Measuring device and measuring method for acoustic absorption coefficient and sound reduction index of sound wave oblique incidence material

A technology of sound absorption coefficient and measuring device, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., to achieve the effect of small sample, improved technology and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] The measuring method of the sound wave oblique incidence material sound absorption coefficient measuring device of the present invention comprises the following steps:

[0067] 1) Preparations before measurement:

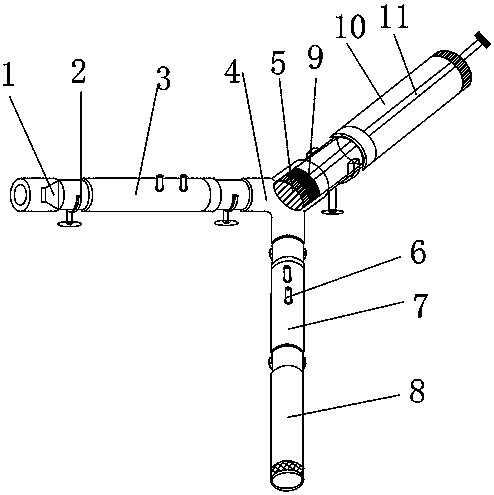

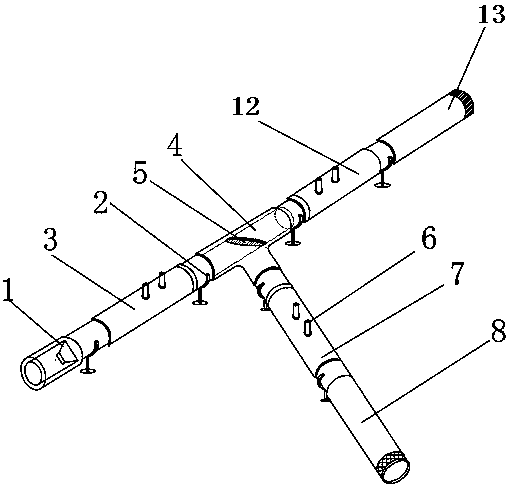

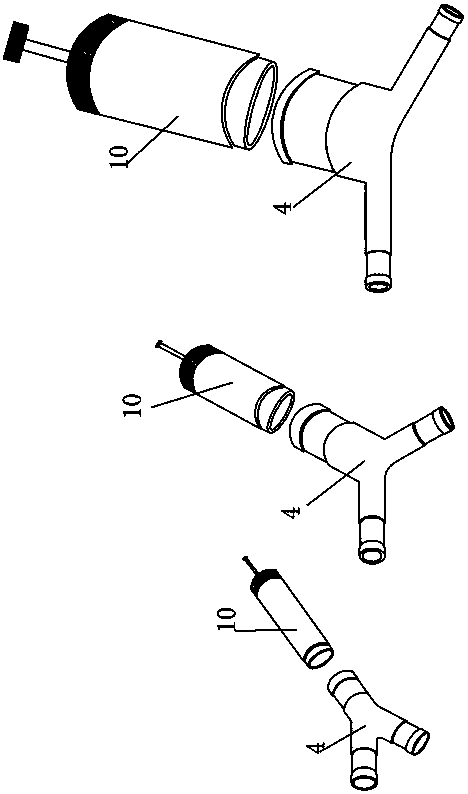

[0068]Put the test piece into the center of the three-way pipe fitting with different diameters. According to the principle of sound wave reflection, the distance from the test piece to the near-end microphone on the sound transmission tube (the microphone closest to the test piece on the sound transmission tube) is the same as the distance from the test piece to the near end of the reflection tube. The distance between the microphones (the microphone closest to the test piece on the reflection tube) is the same, and the distance between the three microphones of the sound tube and the reflection tube is also the same. The distance between the acoustic tube and the nearest microphone on the reflective tube to the specimen) should be greater than twice the tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com