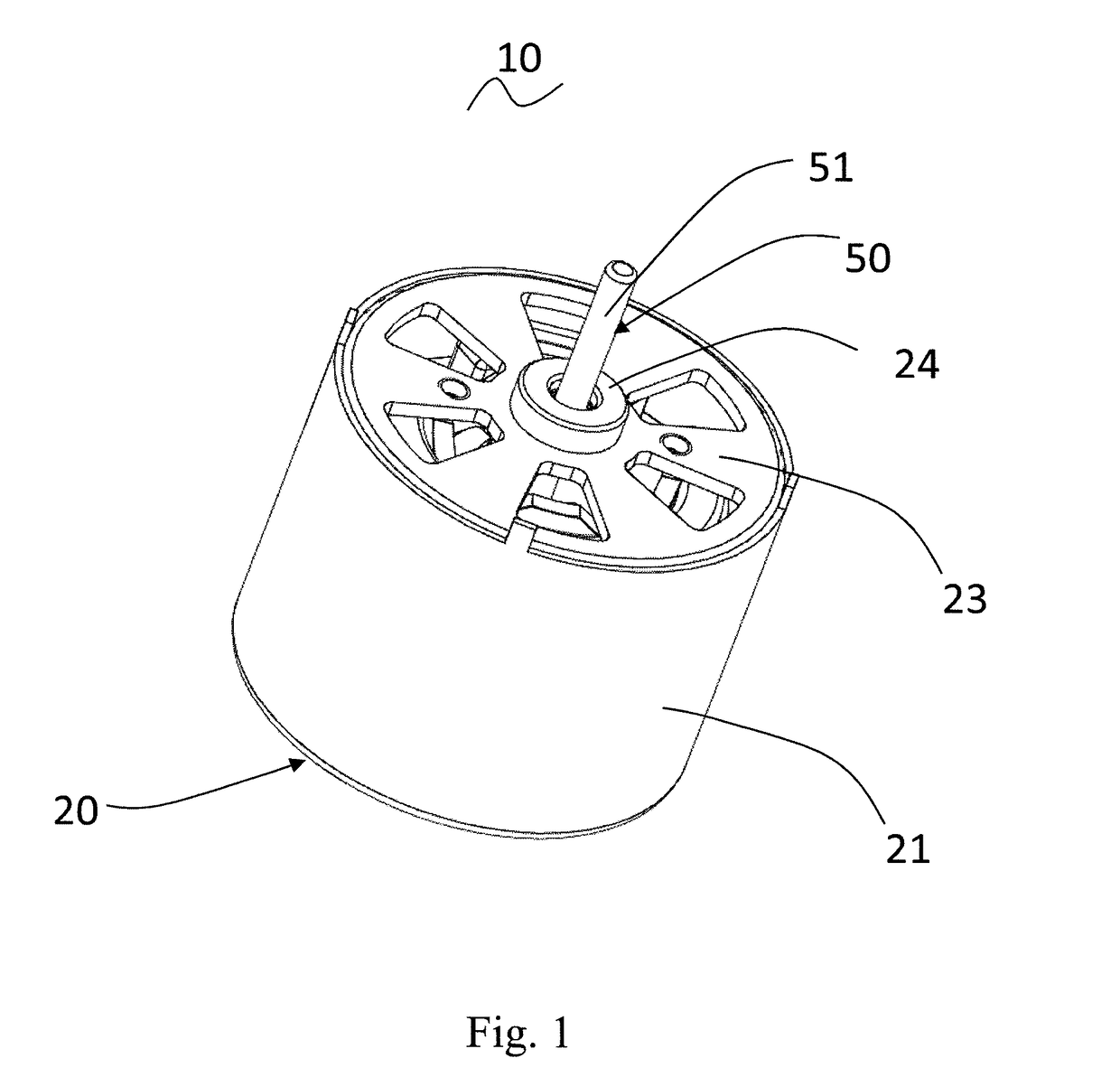

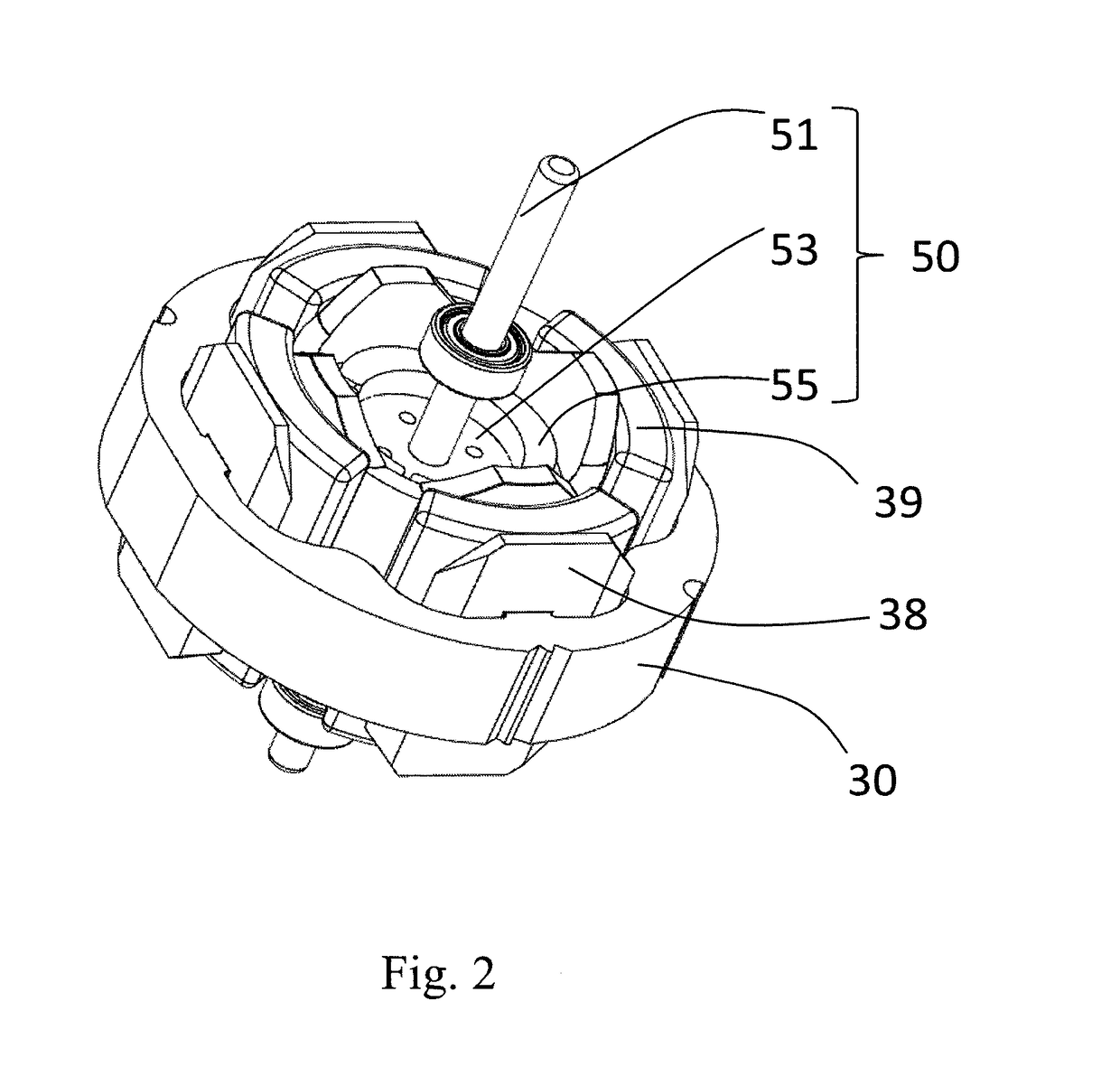

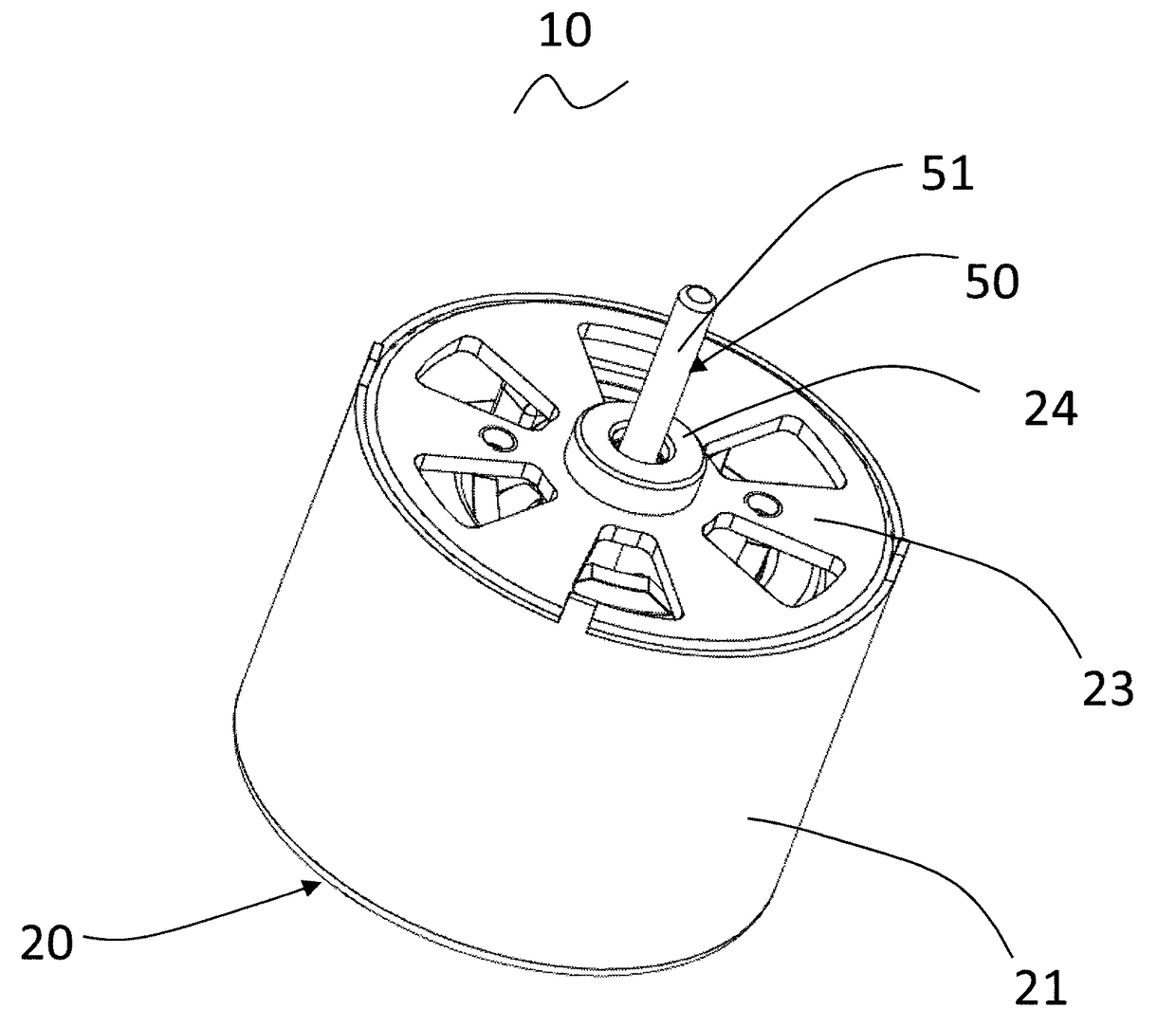

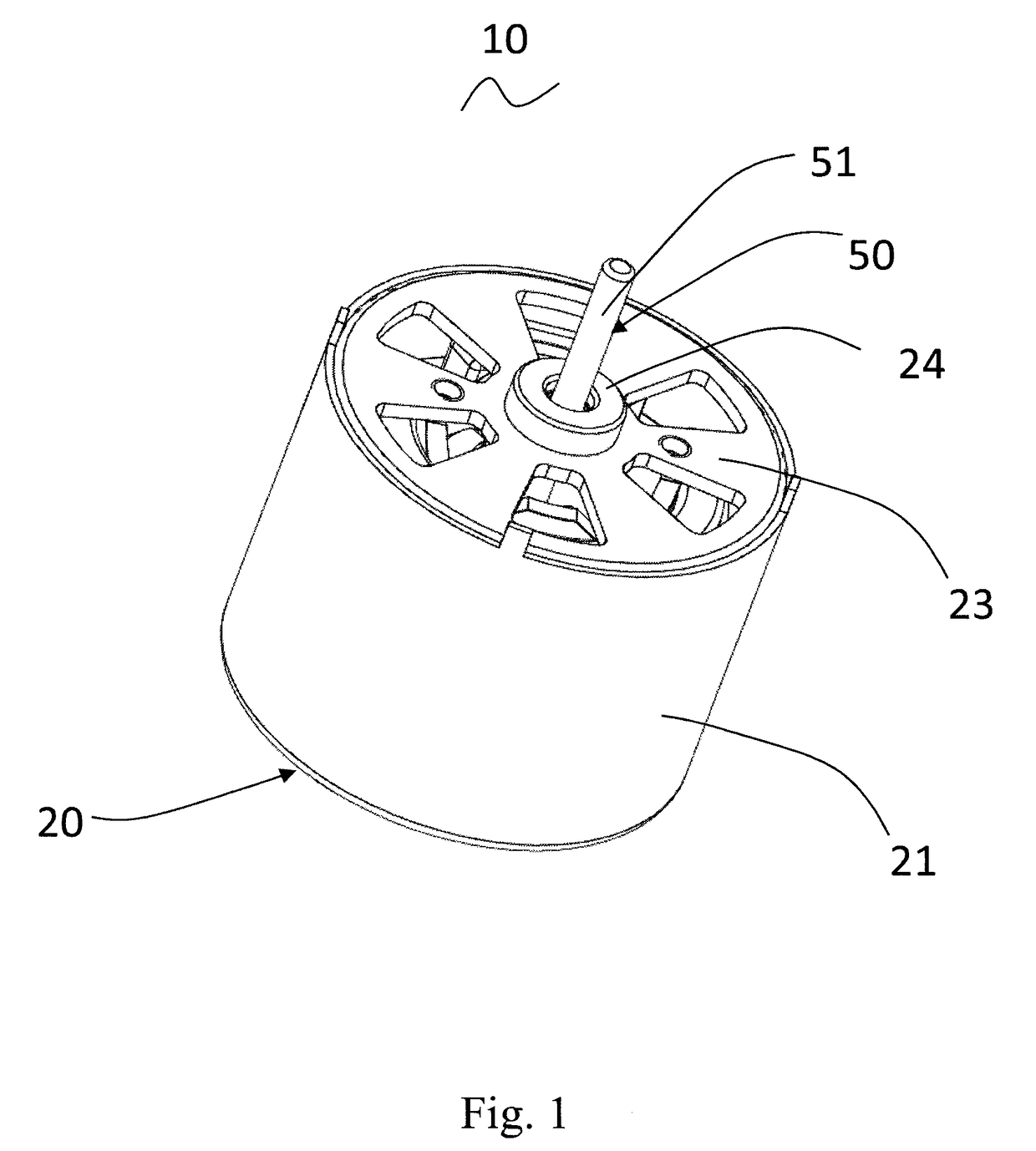

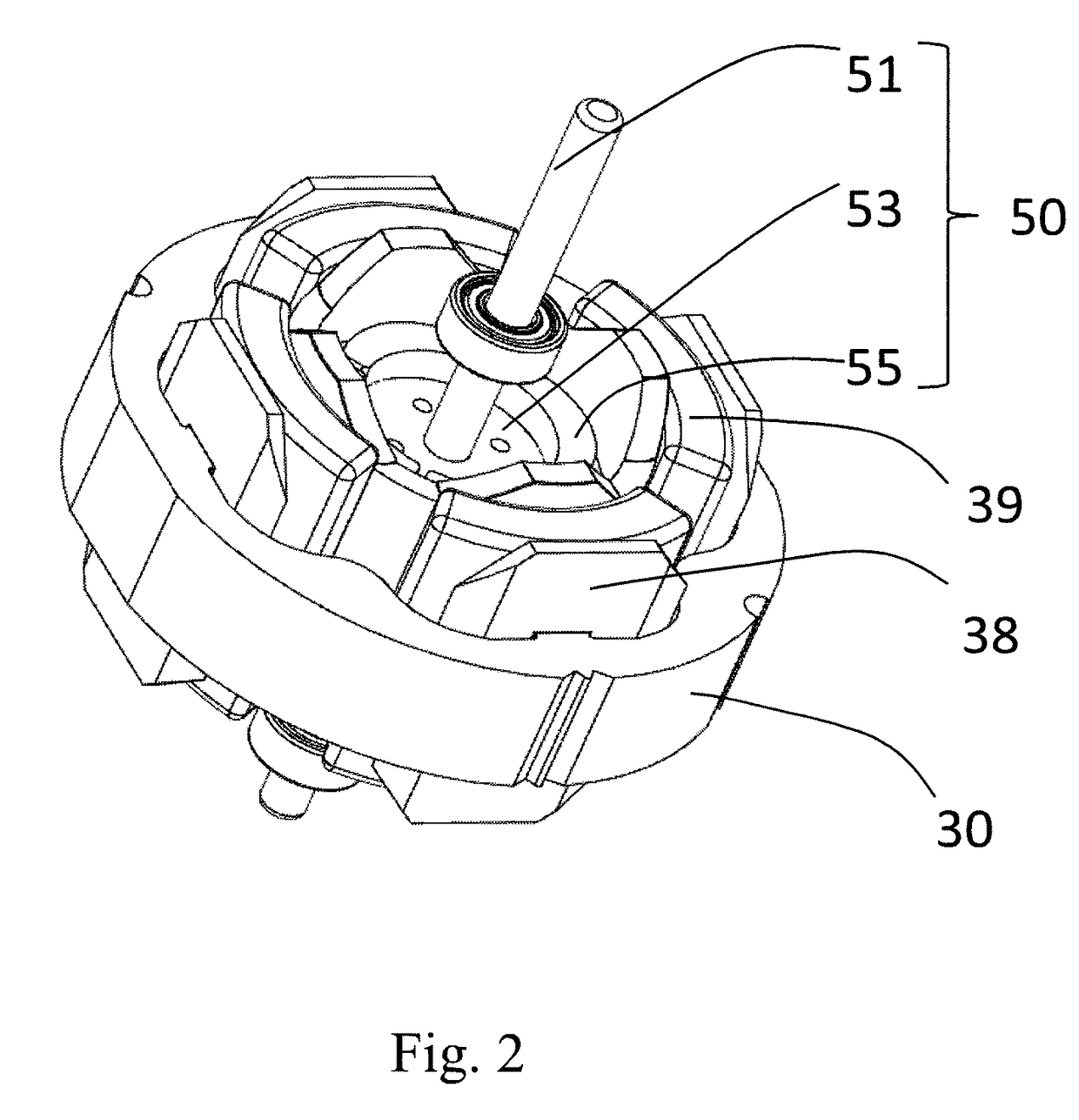

Single-phase motor and rotor thereof

InactiveCN107026523ASmooth startSmall starting currentMagnetic circuit rotating partsSynchronous motorsConductor CoilStart up

The invention relates to a single-phase motor. The motor comprises a stator and a rotor, the stator comprises a stator magnetic core and a winding, the stator magnetic core comprises an external yoke portion and stator teeth, each stator tooth comprises a winding portion and a pole shoe connected to one end of the winding portion, and the winding is wound around the corresponding winding portion. The rotor includes a rotor core and permanent magnets. The permanent magnets are embedded in the rotor core and evenly distributed in the circumferential direction of the rotor core. Each permanent magnet is of a stripe-shaped asymmetric structure, and cross-sectional areas at both ends of each permanent magnet are not equal. Thus, the initial position of the rotor is able to avoid a dead point position, and start-up of the motor is stable. The present invention also provides the rotor of the single-phase motor.

Owner:JOHNSON ELECTRIC SHENZHEN

Integrated fuel gas characterization system

ActiveUS8484981B2Improve startup reliabilityTurbine/propulsion engine ignitionTurbine/propulsion engine startersCombustorBuffer tank

