Thickening and tackifying agent for fracturing fluid

A fracturing fluid and tackifier technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that the suspension stability of the thickening tackifier is difficult to meet high performance standards, and achieve excellent shear resistance. The effect of good performance, viscosity increasing effect and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A fracturing fluid viscosifier, comprising 30wt% white oil, 50wt% acrylamide monomer, 3wt% ethanol, 1.5wt% sorbitan fatty acid ester, 0.5wt% cetyltrimethyl Ammonium bromide, 0.5 wt% suspension stabilizer and 14.5 wt% water.

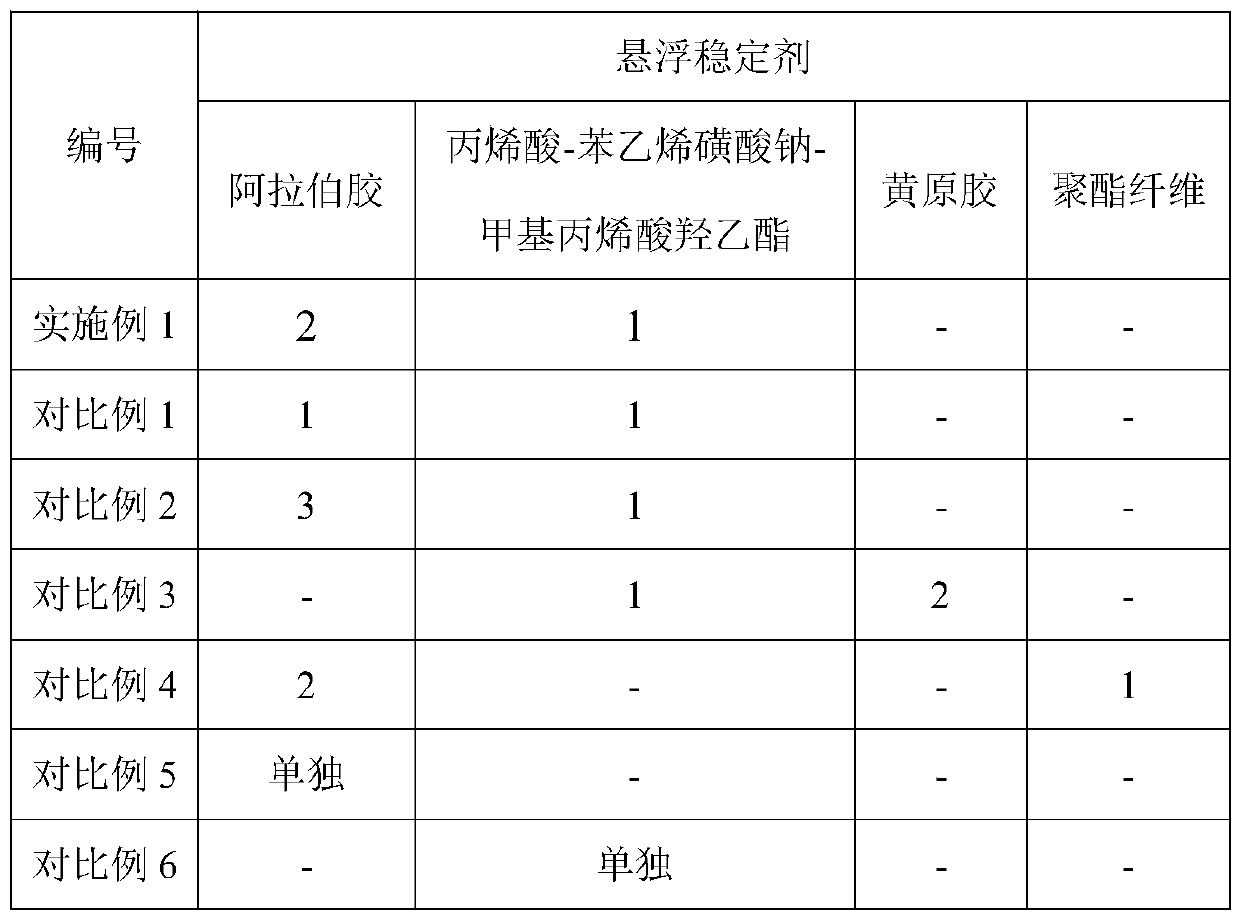

[0026] Wherein, the suspension stabilizer is composed of gum arabic and acrylic acid-sodium styrene sulfonate-hydroxyethyl methacrylate in a mass ratio of 2:1.

[0027] The preparation method of the viscosifying agent for fracturing fluid comprises the following steps:

[0028] Step 1: Pour white oil into the container, add acrylamide monomer, ethanol, sorbitan fatty acid ester under stirring;

[0029] Step 2: Pour distilled water into the container, add cetyltrimethylammonium bromide under stirring state, add suspension stabilizer after fully dissolved;

[0030] Step 3: Slowly add the solution obtained in step 2 to the solution obtained in step 1 to obtain the thickened viscosifier for fracturing fluid.

[0031] 170s-viscosity measured at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com