Patents

Literature

43results about How to "Does not affect molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

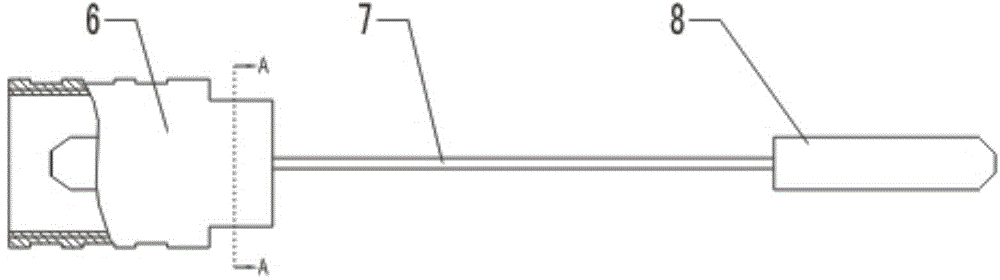

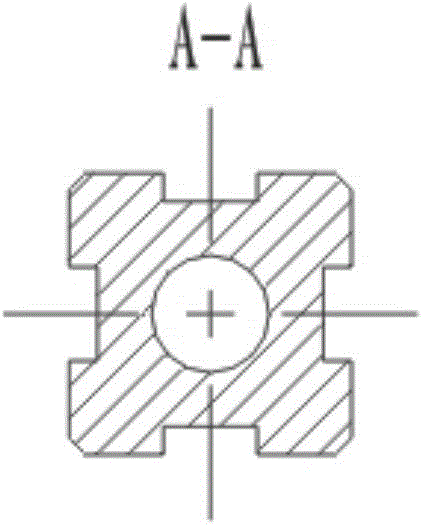

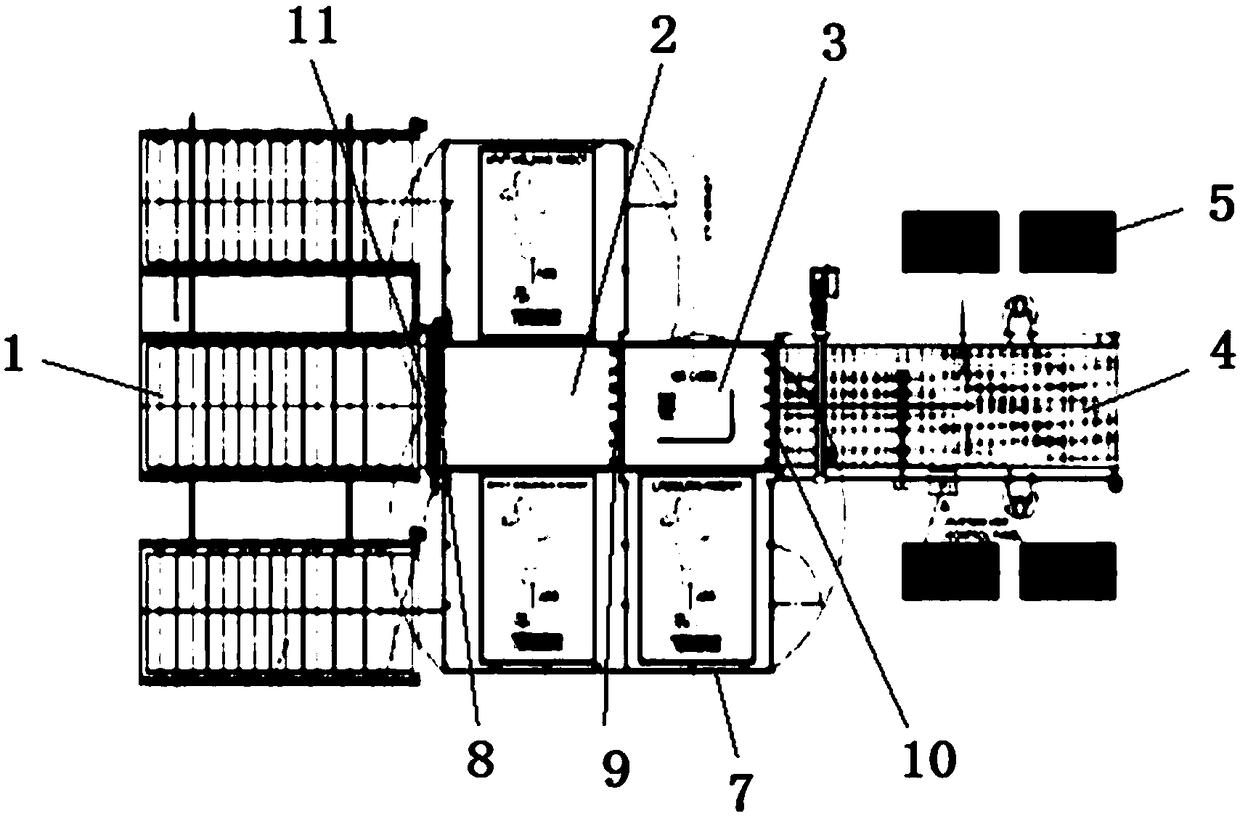

Method for measuring temperature of high-voltage/extra-high-voltage cable connector by using fiber

InactiveCN104977097AExtended service lifeSave installation timeThermometers using physical/chemical changesOperating temperatureBiomedical engineering

Provided is a method for measuring the temperature of a high-voltage / extra-high-voltage cable connector by using a fiber. The method is characterized by comprising an external temperature-measuring fiber 1, an internal temperature-measuring fiber 5, a temperature-measuring probe fixing clamp 9, and a temperature demodulator 13. The external temperature-measuring fiber 1 comprises a ST fiber connector 2, an external fiber 3, and an external fiber connector 4 which are successively connected. The internal temperature-measuring fiber 5 comprises an adapter embedded member 6, an internal fiber 7, and a temperature-measuring probe 8 which are successively connected. The temperature-measuring probe fixing clamp 9 fixes the temperature-measuring probe 8 to an end cap embedded member 11 by means of a screw 10. The internal temperature-measuring fiber 5 is connected with the external fiber connector 4 via the adapter embedded member 6. The external temperature-measuring fiber 1 is connected with the fiber interface 14 of the temperature demodulator 13 through the ST fiber connector 2. The method online monitors the operating temperature of a cable connector in real time.

Owner:西安和其光电科技股份有限公司

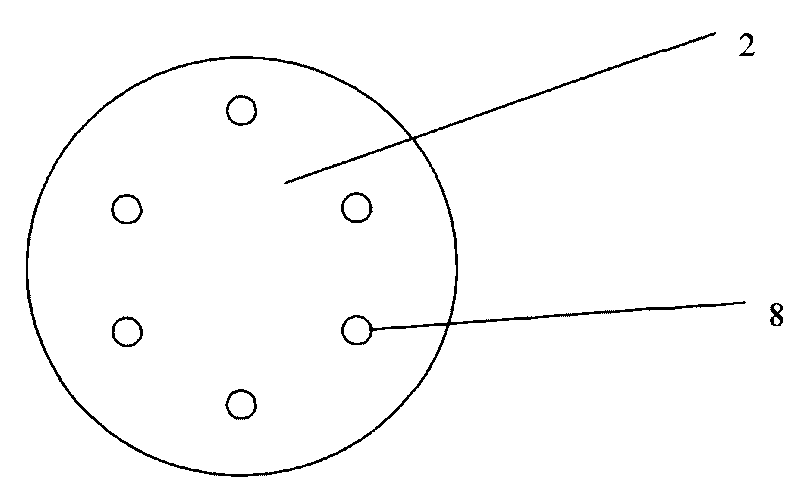

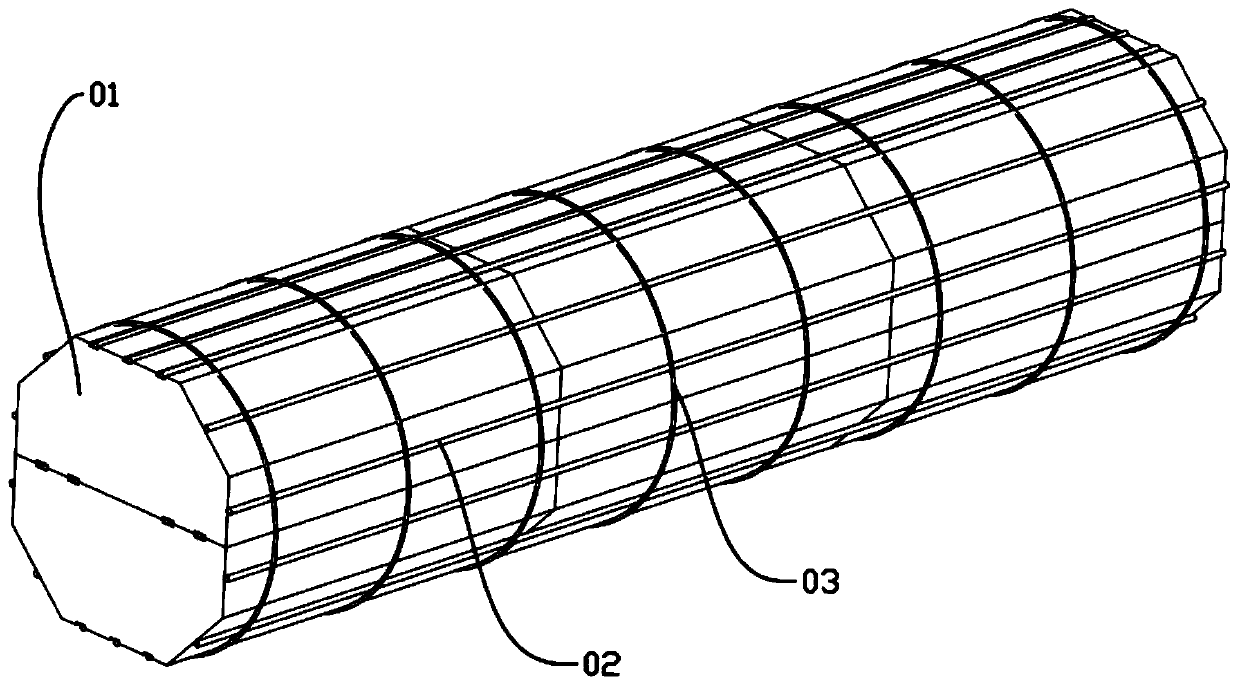

Manufacturing method of spandex heavy denier yarn

ActiveCN101760798ASolve false twistSolve the problem of difficult windingMonocomponent polyurethanes artificial filamentWet spinning methodsYarnEngineering

The invention relates to a manufacturing method of spandex heavy denier yarn, comprising the following steps of: (1) prepolymerization; (2) polymerization and (3) spinning: false twisting spandexes through a high-speed mechanical false twister, guiding the spandexes by using three spandex guiding rollers, applying oil by using an oil applying roller, and then winding the spandexes into yarn rolls on a winder through adjusting a winding angle and a winding parameter, wherein the diameters of the spandex guiding rollers and the oil applying roller are 25%-35% larger than the conventional diameters, the hole diameters of plate holes of a spinning plate are 80%-120% greater than the conventional hole diameters, and the number of the plate holes of the spinning plate is 100%-150% more than the conventional number. The manufacturing method has the advantages of solving the problems of difficult false twisting and winding of the heavy denier yarn and being suitable for the production of the heavy denier yarn, and the product has favorable rebound resilience.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

