Method for carrying out low-frequency noise environmental governance by utilizing super sound absorber

A super-sound absorber and low-frequency noise technology, which is applied in the field of low-frequency noise environmental control using super-sound absorbers to achieve the effects of small space, low cost, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0029] A method for controlling low-frequency noise environment using a super-sound absorber, comprising the following steps:

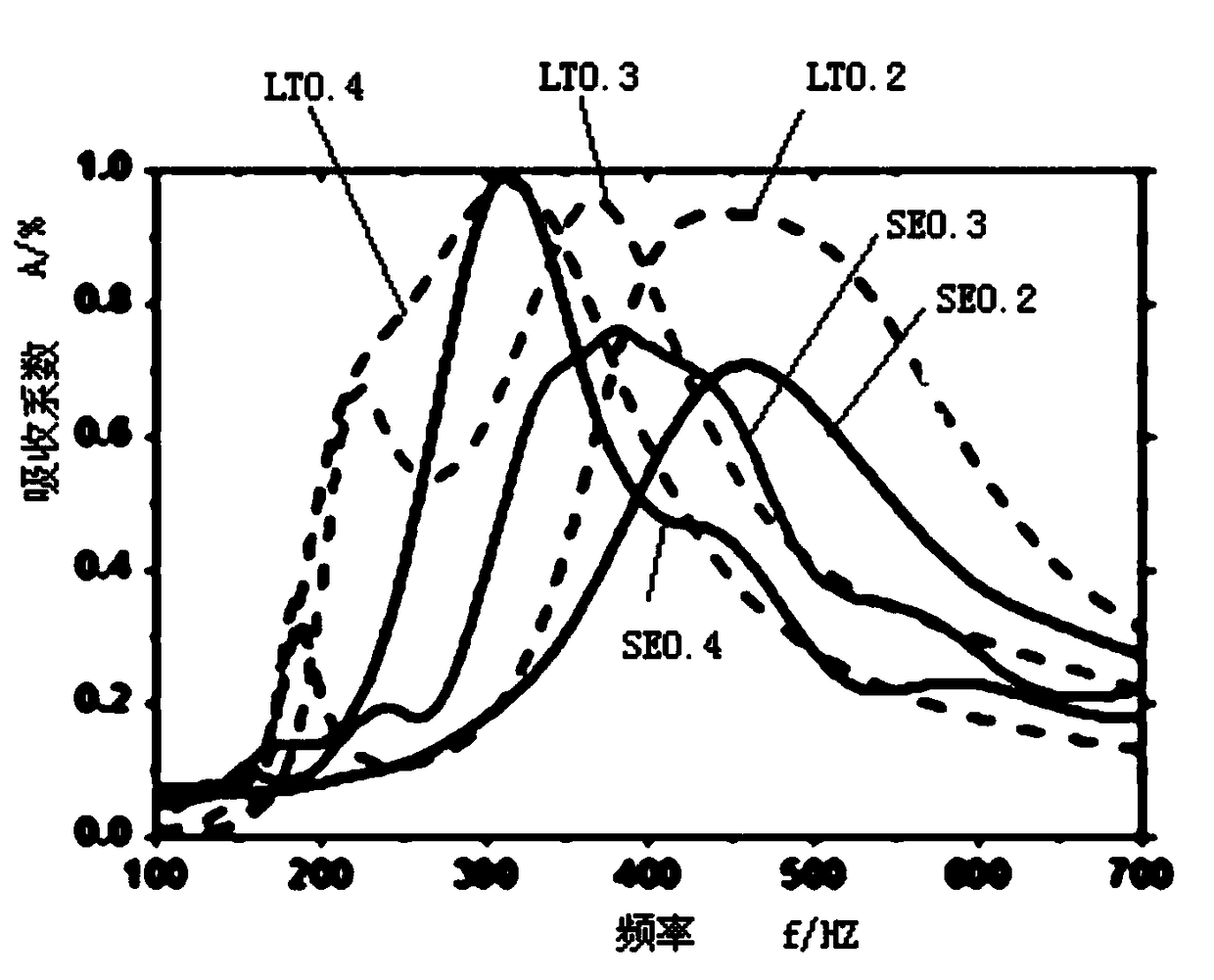

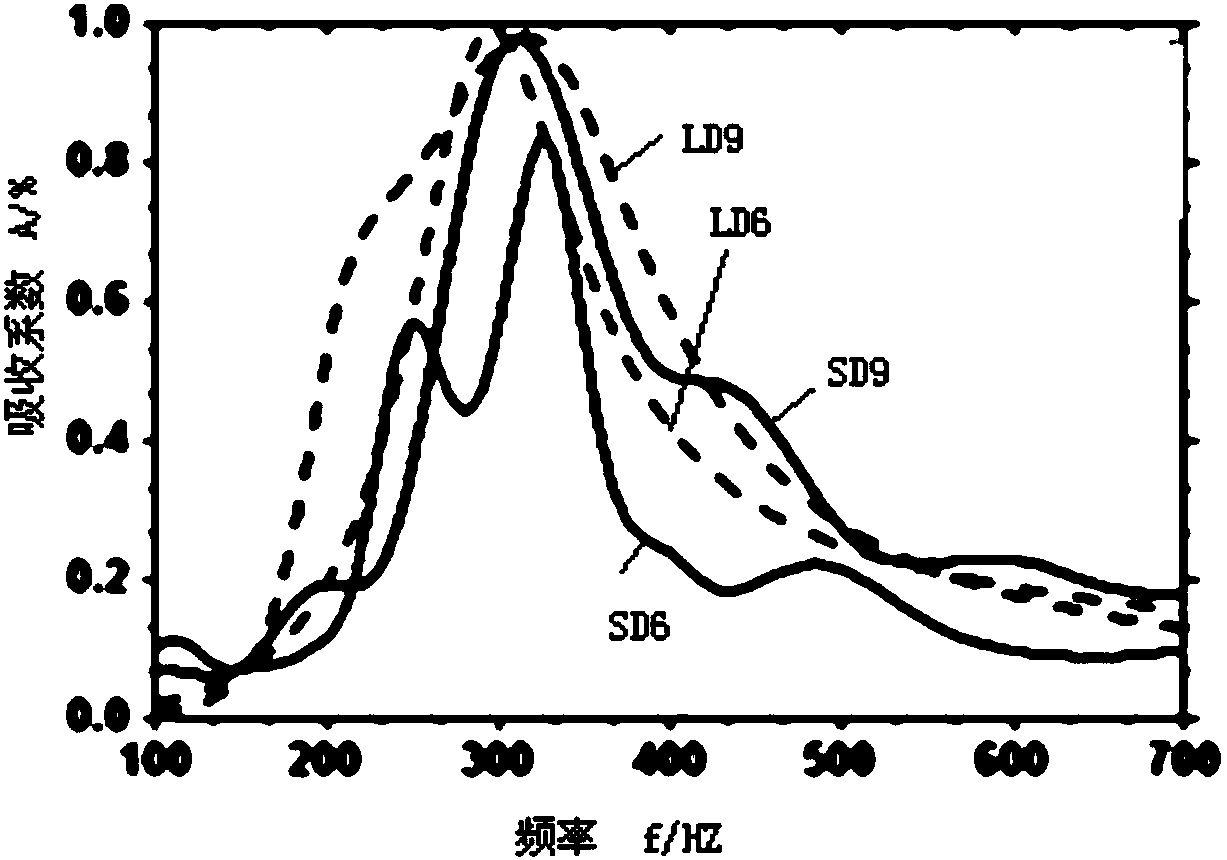

[0030] Step 1. Measure the noise frequency f of the low-frequency noise source with a noise measuring instrument. For example, the