Railway vehicle end internal windshield and installation method thereof and usage method thereof

A rail vehicle and installation method technology, applied to the railway car body, transportation and packaging, railway car body parts, etc., to achieve the effects of optimizing the manufacturing and installation process, ensuring the transition of guidance, and increasing the speed of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

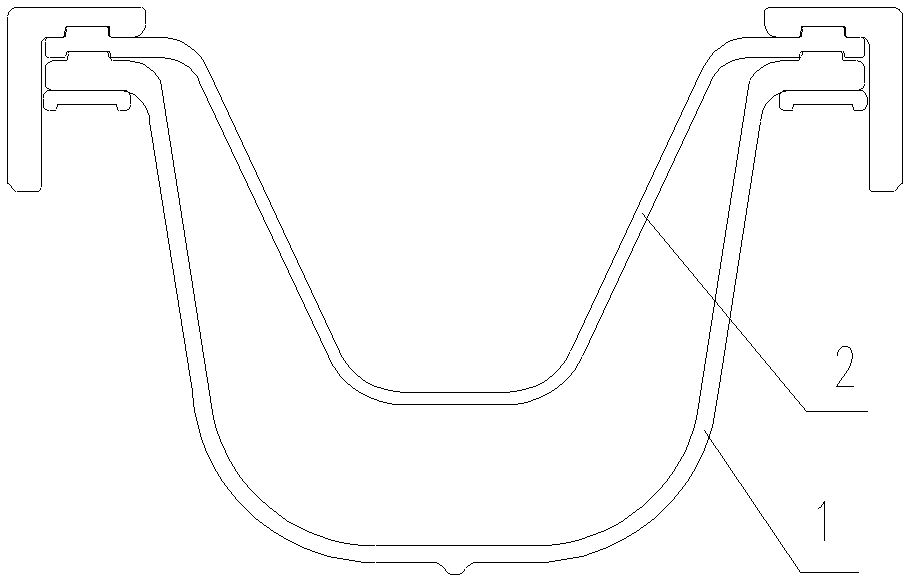

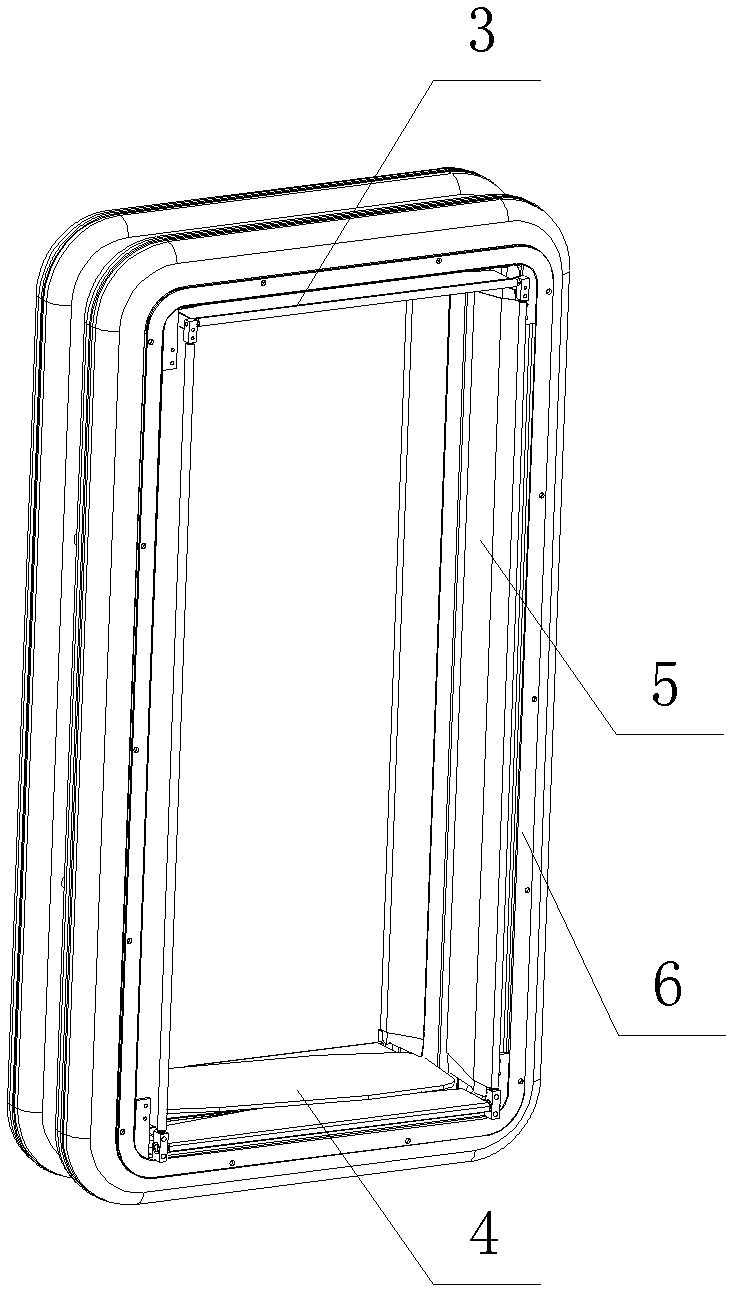

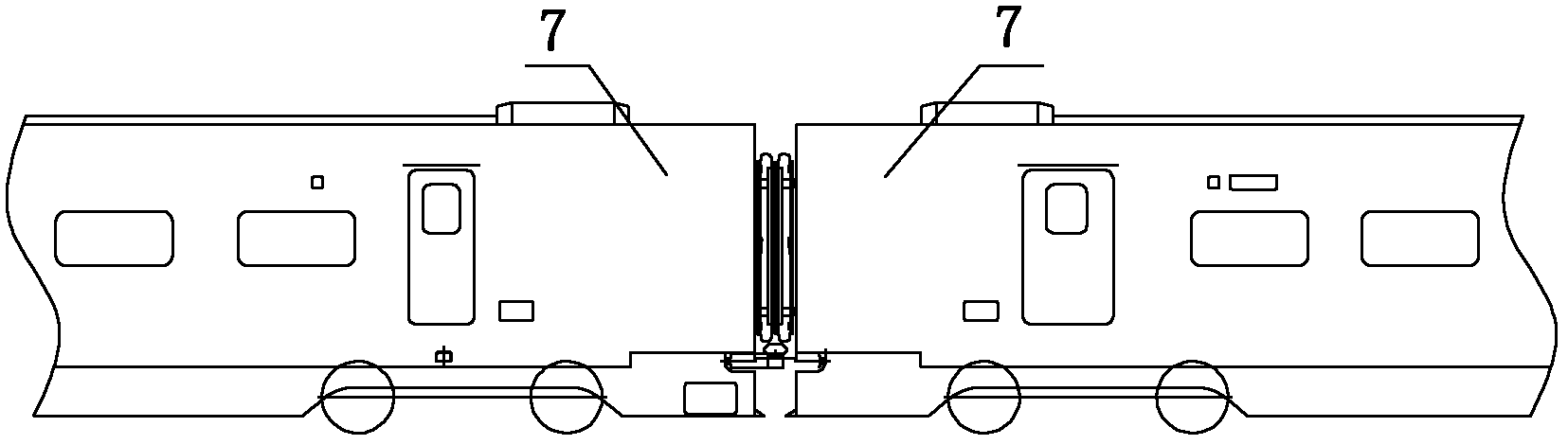

[0060] Example 1, such as figure 1 , figure 2 and Figure 4 As shown, the windshield at the end of the rail vehicle mainly includes a set of frame 6 longitudinally connected between the outer side of the end of the car body 7 and the adjacent inner windshield, the outer capsule 1 installed on the frame 6, Inner layer capsule 2, top plate 3, bottom transition plate 4 and side guard plates 5 on both sides. Between the two vehicle bodies 7, the two opposite frame frames 6 are connected by extruded installation.

[0061] Wherein, the outer capsule 1 and the inner capsule 2 are embedded and overlapped with each other to form an integrated structure, so as to form a whole-circumference double-layer closed sound insulation overall structure, and the circumference of the outer capsule 1 is greater than that of the inner capsule 2. perimeter.

[0062] There is a sliding connection structure between the inner capsule 2 and the frame 6, that is, the inner side of the frame 6 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com