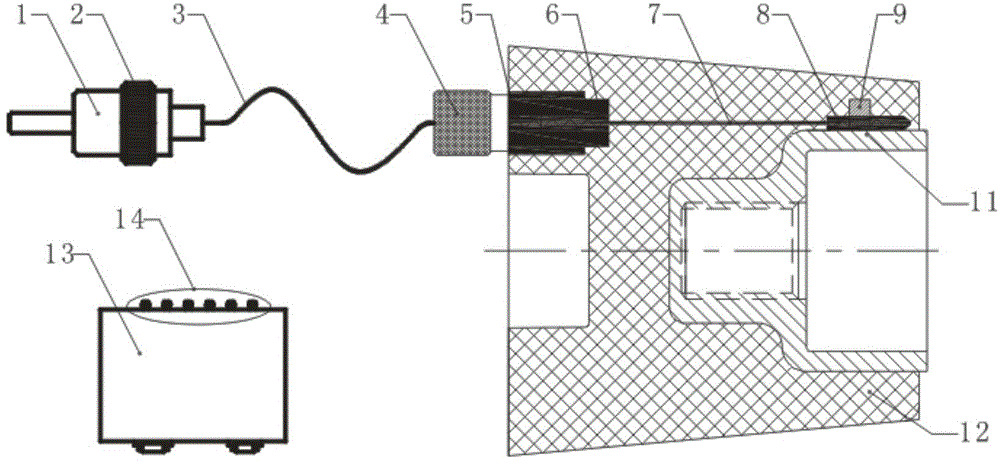

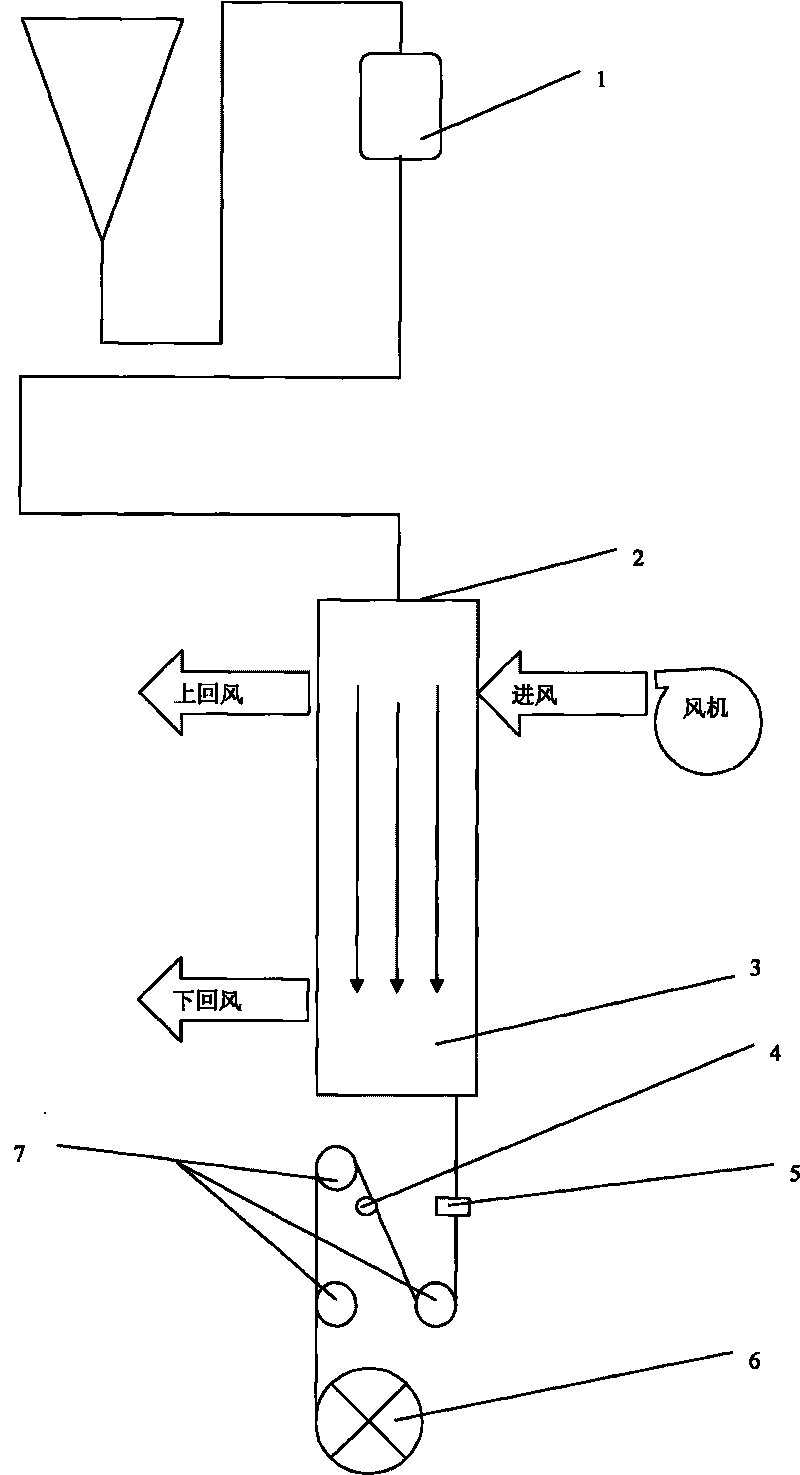

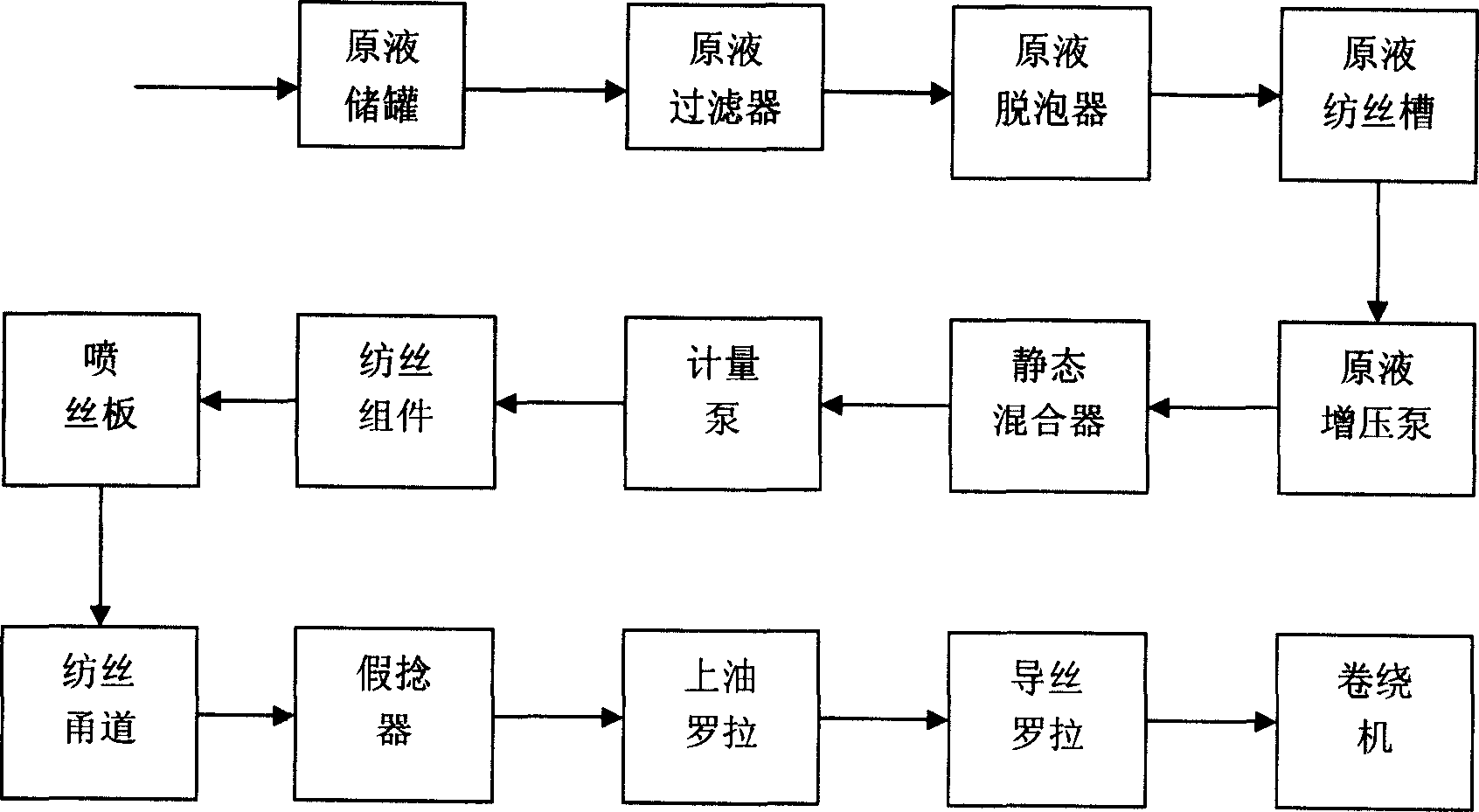

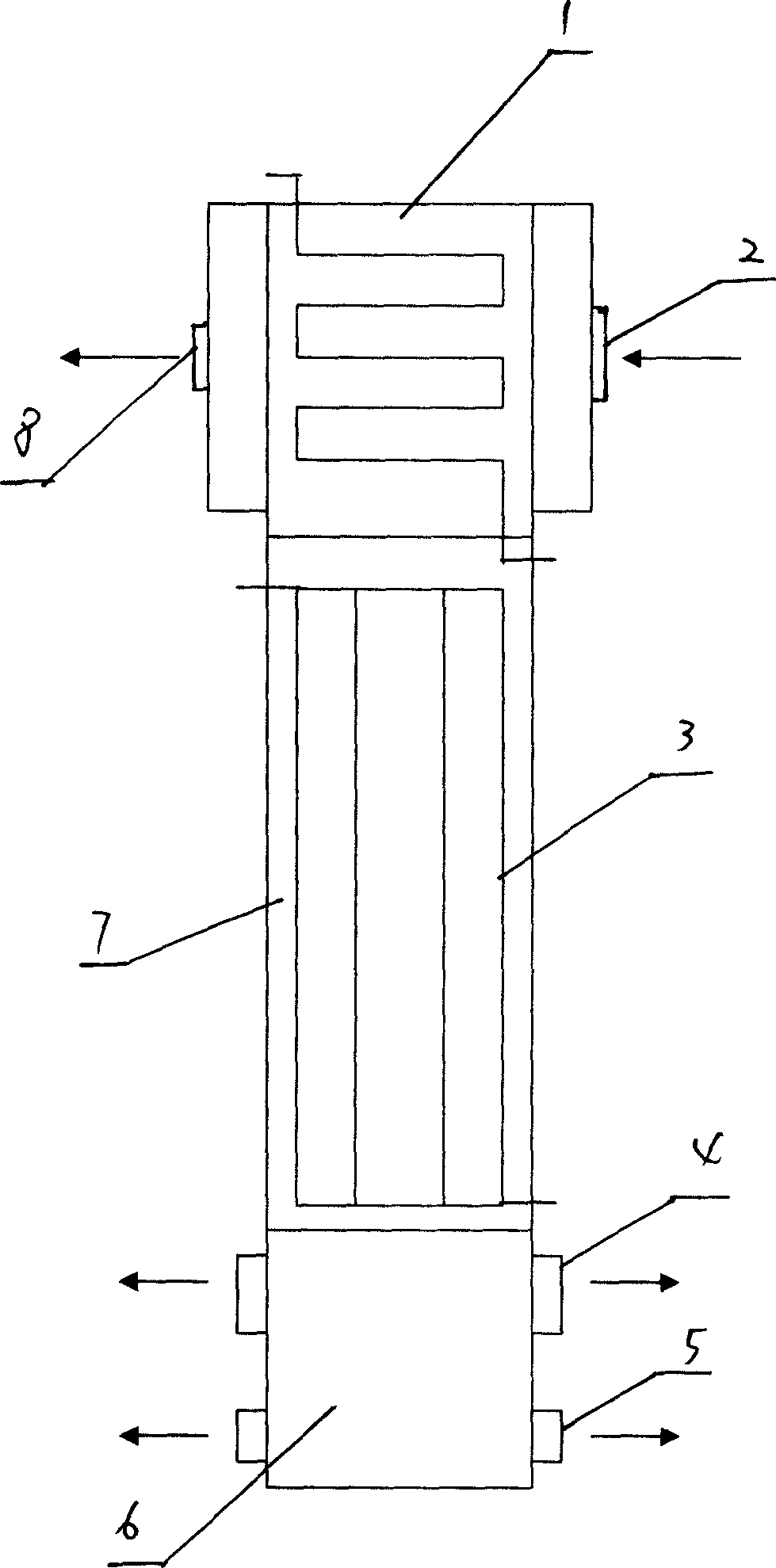

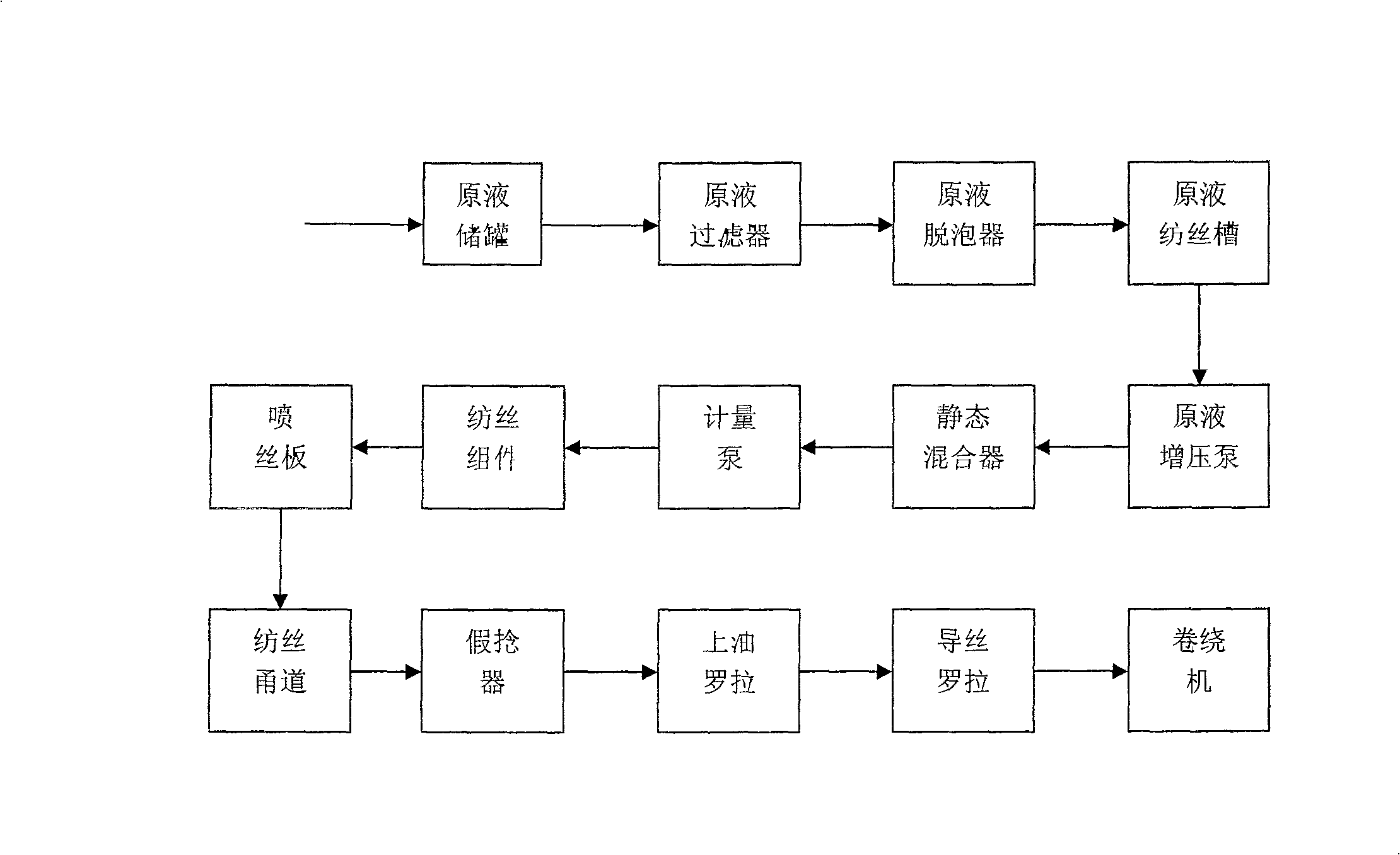

New technology of spandex fiber

InactiveCN1904152AStable temperature controlUniform temperature controlFilament/thread formingFiberFiltration

This invention relates to a new kind of spandex spinning technology. Send stock solution has undergone polymerization to storage jar for ripening, then through filtration, getting out of bubble, and entering spinning slot, pressing send by nitrogen gas and gear pump pressurize it into static mixer; Through the measuring pump to spit out stock solution and filtering it in spinning module, then allocate to spurt filament plate and spurt out from it; Evaporate out solvent in the spinning path and solidify it to spandex ammonia silk beam, then through false twisting, adding oil and rolling on the rolling machine to pack silk roll. This invention increase static mixer to suit 32 head spinning, reduce adverse effect caused by polymer which make gradient difference of temperature, residence time and viscosity along the radial of pipe; control the actuality temperature out of circulatory mediator in jar, spinning slot, static mixer and partner heat equipment, keep the homogenicity and stability after increasing the spinning air quantity and blast temperature, and increase volatilizing speed but not effect strand form.

Owner:连云港杜钟氨纶有限公司

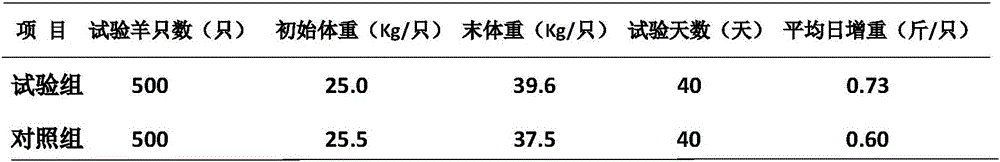

TMR (total mixed ration) biological granular feed for sheep and preparation method of TMR biological granular feed

InactiveCN106306446AIncrease NDF valueDoes not affect moldingFood processingAnimal feeding stuffAnimal scienceHusk

The invention discloses TMR (total mixed ration) biological granular feed for sheep and a preparation method of the TMR biological granular feed. The TMR biological granular feed is prepared from components in parts by weight as follows: 20-60 parts of corn, 4-15 parts of byproducts of cereals, 3-16 parts of soybean meal, 3-12 parts of DDGS, 0.05-0.2 parts of multivitamins, 0.05-0.2 parts of minerals, 2-10 parts of a biological fermentation material, 10-20 parts of rice husks, 10-20 parts of sunflower seed husk and the like. The preparation method of the TMR biological granular feed comprises the following steps: (1) raw material cutting and crushing; (2) raw material weighing and mixing; (3) low-temperature granulation. The TMR biological granular feed and the preparation method of the TMR biological granular feed have the advantages that characteristics of the biological feed are highlighted, the production technology combines a modern microbial fermentation technology, a TMR preparation technology and a low-temperature granulation technology, the production cost is lower, the feed is convenient use, and the breeding requirements for modern, intensive and large-scale animal husbandry are met.

Owner:INNER MONGOLIA YOUMUTE AGRI ANIMAL HUSBANDRY TECH CO LTD

Preparation method of fruit and vegetable enzyme pudding

InactiveCN106722171AFormulation ScienceReasonable formulaFood ingredient functionsAppetiteFruits and vegetables

The invention discloses a preparation method of fruit and vegetable enzyme pudding. The preparation method comprises the following steps of (1) preparation of fruit enzyme; (2) preparation of vegetable enzyme; (3) preparation of fruit and vegetable enzymes; (4) preparation of fruit and vegetable enzyme ice balls; (5) preparation of pudding liquid; (6) preparation of fruit and vegetable enzyme pudding. The preparation method has the advantages that the fruit and vegetable enzyme ice balls are added in the pudding preparation process, so that the influence to the shaping of the pudding is avoided, and the self activity of the enzyme is also maintained; the formula of the enzyme pudding is scientific, the technology is reasonable, the mouth feel is better, and the functions of invigorating stomach and promoting appetite, and tonifying liver are realized.

Owner:ZHEJIANG BAIHUI BIOLOGICAL TECH

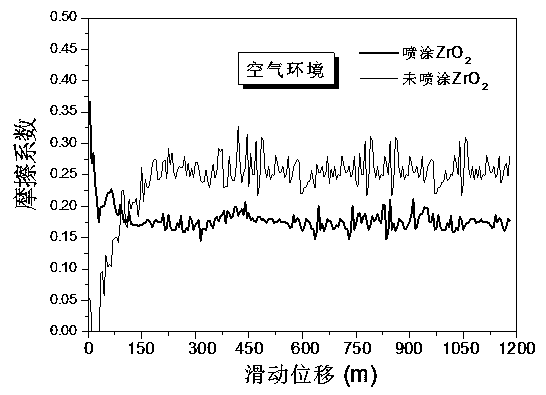

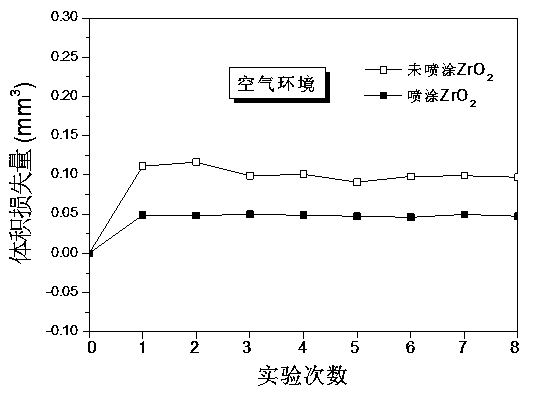

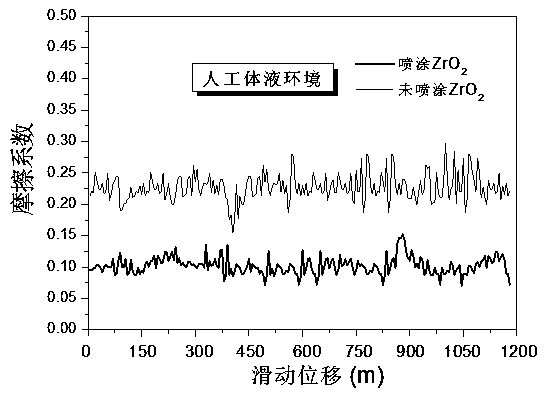

Technology method for improving surface abrasion resistance of laser additive manufacturing metal artificial knee joint

InactiveCN110923613AOvercome wear resistanceOvercome resilienceMolten spray coatingArticular surfacesSand blasting

The invention discloses a technology method for improving surface abrasion resistance of a laser additive manufacturing metal artificial knee joint, and belongs to the technical field of surface treatment. The technology method comprises the following steps that firstly, sand blasting treatment is conducted, sand blasting treatment is conducted on the surface of the artificial knee joint, and thesurface roughness reaches Ra3.2; secondly, preheating treatment is conducted, the artificial knee joint is heated to 40-50 DEG C, and nanometer zirconia powder is sprayed and heated to 40-50 DEG C; and thirdly, spraying is conducted, and zirconia ceramic powder is used for conducting plasma spraying on the sprayed surface. Nanometer zirconia particles are sprayed to the surface of the artificial knee joint, and inherent defects that a traditional knee joint is low in abrasion resistance, and full ceramic joint toughness is poor are overcome. A layer structure with anisotropism is formed on theceramic surface obtained after plasma spraying, the ceramic layer brittle fracture tendency can be greatly reduced through the structure, the structure and other structures are well matched after spraying, inherent forming and moving states of the knee joint cannot be influenced, the service life of the artificial knee joint is prolonged, and the pain of patients is reduced.

