Winding lithium paste battery

A slurry battery and wound-type technology, which is applied in the direction of secondary batteries, battery components, circuits, etc., can solve problems such as early failure, uneven distribution of current density of electrode sheets, and insufficient utilization of active materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described through embodiments below in conjunction with the accompanying drawings.

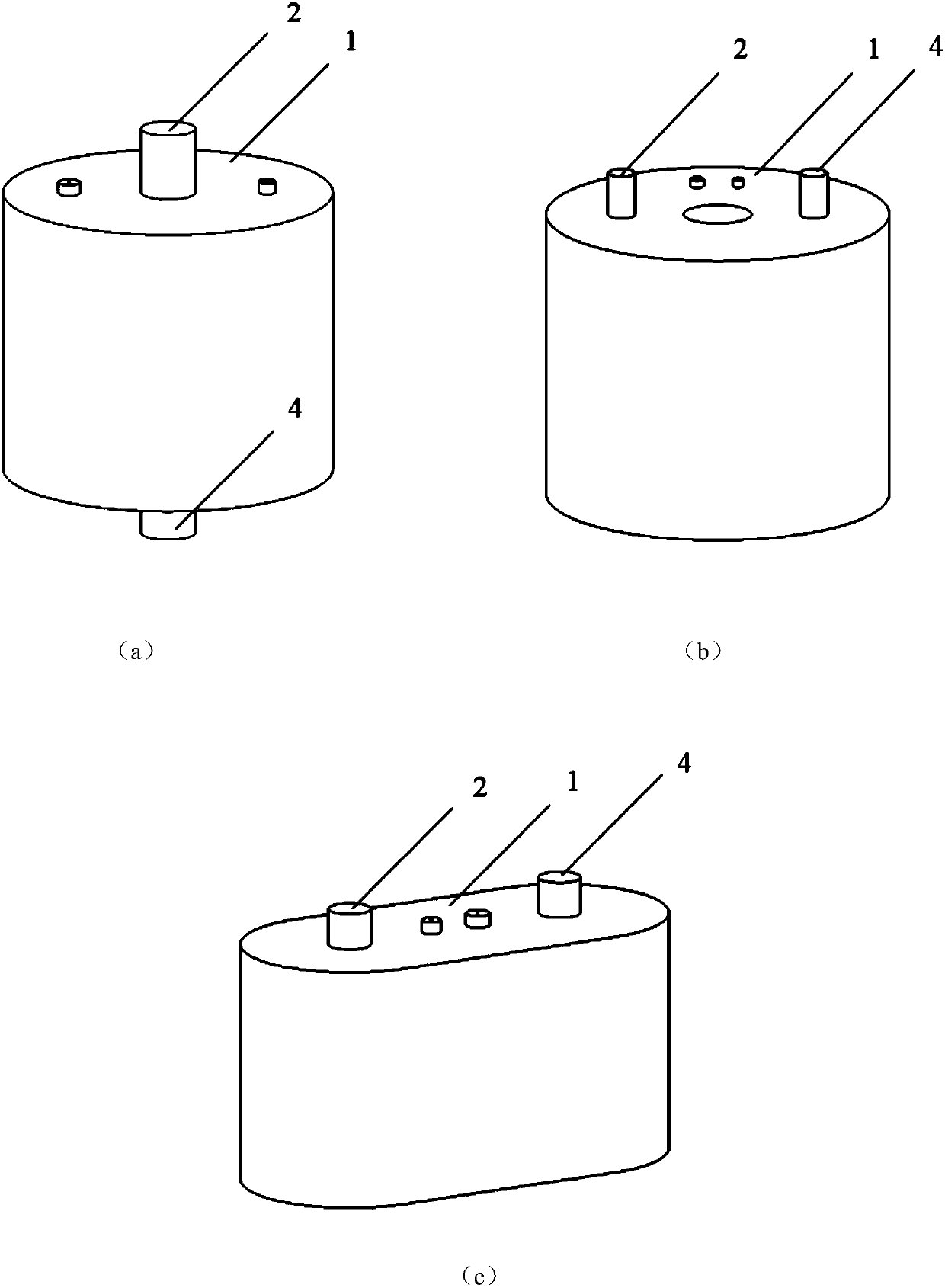

[0076] figure 1 It is a three-dimensional schematic diagram of a wound lithium slurry battery according to the present invention, figure 1 (a)-(c) show different shapes of wound lithium paste batteries. exist figure 1 In (a), the cell and the shell 1 of the wound lithium slurry battery are both cylindrical, and the positive pole 2 and the negative pole 4 of the battery protrude from the upper end surface and the lower end surface of the shell 1 respectively. exist figure 1 In (b), the cell and the shell 1 of the wound lithium slurry battery are both hollow cylinders or toruses, and the positive pole 2 and the negative pole 4 of the battery protrude from the upper end surface of the shell 1 respectively. exist figure 1 In (c), the cell and the shell 1 of the wound lithium slurry battery are both elliptical cylinders, and the positive pole 2 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com