Halogen-free flame retardant glass fiber reinforced polyester composite and preparation method thereof

A flame-retardant glass fiber and polyester composite material technology, applied in the field of halogen-free flame-retardant glass fiber reinforced polyester composite materials, can solve the problem of high environmental hazards of halogen-containing flame retardants, high addition of inorganic flame retardants, and material Poor physical properties and other problems, to overcome the environmental hazards, improve compatibility, and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

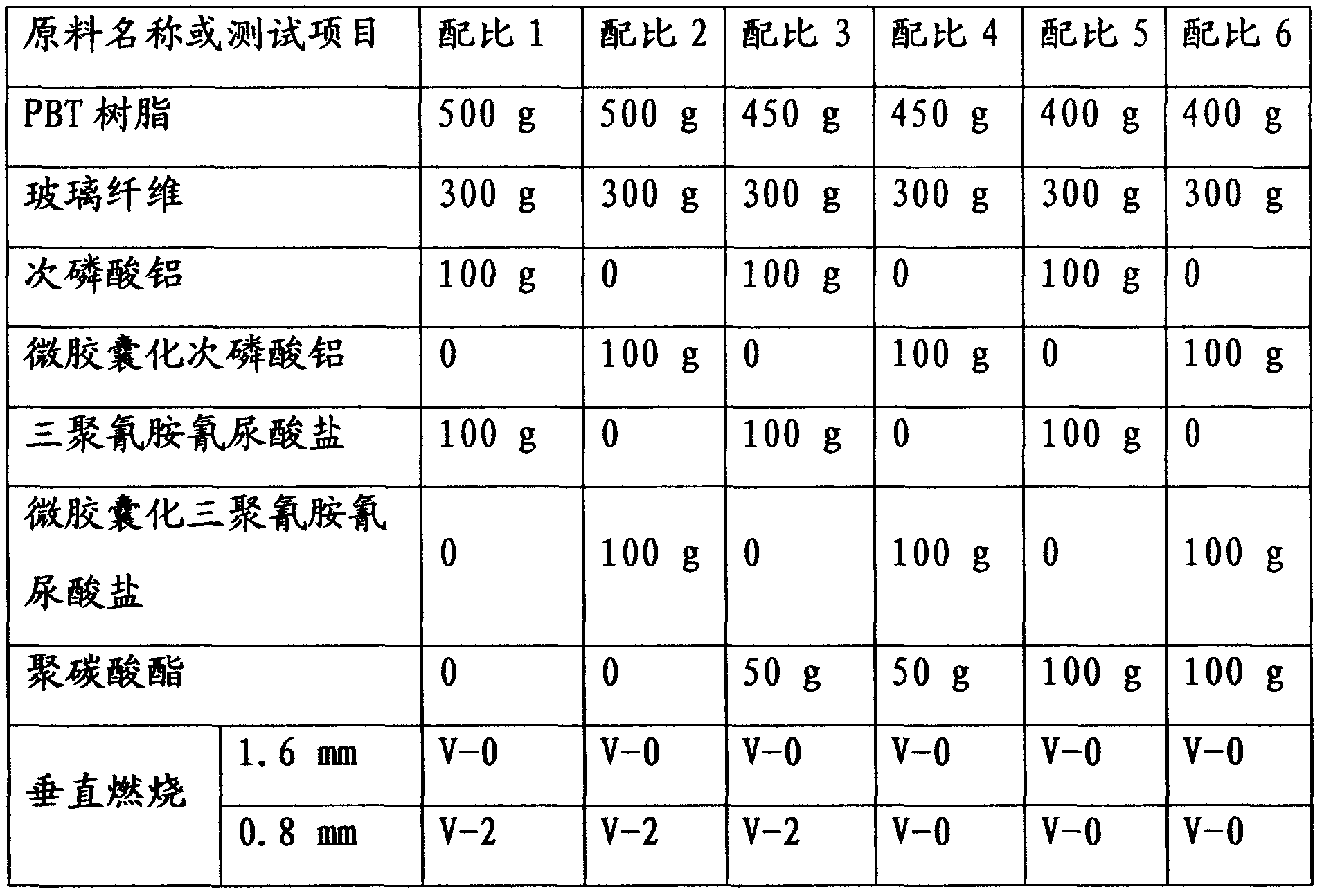

[0027] Prepare the materials according to the formula in the following table, and dry the polybutylene terephthalate (PBT) masterbatch, glass fiber, aluminum hypophosphite or microencapsulated aluminum hypophosphite, melamine cyanurate or microencapsulated Melamine cyanurate and polycarbonate are mixed evenly, heated to 230-240°C in a twin-screw extruder, melted and blended, then extruded, drawn, cooled, pelletized and dried to obtain this product Invented glass fiber reinforced polybutylene terephthalate halogen-free flame retardant composite material. Then the sample strips for oxygen index test, vertical combustion test and tensile strength test are injected by the injection molding machine, and the combustion performance and mechanical performance test are carried out. The oxygen index test is carried out according to the international standard ASTM D2863, the vertical burning test is carried out according to the international standard ASTM D2863, and the tensile strength ...

