A kind of preparation method of micro-crosslinked water-based drilling fluid fluid loss reducer

A technology of water-based drilling fluid and fluid loss control agent, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve problems such as poor fluid loss control performance, increased polymer dissolution time, and increased product costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

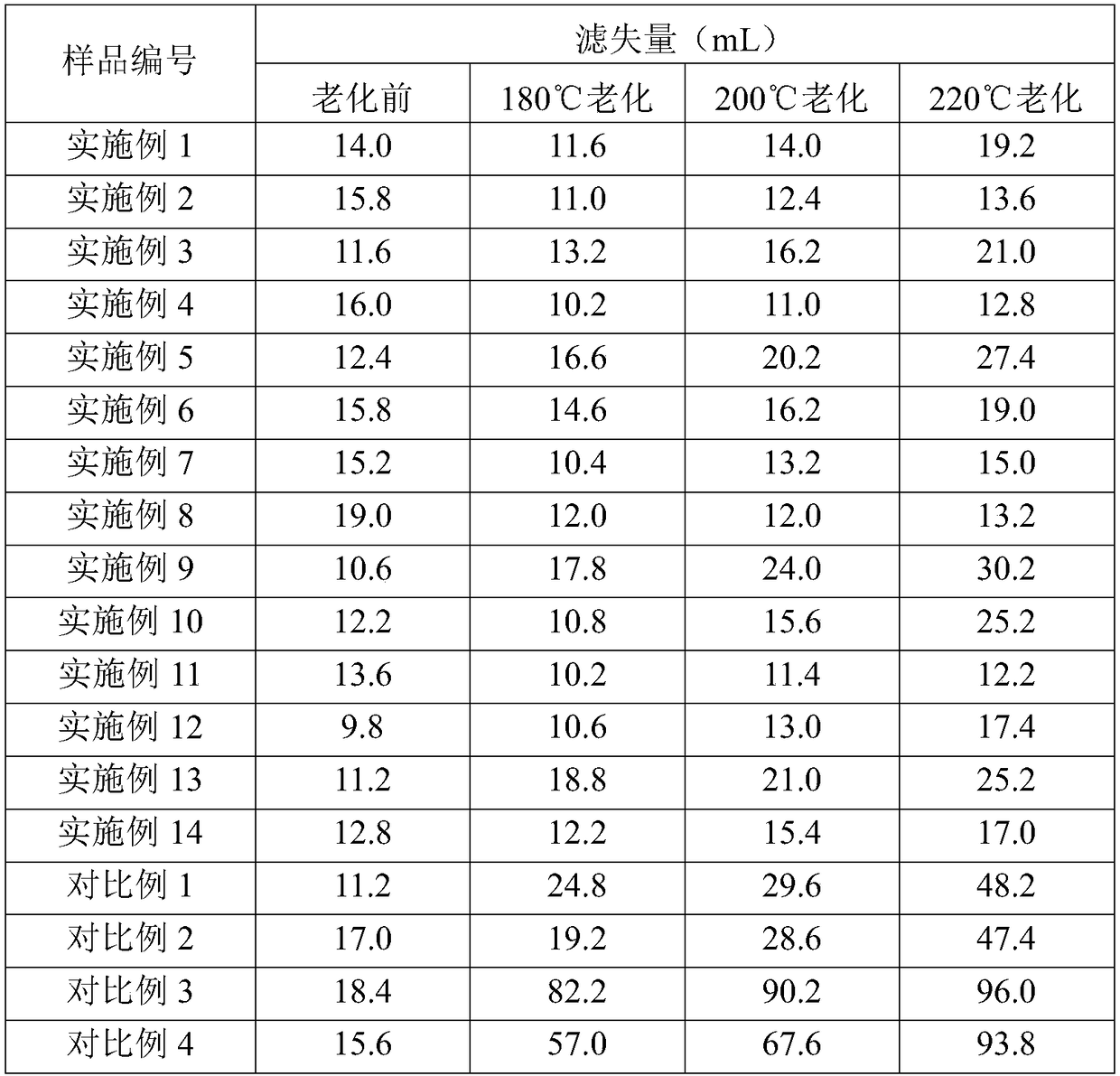

Examples

preparation example Construction

[0011] (1) Preparation of crosslinking agent

[0012] Add polyethylene polyamine, compounds containing halogen atoms and allyl groups, alkali, and acetone into a single-necked flask with magnetic stirring and a spherical condenser, stir to mix the raw materials evenly, control the temperature at 30-60°C, and magnetically stir React for 6 to 48 hours, filter the product, and distill the volatile components under reduced pressure at 50°C to obtain a viscous liquid that is the crosslinking agent; the concentration of polyethylene polyamine in acetone is 10 to 200 g / L; The mass ratio of polyethylene polyamine, halogen atom and allyl group-containing compound to base is 1:(0.5~5):(1~8);

[0013] (2) Preparation of fluid loss reducer

[0014] Add the cross-linking agent, non-ionic water-soluble monomer, anionic water-soluble monomer, and deionized water into a three-necked glass bottle equipped with a stirrer, nitrogen pipe and thermometer, stir until all raw materials are dissolve...

specific Embodiment approach

[0034] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0035] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0036] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

Embodiment 1

[0038] (1) Preparation of crosslinking agent

[0039] Add 10g of tetraethylenepentamine, 22g of allyl chloride, 30g of sodium carbonate, and 100mL of acetone into a single-necked flask with magnetic stirring and a spherical condenser, stir to mix the raw materials evenly, control the temperature at 50°C, and react under magnetic stirring After 18 hours, the product was filtered, and the volatile components were distilled off under reduced pressure at 50°C, and the obtained viscous liquid was the crosslinking agent.

[0040] (2) Preparation of fluid loss reducer

[0041] Add 10 mg of crosslinking agent, 10 g of vinylpyrrolidone, 10 g of 2-acrylamido-2-methylpropanesulfonic acid, and 120 g of deionized water into a three-necked glass bottle equipped with a stirrer, a nitrogen pipe and a thermometer, and stir After all the raw materials are dissolved, nitrogen gas is introduced for 30 minutes, the pH is controlled at 8.5, and the temperature is controlled at 35°C, then 20 mg of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com