High abrasion-resistance nylon composite material for trolley of airport freight train and preparation method thereof

A technology of nylon composite materials and freight vehicles, which is applied in the direction of equipment for transporting goods, etc., can solve the problems of poor dyeing, loud noise, and human ear damage, and achieve the effect of extremely strong hardness, high friction coefficient, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

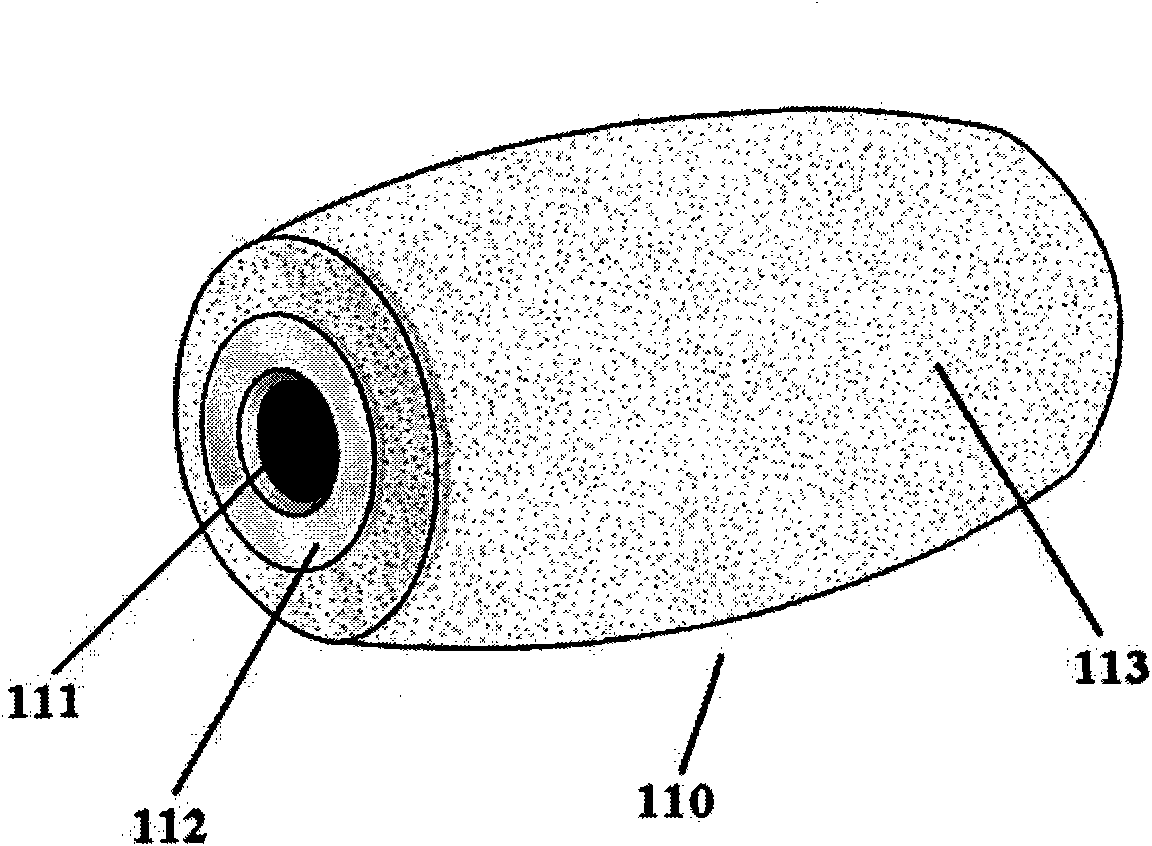

Image

Examples

Embodiment 1-6

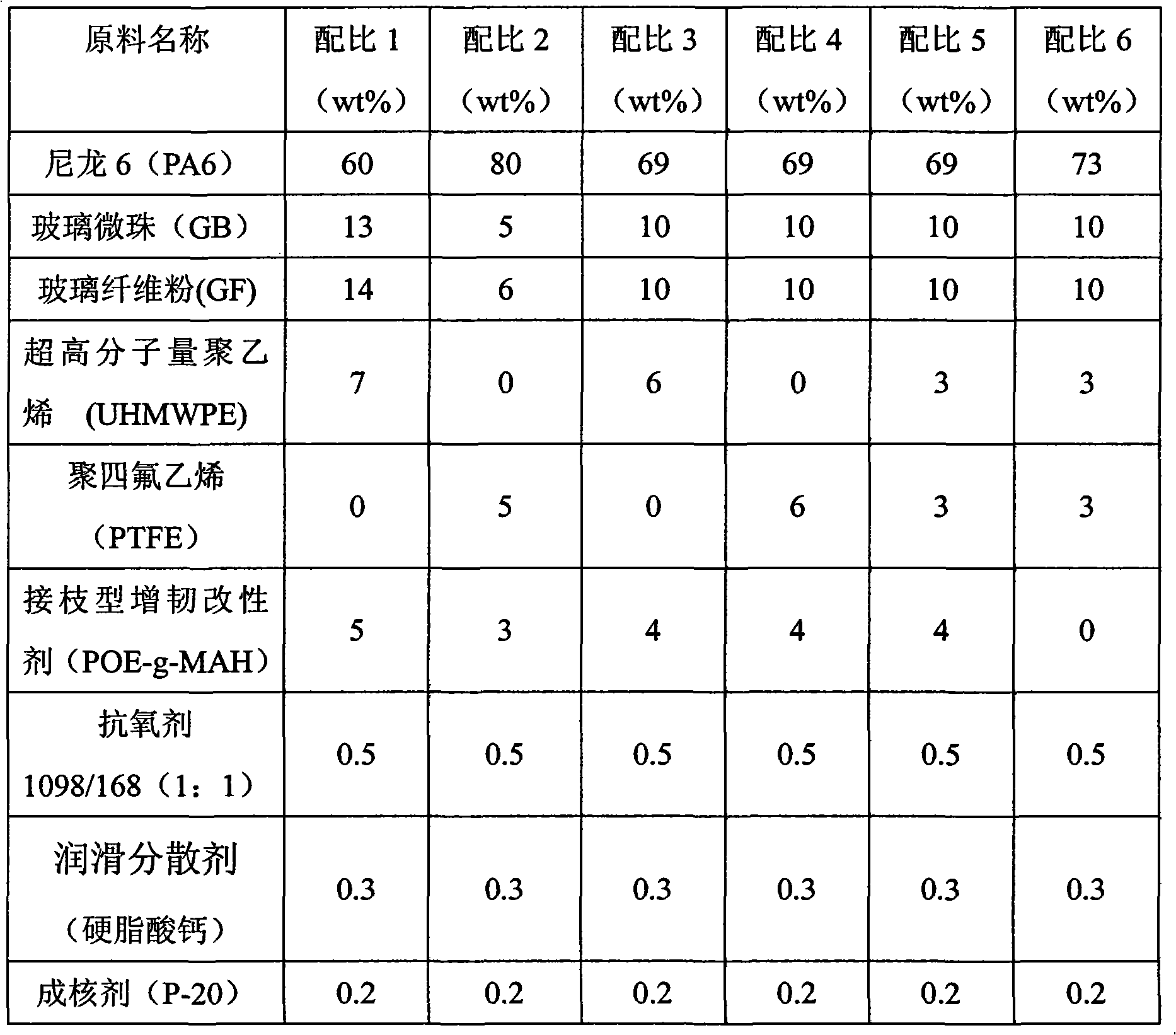

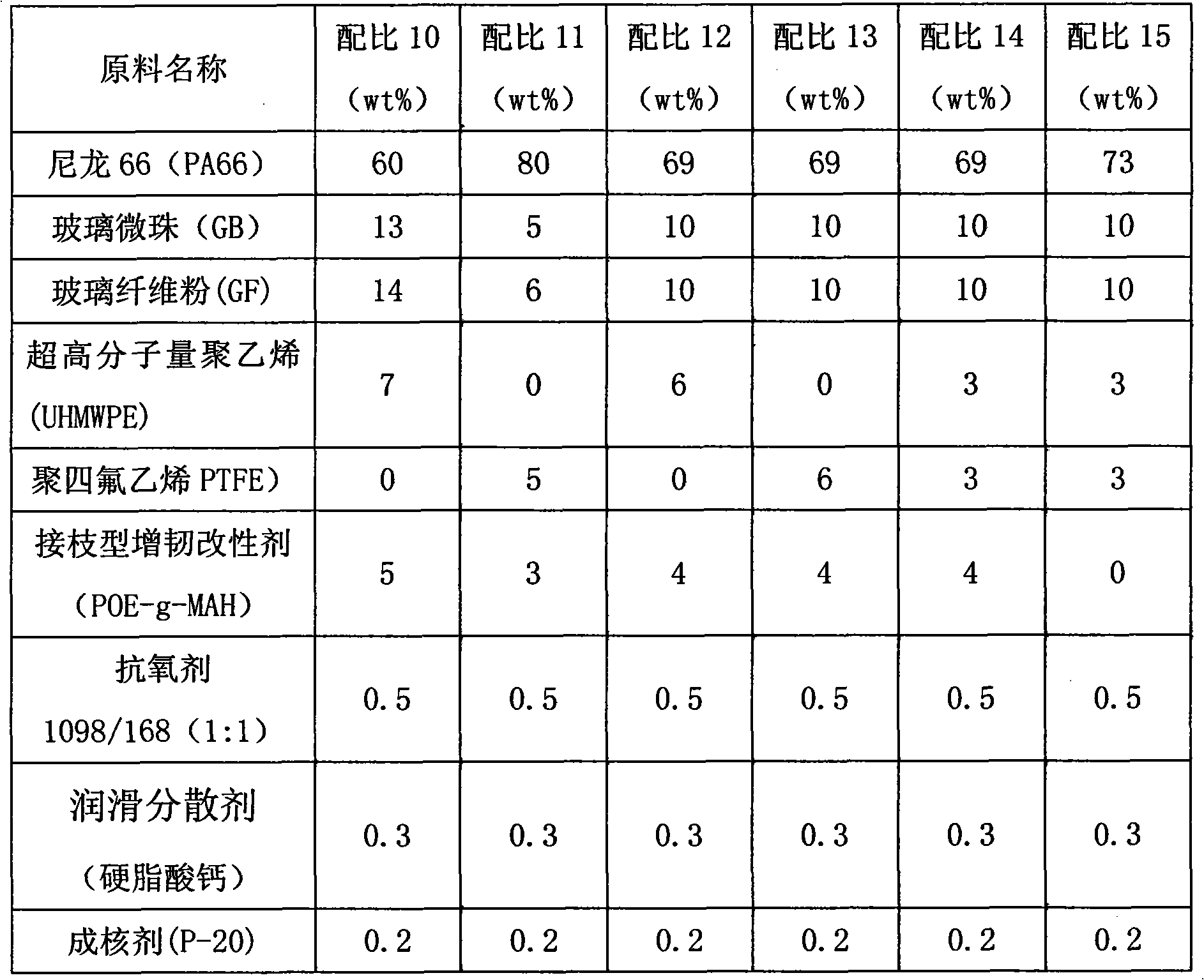

[0068] The high wear-resistant nylon 6 (PA6) composite material uses nylon 6 (PA6), glass microspheres (GB), glass fiber powder (GF) and lubricating and wear-resistant agents as main materials, and the rest are auxiliary materials. The high wear-resistant nylon 6 composite material is made up of the following components and raw materials in weight percentage:

[0069] Table 1: Proportions 1-6

[0070]

[0071] Wherein, the viscosity of the nylon 6 is 2.4; the glass microspheres and glass fiber powder are non-alkali glass microspheres and non-alkali glass fiber powder, the surface of which is treated