Composite brightener, nanocrystalline nickel electroplate liquid and method for nickel plating on surface of workpiece based on nanocrystalline electroplate liquid

A technology of nickel electroplating solution and brightener, applied in the field of electroplating nickel, to achieve the effects of long service life, fast light speed and less decomposition products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Accurately weigh 100g of sodium saccharin, 1.2g of diethylpropargylamine, 10g of pyridinium propanesulfonate, 200g of sodium vinylsulfonate and 0.5g of S-carboxyethylisothiourea betaine, and pour them in sequence to a volume greater than 1000mL Add about two-thirds of deionized water to a container, heat to 40-50°C until it dissolves completely, stir evenly, calibrate to 1000mL after cooling to room temperature, and then transfer to a light-proof container for storage to obtain nano Crystal nickel composite brightener.

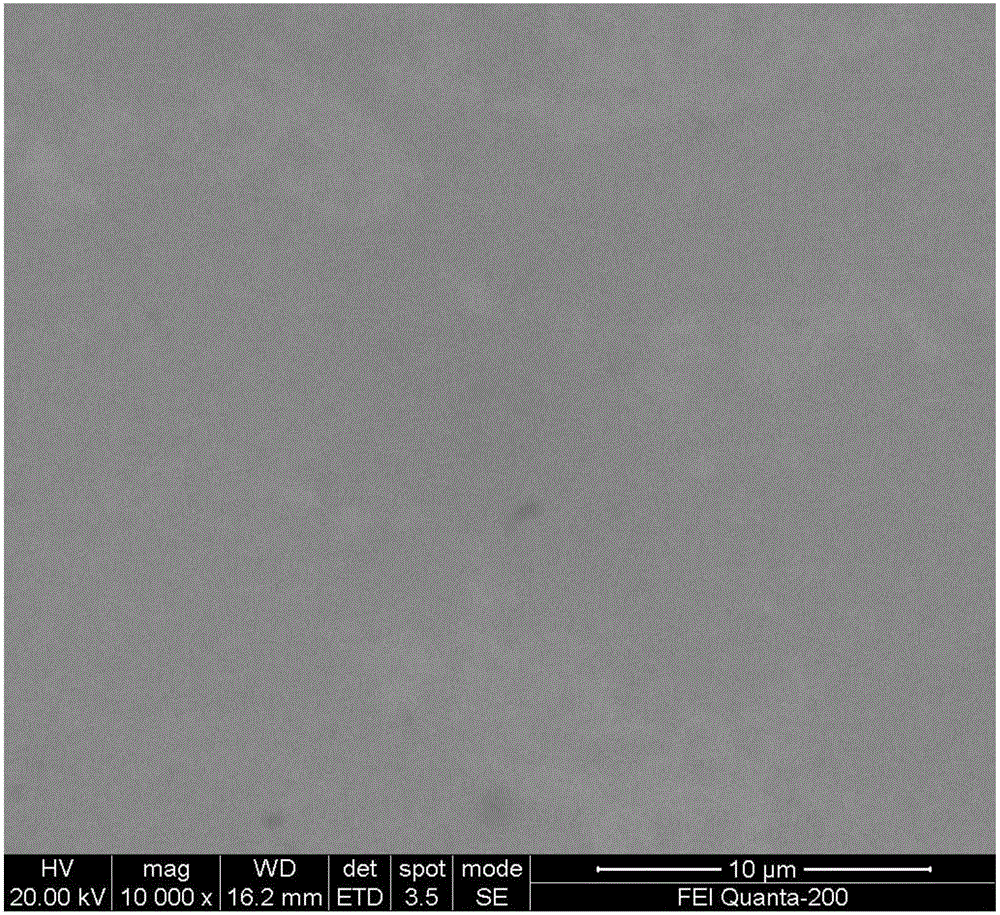

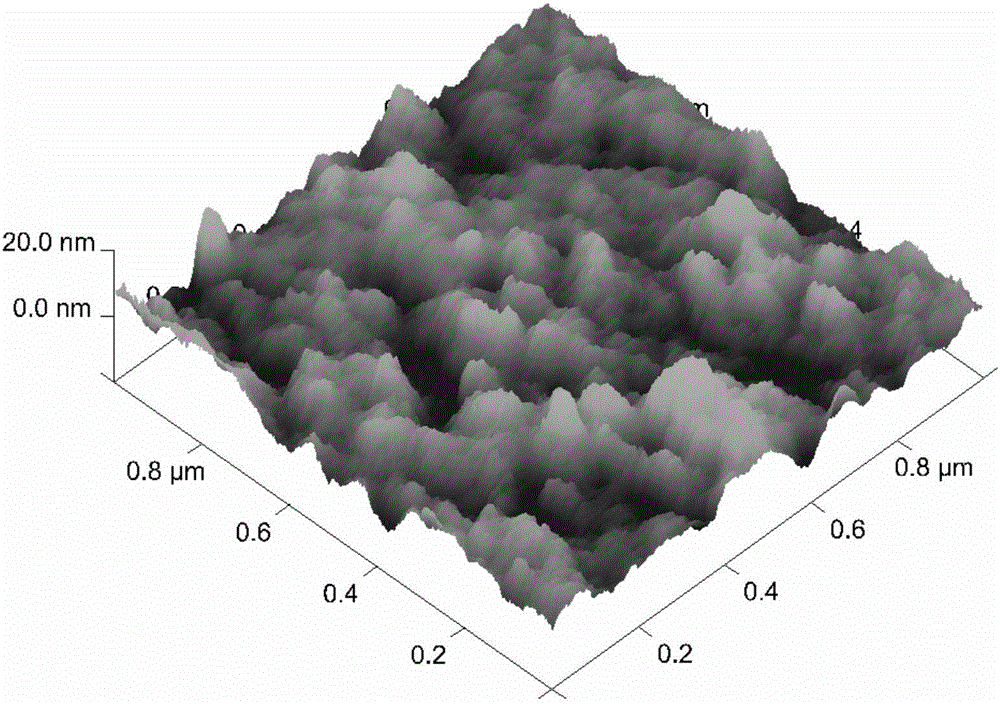

[0029] Accurately weigh nickel sulfate NiSO 4 ·6H 2 O 250g, nickel chloride NiCl 2 ·6H 2 O 40g, boric acid H 3 BO 3 35g and 0.1g of sodium lauryl sulfate were made into the working base liquid, and 10mL of composite brightener was added to the working base liquid, stirred evenly and then calibrated to 1L, and the pH of the solution was controlled within the range of 3.8-4.5 to obtain bright nanocrystals Nickel plating solution.

[0030] When usi...

Embodiment 2

[0033] Accurately weigh 150g of sodium saccharin, 1.3g of diethylpropargylamine, 12g of pyridinium propanesulfonate, 300g of sodium vinylsulfonate and 0.6g of S-carboxyethylisothiourea betaine, and pour them in order to a volume greater than 1000mL Add about two-thirds of deionized water to a container, heat to 40-50°C until it dissolves completely, stir evenly, calibrate to 1000mL after cooling to room temperature, and then transfer to a light-proof container for storage to obtain nano Crystal nickel composite brightener.

