Method of preparing compound conductive fibers, compound conductive fibers obtained by method and application of compound conductive fibers

A technology for compounding conductive and conductive polymers, applied in the direction of fiber chemical characteristics, conductive/anti-static filament manufacturing, single-component synthetic polymer rayon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

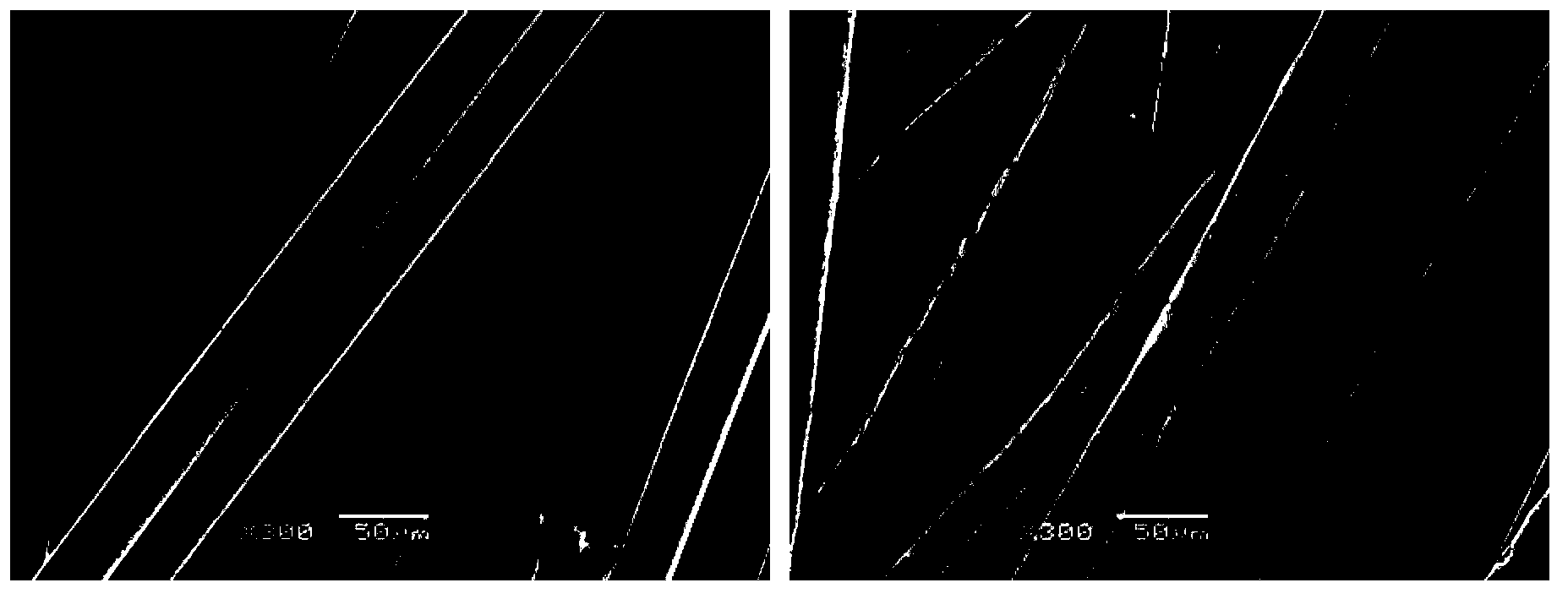

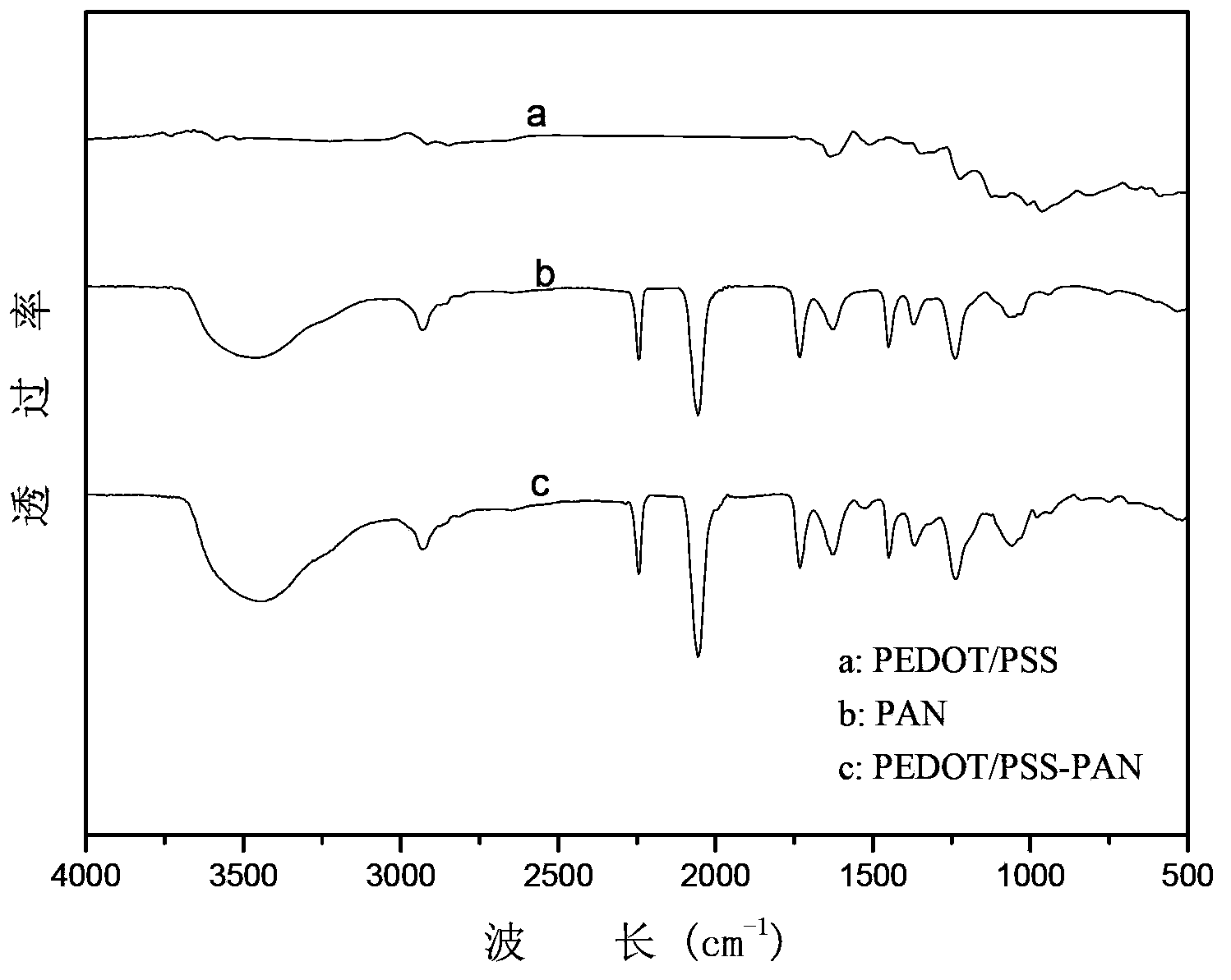

[0069] Embodiment 1—preparation of PEDOT / PSS-PAN composite conductive fiber of the present invention

[0070] At 25°C, 0.1528g of EDOT monomer, 0.3841g of sodium persulfate and 0.45ml of 1mol / L ferric chloride aqueous solution (oxidant) and 0.4138g of polystyrene sulfonate (M w =70000±5000) (dopants) were sequentially added to 20ml of distilled water, reacted for 24 hours under stirring, and then stopped stirring to obtain a dark blue PEDOT / PSS aqueous dispersion.

[0071] Take 20g of the obtained PEDOT / PSS aqueous dispersion, add 80g of water to dilute, and then add 100g of NaSCN to prepare a NaSCN aqueous solution containing PEDOT / PSS. 26 g of PAN (M w =50000±5000, M w / M n =1.3), mechanically stirred at 45-50°C for 4 hours, and vacuum defoamed for 48 hours to obtain a uniform spinning stock solution, which was recorded as spinning stock solution 1.

[0072] Get 20g of gained PEDOT / PSS aqueous dispersion, then this aqueous dispersion is dried, after drying, grind into po...

Embodiment 2

[0077] Embodiment 2—preparation of the PEDOT / PSS-PAN composite conductive fiber with acid red G as co-dopant of the present invention

