Filtrate reducer zwitterionic polymer for drilling fluid

A technology of fluid loss reducer and zwitterion, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor temperature resistance, easy decomposition of fluid loss reducer, and high price of fluid loss reducer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

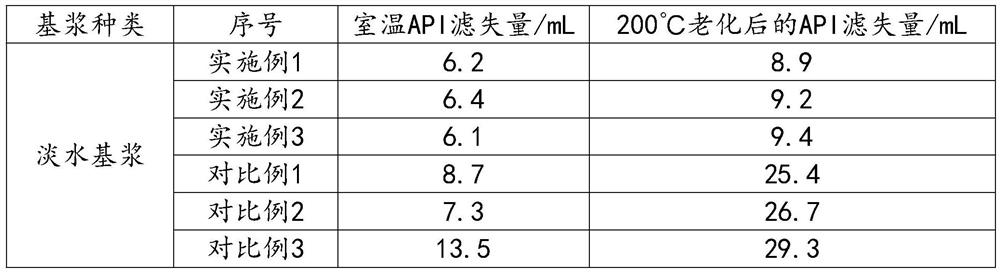

Embodiment 1

[0032] Drilling fluid fluid loss reducer zwitterionic polymer, including the following raw materials in parts by weight: 90 parts of polyacrylamide, 30 parts of 2-acrylamide-2-methylpropanesulfonic acid, 5 parts of dimethyl propyl ammonium chloride , 10 parts of sodium styrene sulfonate, 0.3 parts of initiator, 200 parts of deionized water, 50 parts of sodium hydroxide solution with a mass fraction of 40%, 20 parts of modified tapioca starch, 10 parts of modified conch shell powder, ethylene glycol 300 copies;

[0033] The preparation method of the fluid loss reducer zwitterionic polymer for this drilling fluid is as follows:

[0034] The first step is to divide the deionized water into two parts a and b according to the volume ratio of 1:3, and dissolve 2-acrylamide-2-methylpropanesulfonic acid and deionized water of part a in the reactor. Stir at 100r / min for 30min, then cool for 1h, then gradually add 40% sodium hydroxide solution to the reactor to adjust the pH to 7 to ob...

Embodiment 2

[0051] Drilling fluid fluid loss reducer zwitterionic polymer, including the following raw materials in parts by weight: 100 parts of polyacrylamide, 35 parts of 2-acrylamide-2-methylpropanesulfonic acid, 10 parts of dimethyl propyl ammonium chloride , 13 parts of sodium styrene sulfonate, 0.7 parts of initiator, 250 parts of deionized water, 55 parts of 40% sodium hydroxide solution by mass fraction, 35 parts of modified tapioca starch, 15 parts of modified conch shell powder, ethylene glycol 350 copies;

[0052] The preparation method of the fluid loss reducer zwitterionic polymer for this drilling fluid is as follows:

[0053] The first step is to divide the deionized water into two parts a and b according to the volume ratio of 1:3, and dissolve 2-acrylamide-2-methylpropanesulfonic acid and deionized water of part a in the reactor. Stir at 150r / min for 40min, then cool for 1.5h, then gradually add 40% sodium hydroxide solution to the reactor to adjust the pH to 7 to obtai...

Embodiment 3

[0070] Drilling fluid fluid loss reducer zwitterionic polymer, including the following raw materials in parts by weight: 110 parts of polyacrylamide, 40 parts of 2-acrylamide-2-methylpropanesulfonic acid, 15 parts of dimethyl propyl ammonium chloride , 15 parts of sodium styrene sulfonate, 1 part of initiator, 300 parts of deionized water, 60 parts of sodium hydroxide solution with a mass fraction of 40%, 50 parts of modified tapioca starch, 20 parts of modified conch shell powder, ethylene glycol 500 copies;

[0071] The preparation method of the fluid loss reducer zwitterionic polymer for this drilling fluid is as follows:

[0072] The first step is to divide the deionized water into two parts a and b according to the volume ratio of 1:3, and dissolve 2-acrylamide-2-methylpropanesulfonic acid and deionized water of part a in the reactor. Stir at 200r / min for 50min, then cool for 2h, then gradually add 40% mass fraction of sodium hydroxide solution to the reactor to adjust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com