Owner:SHANDONG UNIV OF TECH

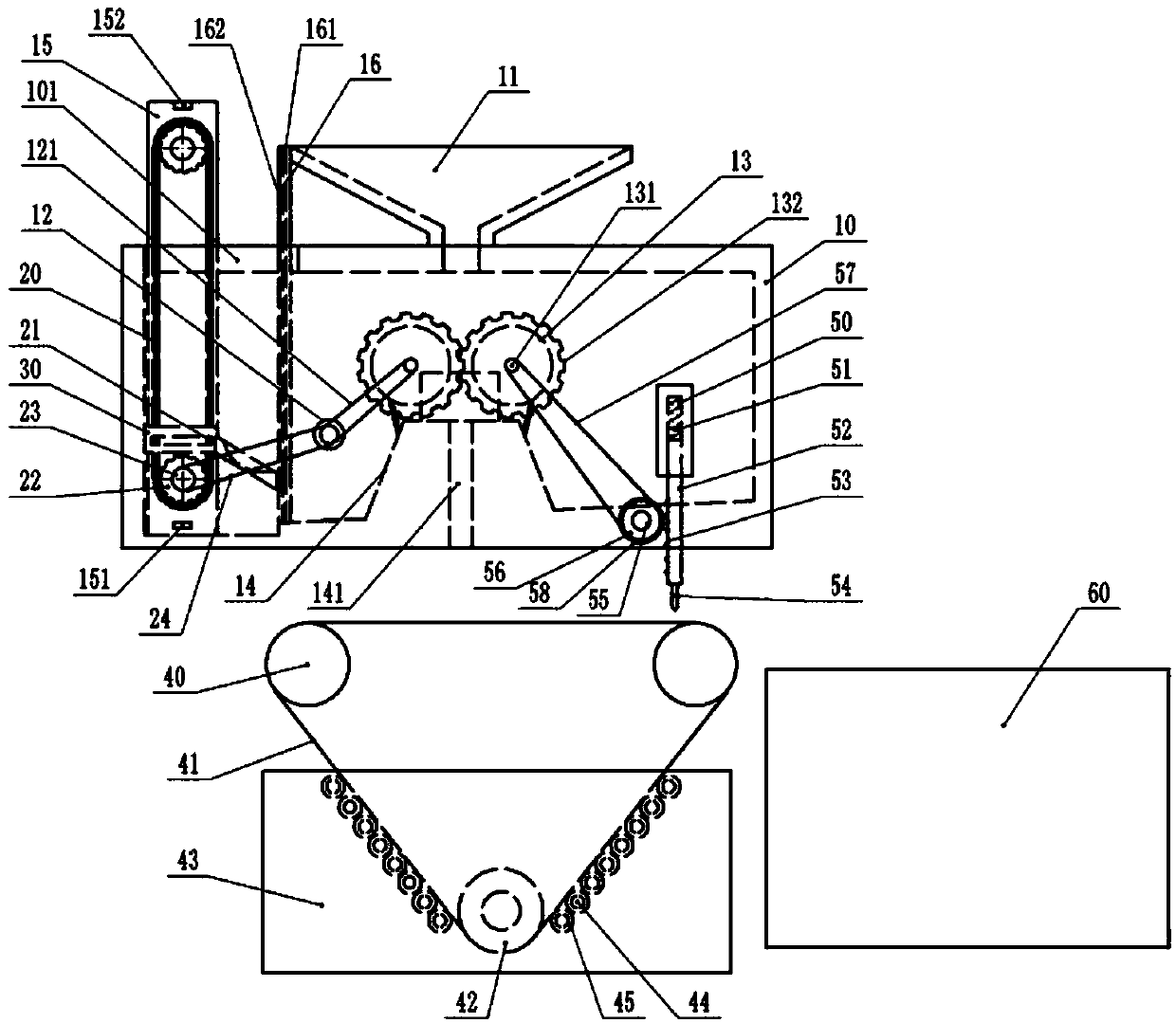

Coating tableting device

The invention belongs to the technical field of powder coating production equipment, and particularly discloses a coating tableting device. The coating tableting device comprises a box body, paired rollers and a conveying mechanism located below the box body, wherein a feeding hopper communicating with the interior of the box body is arranged at the upper end of the box body, a boss is arranged inthe inner middle of the box body, a discharging opening is formed in the boss, the paired rollers are arranged above the boss, the tableting area between the paired rollers is aligned with the lowerend of the feeding hopper, the two sides of the boss are correspondingly provided with scraping plates which are correspondingly abutted against the lower portions of the paired rollers, and a plurality of cooling water channels are formed in the parts, on the two sides of the discharging opening, of the interior of the boss in an embedded mode. Compared with the prior art, the tableting device has the advantages that adsorption of dust impurities in air can be avoided in the coating tableting process, so that the quality of coating tableting is guaranteed, moreover, the air flow does not exist in the coating tableting process, and tableting and molding of a coating are guaranteed.

Owner:CHONGQING QICAIHONG CHEM

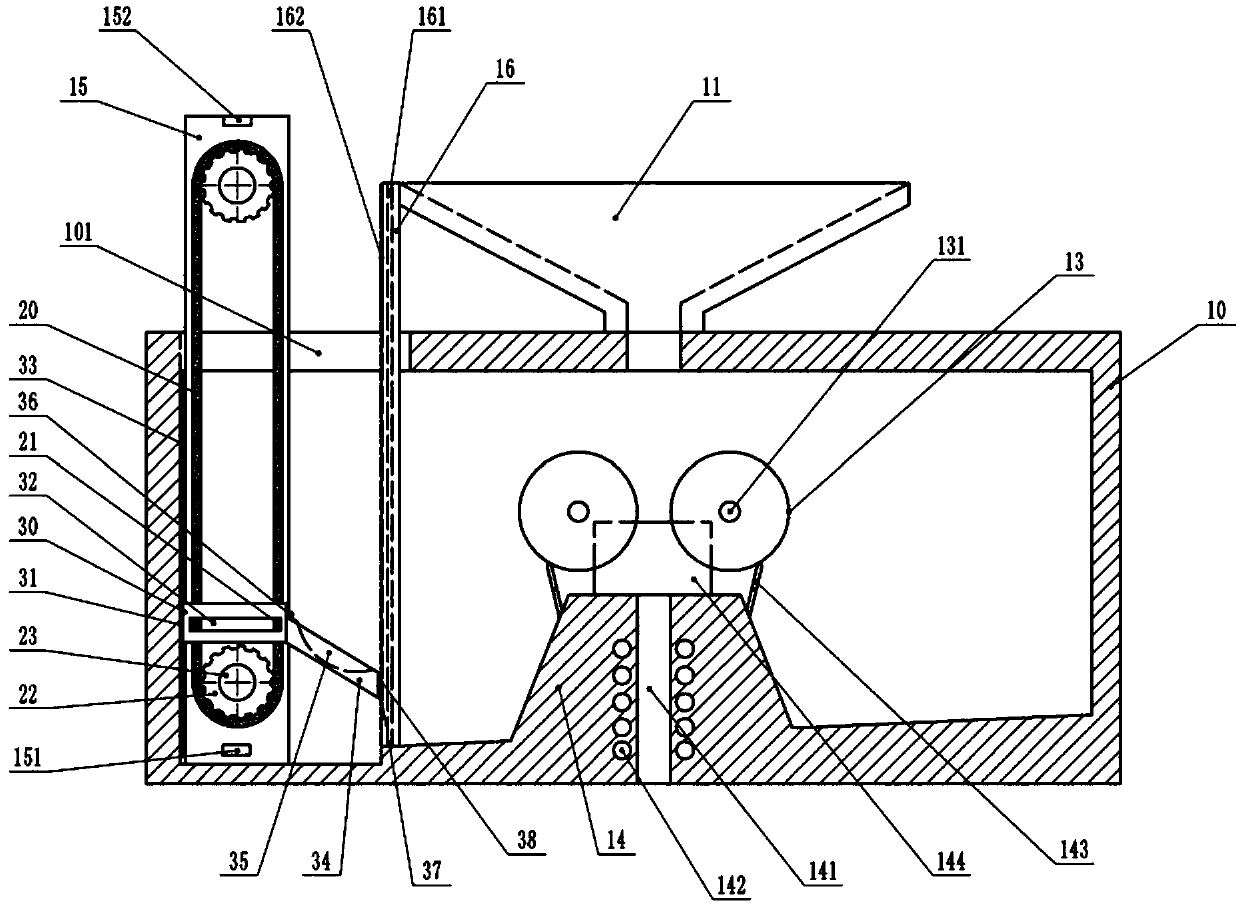

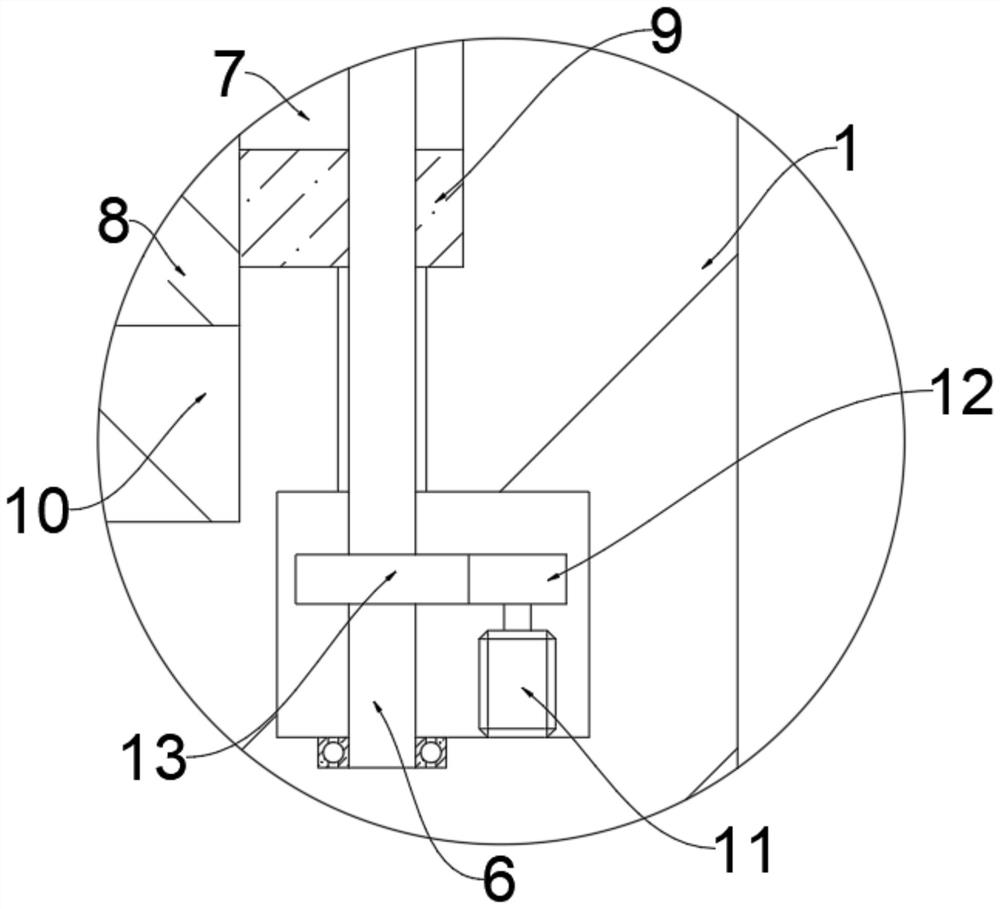

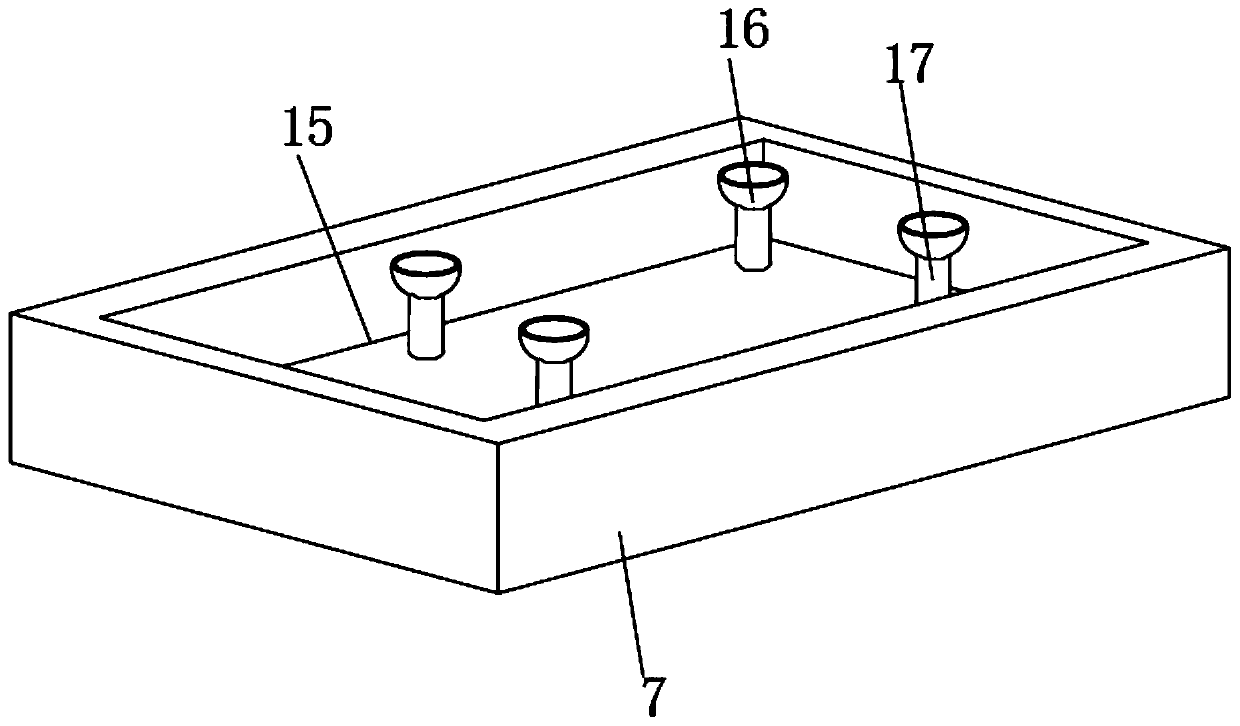

Easy-to-demold lower ejection device for demolding and unloading of die forgings of screw press

InactiveCN111702119AEasy to collectAchieve demouldingForging/hammering/pressing machinesElectric machineGear wheel

The invention discloses an easy-to-demold lower ejection device for demolding and unloading of die forgings of a screw press. The device comprises a main casing; a falling plate is mounted below the main casing; four connecting stand columns are evenly mounted on the upper end surface of the falling plate; a falling spring is arranged among the four connecting stand columns; two motors are evenlymounted inside the main casing; motor gears are fixedly mounted at the front ends of the motors; a transmission gear is mounted on one side of each motor gear; a threaded stand column is fixedly mounted in the middle of each transmission gear; a lifting sliding block is movably mounted on the outer side of each threaded stand column; and guiding sliding grooves are formed between the lifting sliding blocks and the main casing. According to the device, the falling plate, the falling spring, the connecting stand columns, connecting plates, lifting sliding blocks, lifting plates and the threadedstand columns are mounted, formed products can be ejected downwards from a mold after forging forming, product demolding is facilitated, and the device is simple in structure and convenient to operate.

