Double-Wall Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

See FIGS. 1 to 6

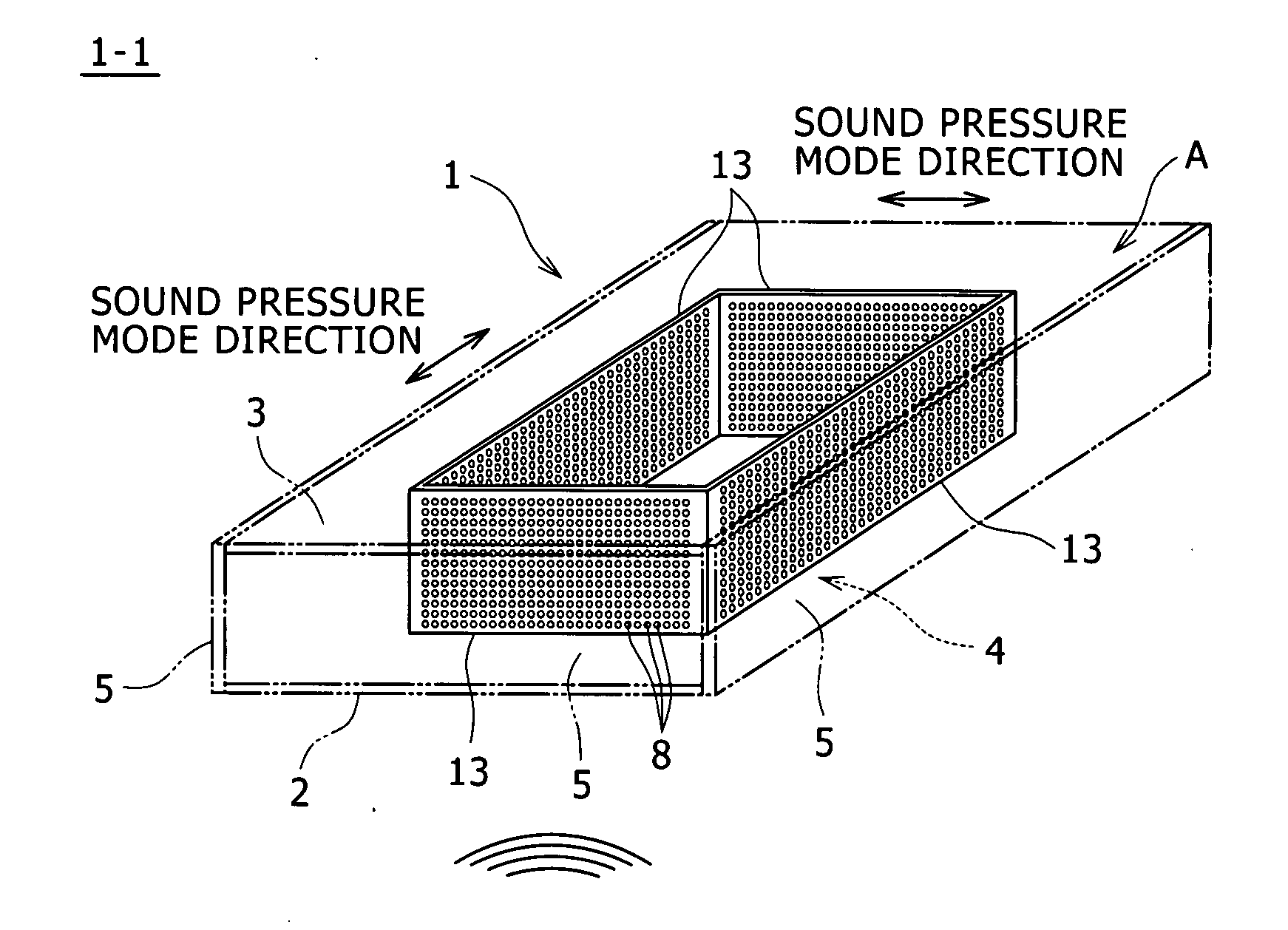

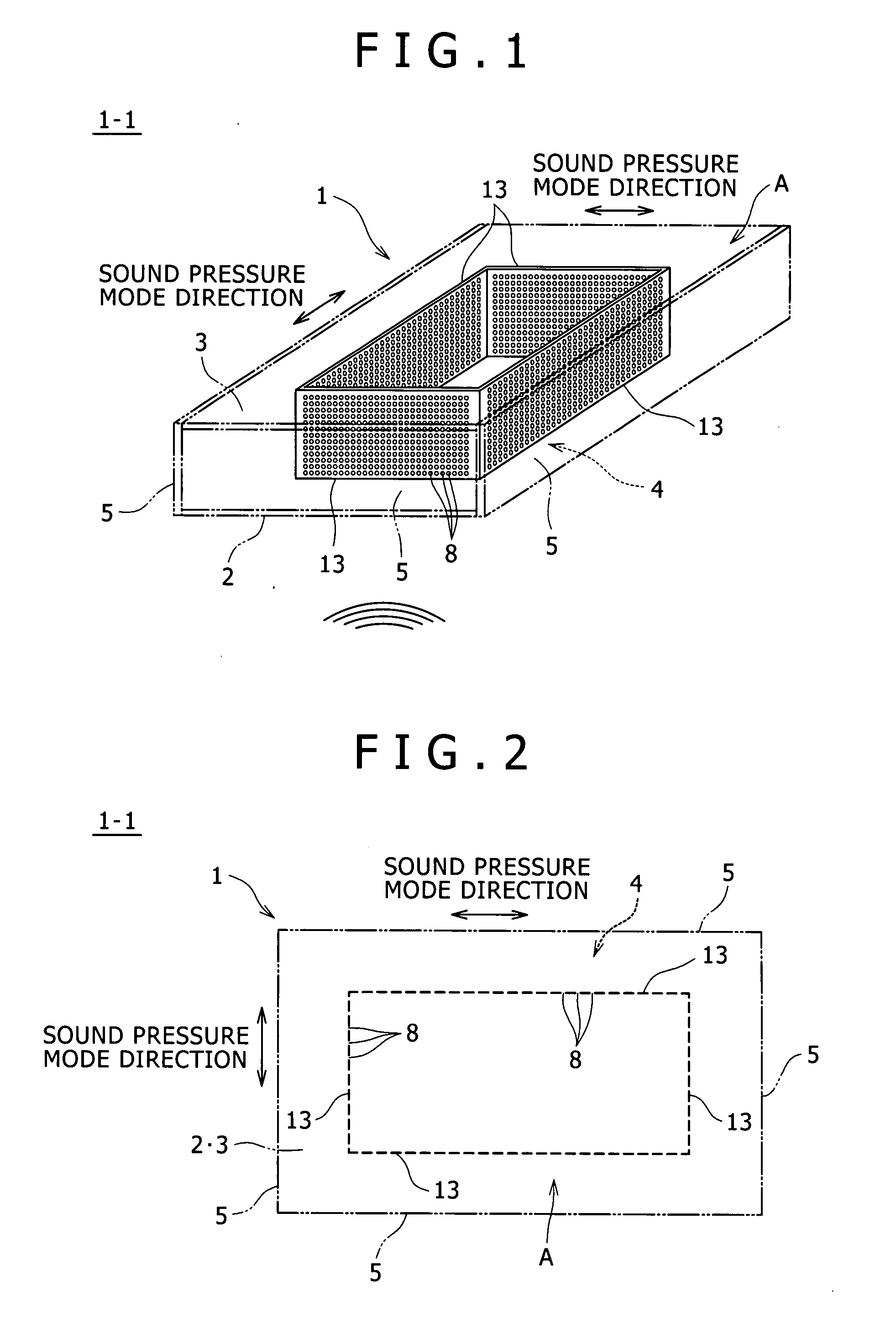

[0047]A double-wall structure of embodiment 1-1 shown schematically in FIGS. 1 and 2 assumes a door as a part of a passenger car. This double-wall structure, indicated at 1, has plate-like members 2 and 3 disposed in parallel with each other and opposed to each other at a predetermined distance. The plate-like members 2 and 3 are each formed in a rectangular shape which is a little longer in one direction and an air space 4 is formed between the two opposed plate-like members 2 and 3. Four side plates (circumferential members) 5 are disposed so as to connect edges of the plate-like members 2 and 3 with one another, whereby the air space 4 is closed substantially. In other words, with the plate-like members 2, 3 as double walls and the side plates 5, the double-wall structure of this embodiment is constituted as a bag structure which encloses the air space 4.

[0048]In this embodiment, finely perforated rectangular plates 13 are disposed so as to partition the air space...