A gas turbine engine that includes a compressor, a combustion stage, a turbine assembly, a fuel gas feed system for supplying fuel gas to a combustion stage of the gas turbine, an integrated fuel gas characterization system, and a buffer tank is disclosed. The integrated fuel gas characterization system may determine the heating value of the fuel and adjust either the airflow to the compressor or the fuel gas flow to the combustor to maintain a design fuel-to-air ratio.

Owner:SIEMENS ENERGY INC

Method and device for the optimized starting of an internal combustion engine

ActiveUS8276559B2Improve startup reliabilityIncrease loadPower operated startersGas pressure propulsion mountingElectrical batteryExternal combustion engine

A method and a device are for the optimized starting of an internal combustion engine using a starter, which is connected to a capacitor store, the capacitor store being connected via a DC / DC converter to a vehicle electrical system of a vehicle, and the vehicle electrical system including an energy store for supplying electrical energy having a nominal voltage, and the starter consuming a starting energy for starting the internal combustion engine, which is a function of a temperature of the internal combustion engine, the temperature of the internal combustion engine being measured by at least one temperature sensor and the capacitor store being charged to a setpoint voltage with the aid of a battery via another DC / DC converter, which connects the battery in parallel to the capacitor store parallel to a switch, the setpoint voltage being set by a control unit such that the electrical energy stored in the capacitor store charged to the setpoint voltage is greater than the starting energy ascertained on the basis of the measured temperature.