Owner:河南邦特威机电设备有限公司

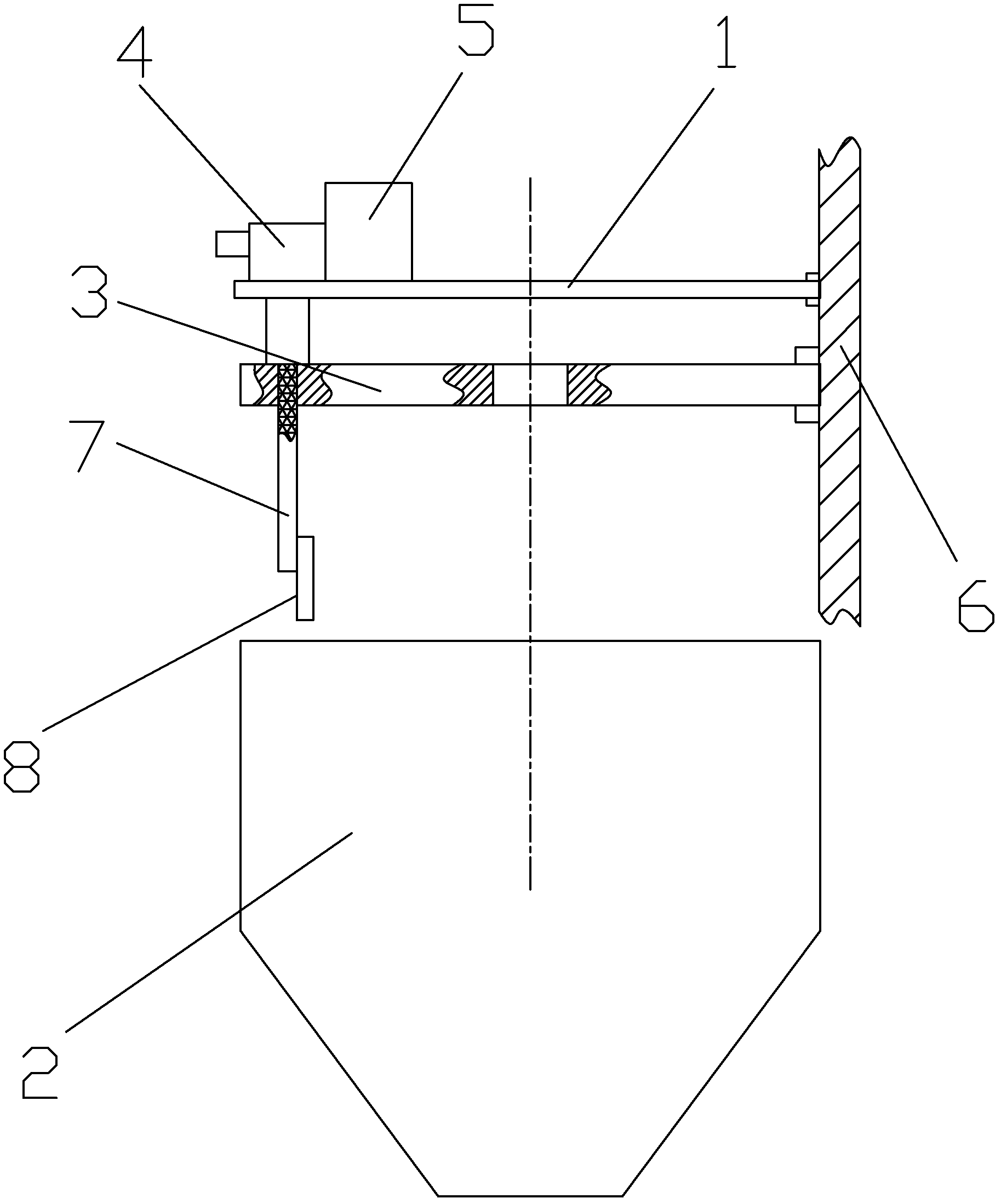

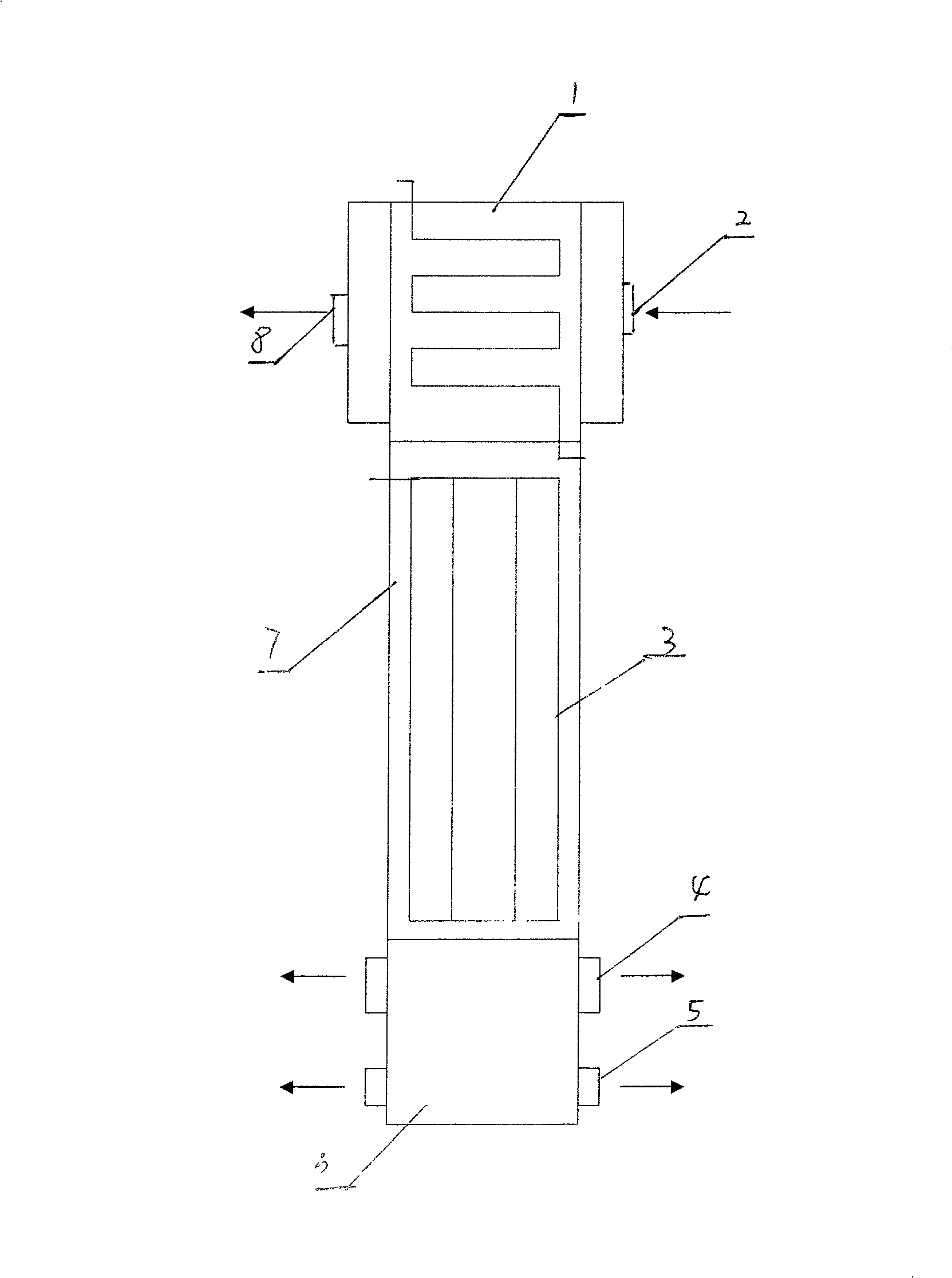

Non-contact temperature measuring device for monitoring of production process of quartz crucible

The invention discloses a non-contact temperature measuring device for monitoring of a production process of a quartz crucible. The non-contact temperature measuring device comprises an installing base, a sensor installing support and an insulation board, wherein the installing base is fixedly connected on a quartz sand distributing device, and the sensor installing support is perpendicular to the installing base and is fixedly connected on one side of the installing base. The insulation board is located over a quartz crucible mold and under the sensor installing support. A non-contact type temperature sensor and a temperature display instrument are arranged above the sensor installing support, wherein the temperature display instrument is connected with the non-contact type temperature sensor. A light sensing tube is installed below the sensor installing support and is located under the non-contact type temperature sensor and penetrates through the insulation board and extends toward the top face of the quartz crucible mold. The insulation board is installed on one side, close to the middle position of the quartz crucible mold, of the light sensing tube. The non-contact temperature measuring device for the monitoring of the production process of the quartz crucible is compact in structure, reasonable in design, convenient to achieve, operate and use, beneficial for improving forming accuracy of the quartz crucible, low in maintenance cost, high in temperature measuring accuracy, good in using effect, and convenient to popularize and use.

Owner:XIAN JINNUO PHOTOELECTRIC TECH

Stamping device for rear tail door shell and working method thereof

ActiveCN111468579AGood effectImprove work efficiencyMetal-working feeding devicesVehicle componentsMachining processStructural engineering

The invention discloses a stamping device for a rear tail door shell and a working method thereof. The stamping device comprises an upper die and a lower die, the upper die is installed on the upper portion of the lower die, an upper die core is installed below the upper die, a plurality of cleaning openings are formed in the bottom of the upper die core, a loading cavity is formed in the position, above the cleaning openings, in the upper die core, and a cleaning structure is installed in the loading cavity. Impurities do not need to be cleaned manually by workers, the working efficiency is improved, and the situation that a door shell is poor in forming due to the fact that the impurities are not cleaned in time is avoided. In the door shell machining process, the workers do not need totake and place the door shell, a conveying belt and an electromagnet are adopted for matched conveying, the working efficiency is improved, and the safety of the workers is guaranteed. A plurality ofdoor shells are sequentially machined and can be normally formed.

Owner:ANHUI JINCEN COMPOSITES

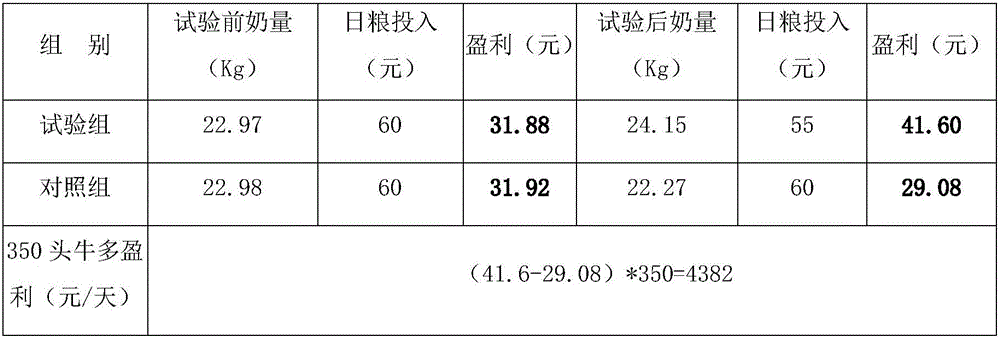

Cattle TMR(Total Mixed Ration) granulated biological feed and preparation method thereof

InactiveCN106376731AIncrease NDF valueDoes not affect moldingFood processingAnimal feeding stuffBiotechnologyFodder

The invention discloses a cattle TMR(Total Mixed Ration) granulated biological feed and a preparation method thereof. The cattle TMR(Total Mixed Ration) granulated biological feed comprises the following components in parts by weight: 14-35 parts of corn, 4-15 parts of cereal by-product, 2-15 parts of soybean meal, 2-10 parts of miscellaneous meal, 2-10 parts of a biological ferment material, 10-20 parts of bean skin, 10-20 parts of cottonseed hull, and 5-20 parts of straw. The method comprises the following steps: 1) cutting raw materials and crushing the raw materials; 2) weighing the raw materials and mixing the raw materials; and 3) granulating the raw materials at low temperature. The granulated biological feed has the advantages that the characteristic of the granulated biological feed is highlighted, a modern microbial fermentation technology, a TMR preparation technology and a low temperature granulating technology are combined, production cost is low, usage is convenient, and the feed accords with modern, intensive and large-scale animal husbandry feeding requirements.

Owner:INNER MONGOLIA YOUMUTE AGRI ANIMAL HUSBANDRY TECH CO LTD

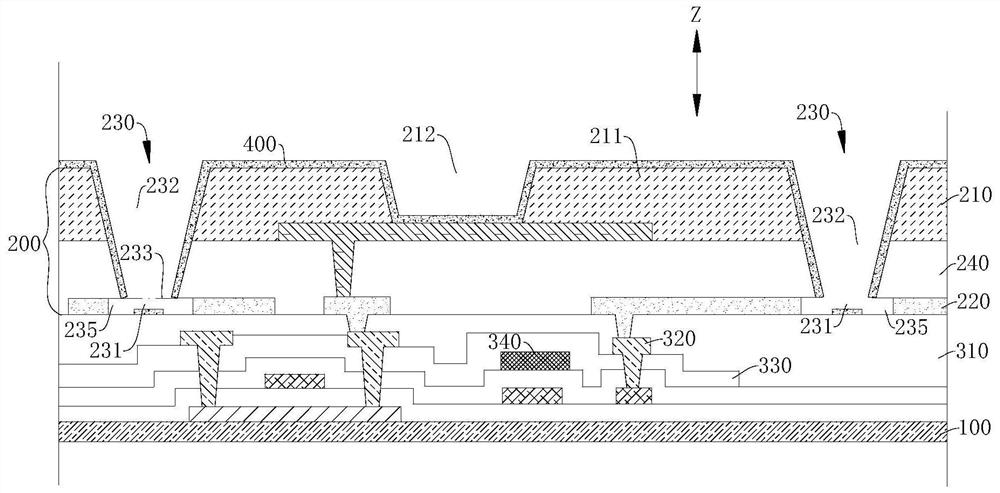

Display panel, manufacturing method of display panel and display device

ActiveCN113410268AImprove the display effectReduce connection areaSolid-state devicesSemiconductor/solid-state device manufacturingComputer hardwareComputer graphics (images)

The embodiment of the invention provides a display panel, a manufacturing method of the display panel and a display device. The display panel comprises a substrate; a functional layer at least comprises an opening layer and a pixel definition layer located on the side, away from the substrate, of the opening layer, the pixel definition layer comprises a body part and a pixel opening penetrating through the body part, and isolation through holes are formed in the functional layer in a penetrating mode; each isolation through hole comprises a first isolation opening located in the opening layer, a second isolation opening located in the side, away from the substrate, of the first isolation opening and a first communication opening communicating the first isolation opening with the second isolation opening, and the first orthographic projection of the first isolation opening on the substrate and the orthographic projection of the pixel opening on the substrate are arranged in a staggered mode; the size of the first orthographic projection is larger than that of the orthographic projection of the first communication port on the substrate, and an isolation gap staggered with the first communication port is formed in the first isolation opening. The display panel can improve low-gray-scale color cast, caused by current crosstalk, of a display picture, and the display effect of the display panel is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

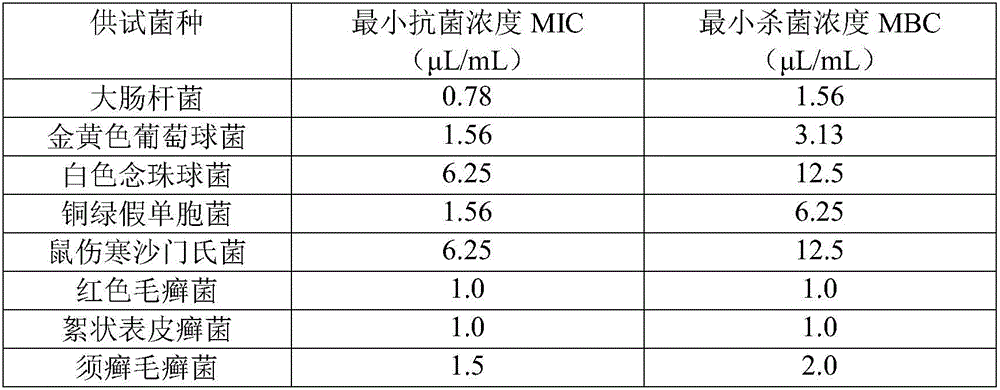

Atractylodes lancea volatile oil-containing antibacterial perfumed soap, and making method and application thereof

InactiveCN106336969AGrowth inhibitionHigh antibacterial activityAlkali/ammonium soap compositionsChemical synthesisSide effect

The invention discloses an Atractylodes lancea volatile oil-containing antibacterial perfumed soap, and a making method and an application thereof. The making method of the above product is simple and safe, and antibacterial active substances and soap base raw materials used in the invention are natural products, so the product is safe and nontoxic, and has no side effects. The use amount of effective components is determined in the invention. Too large content of the natural antibacterial active components influences the emulsification effect of the perfumed soap, and too small content of the natural antibacterial active components does not reach the antibacterial effect. The Atractylodes lancea volatile oil-containing antibacterial perfumed soap overcomes the defects of chemically synthesized antiseptics, can inhibit growth of common bacteria on skins cuticles, has a certain treatment effect on manus and tinea pedis, also has certain nourishing and moisture retention effects on skins, and is suitable for most people. Volatile substances in Atractylodes lancea volatile oil have an inhibition effect on pathogenic microorganisms in air, and have fragrant smell, so the Atractylodes lancea volatile oil-containing antibacterial perfumed soap can clean skins, can purify air, and keeps pleasant home environment.

Owner:HENAN INST OF SCI & TECH

Material cutting method with continuous cutting and automatic layer paving functions

The invention discloses a material cutting method with continuous cutting and automatic layer paving functions. The material cutting method specifically comprises the following steps that 1, continuous fiber fabric is carried to a feeding platform and fed according to the paving sequence of products, and length direction cutting is performed through a fixed cutting knife; 2, the continuous fiber fabric with layers paved is grabbed to a welding platform through a first gripper, and a designed position is welded; 3, the welded fiber fabric is grabbed to a labeling platform through a second gripper, and a label is grabbed through a labeling robot and attached to a designated position of the fabric; 4, the labeled continuous fiber fabric is grabbed to a cutting machine through a third gripper,and pattern cutting is performed according to an input pattern; and 5, cut material blocks are placed on a discharging vehicle after the cutting. According to the material cutting method, rapid cutting of the products can be guaranteed, the machining time is short, and batch production requirements can be met; and the formation of subsequent resin injection is not influenced, the overall movementwithout deformation is convenient.

Owner:康得复合材料有限责任公司

Composition for moxibustion and moxibustion stick production method

InactiveCN106344413ADoes not affect moldingEasy to shapeDevices for heating/cooling reflex pointsPharmaceutical product form changeStem barkCombustion

The invention discloses a composition for moxibustion. The composition is prepared from the following components in parts by weight: 30-90 parts of moxa leaf powder, 10-70 parts of herbal powder and 0.1-10 parts of elm bark powder or / and hemp stem-bark powder, wherein the moxa leaf powder serves as a main acting ingredient of moxibustion, the herbal powder serves as an adhesive, the elm bark powder or / and hemp stem-bark powder serves as an adhesive and a combustion improver, no chemical reagent is used, and all ingredients are purely natural ingredients, so that the molding of the moxa stick is not influenced, normal burning of the moxa stick can be ensured, the prepared moxa stick has small smoke and deep smell when being burnt, and the use safety and moxibustion effect can be improved.