[0034] Accurately weigh nickel sulfate NiSO 4 ·6H 2 O 280g, nickel chloride NiCl 2 ·6H 2 O 45g, boric acid H 3 BO 3 40g and 0.1g of sodium lauryl sulfate were made into the working base liquid, and 10mL of composite brightener was added to the working base liquid, stirred evenly and then calibrated to 1L, and the pH of the solution was controlled within the range of 3.8-4.5 to obtain bright nanocrystals Nickel plating solution.

[0035] When using ...

Embodiment 3

[0038] Accurately weigh 120g of sodium saccharin, 1.4g of diethylpropargylamine, 14g of pyridinium propanesulfonate, 400g of sodium vinylsulfonate and 0.6g of S-carboxyethylisothiourea betaine, and pour them in order to a volume greater than 1000mL Add about two-thirds of deionized water to a container, heat to 40-50°C until it dissolves completely, stir evenly, calibrate to 1000mL after cooling to room temperature, and then transfer to a light-proof container for storage to obtain nano Crystal nickel composite brightener.

[0039] Accurately weigh nickel sulfate NiSO 4 ·6H 2 O 270g, nickel chloride NiCl 2 ·6H 2 O 40g, boric acid H 3 BO 345g and 0.2g of sodium lauryl sulfate were made into the working base liquid, and 10mL of composite brightener was added to the working base liquid, stirred evenly and then calibrated to 1L, and the pH of the solution was controlled within the range of 3.8-4.5 to obtain bright nanocrystals Nickel plating solution.

[0040] When using th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com