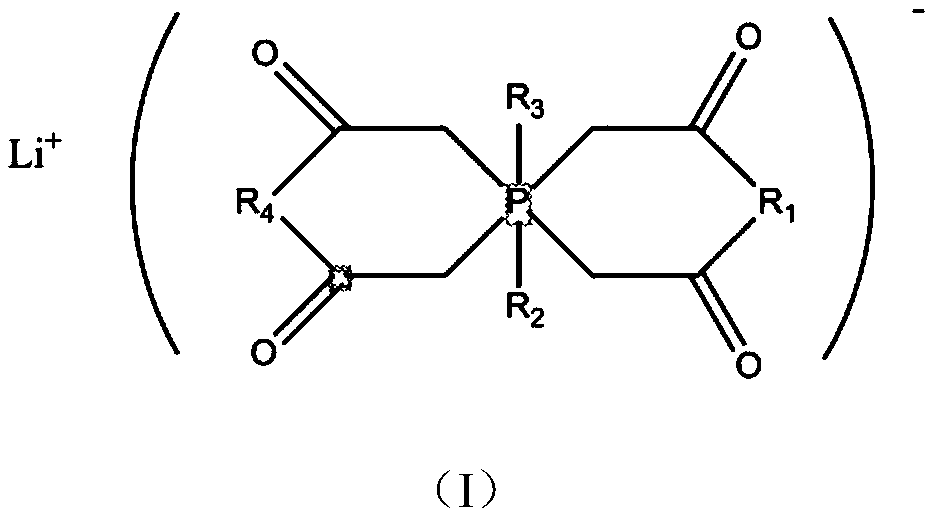

Non-aqueous electrolyte and lithium ion battery containing same

A non-aqueous electrolyte and lithium-ion battery technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of unsatisfactory high and low temperature performance of additives, achieve good performance, long cycle life, high The effect of conducting lithium ion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

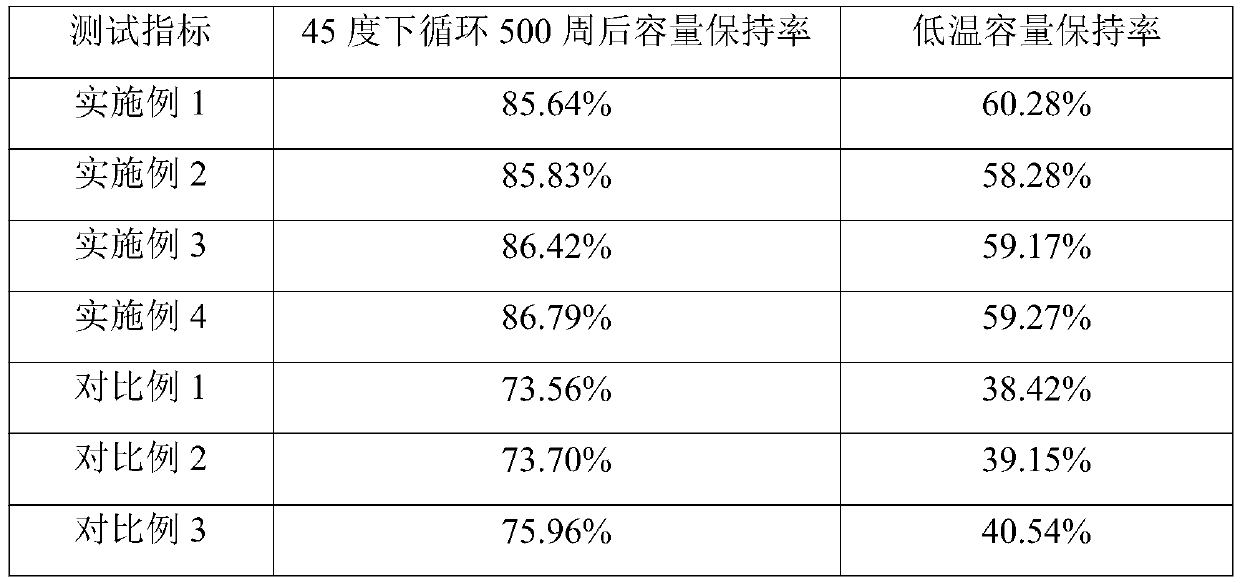

[0018] A kind of nonaqueous electrolytic solution, is made of nonaqueous organic solvent, conductive lithium salt and additive, and described nonaqueous organic solvent accounts for 84.9% of nonaqueous electrolytic solution gross mass, is made of cyclic solvent (ethylene carbonate) and linear solvent ( ethyl methyl carbonate) composition, the mass ratio of ethylene carbonate and ethyl methyl carbonate is 1:2. The conductive lithium salt is lithium hexafluorophosphate, which accounts for 10% of the total mass of the non-aqueous electrolyte. The additives were 0.1% lithium divinylbis(malonate)phosphate and 5% methylene methanedisulfonate. The electrolyte solution of this embodiment is used for LiNi 0.6 co 0.2 mn 0.2 o 2 / graphite pouch battery.

Embodiment 2

[0020] In the non-aqueous electrolytic solution of this embodiment, the non-aqueous organic solvent accounts for 72.9% of the total mass of the non-aqueous electrolytic solution, consisting of a cyclic solvent (ethylene carbonate) and a linear solvent (ethyl methyl carbonate), ethylene carbonate and carbonic acid The mass ratio of methyl ethyl ester is 1:2. The conductive lithium salt is lithium hexafluorophosphate, which accounts for 25% of the total mass of the non-aqueous electrolyte. The electrolyte additive is 2% lithium diphenylbis(malonate) phosphate and 0.1% 1,4-butane sultone. The electrolyte solution of this embodiment is used for LiNi 0.5 co 0.2 mn 0.3 o 2 / graphite pouch battery.

Embodiment 3

[0022] In the non-aqueous electrolytic solution of the present embodiment, the non-aqueous organic solvent accounts for 80% of the total mass of the non-aqueous electrolytic solution, and consists of a cyclic solvent (ethylene carbonate) and a linear solvent (ethyl methyl carbonate, dimethyl carbonate) , the mass ratio of ethylene carbonate, ethyl methyl carbonate and dimethyl carbonate is 1:1:1. Lithium hexafluorophosphate accounts for 15% of the total mass of the non-aqueous electrolyte. The electrolyte additives are 0.5% lithium difluorobis(malonate)phosphate, 0.5% lithium difluorobis(4-fluoromalonate)phosphate, and 4% ethylene sultone. The electrolyte solution of this embodiment is used for LiNi 0.8 co 0.15 Al 0.05 o 2 / graphite pouch battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com