[0078] At 10°C, mix 0.1528g of EDOT monomer, 2.8ml of 1mol / L ferric chloride aqueous solution (oxidant), 0.2069g of polysodium p-styrene sulfonate (M w =70000±5000) (dopant), 0.2150g of acid red G (co-dopant) and 0.0764g of polyoxyethylene laurate (Jiangsu Haian Petrochemical Plant, LAE-4) (emulsifier) in turn Add it into 20ml of distilled water, react under stirring for 24h, stop stirring, and obtain a deep purple PEDOT / PSS dispersion emulsion.

[0079] Take 20g of the obtained PEDOT / PSS dispersion emulsion, add 60g of water to dilute, then add 80g of NaSCN, and prepare the NaSCN aqueous solution containing PEDOT / PSS. 23.9 g of PAN (M w =50000±5000, M w / M n =1.3), mechanically stirred at 45-50°C for 4h to dissolve, and a uniform spinning dope was obtained. The spinning stock solution was degassed in vacuum at 45-50°C for 4 days in a v...

Embodiment 3

[0084] Example 3—Preparation of the PEDOT / PSS-PAN composite conductive fiber of the present invention with Fluorescent Yellow 184 as a co-dopant

[0085] At 20°C, 0.1528g of EDOT monomer, 0.3841g of sodium persulfate and 1ml of 1mol / L ferric chloride aqueous solution (oxidant), 0.1528g of fluorescent yellow 184 (co-dopant) and 0.2069g of polyparaphenylene Sodium ethylene sulfonate (M w =70000±5000) (dopants) were sequentially added to 20ml of distilled water, reacted under stirring for 12 hours, and then stopped stirring to obtain a dark green PEDOT / PSS aqueous dispersion.

[0086] Take 20 g of the obtained PEDOT / PSS aqueous dispersion, add 40 g of water to dilute, and then add 60 g of NaSCN to prepare a NaSCN aqueous solution containing PEDOT / PSS. 17.9 g of PAN (M w =50000±5000, M w / M n =1.3), mechanically stirred at 45°C for 4h to dissolve, and degassed the spinning stock solution in a vacuum oven at 45°C for 4 days to obtain a uniform spinning stock solution without bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity at room temperature | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com