Floating floor air sound insulation detection method

A detection method and air-acoustic technology, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of no monitoring method, low detection efficiency, water ingress corrosion of shock-absorbing panels and sound-absorbing panels, etc., to improve accuracy, Coordinate digital precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

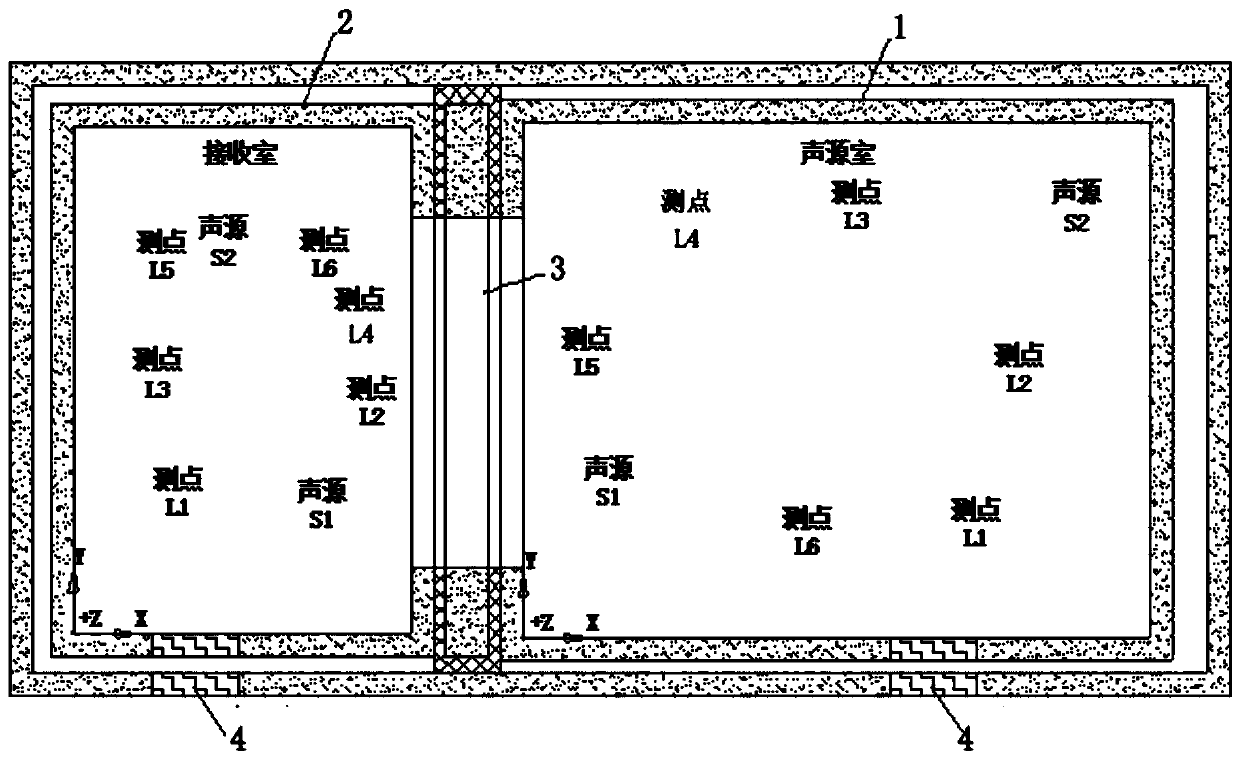

[0036] Such as figure 1 , figure 2 As shown, a floating floor airborne sound insulation detection method includes the following steps:

[0037] a. Establish a laboratory: the laboratory includes a sound source room 1 and a receiving room 2, the sound source room 1 and the receiving room 2 are connected through the test hole 3, and the sound source room 1 and the receiving room 2 are equipped with sound insulation doors 4;

[0038] b. Arrangement of measuring points and sound sources: Arrange multiple sound sources and multiple measuring points in the sound source room and receiving room and determine the coordinate positions of the sound source and measuring points, and install the test piece at the position of the measuring points; among them, the sound source room There are two sound sources and seven measuring points arranged in the receiving room;

[0039] When the coordinate positions of the sound source and measuring point are determined, the corner of the ground of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com