Owner:湖北蕲艾堂科技有限公司

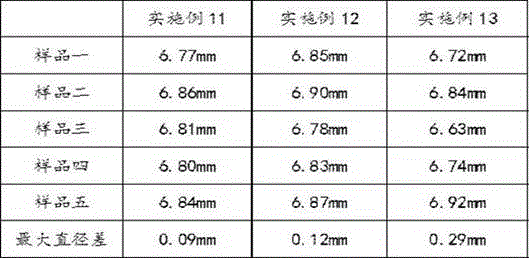

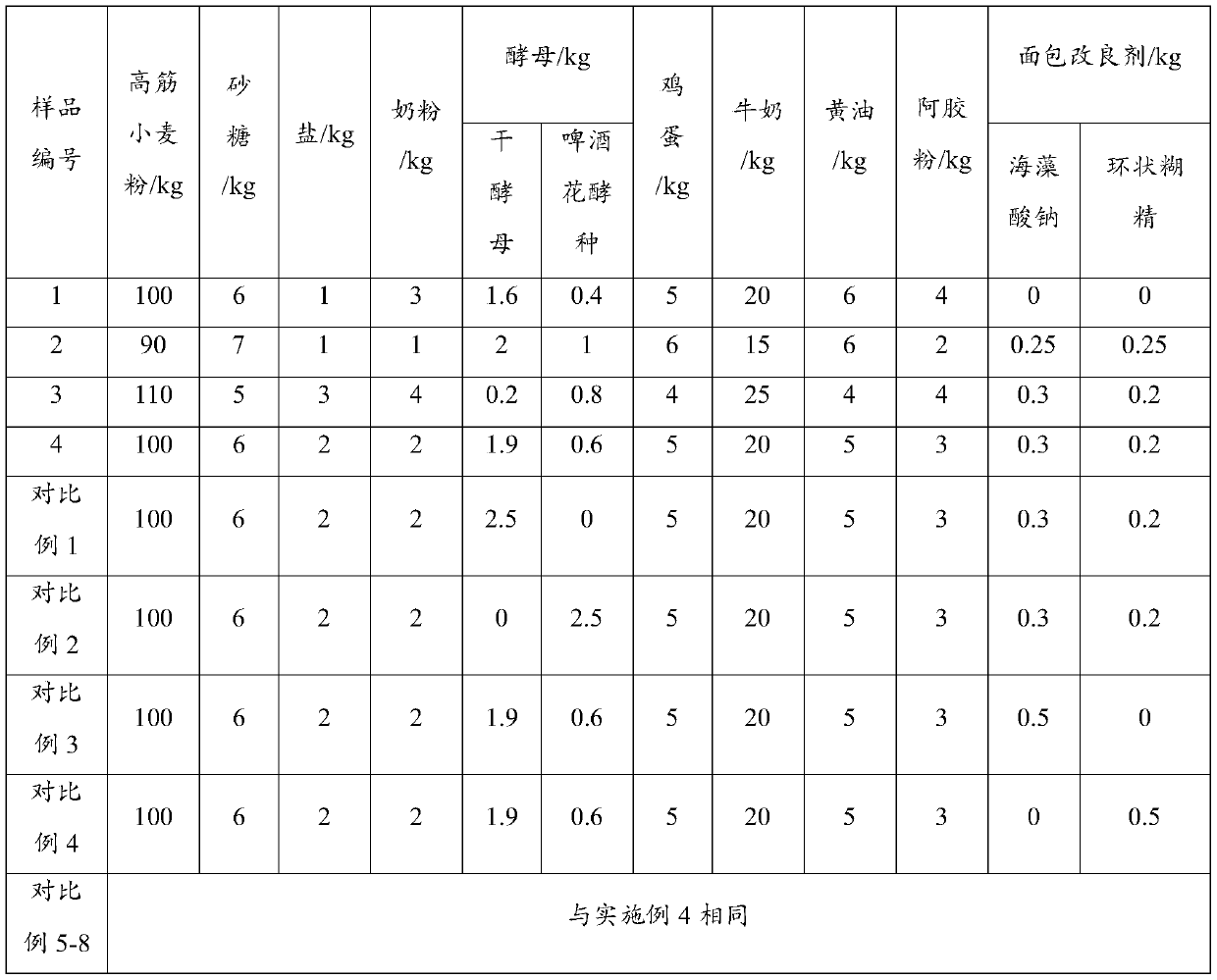

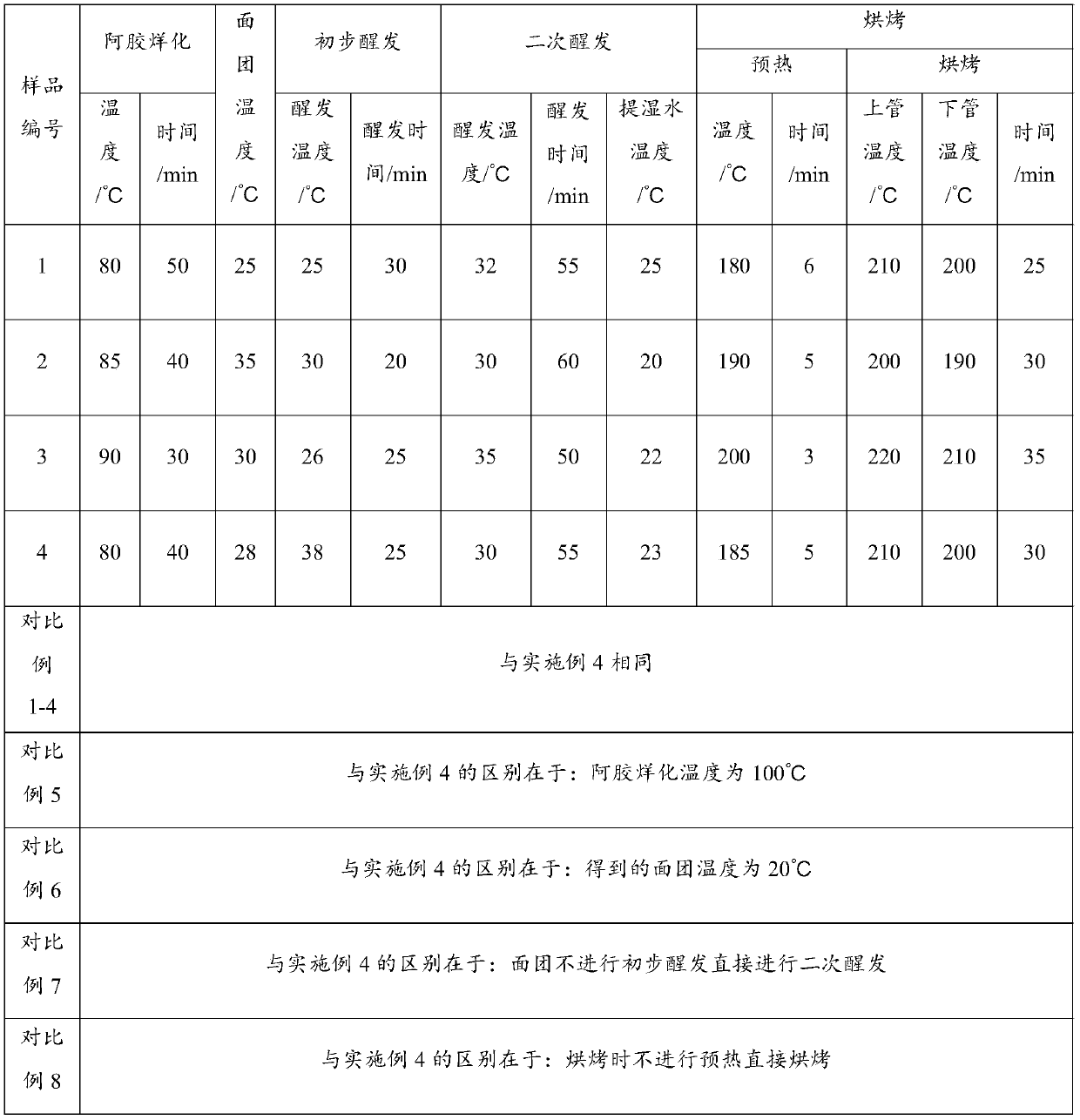

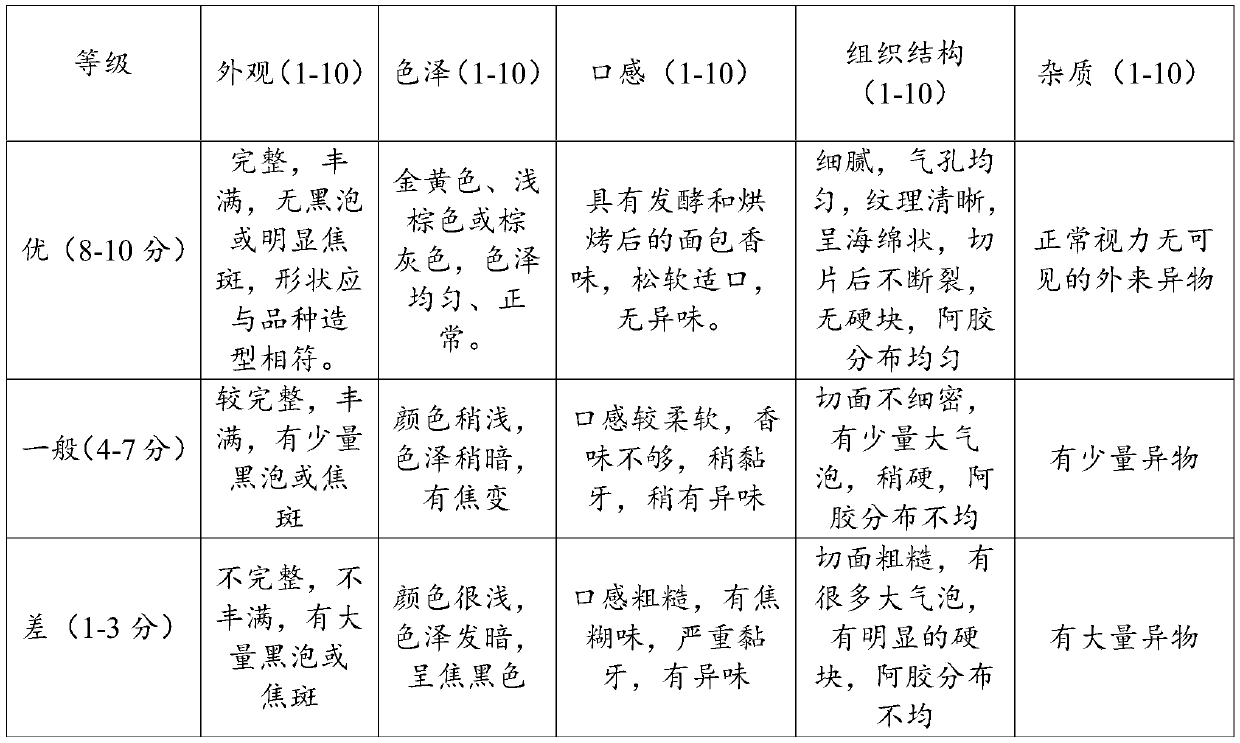

Donkey-hide gelatin toast bread and preparation technology thereof

InactiveCN110367308APromote absorptionIncrease intakeDough treatmentPre-baking dough treatmentYeastSugar

The invention provides donkey-hide gelatin toast bread and a preparation technology thereof. The donkey-hide gelatin toast bread comprises, by weight, 90-110 parts of high gluten wheat flour, 5-7 parts of granulated sugar, 1-3 parts of salt, 1-4 parts of milk powder, 1-3 parts of yeasts, 4-6 parts of eggs, 15-25 parts of milk, 4-6 parts of butter and 2-4 parts of donkey-hide gelatin powder. The yeasts comprise dried yeasts and hop yeasts, and the weight ratio of the hop yeasts to the dried yeasts is 0.2-0.5. The dried yeasts and the hop yeasts serve as the yeasts and are matched with each other to generate synergistic effects. On one hand, the fermentation efficiency of the bread can be improved. On the other hand, caking of donkey-hide gelatin in the fermenting and baking process can be effectively prevented by adding the hop yeasts, so that the donkey-hide gelatin can be uniformly distributed in the bread without affecting the normal forming process of the bread.