Owner:VOLKSWAGEN AG

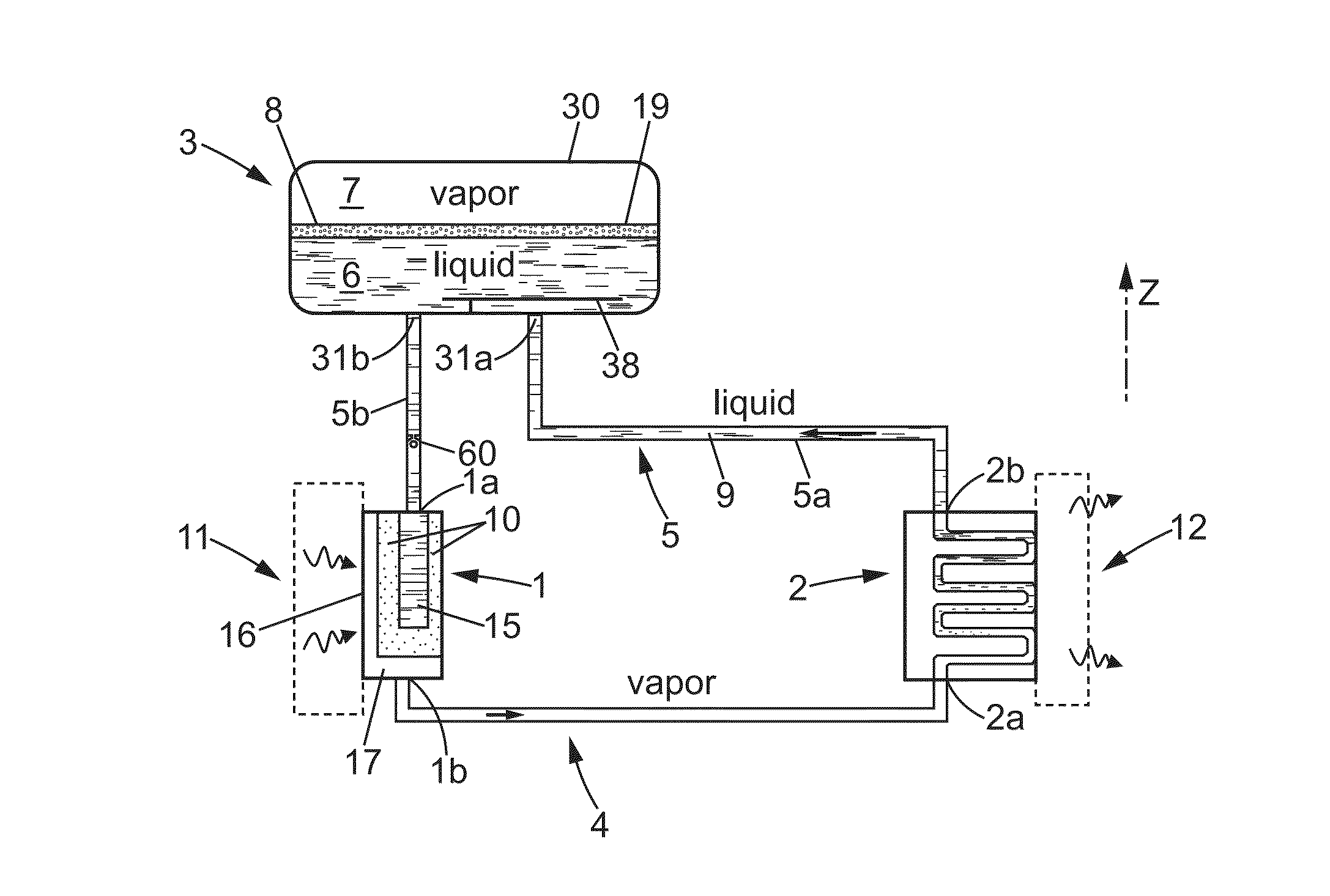

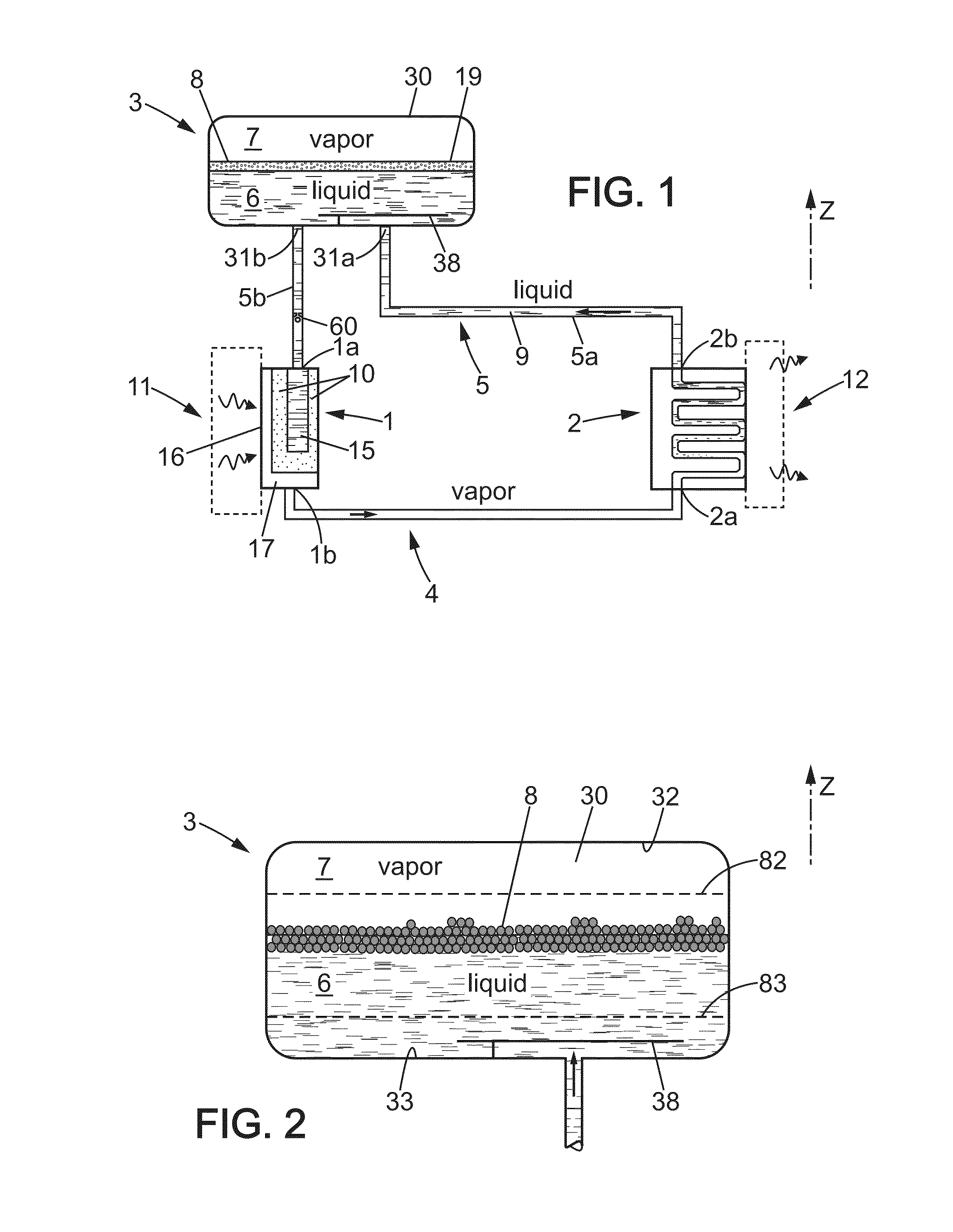

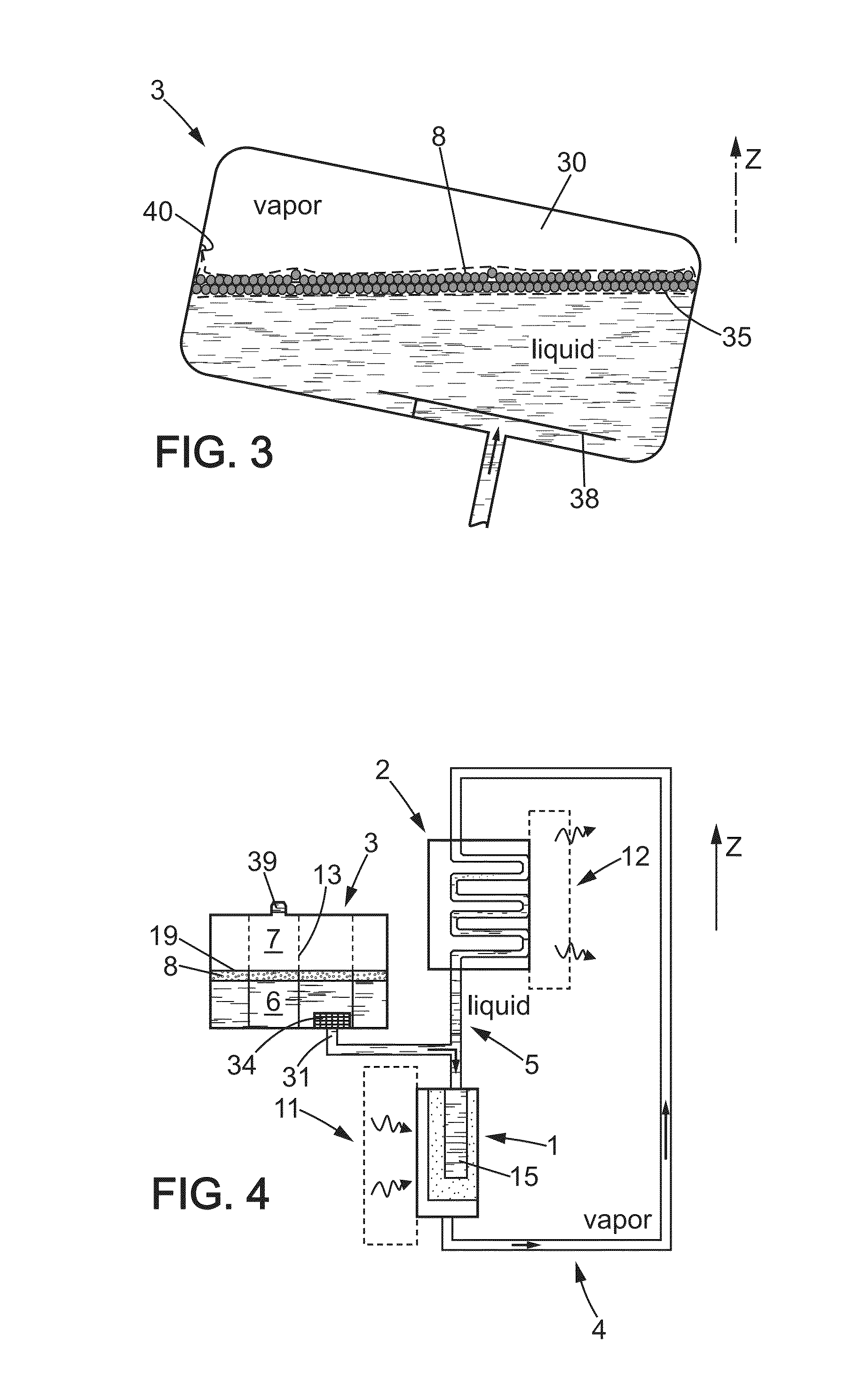

Two-phase heat transfer device

InactiveUS20160116226A1Reduce the impactReduce volatilitySafety devices for heat exchange apparatusVehicle heating/cooling devicesWorking fluidProduct gas

A two-phase heat transfer device that is capillary-driven or gravity-driven, has a two-phase working fluid contained in a closed general circuit, including an evaporator, a condenser, a reservoir having an inner volume with a liquid portion and a gas portion, a first vapor communication circuit, and a second liquid phase communication circuit. The reservoir comprises a plurality of floating bodies separating the liquid portion from the gas portion, by means of which the heat exchanges between the liquid portion and the gas portion are slowed down, which allows to diminish the effect of movement of the liquid portion or of an influx of cold or warm liquid into the reservoir.

Owner:EURO HEAT PIPES

Combustor

InactiveUS20170009994A1Good starting reliabilityImprove reliabilityContinuous combustion chamberElectric spark ignitersCombustion chamberCombustor

A burner includes a pilot burner, a combustion chamber, and a swirler located radially outwardly of the combustion chamber and being adapted to impose a swirling motion on a fuel / air mixture about an axial centerline of the combustion chamber. The pilot burner has a pilot burner face located radially inwardly of the swirler and forms an axially upstream wall of the combustion chamber, the pilot burner face incorporating a pilot fuel injector and an ignitor, both being positioned radially offset from the axial centerline. A recess is positioned radially offset from the axial centerline within the pilot burner face.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