Embodiment 2

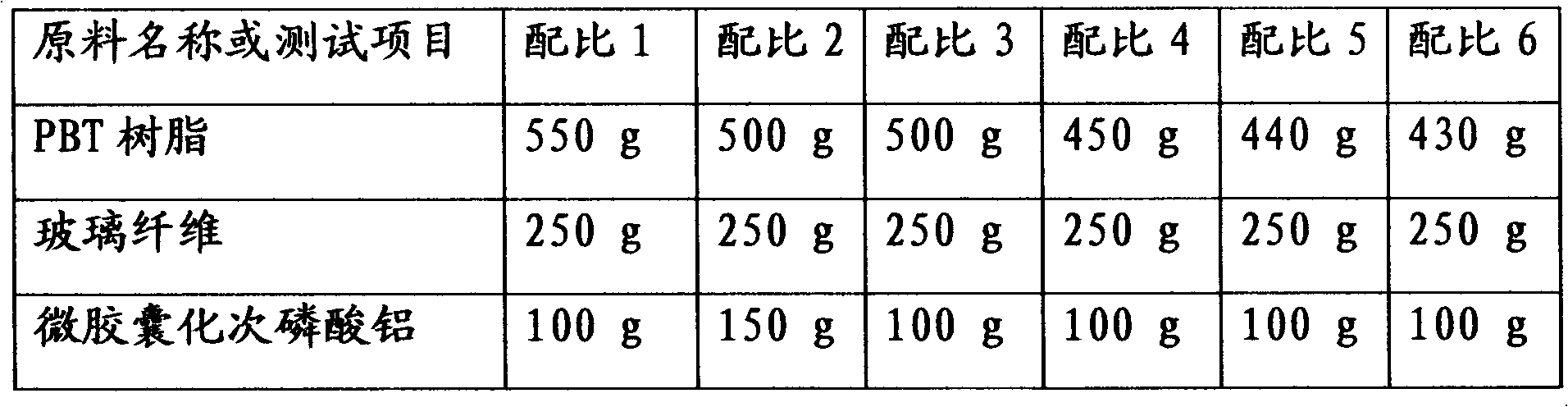

[0033] Prepare the materials according to the formula in the table below, dry polybutylene terephthalate (PBT) masterbatch, glass fiber, microencapsulated aluminum hypophosphite, microencapsulated melamine polyphosphate, polycarbonate, Mongolian Remove soil and mix evenly, heat to 230-240°C in a twin-screw extruder, melt and blend, then extrude, draw, cool, pelletize and dry to obtain the glass fiber reinforced poly Butylene phthalate halogen-free flame retardant composite material. Then the sample strips for oxygen index test, vertical combustion test and tensile strength test are injected by the injection molding machine, and the combustion performance and mechanical performance test are carried out. The oxygen index test is carried out according to the international standard ASTM D2863, and the vertical combustion test is carried out according to the international standard ASTM D2863.

[0034]

[0035]

[0036] It can be seen from the above table that the use of the fl...

Embodiment 3

[0039] Prepare the material according to the formula in the following table, and extrude the dried polyethylene terephthalate (PET) masterbatch, glass fiber, aluminum hypophosphite or microencapsulated aluminum hypophosphite, cerium oxide, Heating in the machine to 265-275°C, melt blending, extrusion, drawing, cooling, pelletizing and drying to obtain the glass fiber reinforced polyethylene terephthalate composite material of the present invention; It is also possible to add melamine cyanurate or microencapsulated melamine cyanurate to the raw material before mixing. Then the sample strips for oxygen index test, vertical combustion test and tensile strength test are injected by the injection molding machine, and the combustion performance and mechanical performance test are carried out. The oxygen index test is carried out according to the international standard ASTM D2863, and the vertical combustion test is carried out according to the international standard ASTMD2863.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com