Method for testing simulated sound reduction index of large wallboard component based on low-temperature test box device

A low-temperature test, large-scale wall panel technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve problems such as inability to provide, and achieve the effects of convenient operation, simple and practical device structure, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be described in further detail below in conjunction with the accompanying drawings.

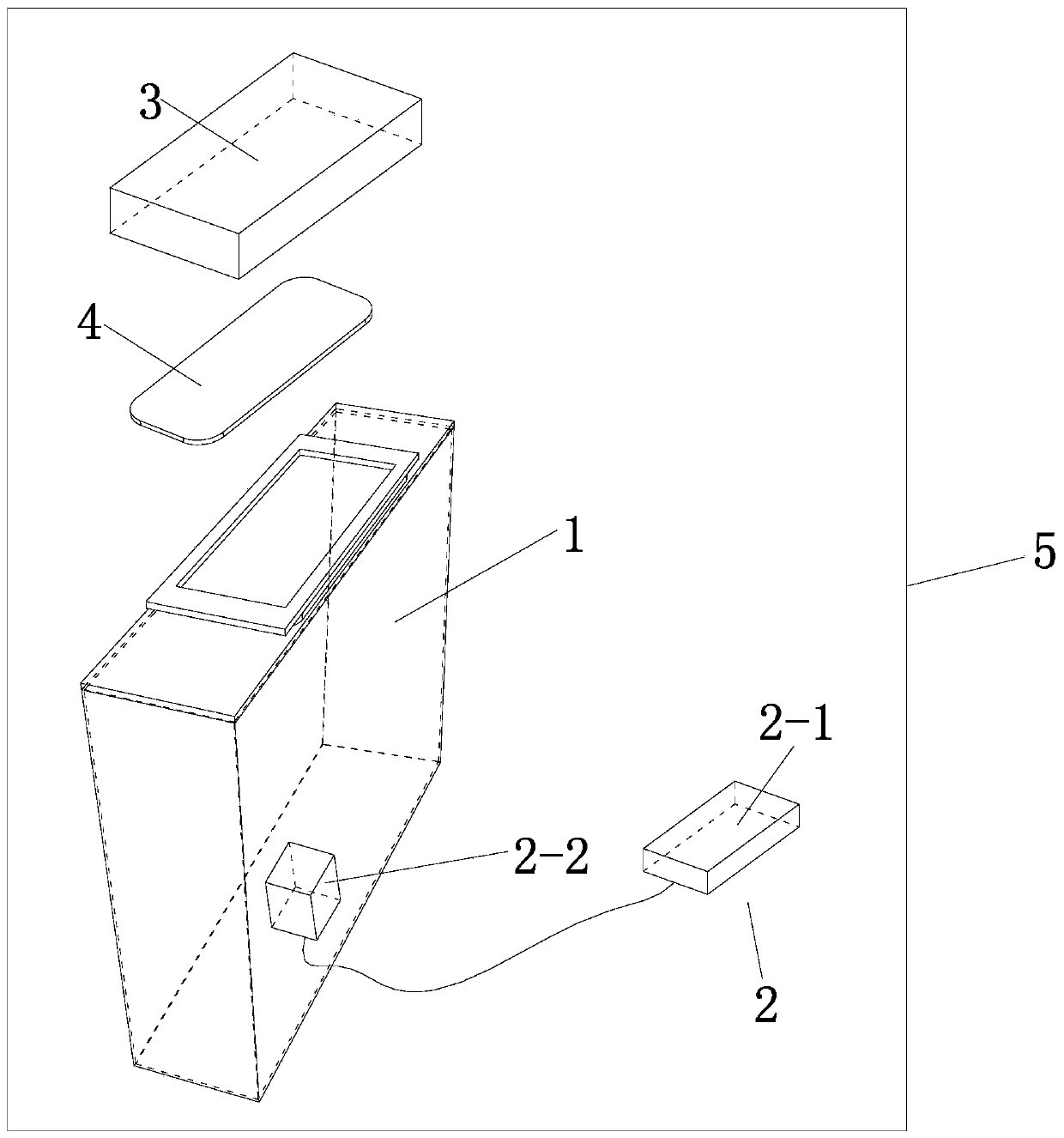

[0034] like Figure 1 to Figure 4 As shown, the large-scale wall panel component simulation sound insulation test method based on the low temperature test chamber device of the present invention comprises the steps:

