Variable-convexity roller type self-adaptive design method based on genetic algorithm

A technology of genetic algorithm and design method is applied in the field of adaptive design of variable crown roll shape based on genetic algorithm, which can solve the problem that the adjustment ability of CVC roll shape is reduced, it cannot meet production requirements, and the service life of variable crown roll shape is shortened. and other problems to achieve the effect of improving actual performance and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

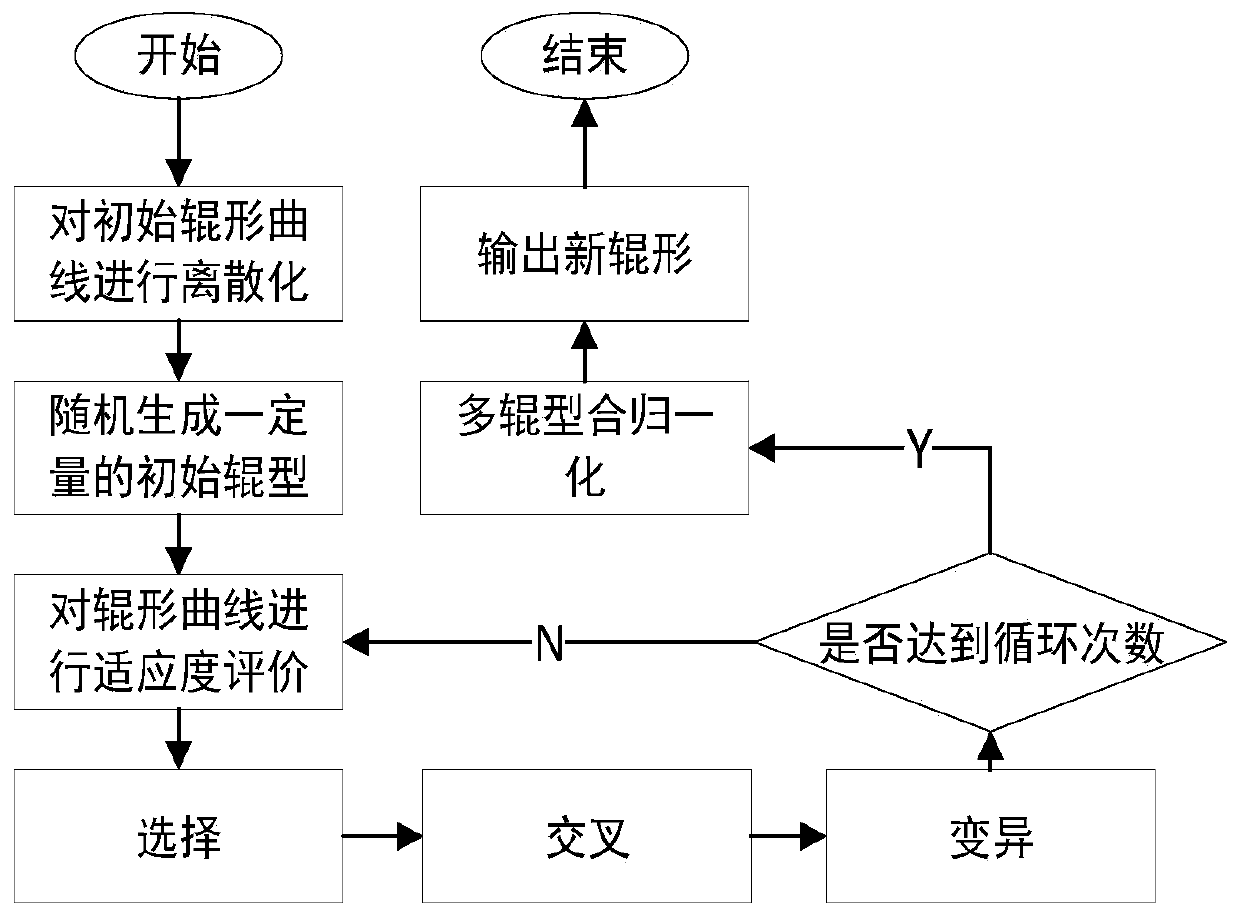

[0094] according to figure 1The shown algorithm flow designs the roll shape. First, the CVC roll shape is selected as the roll shape of the initial iteration, and the CVC roll shape coefficients are shown in Table 1. Set a certain floating range for the coefficient to increase the number of roll shapes.