transformer room and air conditioner are the main sources of low-frequency noise. The noise frequency of the former is about 199Hz, and the noise frequency of the latter is about 314Hz.

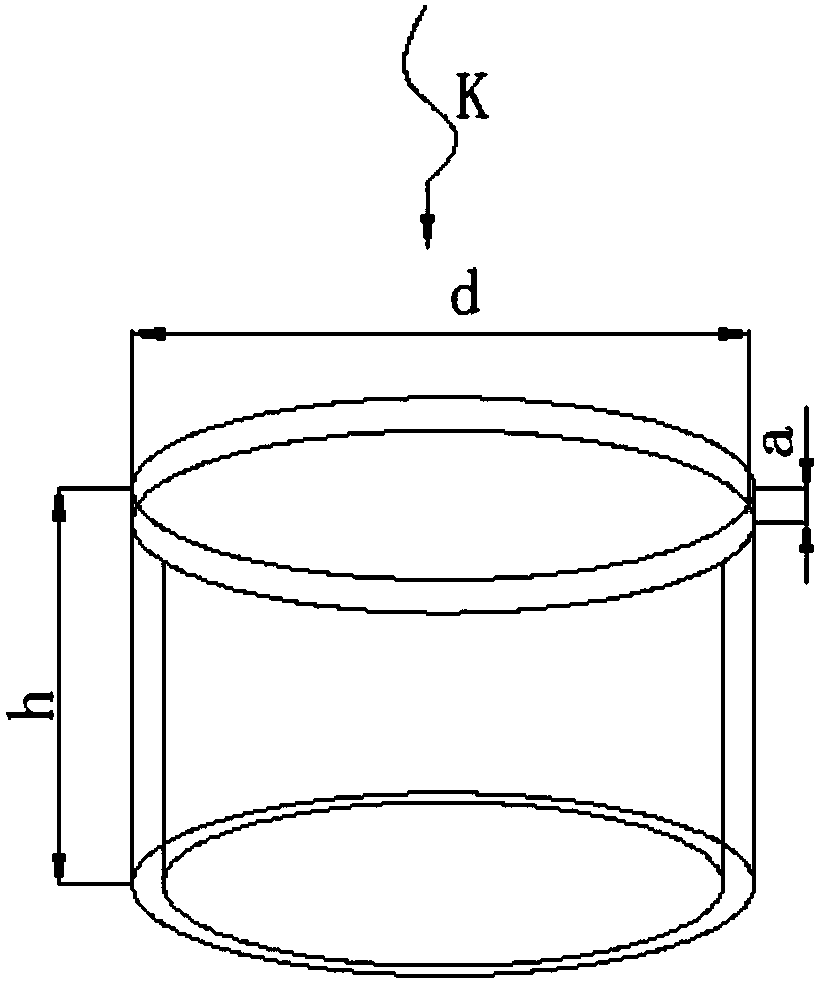

[0031] Step 2: Determine the height h of the super sound absorber according to the spatial distance between the cover of the low-frequency noise source and the low-frequency noise source, and 2cm≤h≤10cm. The low-frequency noise source is usually covered by an enclosure (usually a closed space, such as a soundproof room). In order to reduce noise pollution, a super sound absorber is arranged on the inner wall of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com