Hydrophobic membrane structure wall fixing agent as well as preparation method and application thereof

A technology of hydrophobic membrane and wall-fixing agent, applied in the field of petroleum drilling fluid, can solve the problems of limited hydrophobicity and salt-resistance ability of wall-fixing agent, reduce filtration loss, etc., so as to reduce hydration, enhance temperature resistance and performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

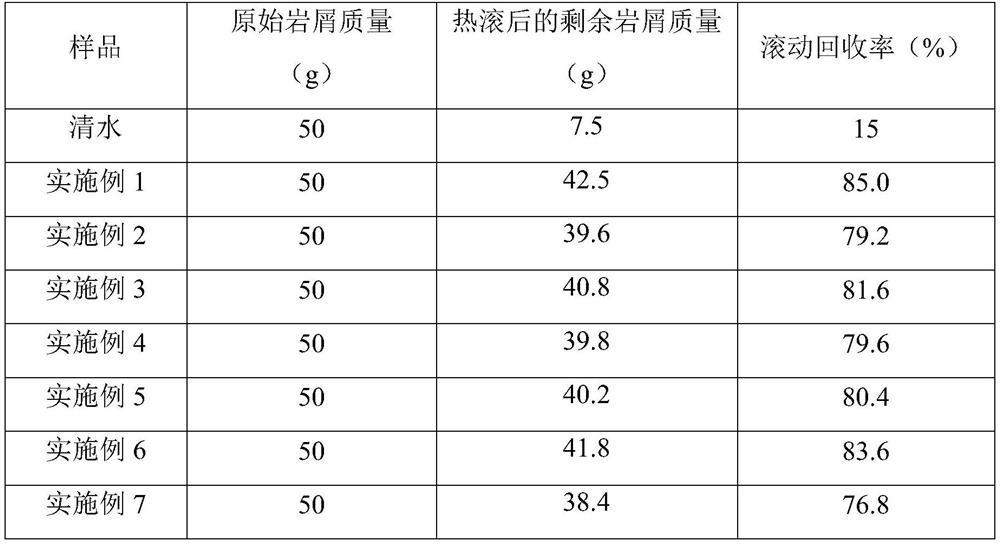

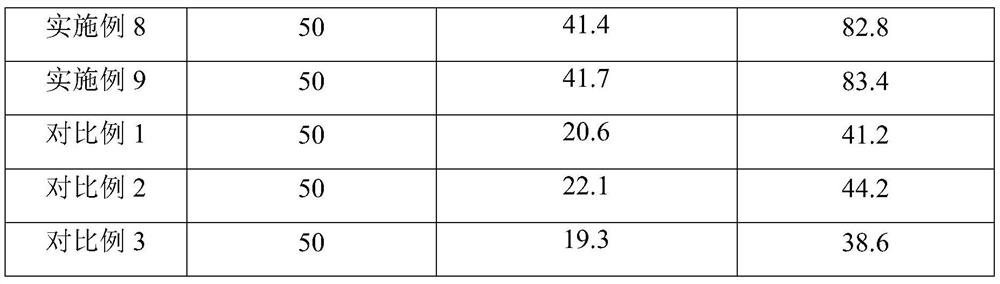

Examples

Embodiment 1

[0053] This embodiment prepares a kind of hydrophobic membrane structure wall-fixing agent, comprises the following steps:

[0054] 1) Preparation of hydrophobically modified acrylamide:

[0055] Slowly add 10g of acrylamide and 36g of lauryl acrylate into a beaker containing 120mL of ethylene glycol, stir for 40min at a magnetic stirring speed of 400r / min, and then transfer to a three-necked flask equipped with a stirring and temperature measuring device , put the three-neck flask in a water bath, set the stirring speed to 400r / min, wait for the temperature to rise to 50°C, add 5g of 25wt% ammonium persulfate aqueous solution, raise the temperature to 70°C, and react at constant temperature and speed for 6h. After the reaction is completed Centrifuge, wash the solid with ethanol several times, place it in a vacuum drying oven at 92°C and dry it to constant weight, and grind it into a powder of no less than 150 mesh.

[0056] 2) Preparation of pre-fluid A:

[0057] Slowly ad...

Embodiment 2

[0063] This embodiment prepares a kind of hydrophobic membrane structure wall-fixing agent, comprises the following steps:

[0064] 1) Preparation of hydrophobically modified acrylamide:

[0065] Slowly add 10g of acrylamide and 36g of lauryl acrylate into a beaker containing 120mL of ethylene glycol, stir for 40min at a magnetic stirring speed of 400r / min, and then transfer to a three-necked flask equipped with a stirring and temperature measuring device , put the three-neck flask in a water bath, set the stirring speed to 400r / min, wait for the temperature to rise to 50°C, add 5g of 25wt% ammonium persulfate aqueous solution, raise the temperature to 70°C, and react at constant temperature and speed for 6h. After the reaction is completed Centrifuge, wash the solid with ethanol several times, place it in a vacuum drying oven at 92°C and dry it to constant weight, and grind it into a powder of no less than 150 mesh.

[0066] 2) Preparation of pre-fluid A:

[0067] Slowly ad...

Embodiment 3

[0073] This embodiment prepares a kind of hydrophobic membrane structure wall-fixing agent, comprises the following steps:

[0074] 1) Preparation of hydrophobically modified acrylamide:

[0075] Slowly add 10g of acrylamide and 36g of lauryl acrylate into a beaker containing 120mL of ethylene glycol, stir for 40min at a magnetic stirring speed of 400r / min, and then transfer to a three-necked flask equipped with a stirring and temperature measuring device , put the three-neck flask in a water bath, set the stirring speed to 400r / min, wait for the temperature to rise to 50°C, add 5g of 25wt% ammonium persulfate aqueous solution, raise the temperature to 70°C, and react at constant temperature and speed for 6h. After the reaction is completed Centrifuge, wash the solid with ethanol several times, place it in a vacuum drying oven at 92°C and dry it to constant weight, and grind it into a powder of no less than 150 mesh.

[0076] 2) Preparation of pre-fluid A:

[0077] Slowly ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com