Self-repairing, breathable and wear-resisting composite coating and preparation method and application thereof

A composite coating, wear-resistant technology, applied in coatings, protein coatings, polyester coatings, etc., to achieve significant popularization and application value, excellent room temperature self-repairing function, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a composite coating with self-repairing, breathable and wear-resistant properties, which specifically includes the following steps:

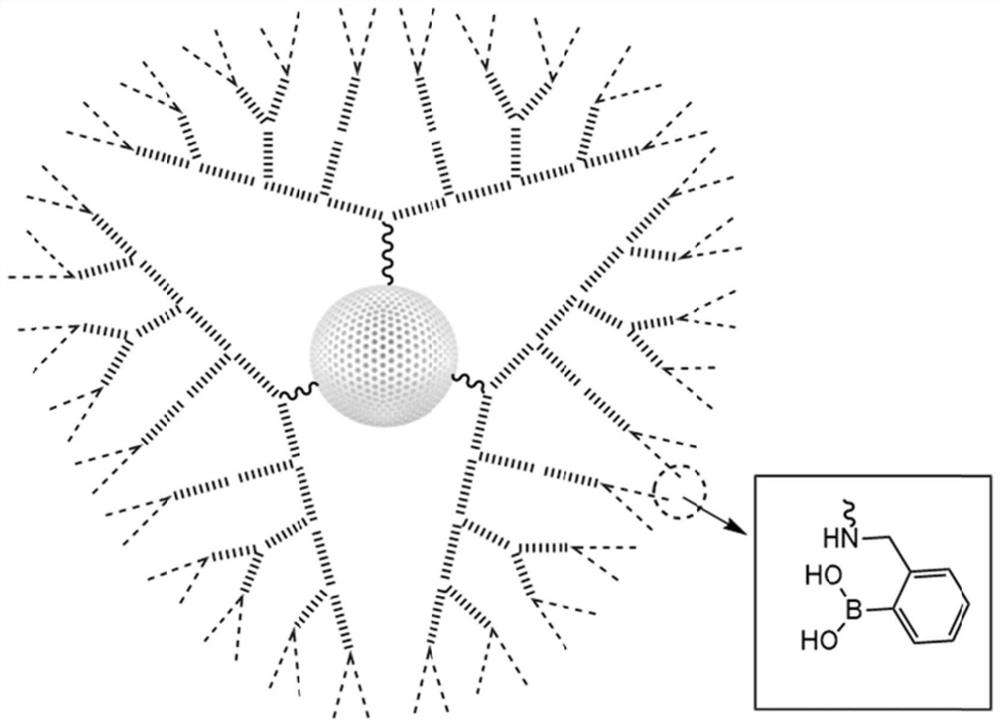

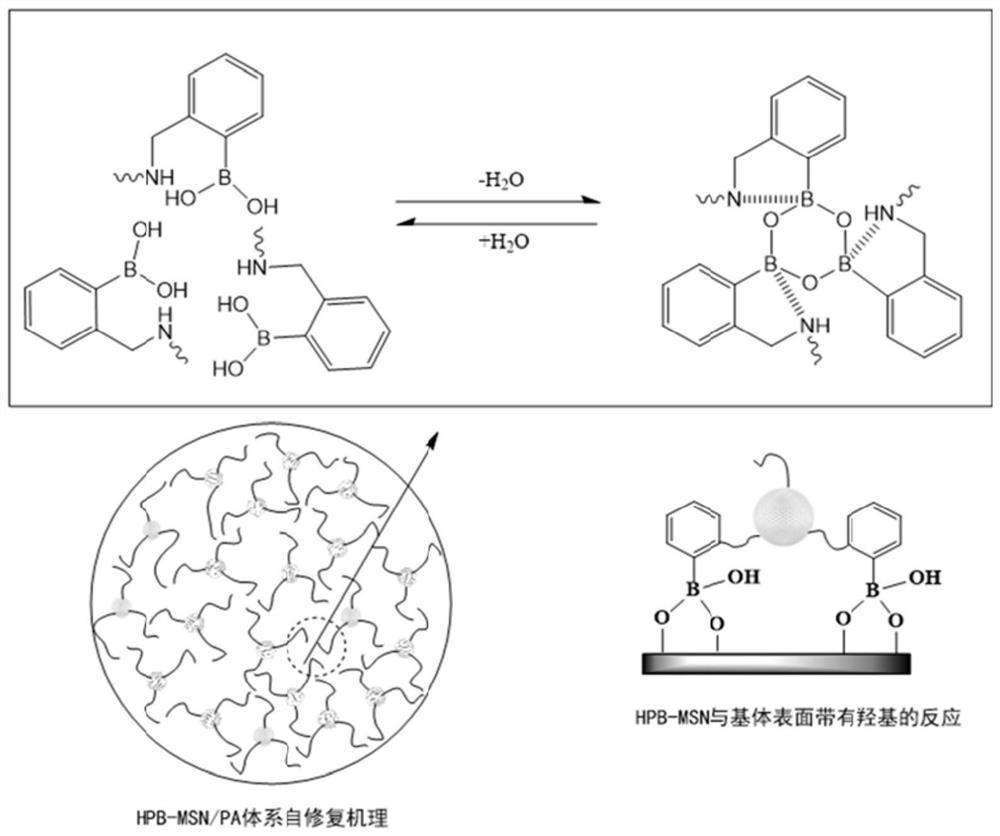

[0033] Step 1. Prepare hyperbranched polyphenylboronic acid-grafted mesoporous silica nanoparticles (HPB-MSN); wherein, the preparation process is as follows:

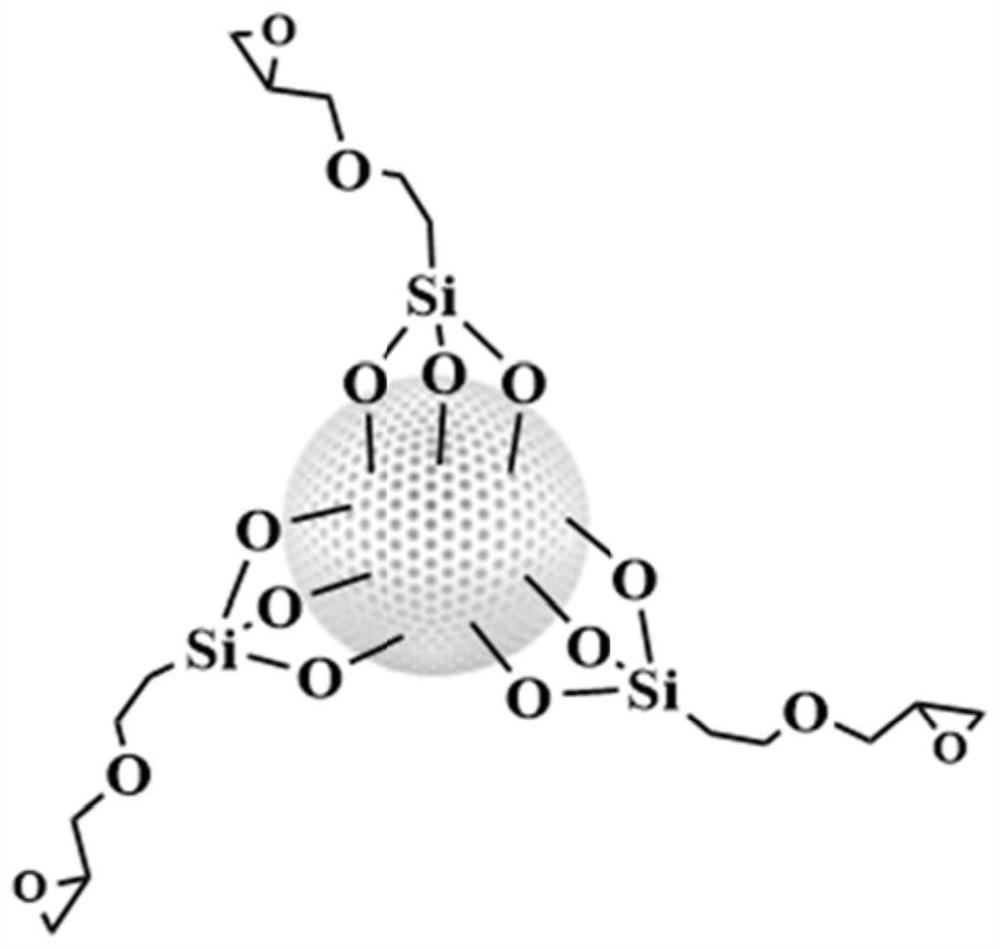

[0034] Step 11. In terms of parts by mass, take 0.1-10 parts of MSN and 0.5-50 parts of KH560 and disperse them in 10-100 parts of the first solvent, adjust the pH of the solution to 4, and stir under ultrasonic stirring and N 2 Under protective atmosphere conditions, carry out hydrolysis condensation reaction, in order to graft KH560 onto the surface of MSN, prepare KH560-MSN; as attached figure 1 shown, with figure 1 The structure diagram of the KH560-MSN is given in ; figure 1 As can be seen in , KH560 grafted MSN was achieved, where MSN was used as nanofiller.

[0035] Wherein, the first solvent is a good solvent of MSN; specifi...

Embodiment 1

[0057] This embodiment 1 provides a method for preparing a composite coating with self-repairing, breathable and wear-resistant properties, which specifically includes the following steps:

[0058] Step 1. Prepare hyperbranched polyphenylboronic acid-grafted mesoporous silica nanoparticles (HPB-MSN); wherein, the preparation process is as follows:

[0059] First, in terms of parts by mass, 0.1 part of MSN and 0.5 part of KH560 were dispersed in 100 parts of methanol solution, and the pH of the solution was adjusted to 4. After ultrasonic stirring and N 2 Under the condition of protective atmosphere, the hydrolysis and condensation reaction is carried out to prepare KH560-MSN.

[0060] Next, put the above-prepared KH560-MSN in 10 parts of tetrahydrofuran, and add 0.2 parts of 4-butanediol diglycidyl ether and 0.2 parts of trimethylol propane trimerglycol ether (amino-terminated) , at a temperature of 55°C, N 2 Under the condition of atmosphere, reflux reaction for 8h; through...

Embodiment 2

[0069] This embodiment 2 provides a method for preparing a composite coating with self-repairing, breathable and wear-resistant properties, which specifically includes the following steps:

[0070] Step 1. Prepare hyperbranched polyphenylboronic acid-grafted mesoporous silica nanoparticles (HPB-MSN); wherein, the preparation process is as follows:

[0071] First, in terms of parts by mass, 1 part of MSN and 10 parts of KH560 were dispersed in 100 parts of ethanol solution, and the pH of the solution was adjusted to 4. After ultrasonic stirring and N 2 Under the condition of protective atmosphere, the hydrolysis and condensation reaction is carried out to prepare KH560-MSN.

[0072] Next, the KH560-MSN prepared above was placed in 50 parts of tetrahydrofuran, and 5 parts of resorcinol diglycidyl ether and 5 parts of tris(3-aminopropyl)amine were added respectively, at a temperature of 55 °C, N 2 Under the condition of atmosphere, reflux reaction for 8h; through the ring-openi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com