Finished automobile sound transmission loss testing method

A test method and a technology of sound transmission loss, applied in the field of automobile manufacturing, can solve problems such as rising project costs, prolonging the development cycle, and providing evidence, so as to reduce project costs, improve development efficiency, and achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

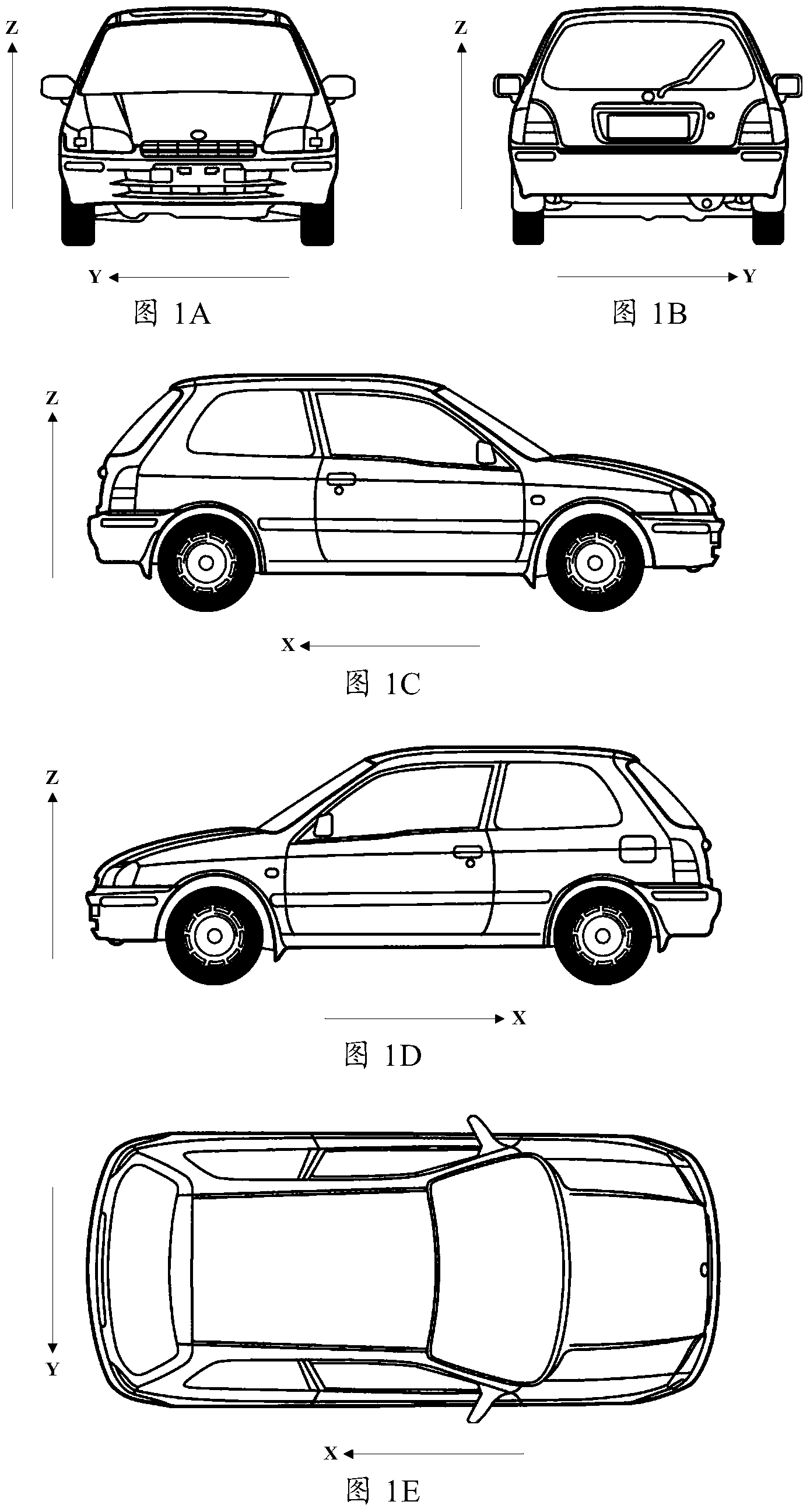

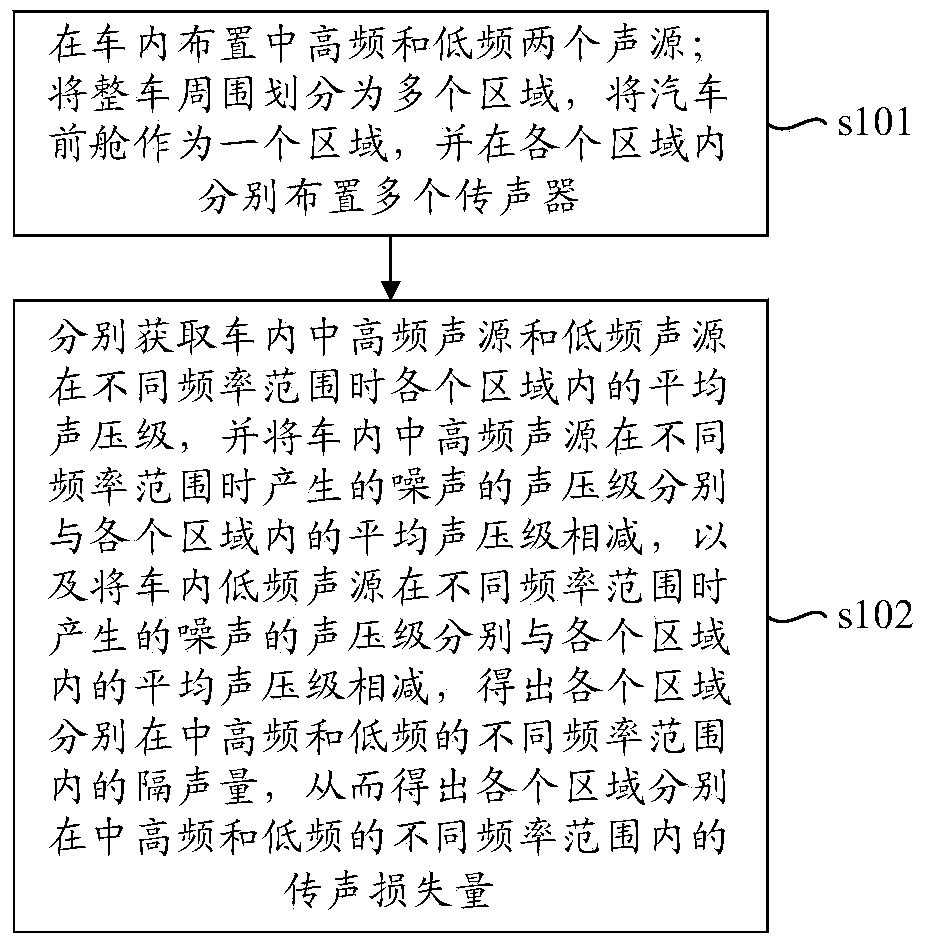

[0049] Such as figure 2 As shown, the present embodiment provides a method for testing sound transmission loss of a vehicle, the test method is based on reciprocity, and includes the following steps:

[0050] S101. Arrange two sound sources of medium and high frequency and low frequency in the car; divide the surrounding area of the whole vehicle into multiple areas, take the front cabin of the car as one area, and arrange multiple microphones in each area.

