Lightweight train window for high-speed train and manufacturing method of lightweight train window

A high-speed train, lightweight technology, used in chemical instruments and methods, window devices, railway car body parts, etc., can solve the problems of glass weight, sound insulation and thermal insulation performance can not meet, achieve light weight, strong impact ability, sound insulation Good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

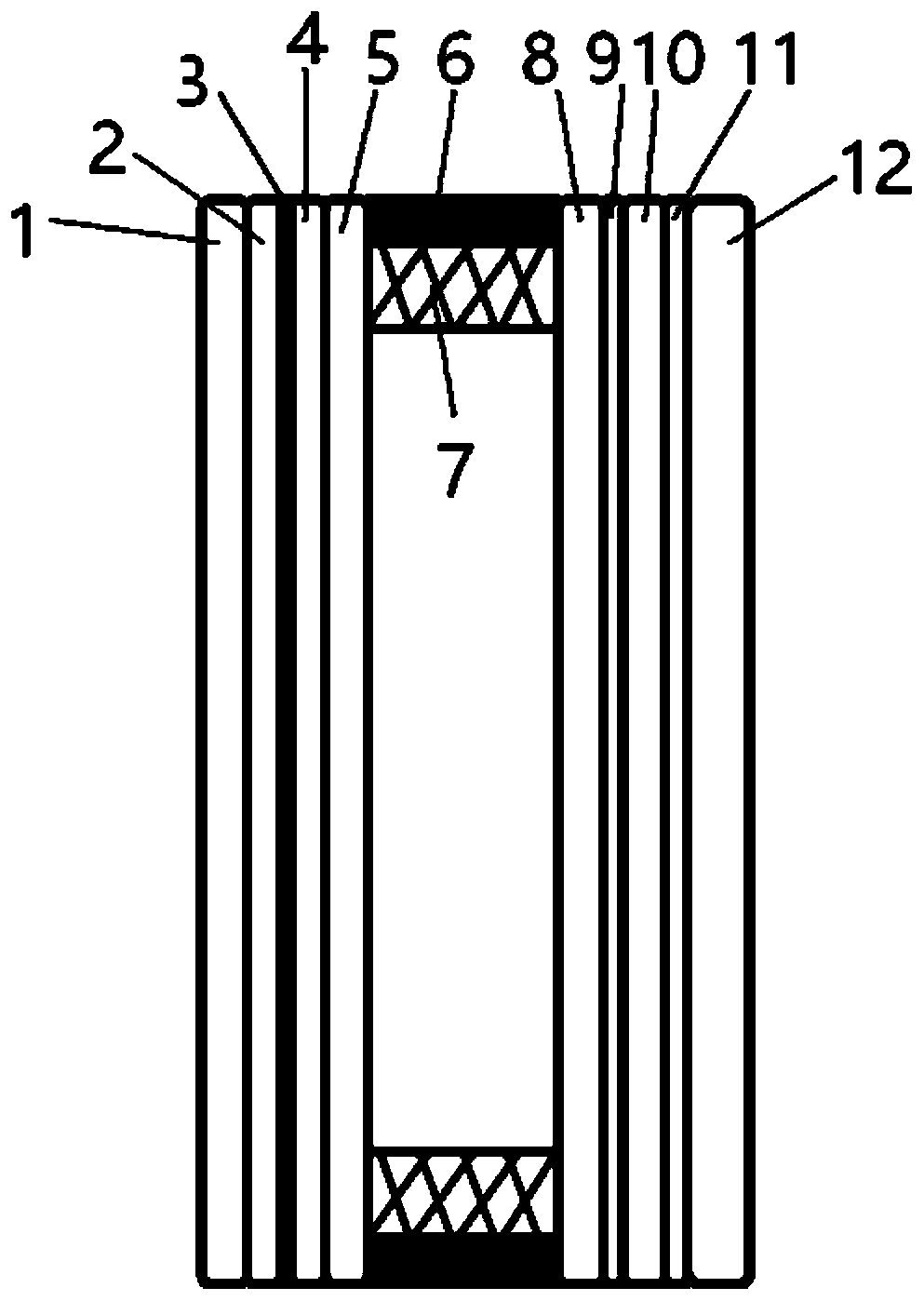

[0039] See attached figure 1 Shown, the step of making this kind of high-speed train lightweight car window is as follows:

[0040] Step 1. Chemically strengthening the first glass layer 1 and the second glass layer 5 with a thickness of 1.8mm, the chemical strengthening temperature is 415°C, and the time is 6h;

[0041] Step 2: Plating SiO sequentially on the PET film 3 2 and NiO x coating, and repeated 2 times, where X=0.7, SiO 2 and NiO x Coating thicknesses are 150nm and 100nm respectively;

[0042] Step 3, the first glass layer 1, the first film layer 2, the PET film 3, the second film layer 4, and the second glass layer 5 are sequentially stacked and laminated, and vacuum bagged;

[0043] Step 4. Send the completed glass into an autoclave for hot pressing to form an inner laminate. When the inner laminate is hot pressed, the cold extraction time is 50 minutes, the hot pressing temperature is 125°C, and the equilibrium time is 110 minutes;

[0044] Step 5. The third...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com