Owner:山东福牌阿胶股份有限公司

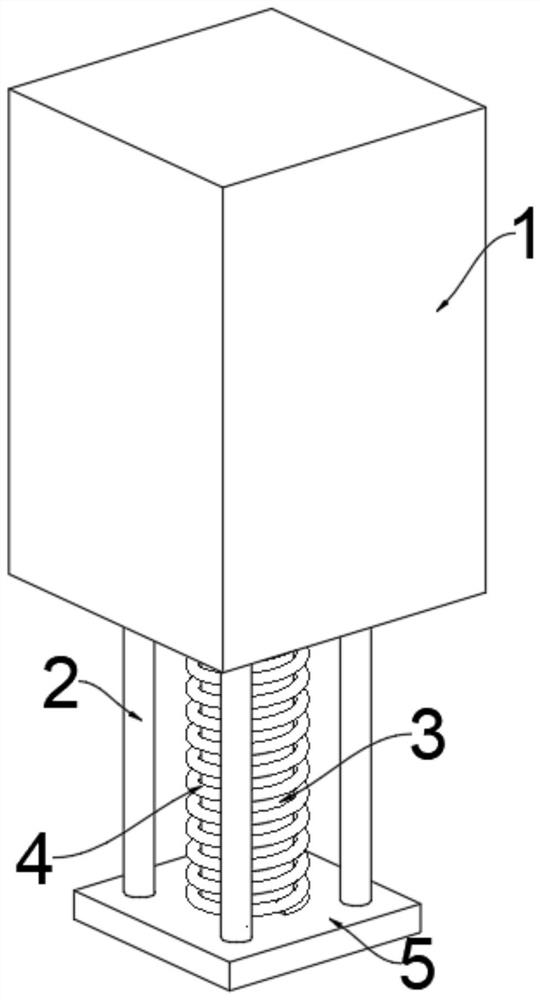

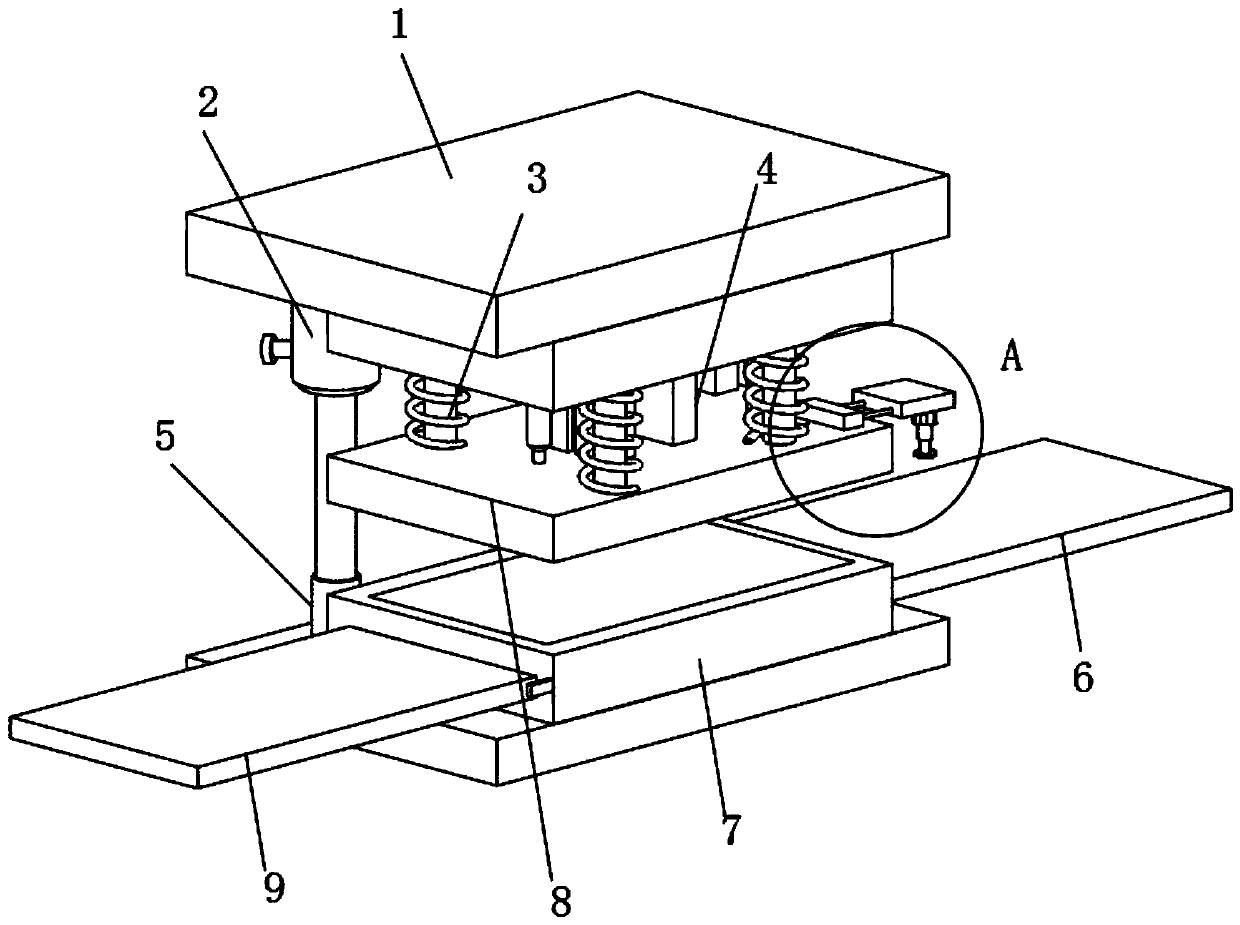

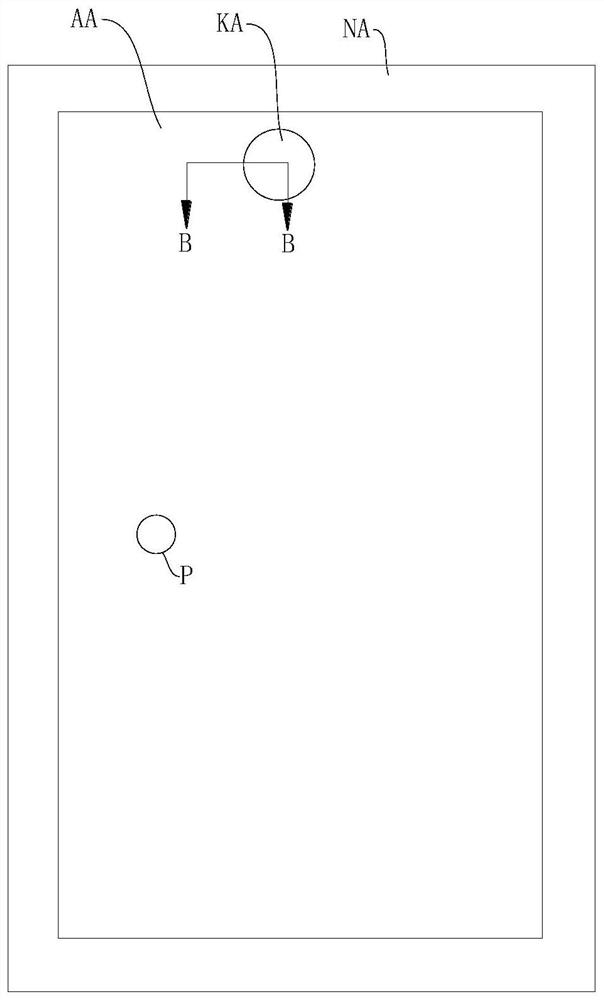

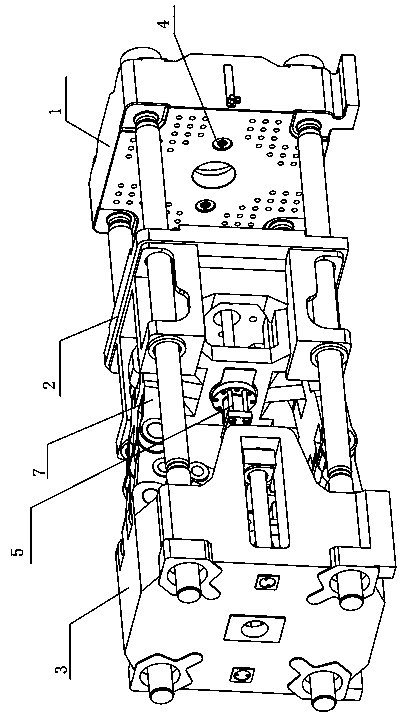

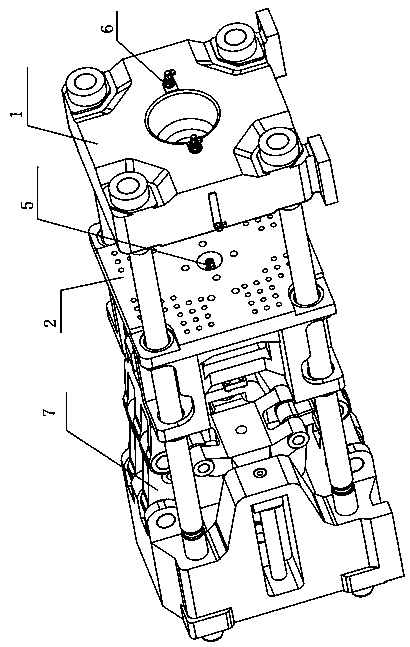

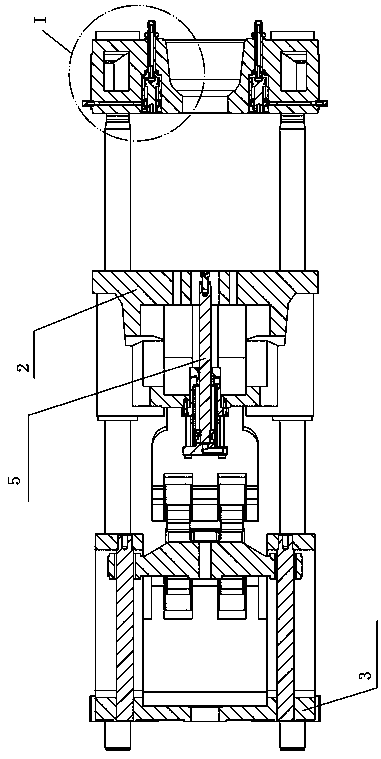

Molding device provided with ejection mechanism

PendingCN109591264ADoes not affect moldingDoes not affect the lengthFluid-pressure actuatorsDie castingEngineering

The invention discloses a molding device provided with an ejection mechanism. The problem that demolding of an existing injection molding machine or a die-casting machine is difficult after products are molded is solved. The molding device comprises a fixed mold plate and a movable mold plate. A containing cavity is formed in the side, close to the movable mold plate, on the fixed mold plate. Theejection mechanism is arranged in the containing cavity and comprises a cylinder cover, a cylinder body and a piston rod. The cylinder cover and the cylinder body cooperate to form a piston cavity. The piston rod is provided with a first position shrinking into the containing cavity of the fixed mold plate during mounting and a second position stretching out of the fixed mold plate during mounting. According to the molding device, the containing cavity is formed in the fixed mold plate and can contain the ejection mechanism, and therefore the surface of the fixed mold plate is level, and product molding cannot be influenced; the ejection mechanism is arranged in the containing cavity, the overall length of products cannot be influenced, large-diameter through holes do not need to be additionally mounted, and the strength and the service life of the fixed mold plate cannot be influenced; and the products can be ejected out reliably, and product continuous machining is facilitated.

Owner:SHENGBANG GRP +2

New technology of spandex fiber

InactiveCN100422398CStable temperature controlUniform temperature controlDry spinning methodsFiberFiltration

This invention relates to a new kind of spandex spinning technology. Send stock solution has undergone polymerization to storage jar for ripening, then through filtration, getting out of bubble, and entering spinning slot, pressing send by nitrogen gas and gear pump pressurize it into static mixer; Through the measuring pump to spit out stock solution and filtering it in spinning module, then allocate to spurt filament plate and spurt out from it; Evaporate out solvent in the spinning path and solidify it to spandex ammonia silk beam, then through false twisting, adding oil and rolling on the rolling machine to pack silk roll. This invention increase static mixer to suit 32 head spinning, reduce adverse effect caused by polymer which make gradient difference of temperature, residence time and viscosity along the radial of pipe; control the actuality temperature out of circulatory mediator in jar, spinning slot, static mixer and partner heat equipment, keep the homogenicity and stability after increasing the spinning air quantity and blast temperature, and increase volatilizing speed but not effect strand form.

Owner:连云港杜钟氨纶有限公司

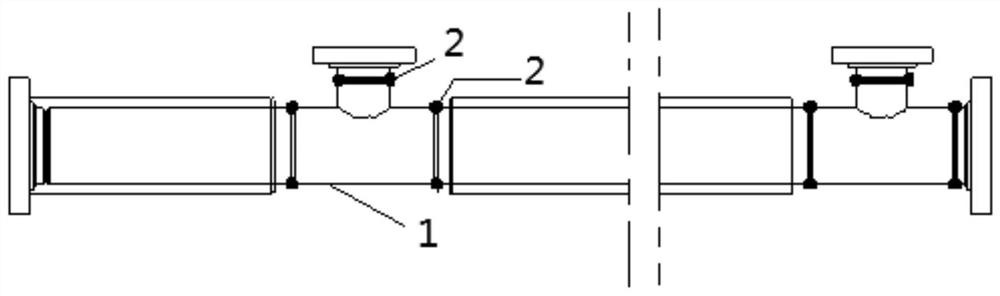

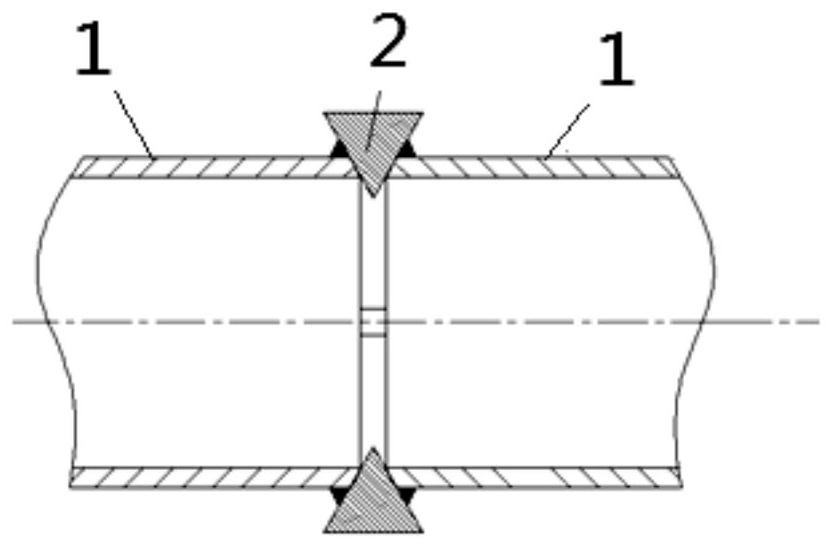

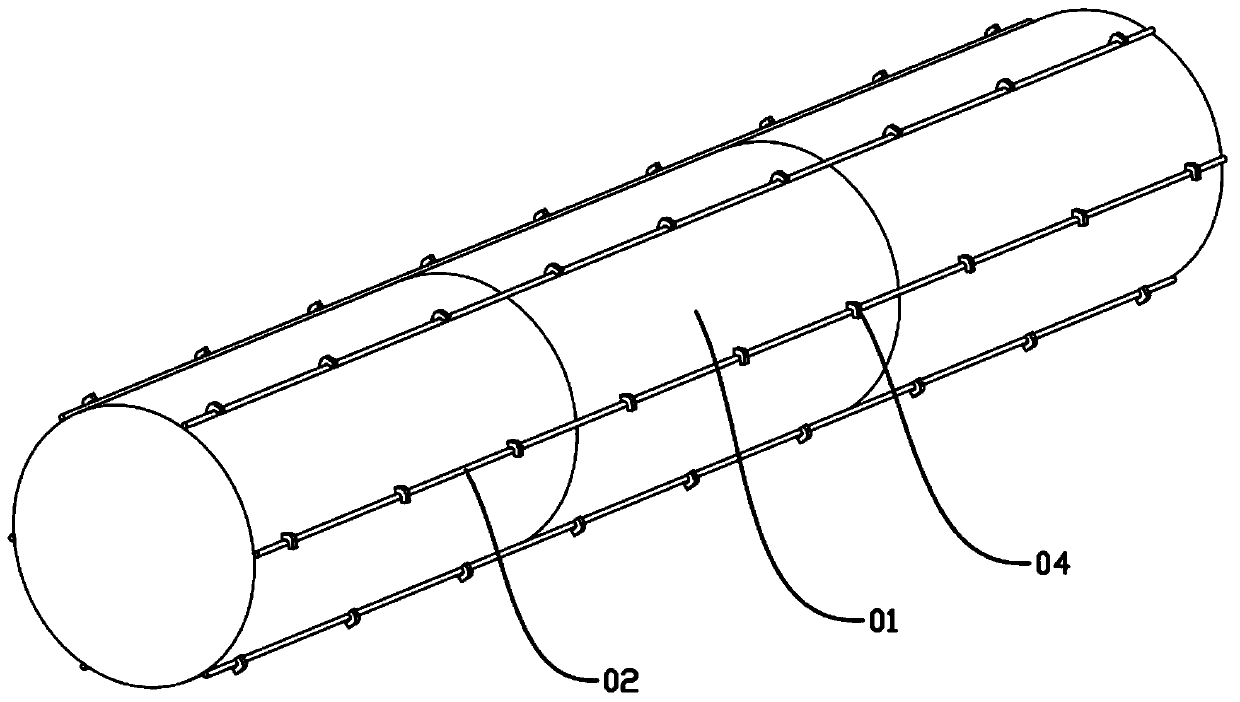

Butt welding assembly method for stainless steel tubes

InactiveCN112427826AImproved accuracy and stabilityClearance and Shrinkage ConsistentWelding/cutting auxillary devicesAuxillary welding devicesSteel tubeContact position

According to a butt welding assembly method for stainless steel tubes, multiple pieces of triangular embedded iron are placed in a butt welding seam between the circumferences of the stainless steel tubes, and by adjusting the depths by which the triangular embedded iron is inserted into the butt welding seam, the size of the welding seam gap between the stainless steel tubes is controlled and kept consistent in the circumferential direction, and spot welding positioning is conducted at the contact position. Argon filling protection is not needed, the operation efficiency is improved, the welding quality of the stainless steel tubes is improved, and the butt welding assembly method has the advantages of being simple in structure, convenient to use, low in process cost, high in precision and stability, wide in application range and the like.

Owner:CSSC MES DIESEL

Method for adding iron in titanium and titanium alloy ingots

ActiveCN111482765ADoes not affect moldingDoes not affect the welding efficiencyProcess efficiency improvementIron powderIngot

The invention discloses a method for adding iron in titanium and titanium alloy ingots. A traditional method is characterized in that iron nails, iron powder or iron intermediate alloys are added intoa raw material, and then mixed and pressed into an electrode, and unlike the traditional method, the method for adding iron in the titanium and titanium alloy ingots is characterized in that iron elements missing in titanium and titanium alloys needing to be prepared are added as long iron wires, so that the distribution uniformity of the iron in the axial direction of the electrode is improved,and reverse segregation distribution is achieved by utilizing the position, the diameter and the length of the iron wires; meanwhile, the difficulty of iron adding when the electrode is formed by non-mixed pressed electrode blocks such as reclaimed material ends is overcome, difficulties in batching calculation and implementation are small by adding the iron wires, and only a small amount of manual work is added without influence on electrode molding and group welding efficiency; and the cost of the iron wires is much less than that of the iron intermediate alloys, and therefore the productioncost can be reduced.