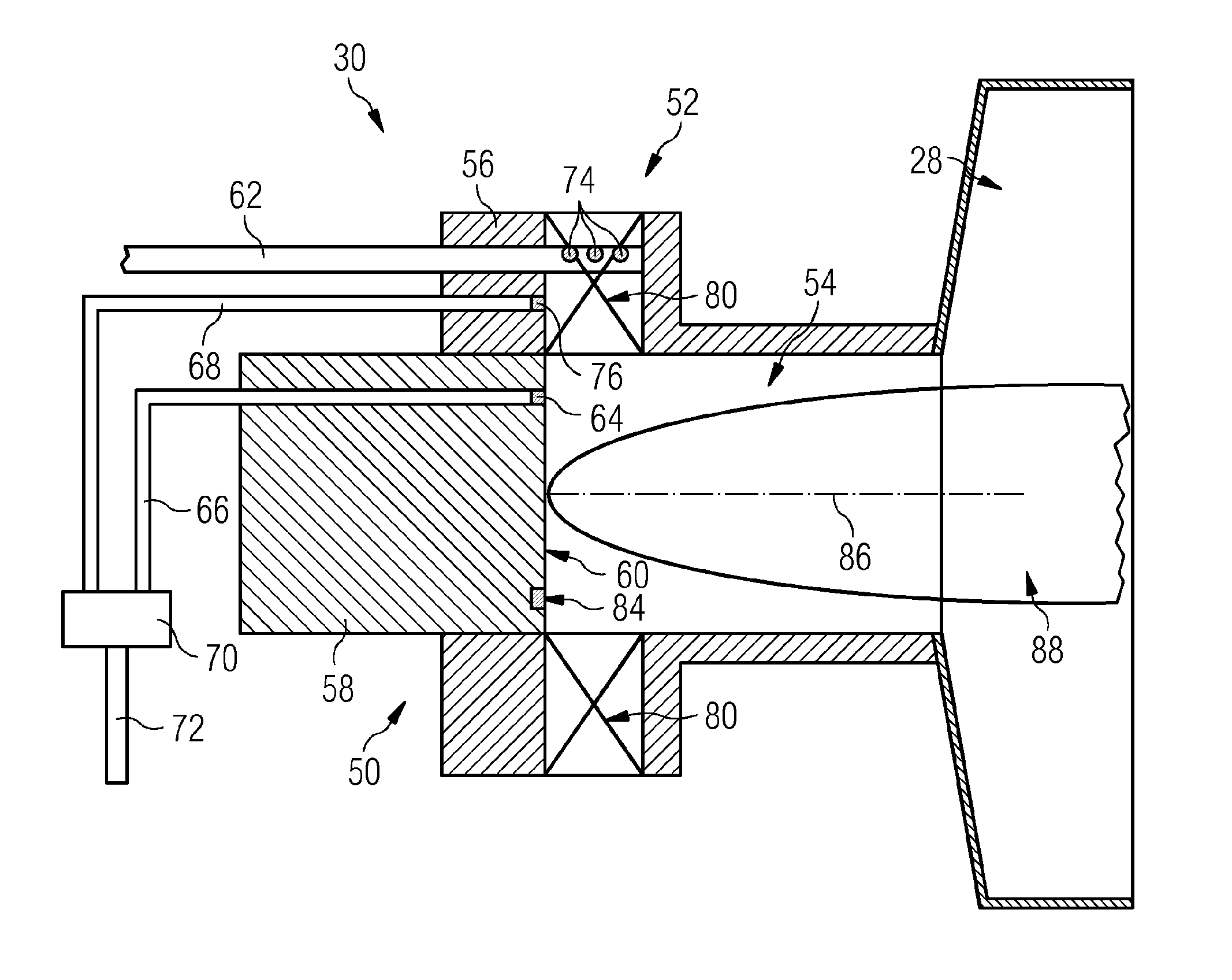

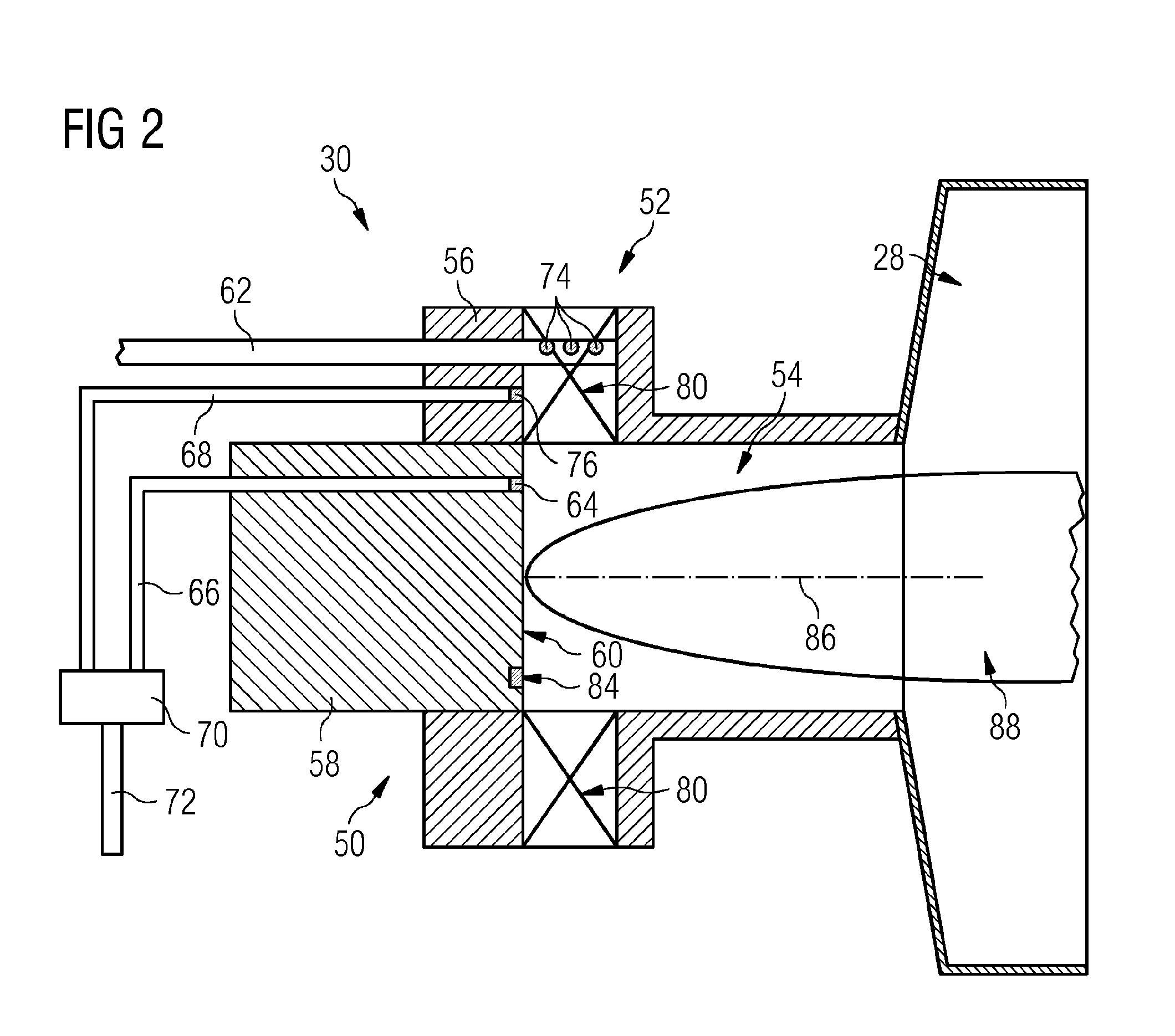

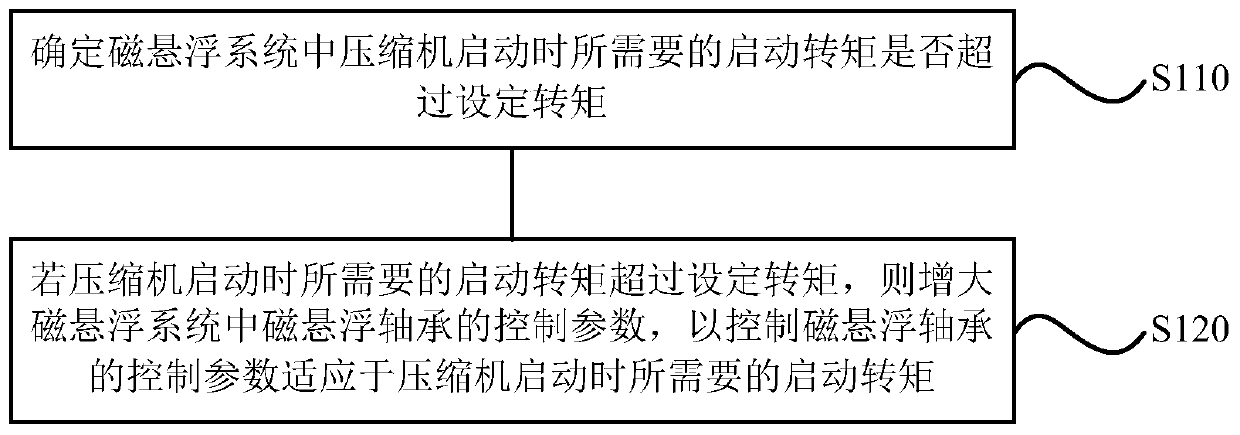

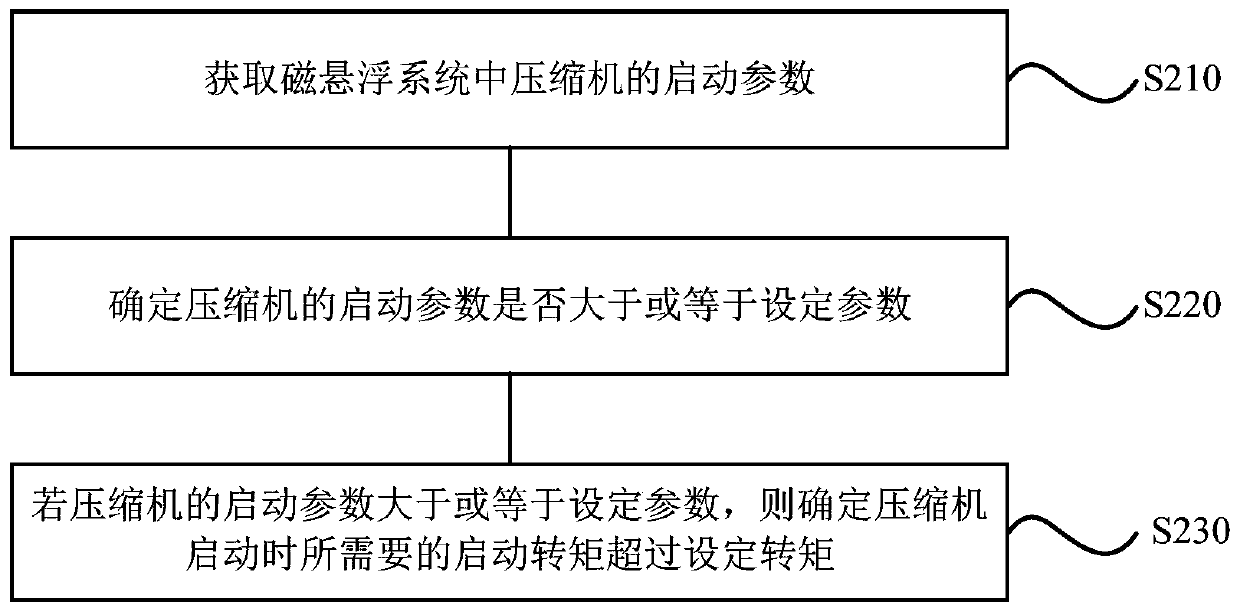

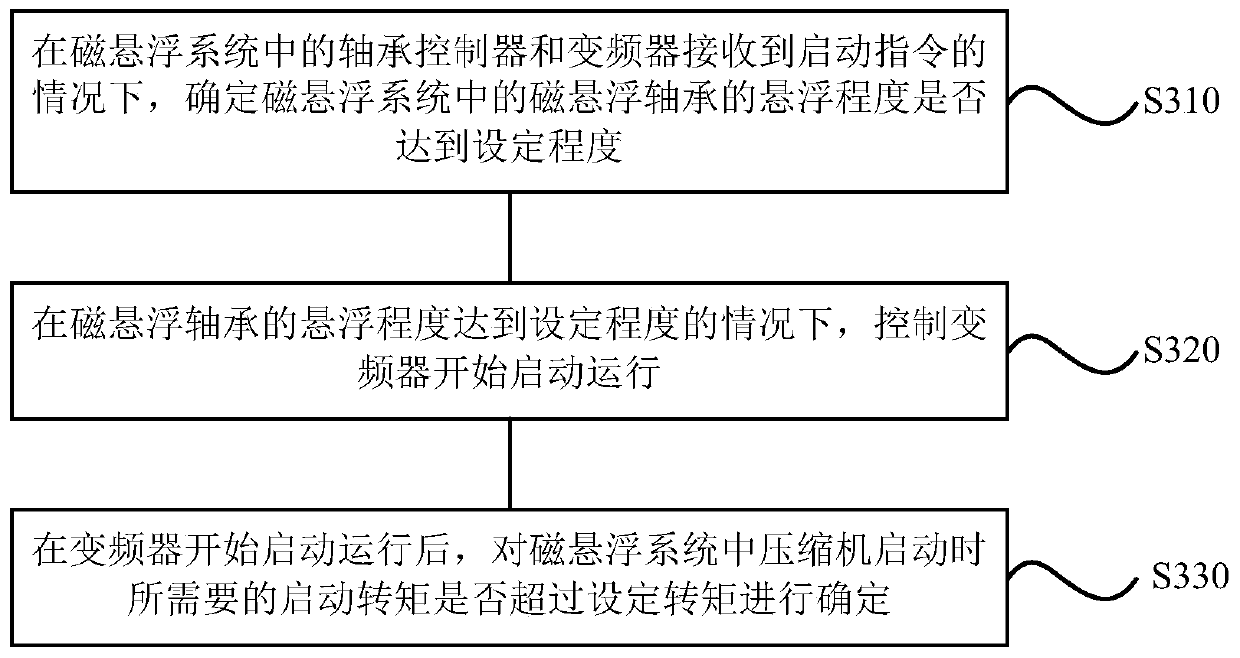

Magnetic levitation bearing control method and device, storage medium, and magnetic levitation system

ActiveCN110939654AGuaranteed control accuracyReliable startRotary/oscillating piston combinations for elastic fluidsShaftsEngineeringMechanical engineering

The invention discloses a magnetic levitation bearing control method and device, a storage medium, and a magnetic levitation system. The method comprises the following steps of determining whether thestarting torque required when a compressor in the magnetic levitation system is started exceeds preset torque or not; and if the starting torque required when the compressor is started exceeds the preset torque, increasing control parameters of the magnetic levitation system to control the control parameters of a magnetic levitation bearing to be adapted to the starting torque required when the compressor is started. According to the scheme disclosed by the invention, the problem that the starting torque is variable to affect the starting reliability can be solved so as to achieve the effectof improving the starting reliability.

