Design method for improving acoustic performance of anti-icing panel of turbo-propeller plane

A technology of acoustic performance and design method, applied in the direction of fuselage bulkhead, fuselage insulation, etc., can solve problems such as attenuation of propeller noise transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention provides a low aerodynamic sound, high sound insulation, easy to replace, high environmental adaptability anti-ice plate structure design method, including the following steps:

[0027] Step 1. Select the type of anti-icing panel according to the design scheme of the original aircraft anti-icing panel;

[0028] Step 2. Test the acoustic performance of the material to be selected according to the material sound absorption coefficient method and the sound insulation performance test method, and select the acoustic inner core of the anti-ice board according to the sound absorption coefficient and sound insulation performance of the material to be selected;

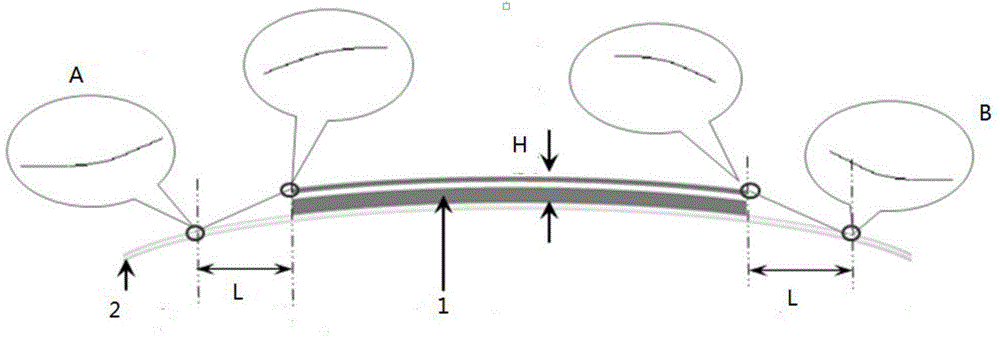

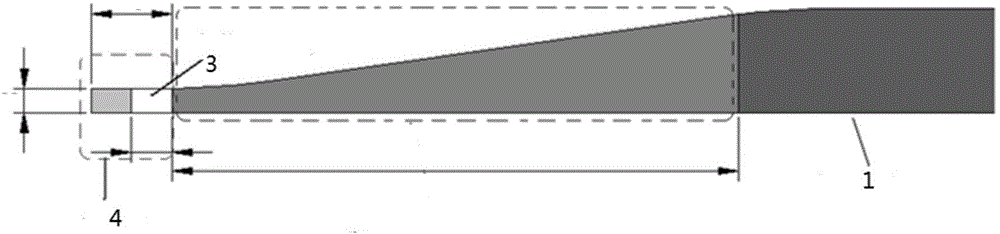

[0029] Step 3. Determine the thickness of the anti-icing plate according to the thickness of the acoustic inner core material and the thickness of the anti-icing panel, and use the aerodynamic calculation acoustic software to calculate the self-excited noise of the anti-icing plate based on the thi...

Embodiment 2

[0040] Similar to Example 1, comprising the following steps:

[0041] Step 1. Select the type of anti-icing panel according to the design scheme of the original aircraft anti-icing panel;

[0042] Step 2. Test the acoustic performance of the material to be selected according to the material sound absorption coefficient method and the sound insulation performance test method, and select the acoustic inner core of the anti-ice board according to the sound absorption coefficient and sound insulation performance of the material to be selected;

[0043]Step 3. Determine the thickness of the anti-icing plate according to the thickness of the acoustic inner core material and the thickness of the anti-icing panel, and use the aerodynamic calculation acoustic software to calculate the self-excited noise of the anti-icing plate based on the thickness of the anti-icing plate. On this basis, modify the aerodynamic The length of the edge banding, calculate the aerodynamic noise of the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com