Multi-copolymer composite dispersant for ceramic phenol water coal water slurry and preparation method of multi-copolymer composite dispersant

A technology of composite dispersant and multi-component copolymer, which is applied in the field of environmental protection utilization of ceramic additives, can solve the problems of phenolic water pollution and environmental protection standard application, poor dispersion effect and stability, complex components of phenolic wastewater, etc., to achieve industrial application and stability Good, good pulping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

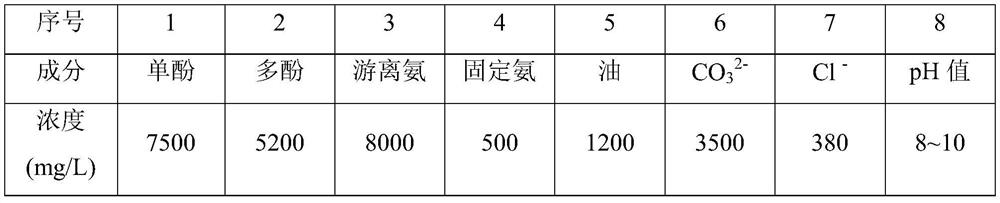

Problems solved by technology

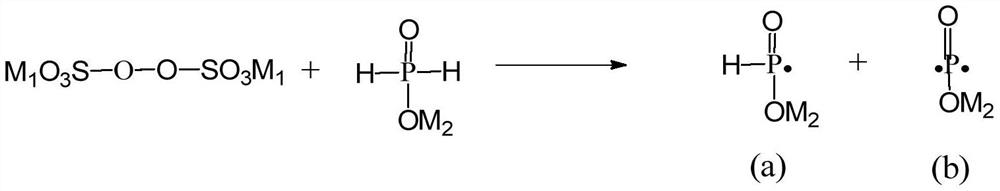

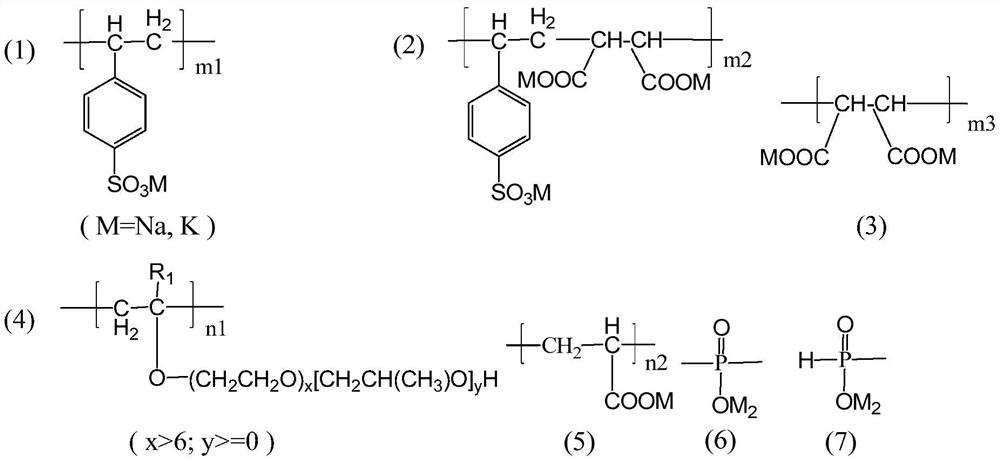

Method used

Image

Examples

example 1-1

[0035] (1) Add 300 grams of water into a 1000 ml four-neck flask equipped with electric stirring, reflux, temperature monitoring and dropping devices, heat to 60°C, add 60 grams of sodium p-styrenesulfonate, 40 grams of horsepower under stirring Toric anhydride, 70 grams of vinyl polyglycol ether EPEG (molecular weight: 1500), 30 grams of acrylic acid and 1.5 grams of sodium hypophosphite, after heating and stirring to dissolve all, heat up to 70 ° C, and then drip at a rate of 10 drops / min. Add 30 grams of 5 wt % potassium persulfate initiator aqueous solution, during the dropwise addition, the temperature rises gradually after the reaction is initiated, and keep the solution dropwise and reflux in the range of 70-85° C. for reaction.

[0036] (2) After the dropwise addition, in addition, 100 grams of acrylic acid, 132.5 grams of water and 30 grams of 5wt% potassium persulfate initiator aqueous solution were mixed uniformly at room temperature, then added dropwise in the react...

example 1-2

[0040]Get 500 grams of P1, add 200 grams of concentration under stirring and be 50wt% sodium silicate water glass (modulus is 2.0), obtain ceramic phenol-water coal-water slurry composite dispersant F1-2, concentration is 38.6wt%.

example 2-1

[0043] (1) Add 250 grams of water into a 1000 ml four-neck flask equipped with electric stirring, reflux, temperature monitoring and dropping devices, heat to 55°C, add 50 grams of sodium p-styrenesulfonate, 45 grams of Toric anhydride, 30 grams of vinyl polyethylene glycol polypropylene glycol ether EPEGPPG (molecular weight is 1000, PPG=200), 50 grams of acrylic acid and 2.5 grams of potassium hypophosphite, after all dissolving, heat up to 70 ° C, and then add 10 drops / Add 30 grams of 5wt% potassium persulfate initiator aqueous solution dropwise at a speed of 1 min. During the dropwise addition, the temperature rises gradually after the reaction is initiated, and the solution is kept dropwise and refluxed in the range of 70-90° C. for reaction.

[0044] (2) After the dropwise addition, in addition, 125 grams of acrylic acid, 131.5 grams of water and 30 grams of 5wt% potassium persulfate initiator aqueous solution were mixed uniformly at room temperature, then added dropwise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com