Owner:宁夏中色金航钛业有限公司

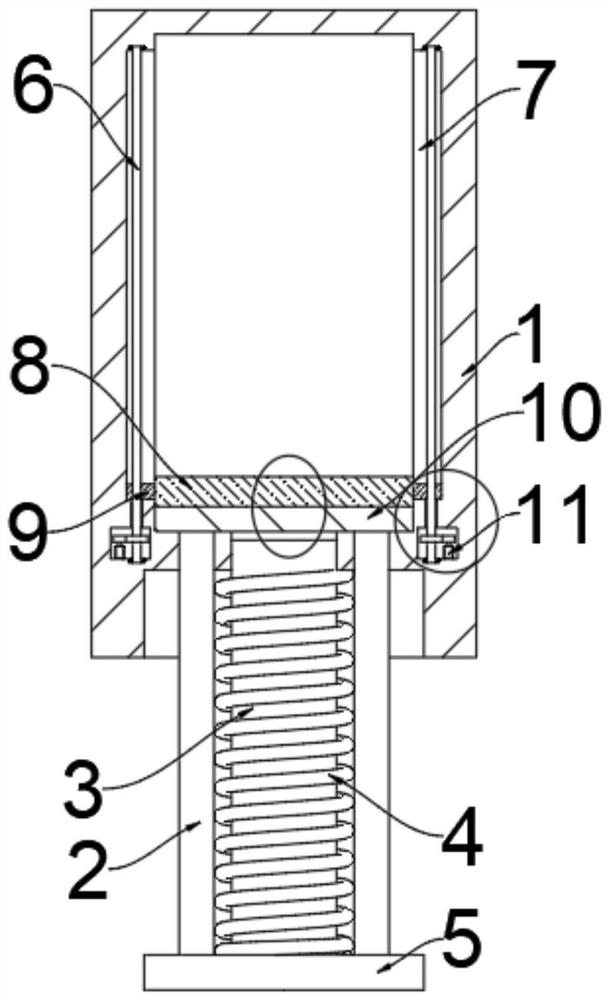

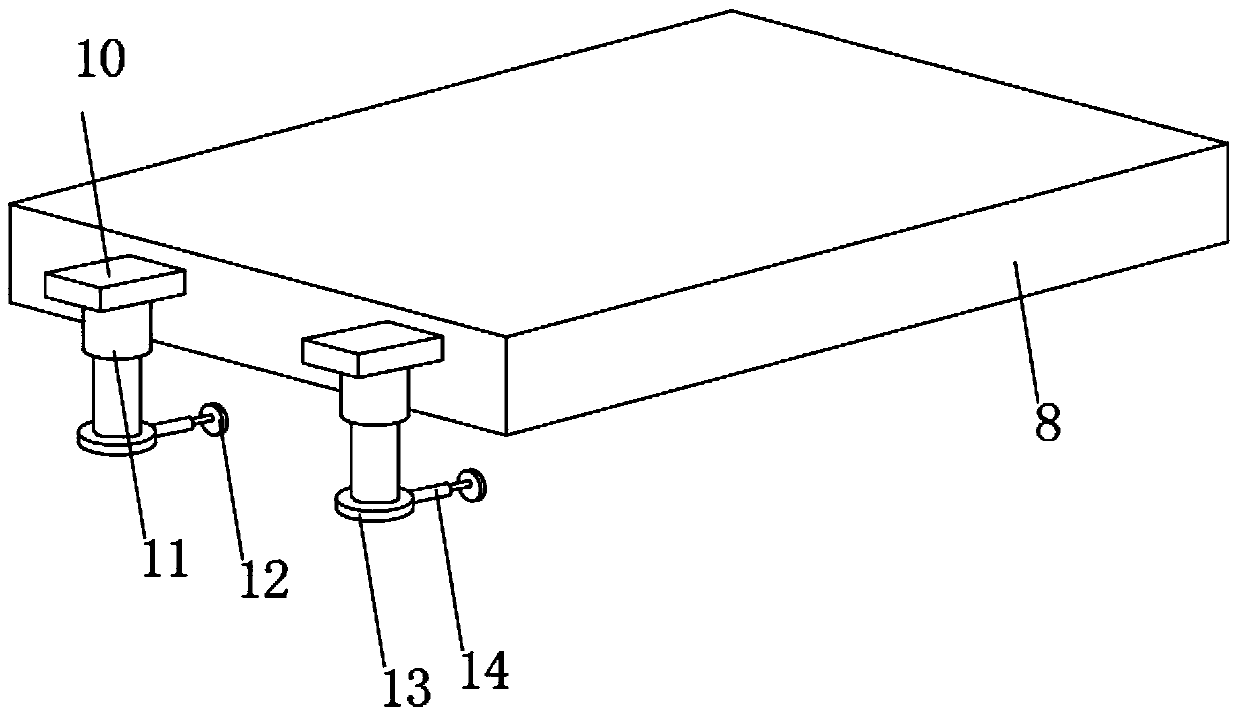

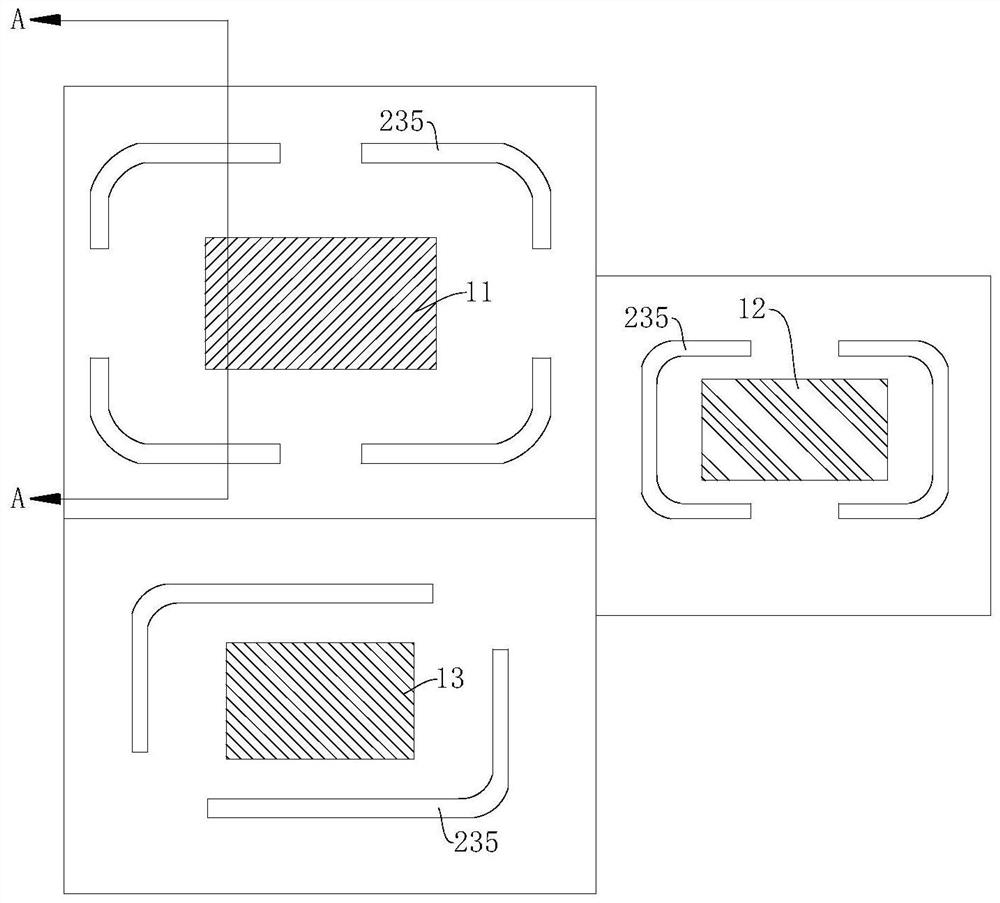

Heat insulation layer for realization of temperature gradient of rutting test specimen

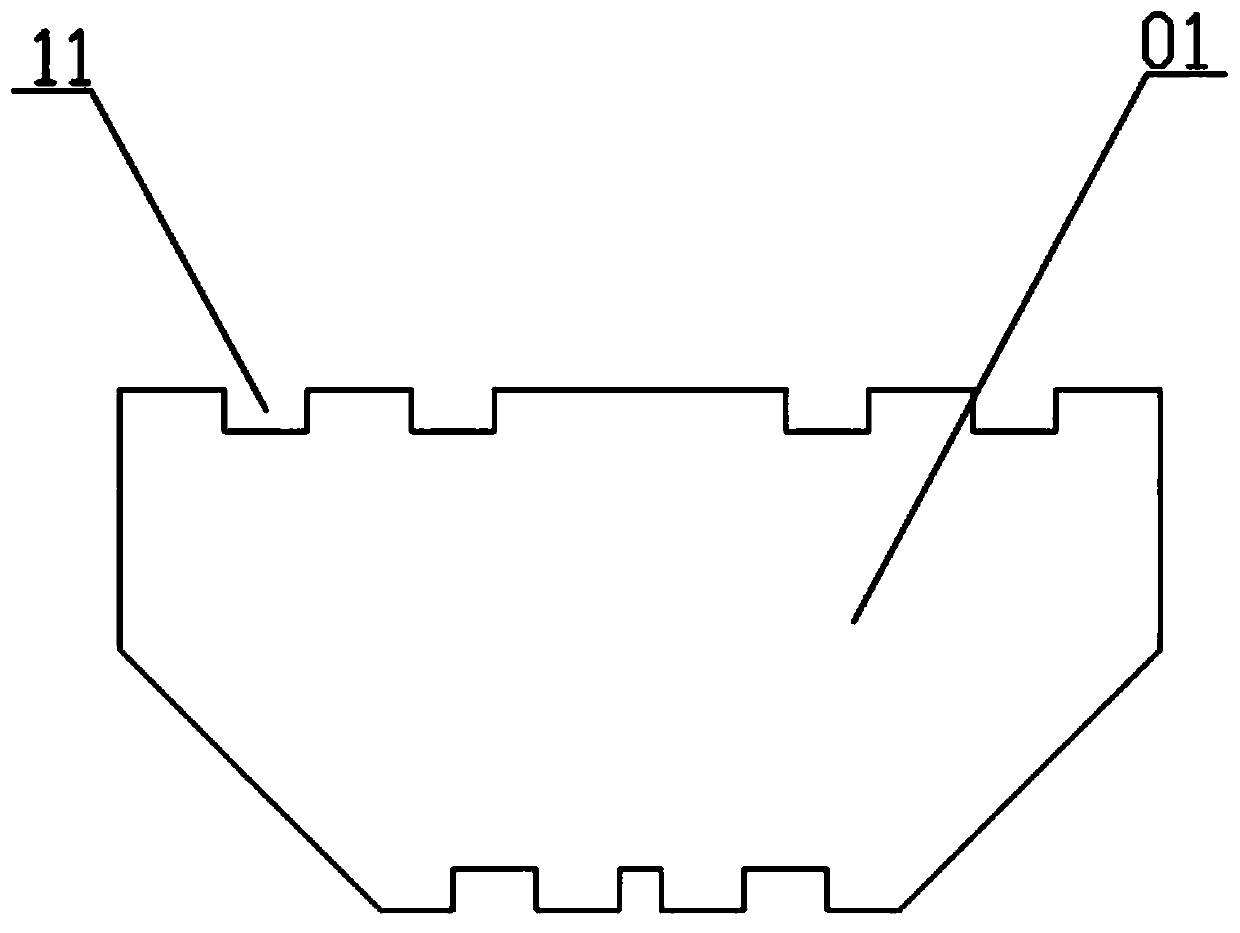

InactiveCN103323302AEffective temperatureDoes not affect moldingPreparing sample for investigationInsulation layerMaterials science

The invention discloses a heat insulation layer for realization of temperature gradient of a rutting test specimen. The heat insulation layer comprises two parts including a left-side heat insulation layer (1) and a right-side heat insulation layer (2), and the two parts are independent and can be combined. Both the left-side heat insulation layer (1) and the right-side heat insulation layer (2) are V-shaped structures and are composed of two mutually vertical cuboids. The left-side heat insulation layer (1) and the right-side heat insulation layer (2) just can be pieced together to form a seamless combination shaped like a Chinese character ''Hui'', combining places can be fixedly connected through the tool buttons (4). Both the left-side heat insulation layer (1) and the right-side heat insulation layer (2) comprise housings and heat insulation layers (3). The heat insulation layers (3) are made from alumina silicate and have a thickness of 3 cm, and the housings are made from Q235 ordinary carbon structure steels and have the thickness of 1.5 mm. The heat insulation layer disclosed by the invention ensures that the external environment temperature dose not transmit to the outside wall of a test mold, can prevent heat dissipation and heat absorption of gaps between the rutting test mold and the heat insulation layer, can very effectively control the temperature of side walls of the rutting test specimen without affection of molding of the test mold, has the advantages of simple structure, low cost, and convenient manufacture, and can be repeatedly used.

Owner:SHANXI PROVINCIAL RES INST OF COMM +2

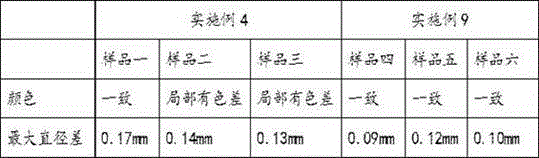

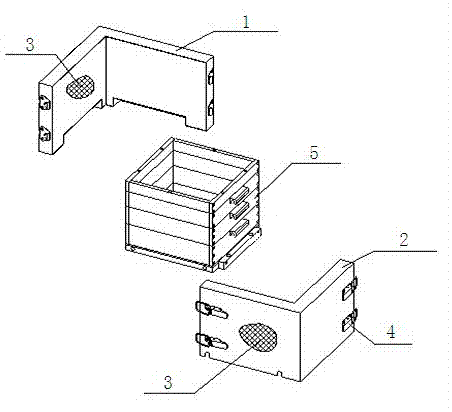

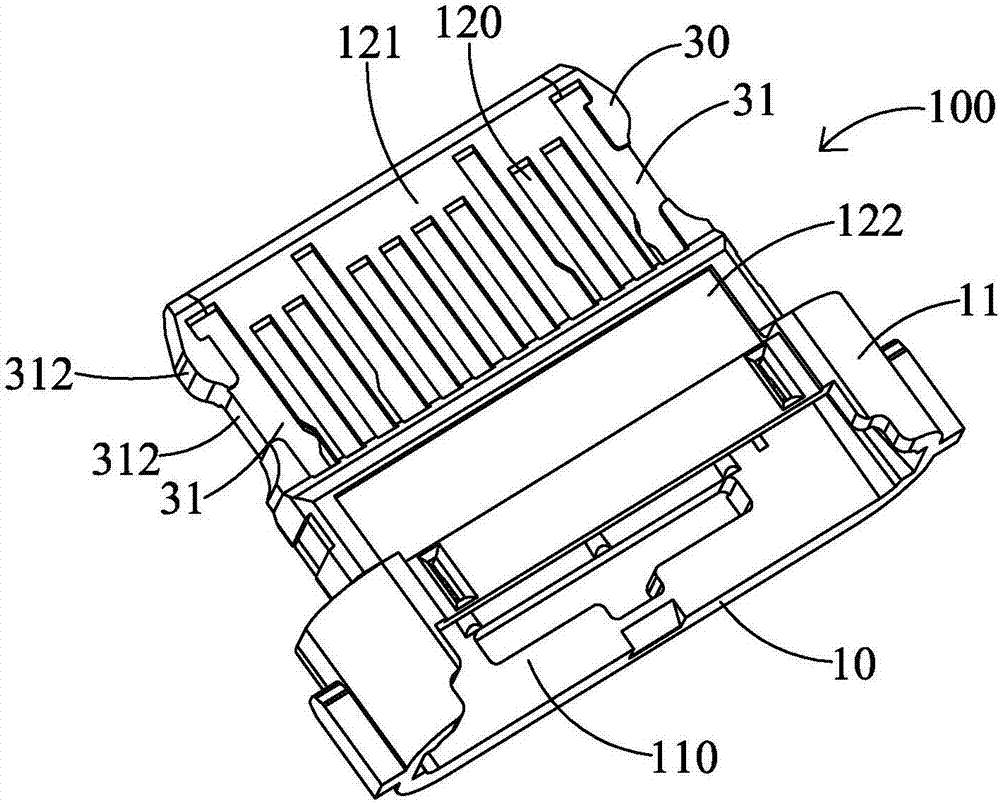

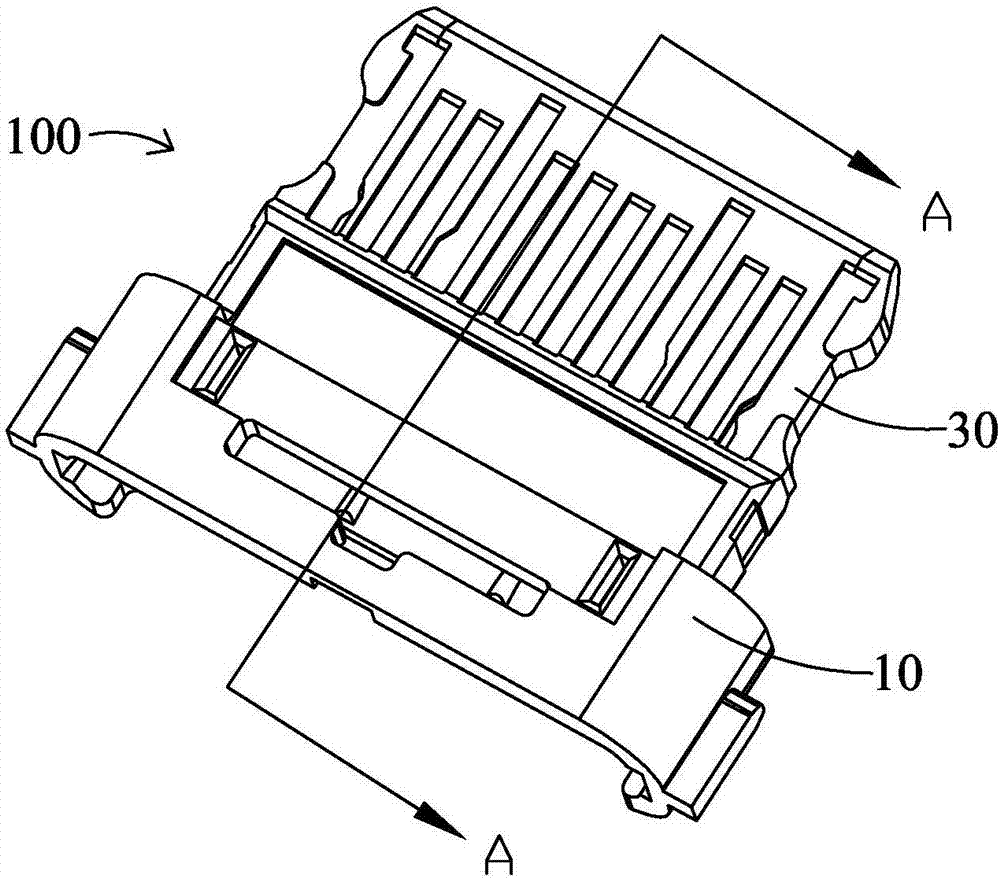

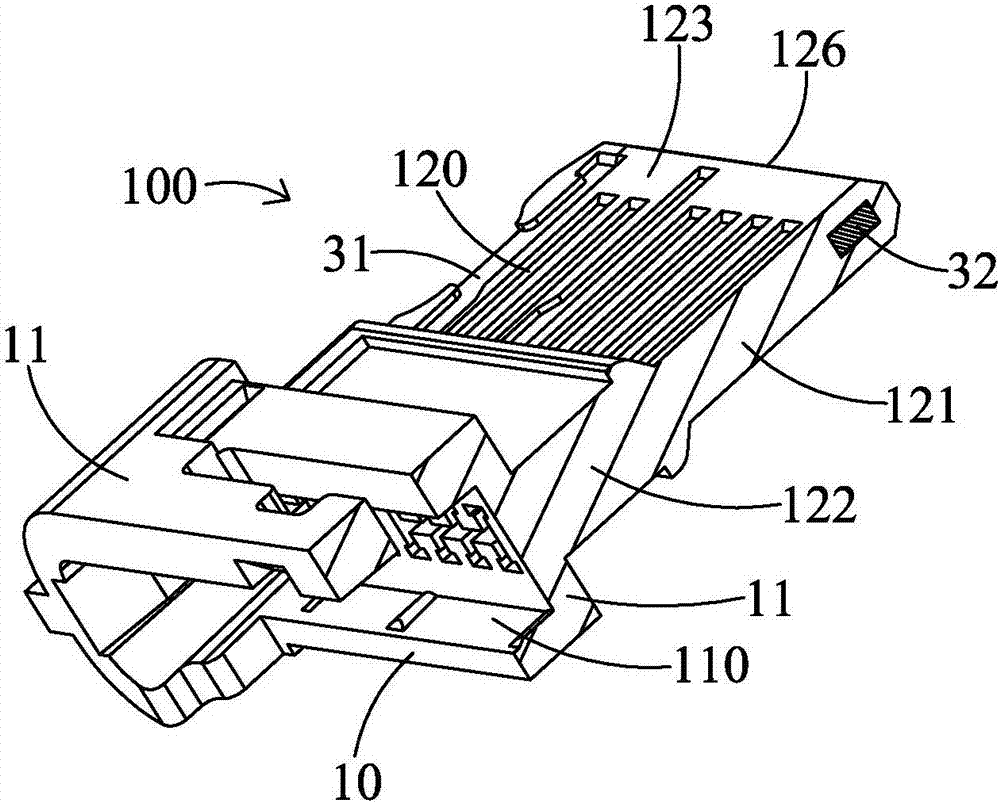

Ceramic piece, USB socket connector and formation method of USB socket connector

ActiveCN107465032AImprove yield rateGuaranteed application functionalityCoupling device detailsTwo-part coupling devicesEngineeringInjection moulding

The invention relates to a ceramic piece, a USB socket connector and a formation method of the USB socket connector. The socket connector comprises an insulation body, a plurality of conductive terminals and the ceramic piece, wherein the insulation body comprises a main body part and a first abutting part, the first abutting part forwards extends from the main body part, the ceramic piece comprises two arm parts which are horizontally parallel to each other, the arm parts and the first abutting part form a tongue plate, a latch groove and a latch convex part are arranged on an outer side surface of each arm part, the latch convex part is arranged in front of the latch groove, the insulation body is arranged on the ceramic piece by injection molding, and the two arm parts are provided with first cutting surfaces for cutting connection parts of the arm parts and a first material bridge before the injection molding of the insulation body. The first material bridge is connected with the two arm parts, thus, the structural strength of the ceramic piece is favorably improved, and the deformation of the ceramic piece and the arm parts thereof can be substantially reduced during the injection, sintering and post-treatment process of the ceramic piece.