Owner:GREE ELECTRIC APPLIANCES INC

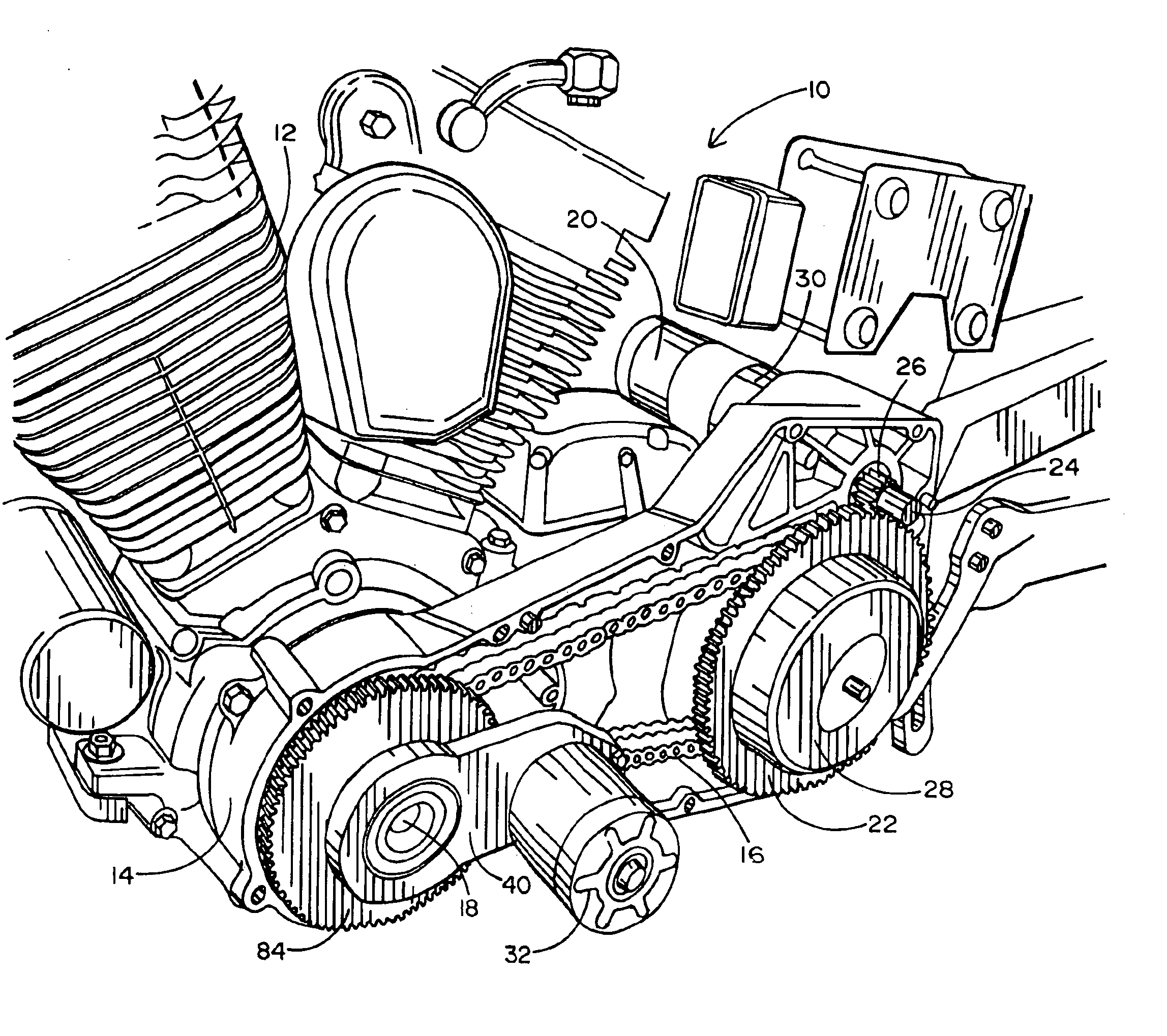

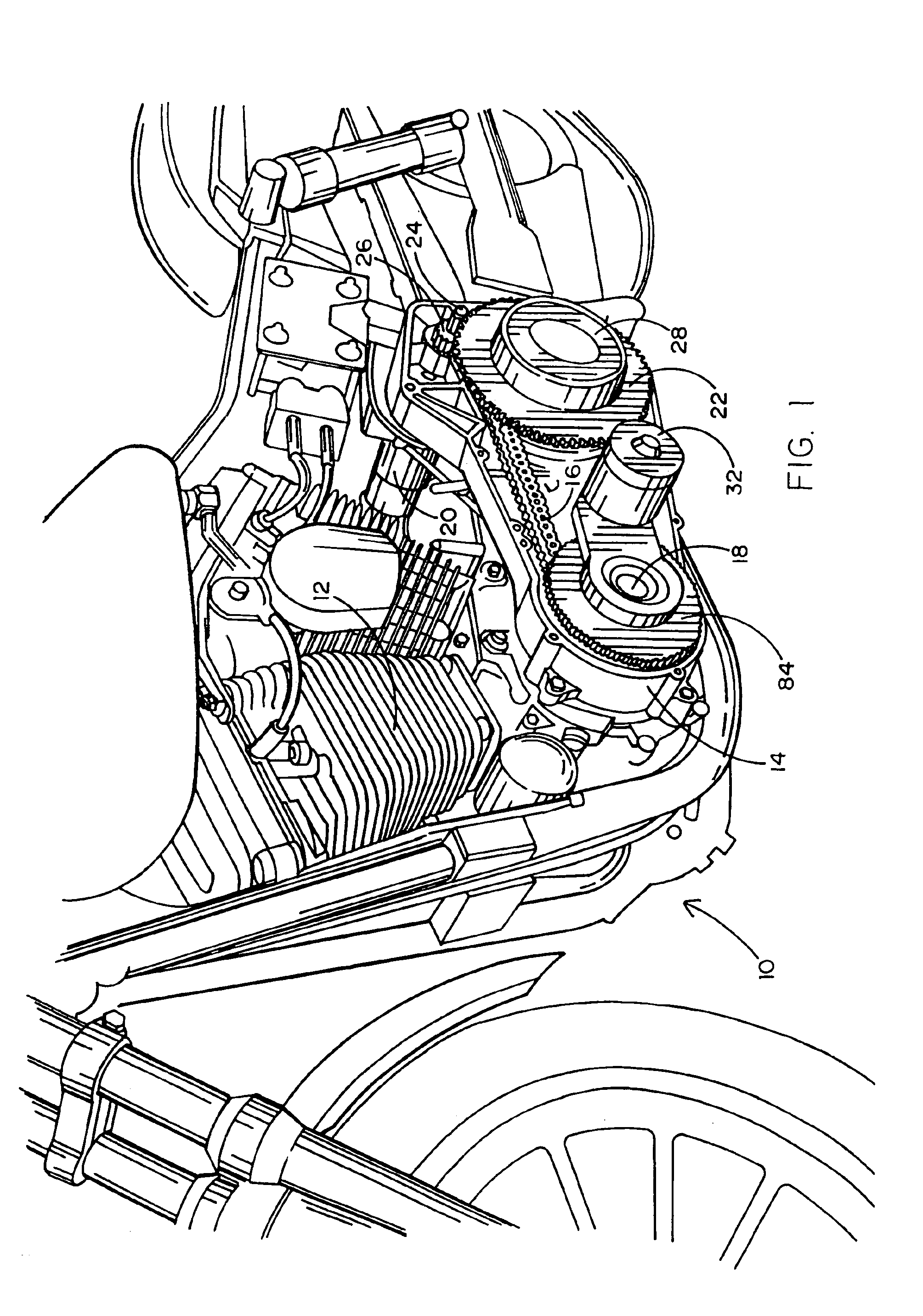

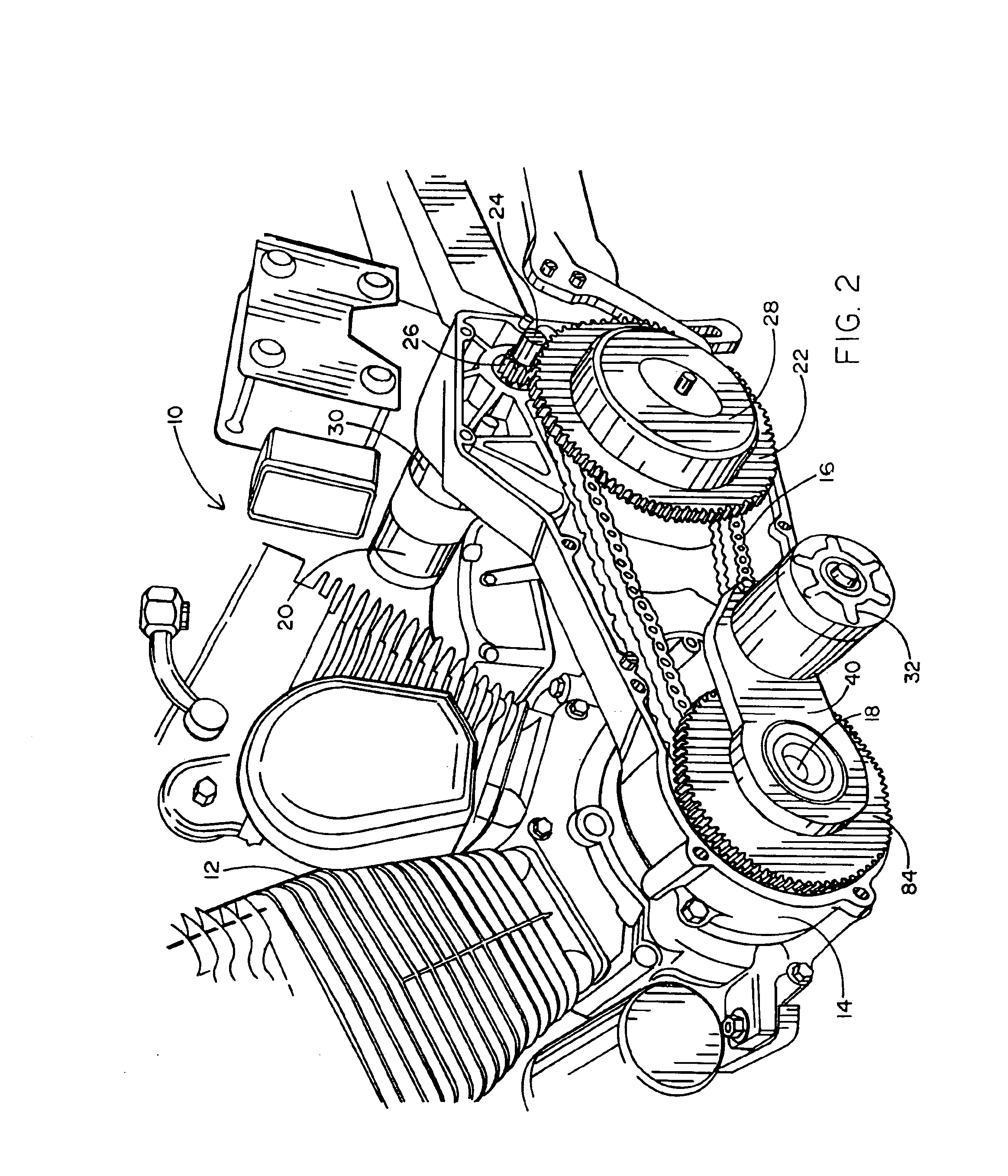

Direct drive cranking system for belt or chain-driven V-Twin motorcycle engines

InactiveUS6895915B2Efficient removalRaise the ratioPower operated startersElectric motor startersPower capabilityCrankshaft

A method and apparatus for achieving reliability in starting V-Twin chain or belt-driven motorcycle engines using a conventional motorcycle battery and specially modified automotive cranking motor. The apparatus in its preferred embodiment utilizes a direct drive cranking motor configuration employing a cammed bearing clutch which is placed onto the engine's crankshaft along with a ring gear. The ring gear engages the geared shaft of the cranking motor directly, thereby bypassing the chain or belt-drive and thus effectively removing the main drive chain or belt from the cranking system. The gear ratio between the cranking motor and the ring gear may thus be selected to be optimum for the cranking motor so that the battery and cranking motor may be operated at near optimum power capabilities simultaneously. The method of the invention relates to converting from a remote cranking motor configuration to a direct drive cranking motor configuration to remedy the deficiencies of existing V-Twin chain or belt-driven motorcycle engines.