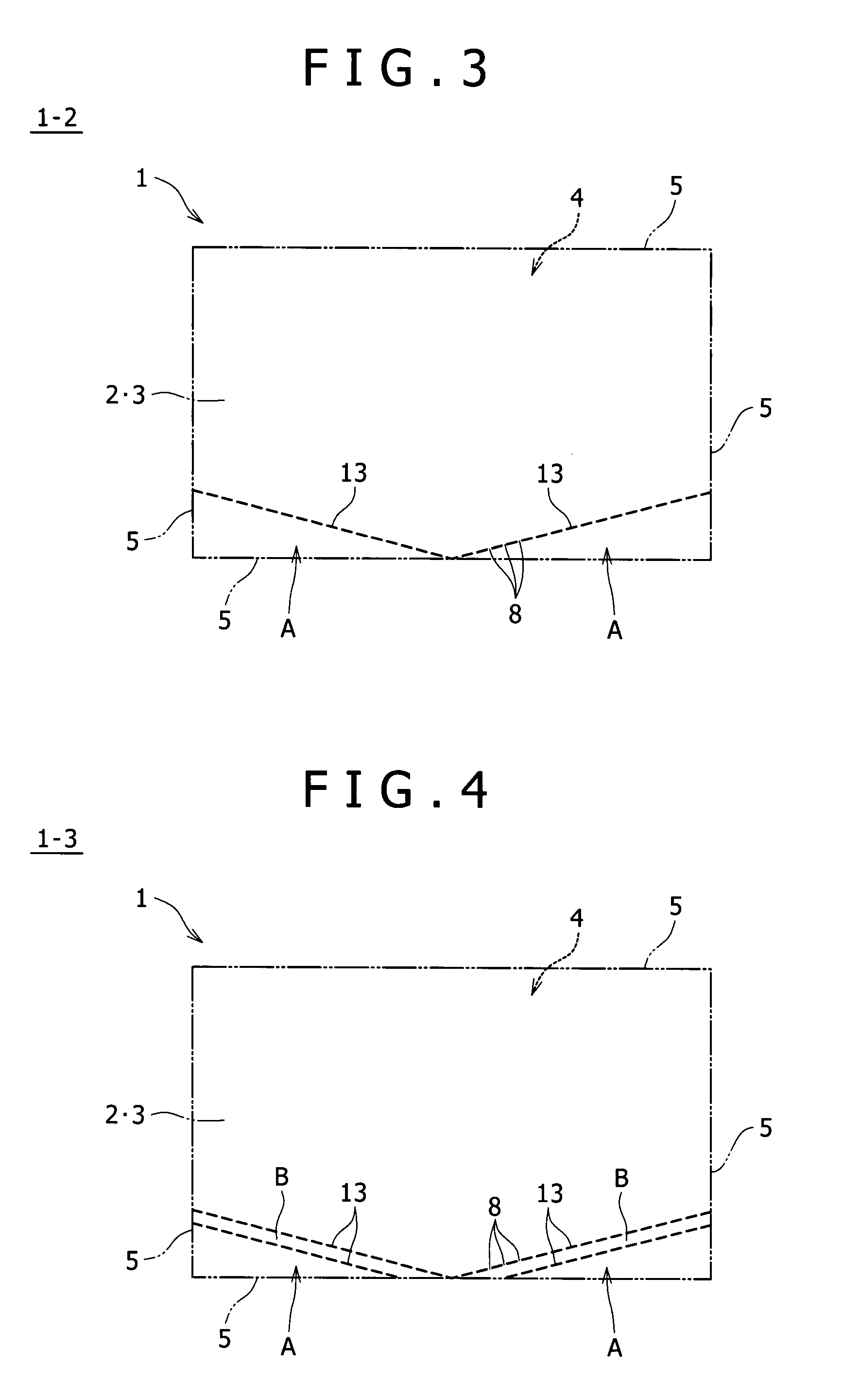

second embodiment

See FIGS. 7 to 12

[0053]According to the configuration of embodiment 2-1 (FIG. 7), which is a modification of embodiment 1-1 (FIGS. 1 and 2), plural plate-like partition members 9 are provided so as to provide connections between side plates 5 and finely perforated plates 13. With the partition members 9, the layer of air A interposed between the side plates 5 and the finely perforated plates 13 is partitioned in both longitudinal and transverse directions of the double-wall structure 1. It is preferable that the partition members 9 be disposed at positions where a resonance phenomenon occurring in the extending direction of the layer of air between the finely perforated plates 13 and the side plates 5 is difficult to occur at a desired frequency. More specifically, the partition members 9 are disposed at a spacing not coinciding with an integer multiple of a half of the wavelength for the frequency intended to improve the sound insulating performance. As a result, it is possible to ...

third embodiment

See FIGS. 13 and 14

[0058]FIG. 13 is a sectional view of a double-wall structure 1 according to embodiment 3-1-1. As shown in FIG. 13, there is a case where a finely perforated plate 13 cannot contact the plate-like member 2 on the vibration generating side and the plate-like member 3 on the opposite side in a completely airtight manner and certain slits are formed. The absence of such slits is preferred, so in this embodiment a vibration damping / isolating member 16 formed of, for example, rubber or urethane is installed in each of the portions corresponding to the slits. As a result, it is possible to enhance the sound absorbing performance of sound absorbing mechanism. As shown in embodiment 3-1-2 (FIG. 14), the vibration damping / isolating member 16 may be disposed between the finely perforated plate 13 and only one of the two plate-like members 2 and 3. If the above slits are fine slits, the vibration damping / isolating member 16 may be omitted and it is possible to let the slits t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com