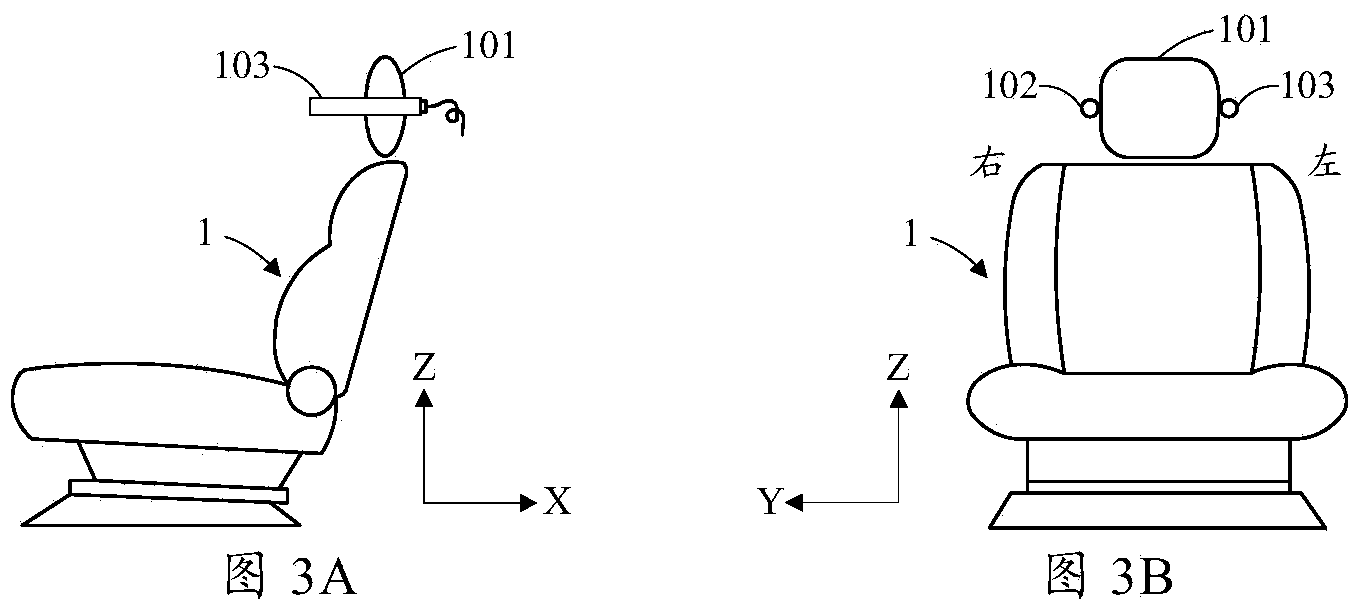

[0051] Reasonably arranging the position of the sound source and the microphone is the premise of the whole test. Considering the importance of the sound pressure level on the driver's side, the driver's seat is used as the reference position. Preferably, in step S101, as image 3 As shown, the low-frequency sound source 103 and the medium-high frequency sound source 102 arranged in the vehicle are respectively arranged on both sides of the headrest 101 of the driver's seat 1, for example, the low-frequency sound sourc...

Embodiment 2

[0081] This embodiment mainly describes the arrangement position of each microphone in the area where the front cabin of the automobile is located. The front compartment of the car is located at the noise source of the powertrain, and the noise source of the powertrain mainly includes the noise generated by the engine and its accessories, and the noise generated by the gearbox and its accessories. Compared with other areas of the vehicle, the front compartment of the car The area where the noise is located is the key investigation area for noise. The microphone located in the area where the front cabin of the car is located is mainly used to evaluate the sealing of the transmission path from the front cabin of the car to the driver's seat in the car.

[0082] In this embodiment, the plurality of microphones arranged in the area where the front compartment of the automobile is located are respectively located near the outer envelope surfaces of the engine and the gearbox, that i...

Embodiment 3

[0089] This embodiment mainly describes the layout positions of the microphones in multiple areas divided around the entire vehicle.

[0090] In this embodiment, the surrounding area of the whole vehicle is divided into multiple areas: the area where each tire is located, the area where the rear bumper is located, the area where the bottom of the vehicle body is located, and the area where each door is located.

[0091] In the following, each area divided around the vehicle will be described respectively.

[0092] (1). The area where each tire is located

[0093] Each tire is located at the source of tire noise. Tire noise is generated by the friction between the tire and the road when the vehicle is running at high speed. The microphone located in the area where each tire is located is mainly used to evaluate the distance between each tire and the driver's seat in the car. The tightness of the delivery path.

[0094] The multiple microphones arranged in the region where e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com