Owner:SPYKE

Single-phase permanent magnet motor

ActiveCN106849424AAvoid starting dead pointImprove startup reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet motorPole piece

The invention discloses a single-phase permanent magnet motor. The single-phase permanent magnet motor comprises a stator and a rotor, wherein the stator comprises a stator magnetic core and a winding which is wound around the stator magnetic core; the stator magnetic core comprises an external yoke part and a plurality of stator teeth; each stator tooth comprises a winding part and a pole shoe connected with one end of the winding part; the winding winds the corresponding winding part; each pole shoe comprises a pole face; a first positioning groove which extends in the direction of a stator axis is formed in the middle position of the pole face; at least one second positioning groove is also formed in each pole face; the second positioning groove is formed in the same side of the first positioning groove; and by virtue of the first and second positioning grooves, the initial position of the motor rotor which is rotationally accommodated in the stator deviates from a dead point position. By virtue of the stator, the rotor starting is high in reliability.

Owner:JOHNSON ELECTRIC SHENZHEN

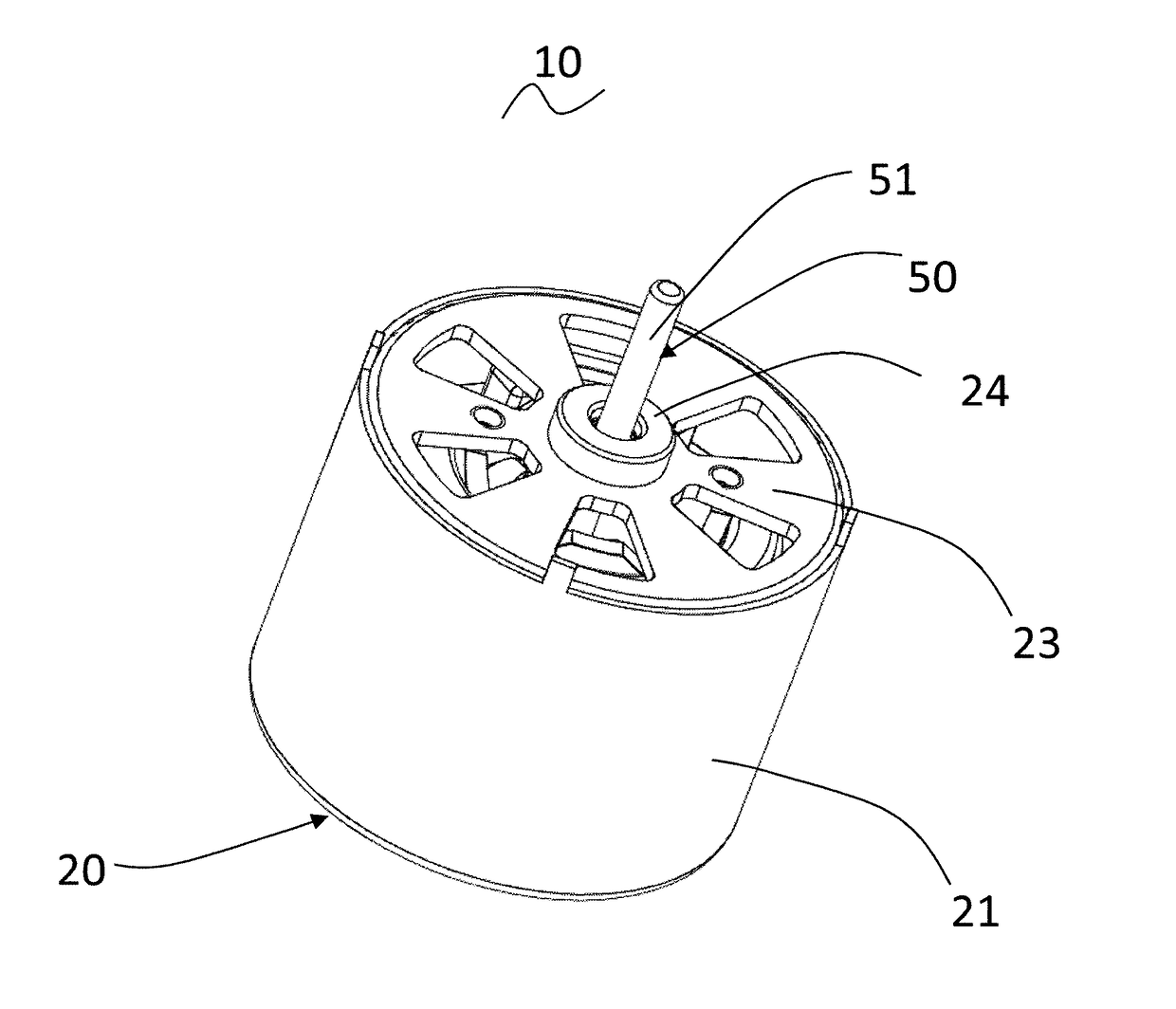

Single Phase Permanent Magnet Motor And Method For Making Same

InactiveUS20170063208A1Easy windingImprove startup reliabilityMagnetic circuit rotating partsSynchronous motorsEngineeringPole piece

A single phase permanent magnet motor and a method for making the same are provided. The method includes the steps of: configuring a stator core, wherein the stator core comprises a first ring portion, tooth bodies, and a pole shoe extending from each tooth body, a slot opening is defined between each two adjacent pole shoes, at least one pole shoe includes a main portion, a connecting portion and an easily bendable tip, the easily bendable tip is bent relative to the main portion about the connecting portion; winding a stator winding around the stator core; and bending the easily bendable tip about the connecting portion to narrow the slot opening. The present invention can change the size of the slot opening, thus more rapidly finishing the winding of the stator winding and enhancing the efficiency of the motor fabrication.

