Foamed material, and applications thereof

A foam material and raw material technology, which is applied in the field of foam material preparation, can solve the problems of poor mechanical properties, difficult degradation of 3D printing foam materials, etc., and achieves good sound insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

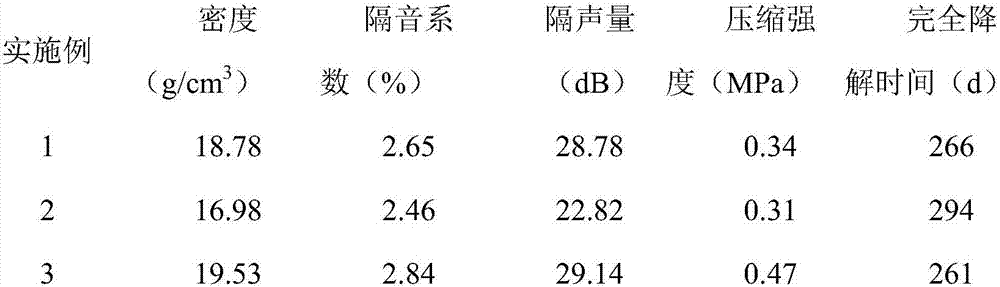

Examples

preparation example Construction

[0057] The preparation method of described adhesive comprises the following steps:

[0058] (A) preparation concentration is 28-34Be ', and the tapioca starch slurry I that pH value is 3.5-3.9;

[0059] (B) Add dimethyl glutarate, saturated octadecylamide, 2,5-dimethyl-2,5-bis(benzyl) with a concentration of 10%-14% to the tapioca starch slurry I in step A Acyl peroxy)-hexane, vanadium pentoxide, and then carry out cross-linking and grafting reaction at a microwave power of 100-130W, a temperature of 46-52°C, and a stirring speed of 100-160r / min for 1.4-2h to obtain Slurry II;

[0060] (C) Add potassium hydroxide to the slurry II in step B, adjust the pH value to 9.7-10, then add epichlorohydrin and urea, and then stir at a microwave power of 80-100W and a temperature of 62-66°C Carry out the crosslinking reaction for 1-1.5 hours at a rotational speed of 120-180r / min to prepare slurry III;

[0061] (D) adjust the pH value of the slurry III in step C to 8.2-8.4, raise the te...

Embodiment 1

[0073] A foam material, in parts by weight, is made of the following raw materials: 3 parts of graphene, 223 parts of polyvinyl chloride, 130 parts of ethylene propylene rubber, 92 parts of polyoxypropylene triol, 28 parts of caprylic triglyceride , 20 parts of methacrylate polymer, 18 parts of chlorinated paraffin, 16 parts of ceramic fiber, 10 parts of maleic anhydride, 8 parts of ethylene-ethyl acrylate copolymer, 12 parts of vinyl acetate ethylene copolymer emulsion, triisopropanol 6 parts of amine, 20 parts of adhesive, 0.5 part of dispersant, 0.7 part of tackifier, 1.2 part of crosslinking agent, 0.8 part of catalyst, 1 part of plasticizer, 0.8 part of toughening agent, 0.7 part of foaming agent, 0.4 parts of foam regulator, 0.3 parts of foam stabilizer, 0.7 parts of curing agent, 2 parts of degradation agent, 0.5 parts of stabilizer;

[0074] The adhesive, in parts by weight, includes the following raw materials: 105 parts of tapioca starch, 6 parts of dimethyl glutarat...

Embodiment 2

[0102] A foam material, in parts by weight, made of the following raw materials: 2.2 parts of graphene, 189 parts of polyvinyl chloride, 102 parts of ethylene propylene rubber, 78 parts of polyoxypropylene triol, 22 parts of caprylic triglyceride , 15 parts of methacrylate polymer, 14 parts of chlorinated paraffin, 12 parts of ceramic fiber, 8 parts of maleic anhydride, 6 parts of ethylene-ethyl acrylate copolymer, 9 parts of vinyl acetate ethylene copolymer emulsion, triisopropanol 4 parts of amine, 18 parts of adhesive, 0.4 part of dispersant, 0.5 part of tackifier, 0.9 part of crosslinking agent, 0.6 part of catalyst, 0.8 part of plasticizer, 0.6 part of toughening agent, 0.5 part of foaming agent, 0.3 parts of foam regulator, 0.2 parts of foam stabilizer, 0.6 parts of curing agent, 1.5 parts of degradation agent, 0.3 parts of stabilizer;

[0103] The adhesive, in parts by weight, includes the following raw materials: 46 parts of tapioca starch, 4 parts of dimethyl glutarat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com