Owner:LINKCONN ELECTRONICS

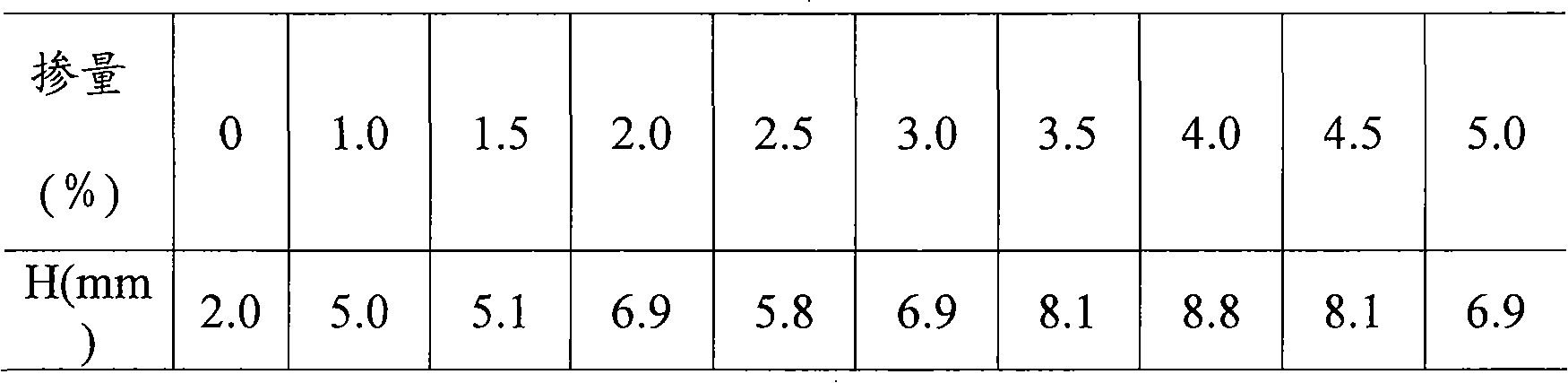

Use of sodium carbonate as fired fly ash brick blank plasticizer

Owner:HARBIN INST OF TECH

A kind of preparation method of multifunctional polypropylene fiber

ActiveCN106757471BRealize the loadGood compatibilityMonocomponent polyolefin artificial filamentArtifical filament manufactureModified carbonIon exchange

The invention discloses a preparation method of multifunctional polypropylene fiber, and belongs to the technical field of preparation of functional materials and functional fiber. The preparation method comprises the following steps: 1, enabling functional metal ions to enter alpha-ZrP through ion exchange to form functional alpha-ZrP, then modifying the functional alpha-ZrP through KH550, acidifying a carbon material to obtain an acidified carbon material, modifying the acidified carbon material through an epoxy modifier E51 to obtain a modified carbon material, and adding the KH550-modified functional alpha-ZrP into the modified carbon material to form a multifunctional nanocluster; and 2, blending and granulating the multifunctional nanocluster and a polypropylene matrix at 180 to 230 DEG C, then carrying out drying, and finally preparing the multifunctional polypropylene fiber by adopting a melt spinning method. The adding amount of an antibacterial object component in the multifunctional polypropylene fiber is small, and the antibacterial object component is uniformly dispersed; and the multifunctional polypropylene fiber has a persistent function, and the preparation method is easy and convenient to operate.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS +1

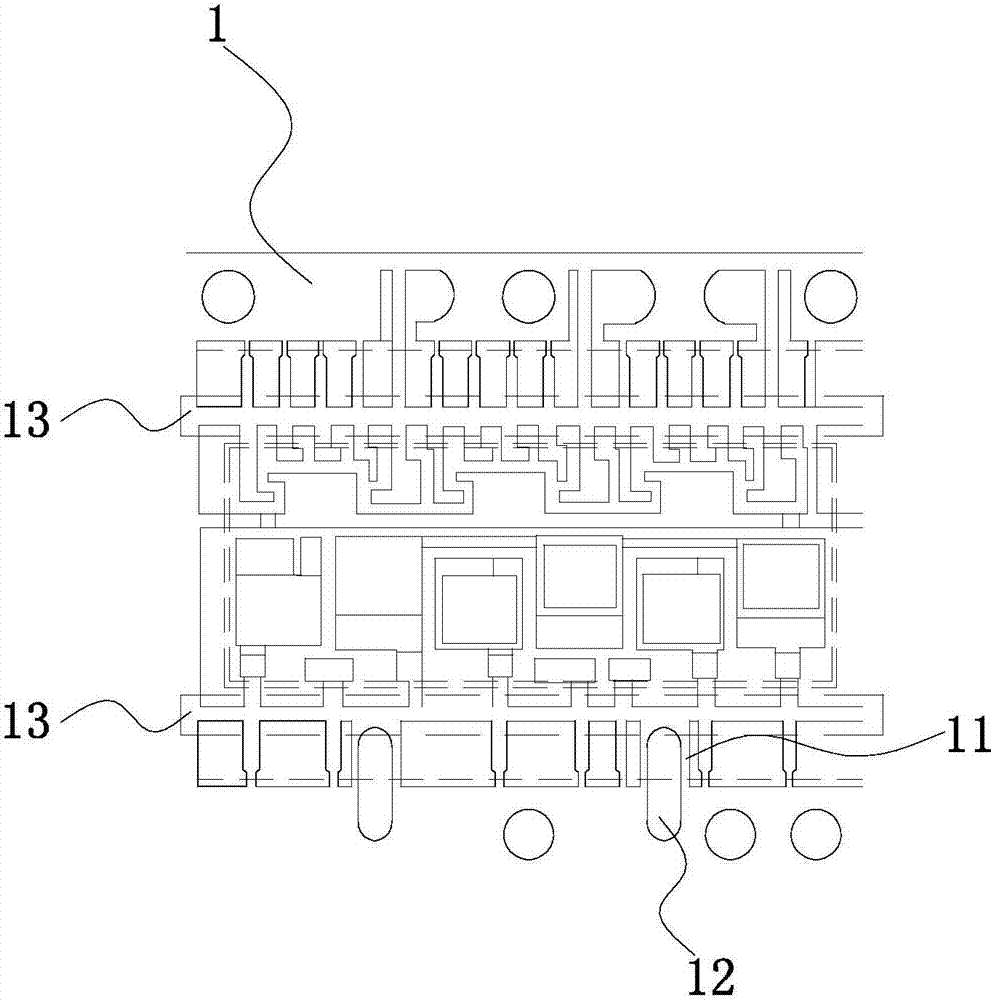

Lead frame of IPM module

ActiveCN107346763AReduce contact areaSolve residual problemsSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The invention discloses a lead frame of an IPM module. The lead frame comprises a lead frame panel and a feeding channel arranged on the lead frame panel, wherein at least one through hole is formed in the feeding channel; and the through hole in the feeding channel can effectively reduce the contact area between a molding compound and the lead frame and reduce an adhesive force between the molding compound and the lead frame at the position of the through hole. The lead frame does not require modification of the process of the existing equipment, thereby saving the production cost; the lead frame does not need to replace the molding compound, thereby avoiding the influence caused by replacing the molding compound on the product quality; and the problem of molding compound residue can fundamentally solved in a short time.

Owner:WUXI CHINA RESOURCE MICRO ASSEMBLY TECH

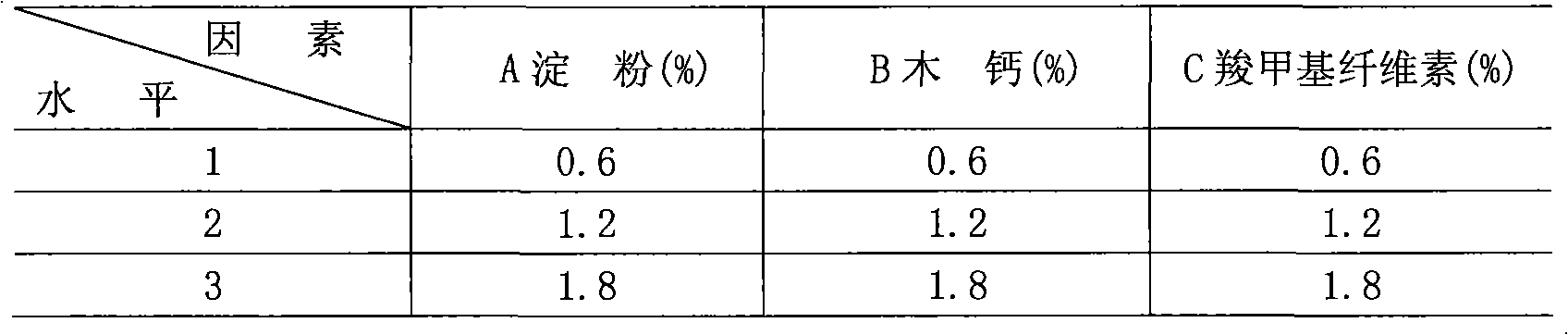

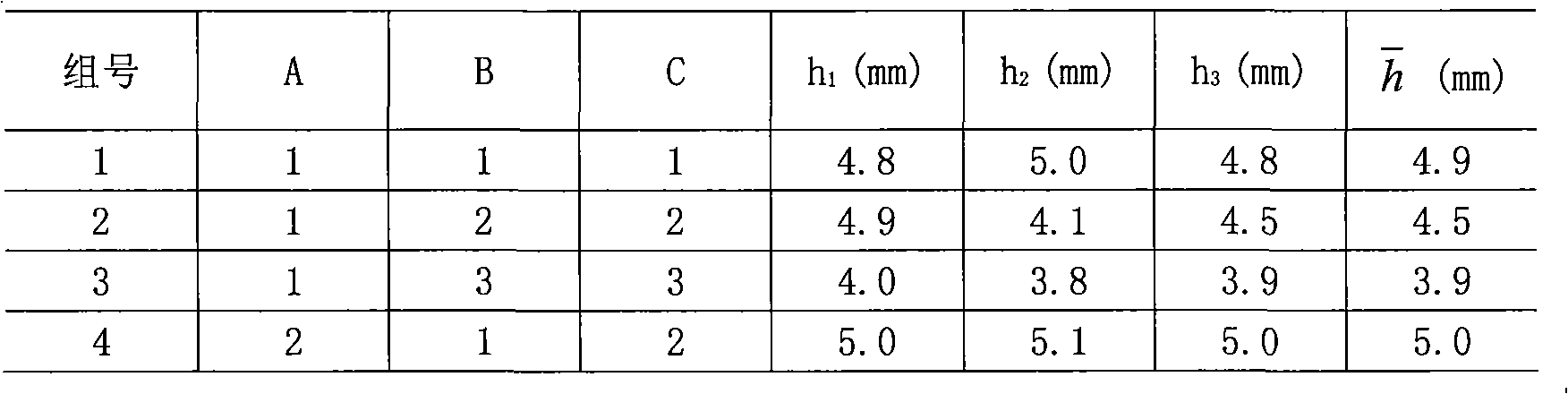

Sintering flyash tile blank composite plasticizer and preparation method thereof

InactiveCN101602585ALow priceImprove plasticizing effectBuilding componentsCarboxymethyl cellulosePlasticizer

The invention discloses a sintering flyash tile blank composite plasticizer and a preparation method thereof, which belongs to the field of construction material. The sintering flyash tile blank composite plasticizer comprises components of starch, wood calcium and carboxymethyl cellulose, which has the advantages of low price, good plasticizing effect and non-influence to admixture formation and the like.

Owner:HARBIN INST OF TECH

A kind of preparation method of multifunctional polyamide fiber

ActiveCN106702524BRealize the loadGood compatibilityArtifical filament manufactureMonocomponent polyamides artificial filamentEpoxyModified carbon

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS +1

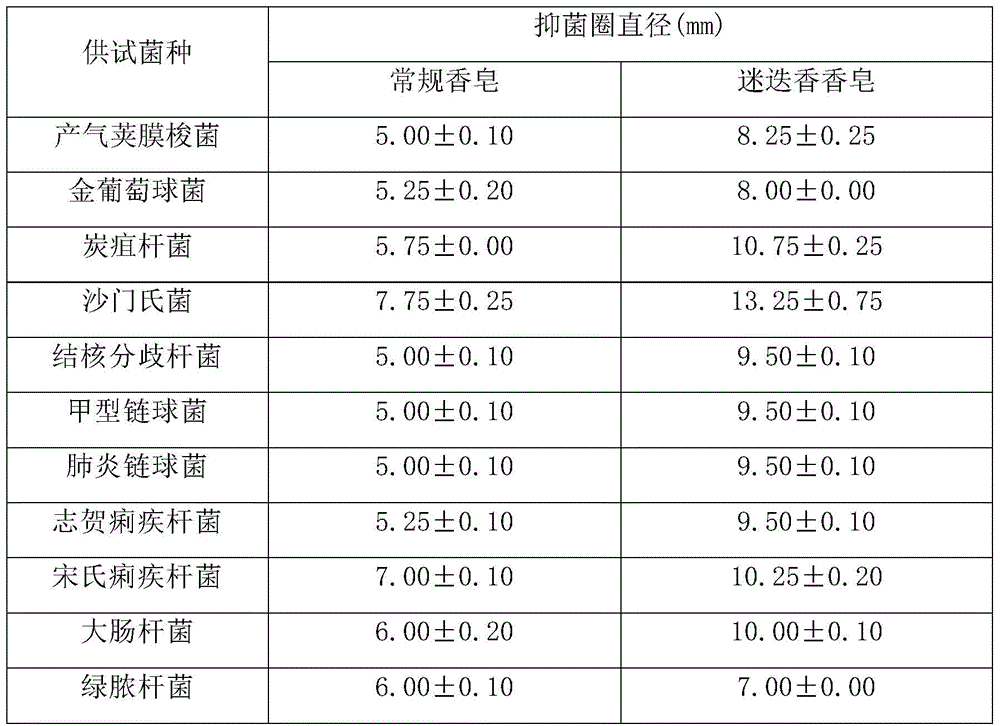

Rosemary natural extract and use of the extract to prepare antibacterial soap and its preparation method and application

ActiveCN104815454BGrowth inhibitionHigh antibacterial activitySolid solvent extractionAlkali/ammonium soap compositionsChemical synthesisMedicine

The invention provides rosemary natural extract, bacteriostatic soup prepared from the rosemary natural extract, and a preparation method and a use of the bacteriostatic soup. The rosemary natural extract overcomes synthetic bacteriostatic agent defects. The bacteriostatic soup can deep clean skin, has good bacteriostatic effects, has a good and lasting common pathogenic bacterium cleaning capability, has a certain care effect on skin and is especially suitable for women, children and people with poor immunity.

Owner:HENAN INST OF SCI & TECH

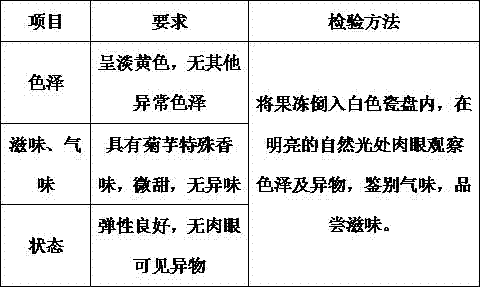

Helianthus tuberosus pulp jelly and preparation method thereof

InactiveCN107173762AKeep the smellRetain nutrientsFood ingredient as antioxidantFood additivePolyfructose

The invention provides helianthus tuberosus pulp jelly and a preparation method thereof. The helianthus tuberosus pulp jelly is prepared from 5-15 parts of helianthus tuberosus tuber, 80-90 parts of helianthus tuberosus homogenate, 0.5-1.5 parts of composite gel, 6-12 parts of polyfructose and 0.1-0.5 parts of a food additive, wherein the helianthus tuberosus homogenate is prepared from the helianthus tuberosus tuber and an antioxidant solution through mixing. According to the helianthus tuberosus pulp jelly, the fresh helianthus tuberosus tuber is taken as a raw material and cut into pieces to be added, so that unique smell and nutritional ingredients of the helianthus tuberosus are reserved, and the helianthus tuberosus pulp jelly has better taste; the helianthus tuberosus tuber is blanched with the antioxidant solution, therefore, activity of oxidation related enzymes in the helianthus tuberosus can be passivated, oxidation loss of nutrient substances is inhibited, the browning reaction is retarded, and the jelly has good color and luster.

Owner:SHENZHEN RUIDEYUAN HEALTH TECH CO LTD

A kind of preparation method of multifunctional polyester fiber

ActiveCN106757482BRealize the loadGood compatibilityMonocomponent polyesters artificial filamentArtifical filament manufactureModified carbonIon exchange

The invention discloses a preparation method of multifunctional polyester fiber, and belongs to the technical field of preparation of functional materials and functional fiber. The preparation method comprises the following steps: 1, enabling functional metal ions to enter alpha-ZrP through ion exchange to form functional alpha-ZrP, then modifying the functional alpha-ZrP through KH550, acidifying a carbon material to obtain an acidified carbon material, modifying the acidified carbon material through an epoxy modifier E51 to obtain a modified carbon material, and adding the KH550-modified functional alpha-ZrP into the modified carbon material to form a multifunctional nanocluster; 2, blending and granulating the multifunctional nanocluster and a polyester matrix at 250 to 270 DEG C, then carrying out drying, and finally carrying out a melt spinning method to preparing the multifunctional polyester fiber by adopting a melt spinning method. The adding amount of an antibacterial object component in the multifunctional polyester fiber is small, and the antibacterial object component is uniformly dispersed; and the multifunctional polyester fiber has a persistent function, and the preparation method is easy and convenient to operate.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com