Owner:JOHNSON ELECTRIC SA

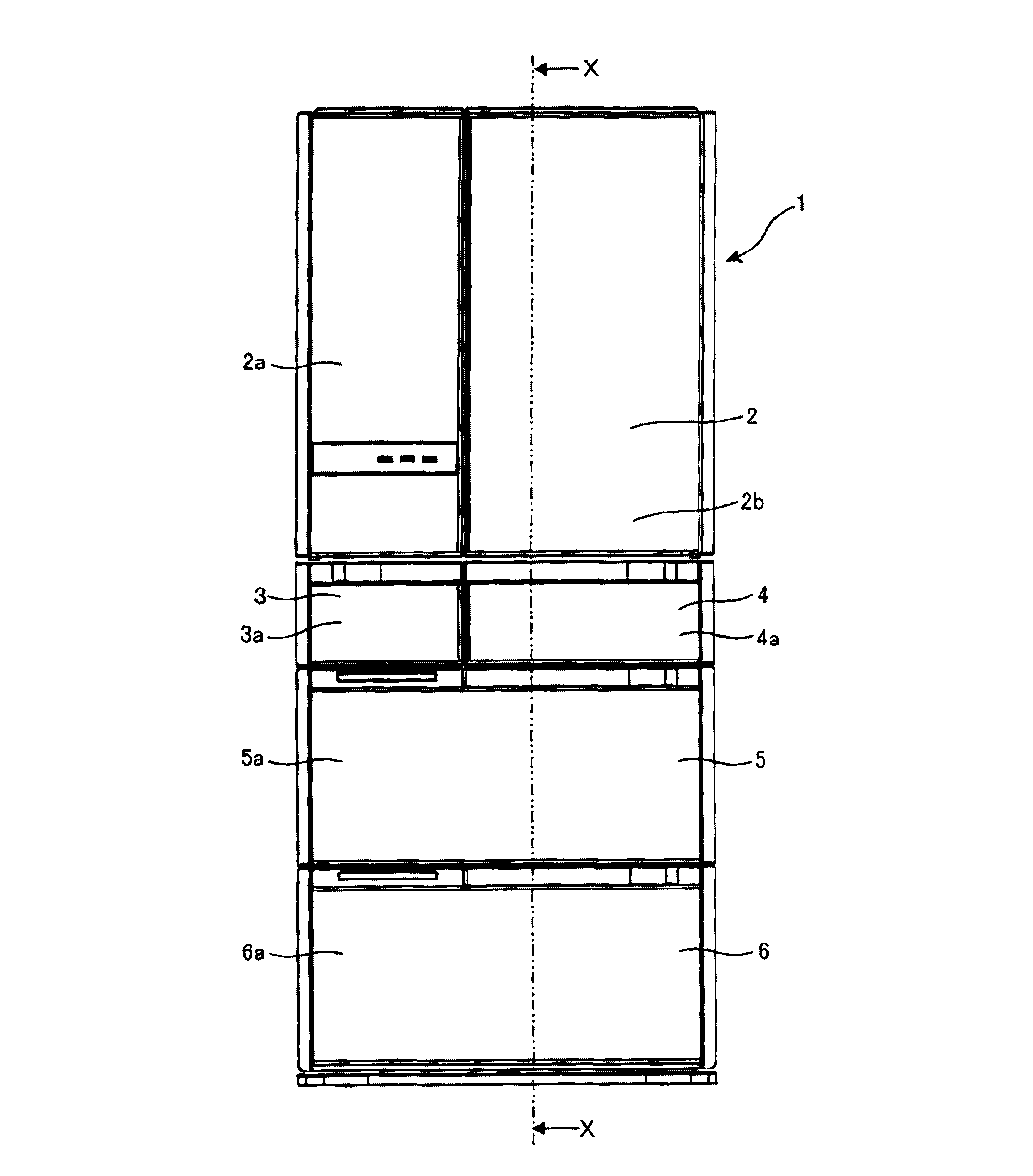

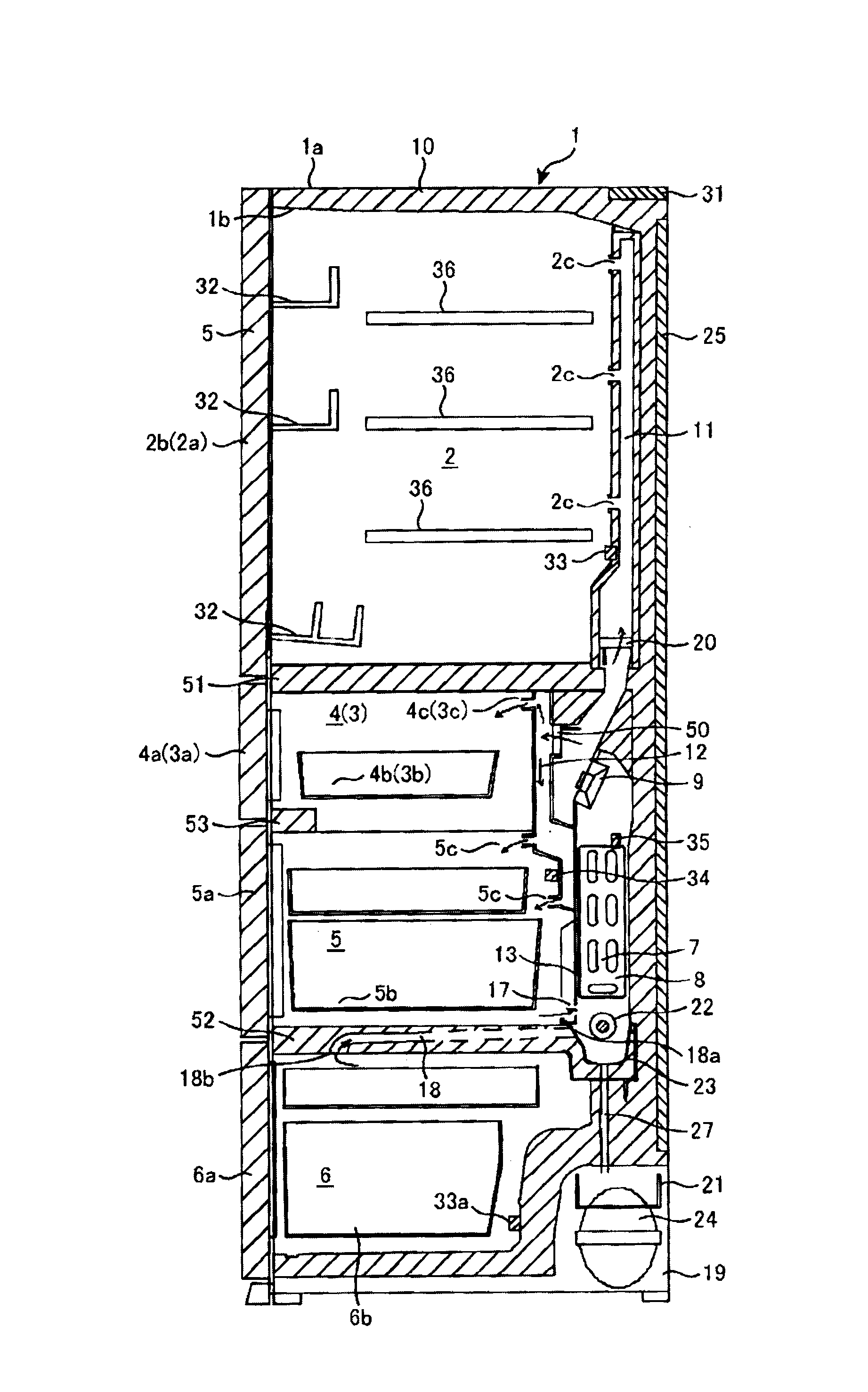

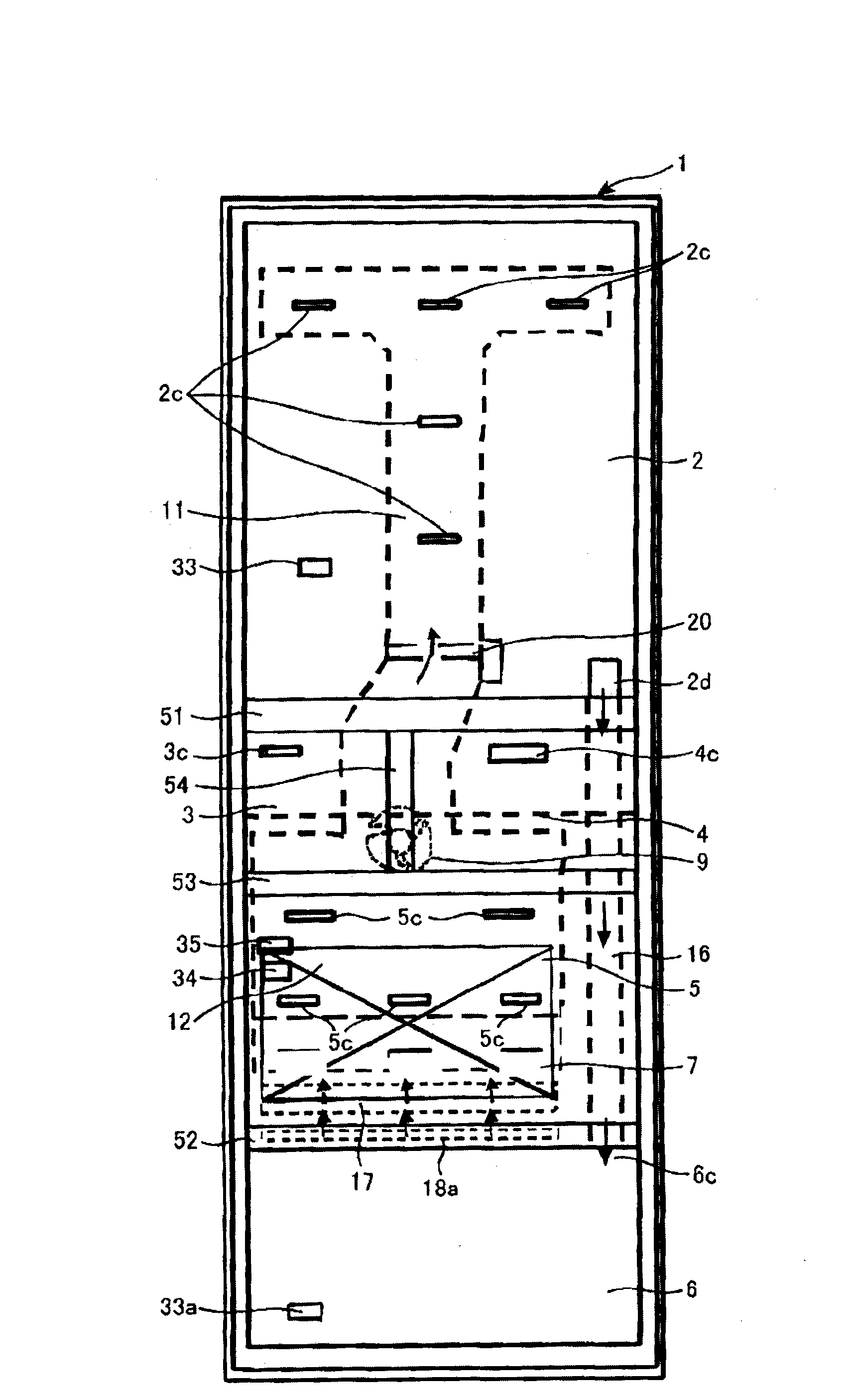

Refrigerator

InactiveCN102410690AImprove startup reliabilityGood energy saving effectMechanical apparatusDomestic refrigeratorsHigh energyEngineering

The invention aims at providing a refrigerator capable of improving reliability of startup of a compressor and high energy saving. The refrigerator is provided with: a compressor connecting and pressing a refrigerant via a pipe which the refrigerant passes by, a condenser making the refrigerant output from the compressor in heat dissipation, a decompression device decompressing the refrigerant output from the condenser, freezing circulation of an evaporator evaporating the refrigerant output from the decompression device and cooling air, and a refrigerant flow adjustment device disposed between the condenser and the evaporator, and controlling the refrigerant flow in a pipe. The refrigerator is provided with a pressure prediction device, the pressure prediction device predicts pressure at an intake side and an exhaust side of the compressor based on evaporator temperature, condenser temperature, and external air temperature when the compressor stops, rotation number before the compressor stops, and any time or combination of time passed after the compressor stops, via the pressure prediction device, whether startup of the compressor is allowed is determined by the pressure prediction device, and the compressor is started under the condition of pressure.

Owner:HITACHI APPLIANCES INC

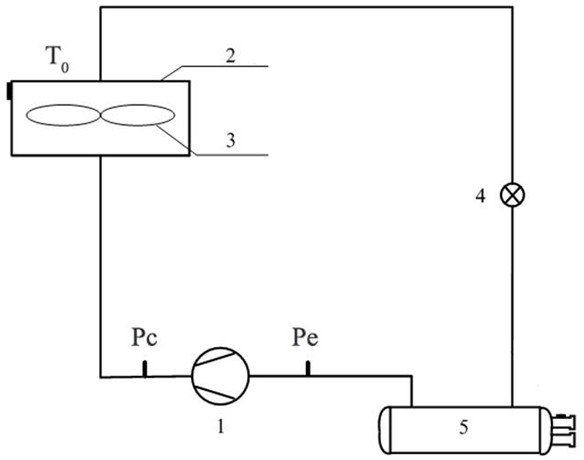

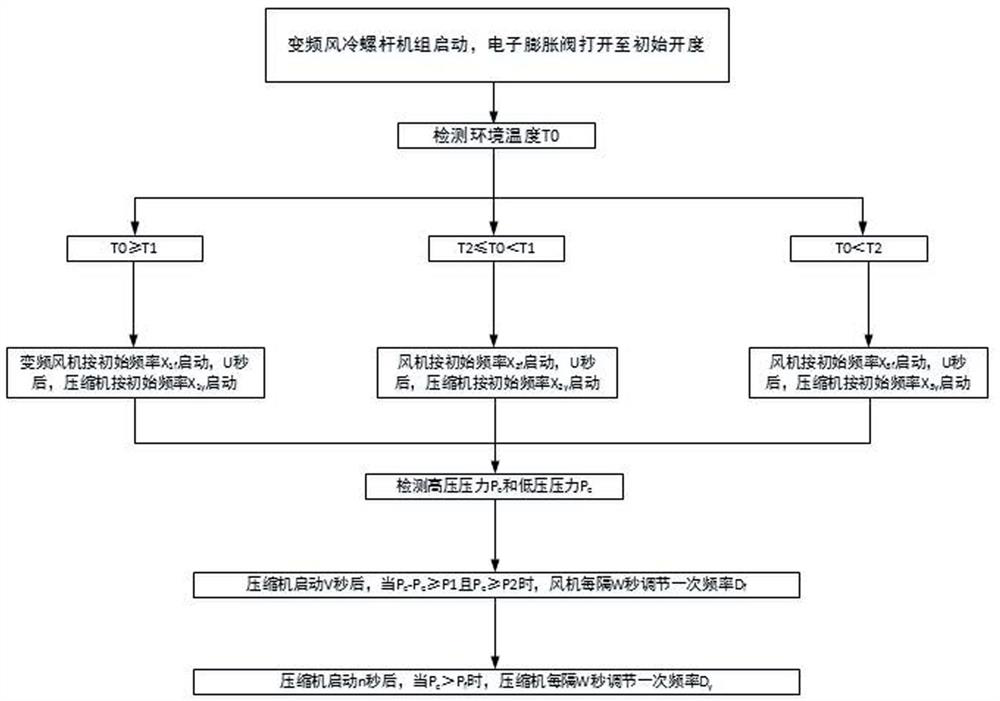

Variable-frequency air-cooled water chilling unit and variable-working-condition starting control method thereof

ActiveCN112393482AImprove startup reliabilityRefrigeration safety arrangementEfficient regulation technologiesEngineeringPressure sensor

The invention discloses a variable-frequency air-cooled screw water chilling unit and a variable-working-condition starting control method thereof. The variable working condition starting control method comprises the following steps that the initial frequency of a variable frequency fan and the initial frequency of a variable frequency compressor are controlled according to the interval where theenvironment temperature detected during starting is located; after the compressor is started for v seconds, the frequency of the variable frequency fan is adjusted according to the comparison result of the difference value of the high-pressure pressure and the low-pressure pressure and the first preset pressure and the comparison result of the low-pressure pressure and the second preset pressure;and after the compressor is started for n seconds, the frequency of the variable frequency compressor is adjusted according to the comparison result of the high-pressure pressure and the variable frequency fan closing pressure. The unit is provided with a high-low pressure sensor and an environment temperature sensor to adjust the frequency of the compressor or the frequency of the fan, and the purpose of optimizing the starting reliability of the compressor under different working conditions is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Modified startup strategy to improve startup reliability after extended off time

InactiveUS20090305088A1Improving fuel cell system start-up reliabilityImprove reliabilityFuel cell auxillariesFuel cellsRemedial action

A system and method for improving fuel cell system start-up reliability. The method includes determining if the resistance of the membranes in a fuel cell stack is too high, where the reliability of system start-up will be reduced, and if so, providing one or more remedial actions to help ensure that the start-up is more reliable. In one embodiment, the system and method determine that the fuel cell membranes are too dry based on the time that has gone by since the last shut-down. If the time threshold has been exceeded, a special start-up procedure is used that increases the reliability that the start-up will be successful using the remedial actions, such as reducing cathode airflow and turning on stack end cell heaters.