with a silane coupling agent; the ultra-high molecular weight polyethylene is the first lubricant Anti-wear agent; the polytetrafluoroethylene is the second lubricating anti-wear agent; the graft type toughening modifier is the oligomer of polyolefin elastomer (POE) grafted unsaturated acid or acid anhydride graft polymerization, Its melt index is 1.0-5.0g / 10min, and graft rate...

Embodiment 7

[0079] The present invention also provides a preparation method of a high wear-resistant nylon 6 (PA6) composite material, the preparation process steps are as follows: Step 1: take the raw material according to the following weight percentage, nylon 6 is 69%, and the surface is treated with a silane coupling agent 10% of processed glass beads, 10% of glass fiber powder treated by silane coupling agent on the surface, 3% of the first lubricating and wear-resistant agent (ultra-high molecular weight polyethylene), the second lubricating and wear-resistant agent (polytetrafluoroethylene) 3%, 4% of grafted toughening modifier, 0.5% of antioxidant 1098 / 168 compound system compounded according to the weight ratio of 1:1, 0.2% of lubricating and dispersing agent calcium stearate, and 0.3% of nucleating agent %; Step 2: put the above raw materials into a high mixer and mix for 5 minutes, then discharge, and then extrude and granulate with a twin-screw extruder, the processing temperat...

Embodiment 8

[0082] The present invention also provides another preparation method of high wear-resistant PA6 composite material. The preparation process steps are as follows: Step 1: The raw material weighed by weight percentage, nylon 6 accounts for 70%, and the glass surface is treated with silane coupling agent Microbeads account for 10%, glass fiber powder treated with silane coupling agent on the surface accounts for 10%, graft type toughening modifier 3%, the first lubricating and wear-resistant agent (ultra-high molecular weight polyethylene) accounts for 3%, the second Two lubricating and wear-resistant agents (polytetrafluoroethylene) account for 3%, according to the weight ratio of 1: 1 composite antioxidant 1098 / 168 composite system accounts for 0.3%, and the lubricating and dispersing agent calcium stearate accounts for 0.2%. The nucleating agent accounts for 0.5%; Step 2: Put the above raw materials into a high-mixer and mix for 3 minutes, press and discharge, and then extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com