[0095] Table 1 CVC roll shape coefficient table

[0096]

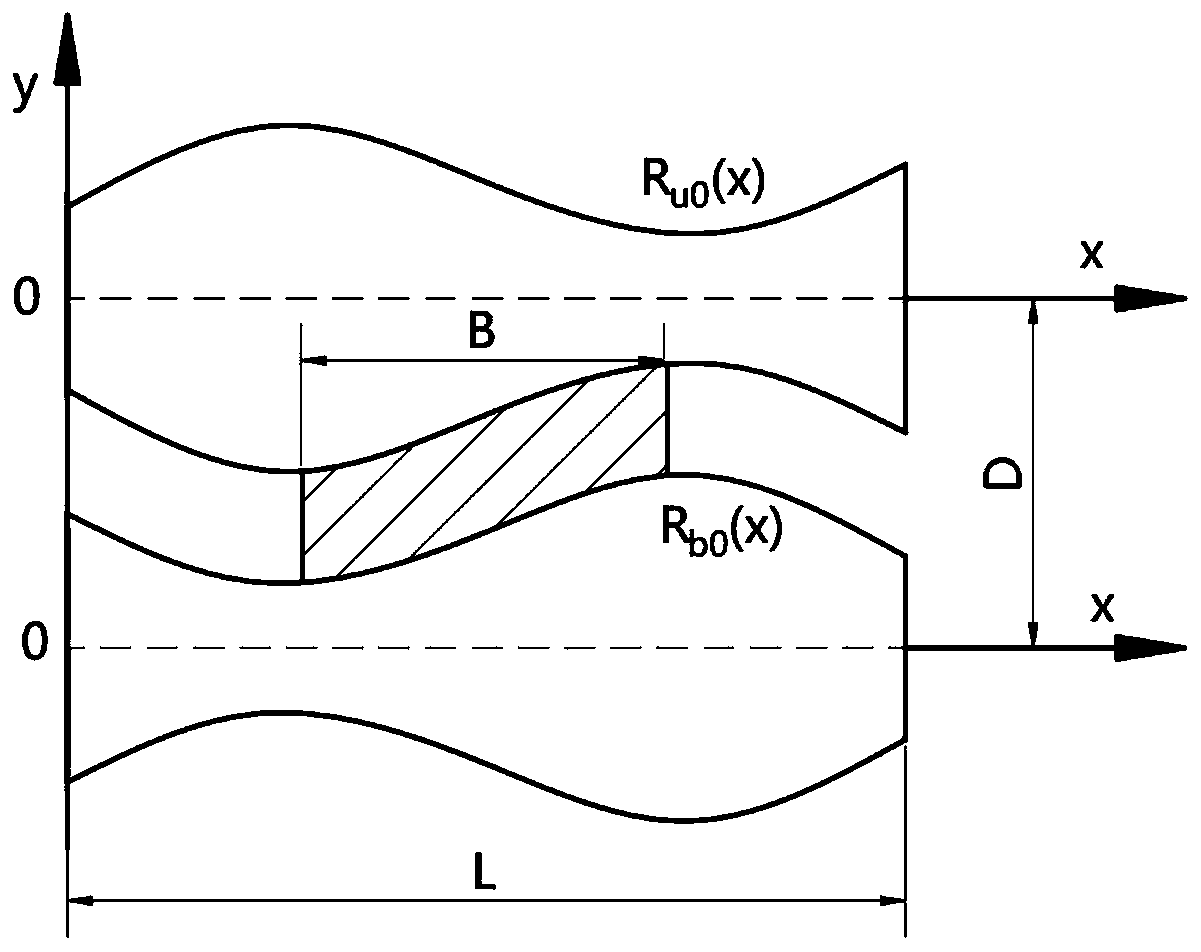

[0097] Let the population size be 800, randomly generate the initial iterative population r N×M = r 1 (i),r 2 (i),...r N (i). Calculate G 0 The fitness of each roll shape curve in , and the parameters in the fitness function are shown in Table 2.

[0098] Table 2 Design parameters of roll shape

[0099]

[0100] The genetic algorithm is used to process the initial discretized roll shape curve, and its parameter settings are shown in Table 3. The code length is selected from the roll shape curve design program library of the roll grinder, and the number of populations, crossover probability, mutation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com