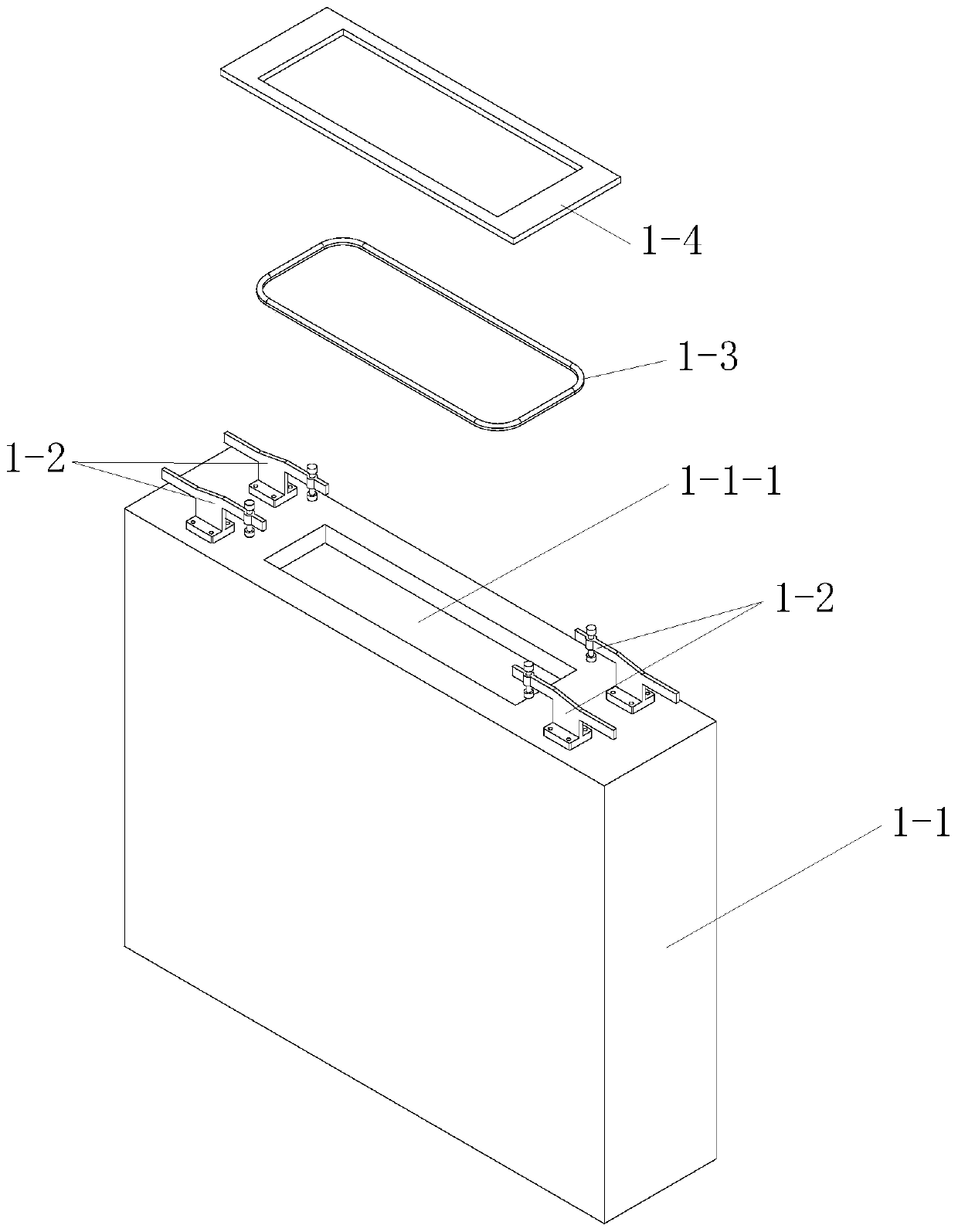

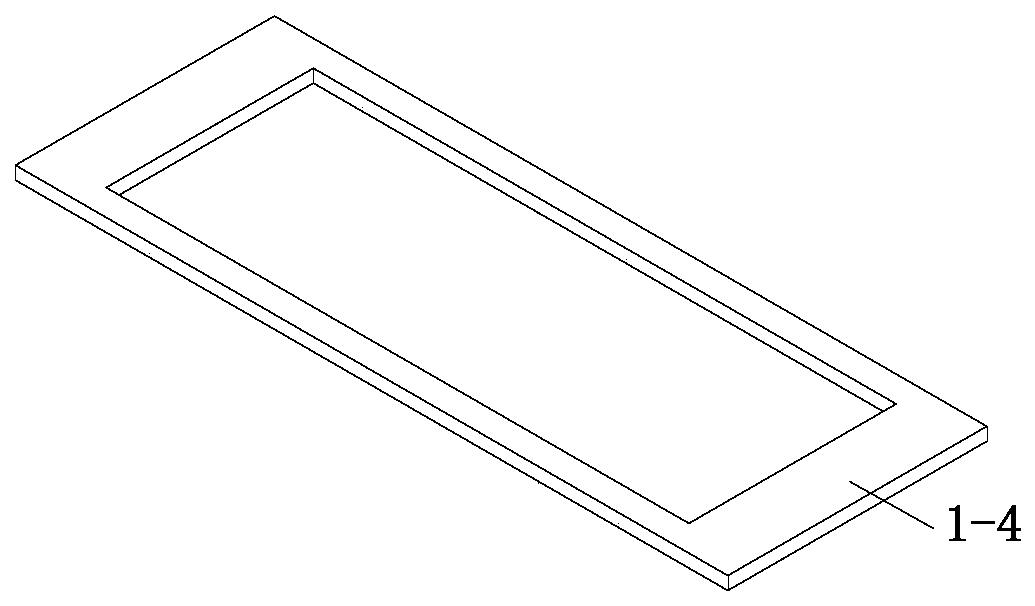

[0035] Step 1: Make the basic model device of the low-temperature test chamber with uncertain port size; the basic model device of the low-temperature test chamber with uncertain port size includes the basic model of the low-temperature test chamber 1, the test sound generator 2 and the sound level meter 3. The basic model 1 of the low-temperature test box includes a low-temperature box body 1-1, four fast vertical clamps 1-2, a thermal insulation and sound insulation sealing ring 1-3 and a window pressure plate 1-4, and the center of the upper end surface of the low-temperature box body 1-1 There is a vertical rectangular simulation test window...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com