Method for preparing coal water slurry from butanediol (BDO) wastewater

A coal-water slurry and wastewater technology, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of subsequent treatment system poisoning and complicated treatment procedures, and achieve good slurry-forming and combustible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

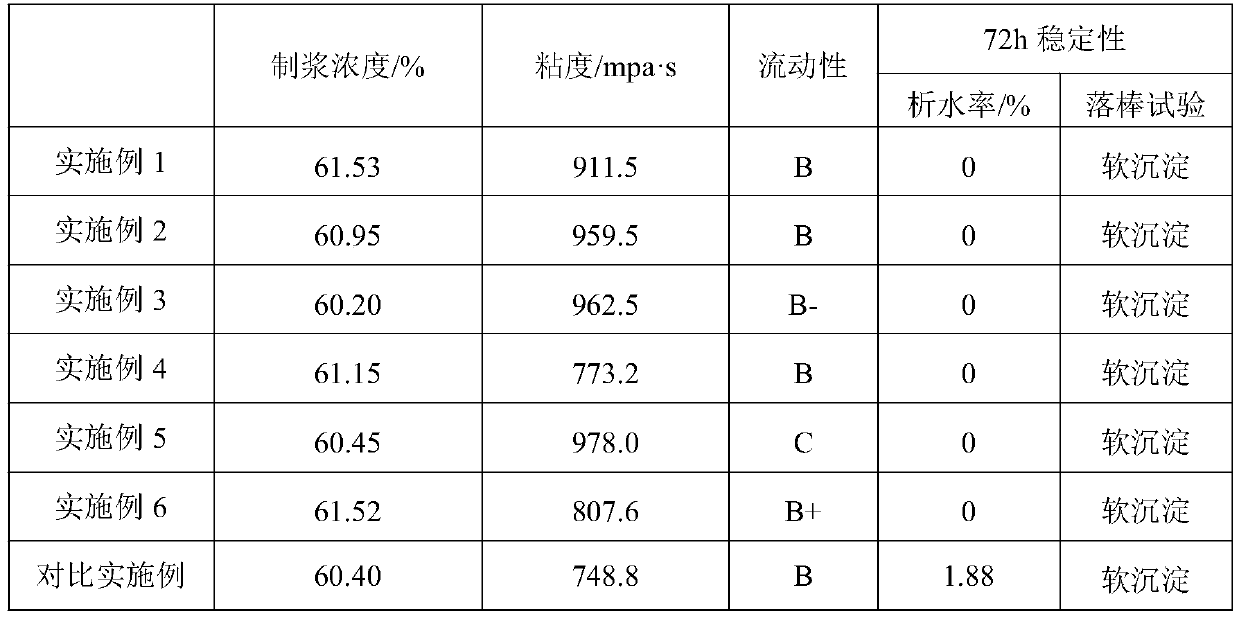

Examples

Embodiment 1

[0018] Weigh 20 parts of deionized water and 0.1 part of dispersant and pour them into the container, stir well and mix well, then add 3 parts of BDO waste water and stir to dissolve, add coal powder quickly while stirring at 200r / min, and then add it at 1200r / min After stirring for 5 minutes at a certain speed, the coal-water slurry was obtained.

[0019] Among them: the slurry concentration of coal powder is 61%, and the dispersant is a naphthalene-based coal water slurry dispersant.

Embodiment 2

[0021] Weigh 35 parts of deionized water and 0.2 parts of dispersant and pour them into the container, stir and mix well, then add 5 parts of BDO waste water and stir to dissolve, and quickly add coal powder while stirring at 350r / min, and then at 1500r / min After stirring for 7 minutes at a certain speed, the coal-water slurry was prepared.

[0022] Among them: the slurry concentration of coal powder is 61%, and the dispersant is a naphthalene-based coal water slurry dispersant.

Embodiment 3

[0024] Weigh 50 parts of tap water and 0.3 parts of dispersant and pour them into the container, stir well and mix evenly, add 7 parts of BDO wastewater and stir to dissolve, and quickly add coal powder while stirring at 500r / min, and then at a speed of 1800r / min After stirring for 10 minutes, the coal water slurry was obtained.

[0025] Among them: the slurry concentration of coal powder is 61%, and the dispersant is a naphthalene-based coal water slurry dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com