Technology method for improving surface abrasion resistance of laser additive manufacturing metal artificial knee joint

An artificial knee joint, laser additive technology, applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of poor toughness, high difficulty, shortened service life, etc., to reduce the tendency of brittle fracture and reduce Penetration and erosion, life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The process for improving the wear resistance of the surface of the laser additively manufactured metal artificial knee joint comprises the following steps:

[0040] 1) Sandblasting treatment: sandblasting treatment is carried out on the surface of the articular surface of the artificial knee joint, and the surface roughness reaches Ra3.2. White corundum is used for sandblasting, the particle size is 46 mesh, the sandblasting pressure is 0.5Mpa, and the spraying distance is 250mm.

[0041] 2) Preheating treatment: Cobalt-chromium-molybdenum alloy is heated to 45°C, and the sprayed nano-zirconia powder is heated to 45°C, and the heat of the alloy is kept during the spraying process.

[0042] 3) Plasma spraying of the sprayed surface with zirconia ceramic powder: a layer of 250 μm zirconia ceramic layer is prepared by plasma spraying on the cobalt-chromium-molybdenum artificial knee joint surface, which has excellent wear resistance. The current of the plasma spraying pr...

Embodiment 2

[0045] The process for improving the wear resistance of the surface of the laser additively manufactured metal artificial knee joint comprises the following steps:

[0046] 1) Sandblasting treatment: sandblasting treatment is carried out on the surface of the articular surface of the artificial knee joint, and the surface roughness reaches Ra3.2. White corundum is used for sandblasting, the particle size is 46 mesh, the sandblasting pressure is 0.5Mpa, and the spraying distance is 250mm.

[0047] 2) Preheating treatment: Cobalt-chromium-molybdenum alloy is heated to 45°C, and the sprayed nano-zirconia powder is heated to 45°C, and the heat of the alloy is kept during the spraying process.

[0048] 3) Plasma spraying of the sprayed surface with zirconia ceramic powder: a layer of 250 μm zirconia ceramic layer is prepared by plasma spraying on the cobalt-chromium-molybdenum artificial knee joint surface, which has excellent wear resistance. The current of the plasma spraying proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

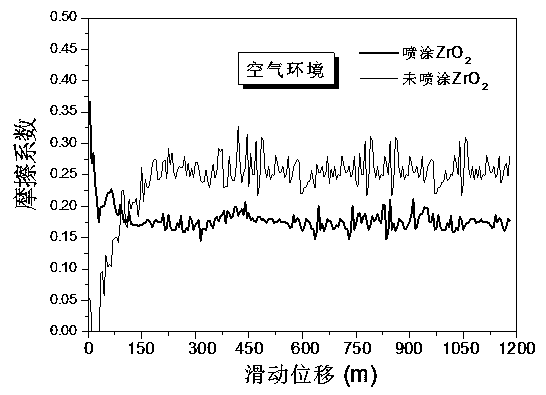

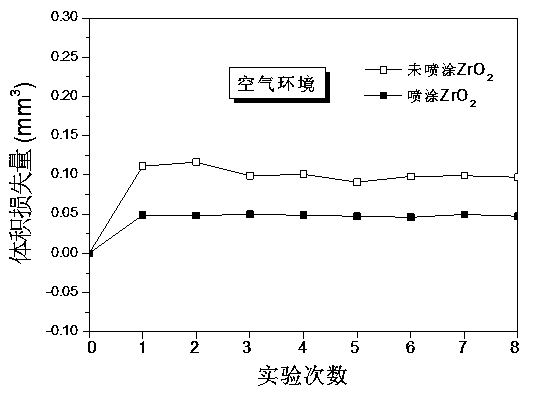

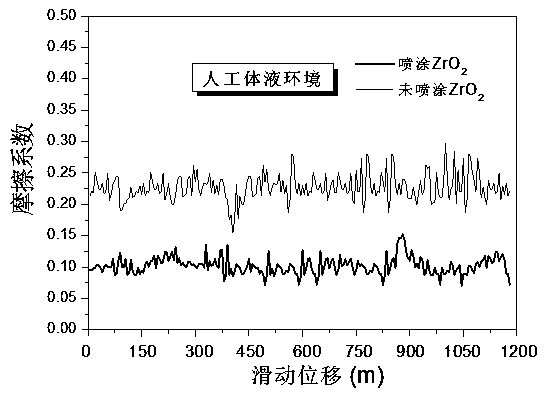

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com