Owner:GM GLOBAL TECH OPERATIONS LLC

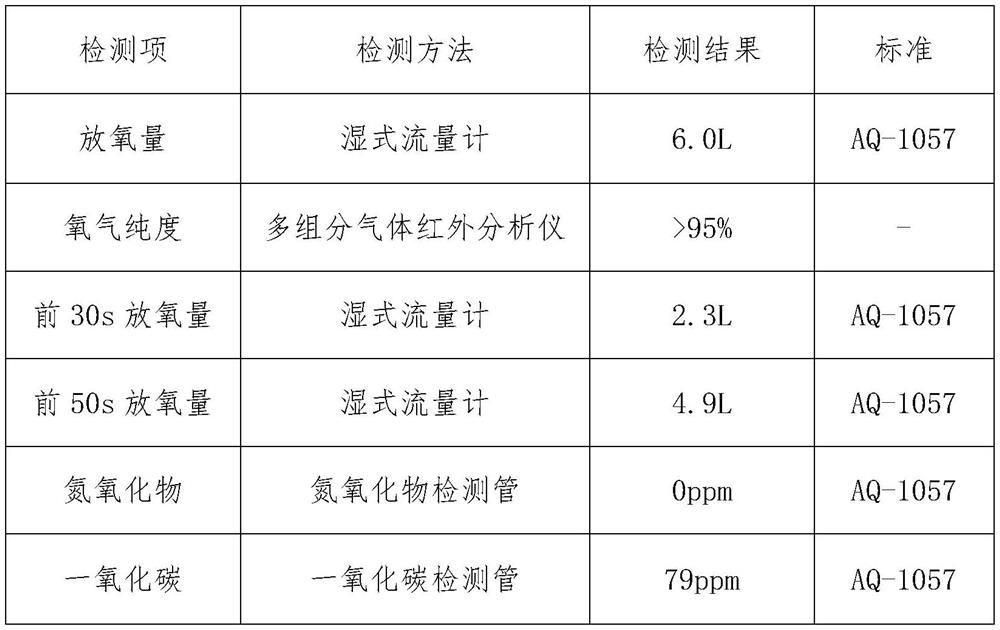

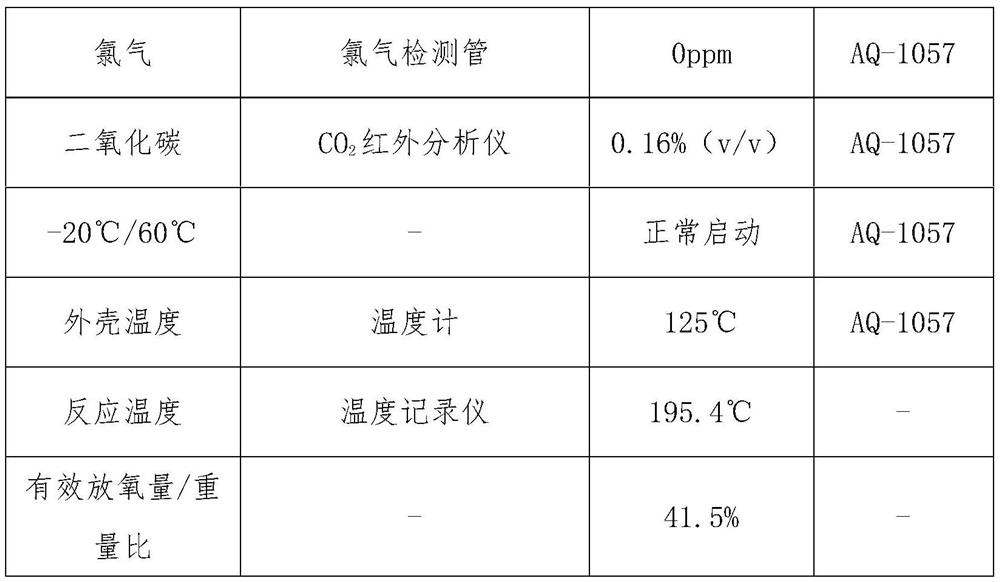

an oxygen candle

ActiveCN108083234BLower decomposition temperatureReduce demandOxygen preparationChlorate ionPtru catalyst

An oxygen-generating candle, comprising an absorption flammable layer, a heat generating layer and a main candle body layer; the heat generating layer is provided between the absorption flammable layer and the main body layer; according to mass percentage, the main body layer is made of 90% to 96% chlorate, 1.5% to 5% catalyst, 0 to 3% fuel, 1.5% to 2.5% binder and 0.5% to 1.5% stabilizer; the heat generating layer is made of 70% to 80% chlorate, 5% to 15% catalyst, 5% to 12% fuel and 3.0% to 6.0% binder; the absorption flammable layer is made of 5% to 15% fuel, 80% to 90% strontium chromate, 3% to 5% binder and 0 to 1% chlorate; the catalyst is a combination of two or more from among cobalt oxide, manganese dioxide and titanium oxide; the amount of catalyst in the main candle body layer is 4-5 times greater than the amount of the catalyst of the heating layer; the fuel comprises one or more from among magnesium powder, titanium powder, cobalt powder, and zirconium powder. Due to the adjustment of the type and proportion of the catalyst, the decomposition temperature of the oxidizing agent chlorate is lowered and the demand for an active metal of the flammable layer is lowered; in addition, the addition of a flame retardant may control the rate of energy release of the active metal.

Owner:SHAANXI STAR EXPLOSION SAFETY POLYTRON TECH INC

Single-phase permanent magnet motor

InactiveCN106487111AStart and turn smoothlyImprove startup reliabilityMagnetic circuit rotating partsMagnetic circuit stationary partsMiddle linePhysics

The invention discloses a single-phase permanent magnet motor. The single-phase permanent magnet motor comprises a stator and a rotor which can rotate relative to the stator, wherein the stator comprises a stator magnetic core and a winding which is wound around the stator magnetic core; the stator magnetic core comprises an outer ring part, multiple tooth bodies which extend from the outer ring part to the inner side, and pole shoes which extend from the tail end of each tooth body to two sides circumferentially, wherein the rotor is accommodated in a space formed by the pole shoes in a surrounding manner; the rotor comprise multiple permanent magnetic poles arranged in the circumferential direction of the rotor; and the distances from the outer side surface of each permanent magnet pole to the rotor axis are gradually decreased from the circumferential center to the circumferential two sides, so that non-uniform air gaps, which are symmetrical around the middle line of the permanent magnetic poles, are formed between the outer side surfaces of the permanent magnetic poles and the inner circumferential surfaces of the pole shoes. By adoption of the single-phase permanent magnet motor, the starting reliability is improved, and starting dead points are reduced.

Owner:JOHNSON ELECTRIC SHENZHEN

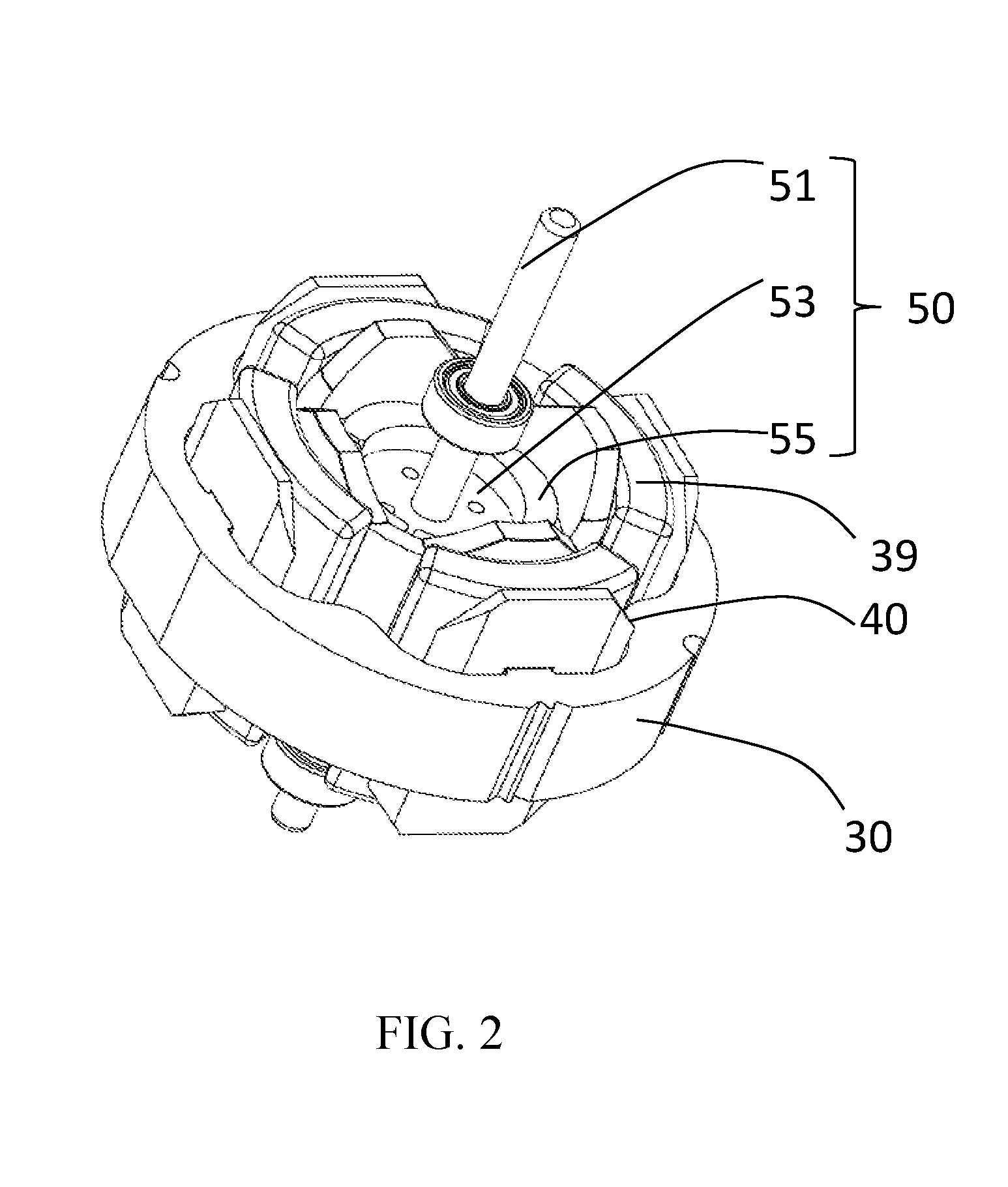

Single-phase brushless motor

ActiveCN106487191AEasy to adjustImprove startup reliabilityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsBrushless motorsMagnetic poles

The invention provides a single-phase brushless motor, which comprises a stator and a rotor, wherein the stator comprises a stator core and windings wound on the stator core; the stator core comprises outer yokes, tooth bodies extending inwards from the corresponding outer yokes, and pole shoes extending towards two circumferential sides from radial inner ends of the corresponding tooth bodies; an accommodating space is enclosed by the pole shoes; the rotor is accommodated into the space and comprises a plurality of magnetic poles; the distance from the peripheral surface of each magnetic pole to the axis of the rotor is gradually reduced from the circumferential center to the two circumferential sides; each pole shoe comprises a first arc-shaped part and a second arc-shaped part; the center of each first arc-shaped part deviates from the center of the corresponding tooth body; and when the windings are not electrified, the acting force between one first arc-shaped part and the corresponding magnetic pole is greater than that between the corresponding second arc-shaped part and magnetic pole, so that the center of the corresponding magnetic pole deviates from the center of the corresponding tooth body. According to the single-phase brushless motor, the startup reliability of the motor is improved and possible startup dead points are reduced.

Owner:JOHNSON ELECTRIC SHENZHEN

Single phase permanent magnet motor and hair dryer using the same

InactiveUS20170055669A1Simplify the manufacturing processReduce manufacturing costMagnetic circuit rotating partsSynchronous motorsImpellerPermanent magnet motor

A single phase motor and a hair dryer are provided. The motor includes a stator and a rotor. The stator includes a stator core and a stator winding. The stator core includes an outer ring portion, teeth extending inwardly from the outer ring portion, and two pole shoes extending from a distal end of each tooth. A winding slot is formed between each two adjacent teeth. A slot opening is disposed between the pole shoes of the adjacent teeth, and is offset from one of the two adjacent teeth. The air supplying unit includes the single phase motor and an impeller. The startup angle and cogging torque of the motor are adjustable by adjusting the position / width of the slot opening, without the need of additional positioning slots or positioning holes defined at the pole shoes, which makes the motor structure simple.

Owner:JOHNSON ELECTRIC SA

Single Phase Permanent Magnet Motor

ActiveUS20170077769A1Improve startup reliabilityReduce disadvantagesMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet motorSingle type

A single phase permanent magnet motor includes a stator and a rotor relative to the stator. The stator includes a stator core with a winding wound therearound. The stator core includes stacked first and second stator core laminations. The first stator core lamination includes a plurality of first pole shoes. The second stator core lamination includes a plurality of second pole shoes. The structures of the first pole shoes and the second pole shoes are different. The first pole shoes and the second pole shoes are stacked substantially along the axial direction of the motor. The present invention reduces vibration and noise caused by the use of a single type of core laminations in the prior art.

Owner:JOHNSON ELECTRIC SA

Single Phase Permanent Magnet Motor

InactiveUS20170077791A1Reduce vibrationReduce noiseWindings insulation shape/form/constructionMagnetic circuit rotating partsMagnetic polesPermanent magnet motor

A single phase permanent magnet motor includes a stator and a rotor rotatable relative to the stator. The stator includes a stator core and a winding wound around the stator core. The rotor includes a rotor core and a plurality of permanent magnetic poles. The stator core includes at least one first stator core lamination and at least one second stator core lamination stacked with the first stator core lamination. Inner structures of the first stator core lamination and the second stator core lamination are different. This structure reduces motor's vibration and noise, avoids possible startup dead point and improves the motor startup reliability.

Owner:JOHNSON ELECTRIC SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com