Research method for conducting low-frequency noise processing by using COMSOL and resonant cavity models

A low-frequency noise, resonant cavity technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves to achieve the effect of small space and low material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0026] A kind of research method that utilizes COMSOL and resonant cavity model to carry out low-frequency noise processing, is characterized in that, comprises the following steps:

[0027] Step 1. Make resonator models of different specifications;

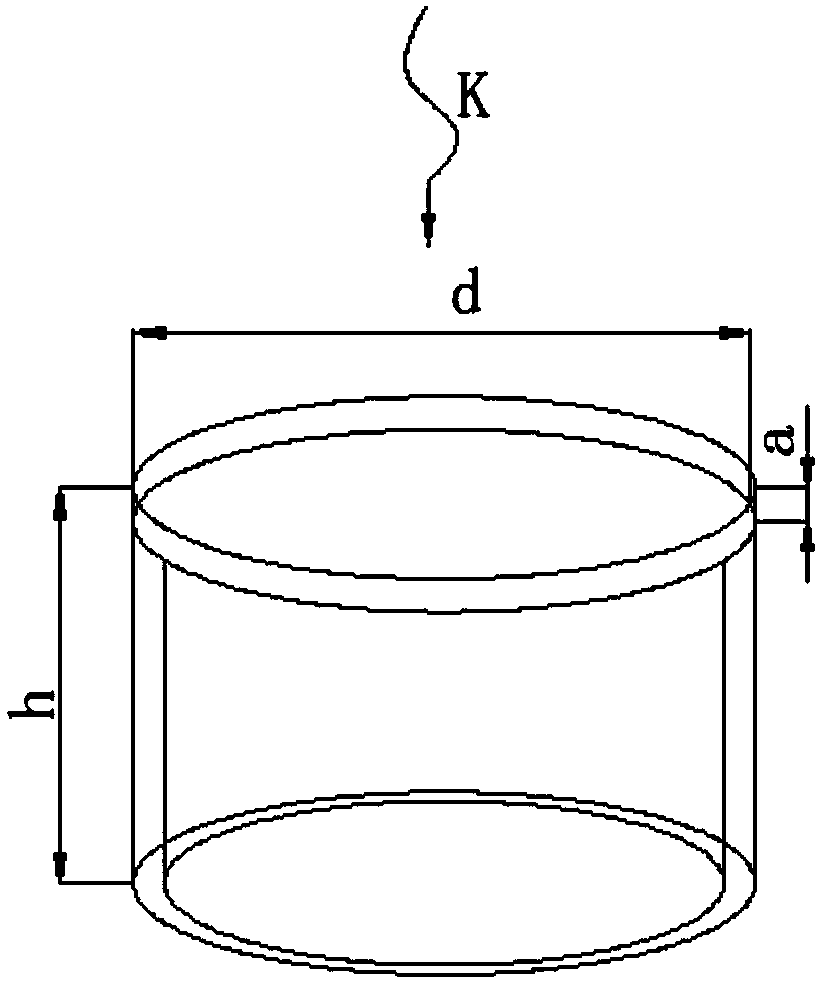

[0028] Such as figure 1 As shown, the resonant cavity model consists of two parts: the resonant cavity body and the resonant cavity cover. The resonant cavity is made of PLA material 3D printer, and the resonant cavity is a hollow cylinder with one end open. The resonant cavity cover is made of evenly stretched elastic film, and the resonant cavity cover just covers the open end of the resonant cavity and is fixed with silica gel, thus forming a closed resonant cavity model. The three parameters of the resonator model are height h, diameter d, and film thickness a.

[0029] In order to use the controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com