Technology for repairing dentures by using 3D printing titanium-based composite material

A titanium-based composite material and 3D printing technology, which is applied in the field of denture restoration, can solve the problems of high porcelain collapse rate and poor bonding of human tooth tissues, and achieve the effects of good wear resistance, low porcelain stretching efficiency, and good comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The step (4) 3D printing generates the denture prosthesis by accumulating and printing layer by layer from bottom to top, and a gradual filling rate of 10% for each layer is used during the accumulative printing, that is, the density will gradually increase from bottom to top.

[0031] The particle size of the titanium-zirconium alloy powder in the step (4) is 60-70nm, and the particle size of the nanometer powder is 60-80nm.

[0032] The mass ratio of the mixed powder of magnesium oxide and aluminum oxide is 1:9.

Embodiment 2

[0034] The step (4) 3D printing generates the denture prosthesis by accumulating and printing layer by layer from bottom to top. During the accumulative printing, a gradient filling rate of 20% is used for each layer, that is, the density will gradually increase from bottom to top.

[0035] The particle size of the titanium-zirconium alloy powder in the step (4) is 60-70nm, and the particle size of the nanometer powder is 60-80nm.

[0036] The mass ratio of the mixed powder of magnesium oxide and aluminum oxide is 1:9.

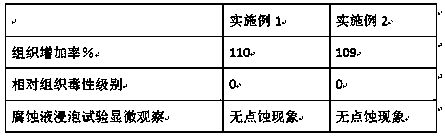

[0037] Biocompatibility and corrosion resistance test of the present invention (corrosion resistance: soaked in sodium chloride 10g / L + sodium bicarbonate 5g / L aqueous solution, PH=6.7)

[0038]

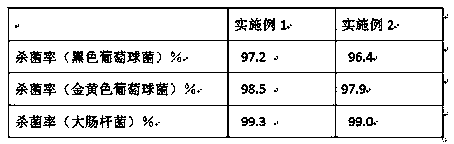

[0039] Antibacterial test of the present invention

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com