Method for performing online Raman spectral analysis on drilling fluid

A technology of Raman spectroscopy and analysis method, which is applied in the field of online determination of the types and concentrations of various components in drilling fluids. It can solve the problems of inability to measure non-fluorescent components and affect the judgment of oil and gas layers, and achieve short analysis period and high accuracy. The effect of reliability, high measurement sensitivity and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

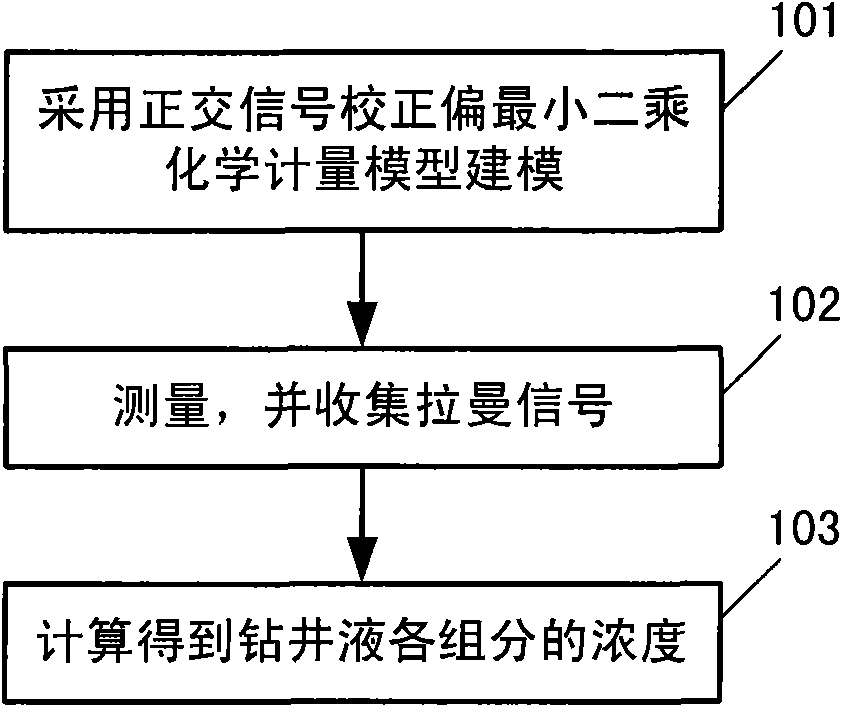

[0043] refer to figure 1 , the specific implementation steps of this application are as follows:

[0044] Step 101, modeling: adopting orthogonal signal correction partial least squares stoichiometric model modeling, and obtaining parameters including coefficient B, weight W and load P in the pre-stored model;

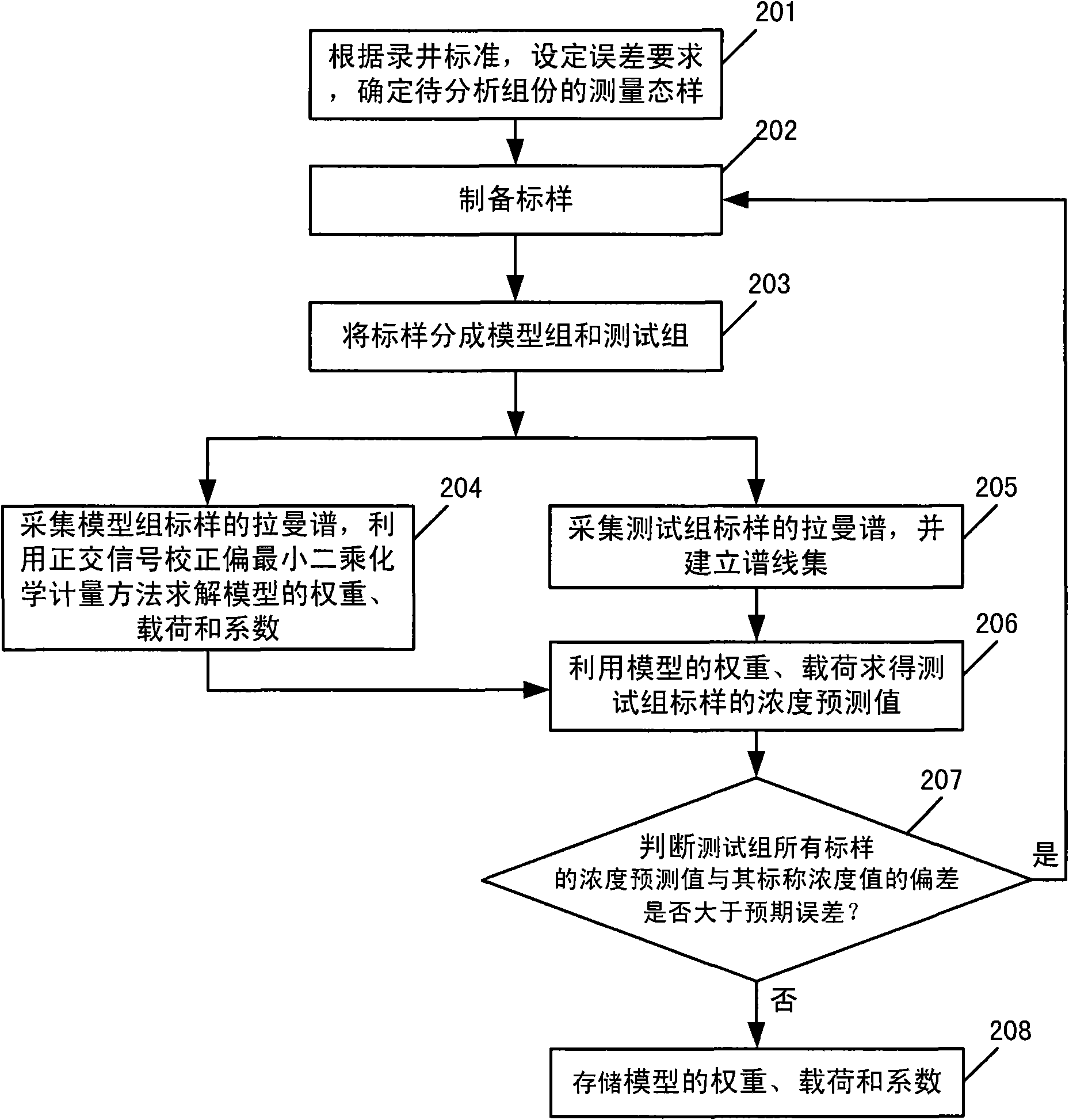

[0045] attached figure 2 The flow chart of the modeling is given, as follows:

[0046] Step 201, according to mud logging standards, set error requirements, and determine the measurement pattern of the components to be analyzed;

[0047] Step 202, prepare a standard sample, and make the components to be analyzed into a pure and mixed standard sample according to the site requirements. The components of the standard sample can be light hydrocarbons, volatile heavy hydrocarbons, oil and other non-hydrocarbon groups according to the site requirements. Minute;

[0048] Step 203, grouping, that is, dividing the standard sample into a model group and a test group;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com