Atractylodes lancea volatile oil-containing antibacterial perfumed soap, and making method and application thereof

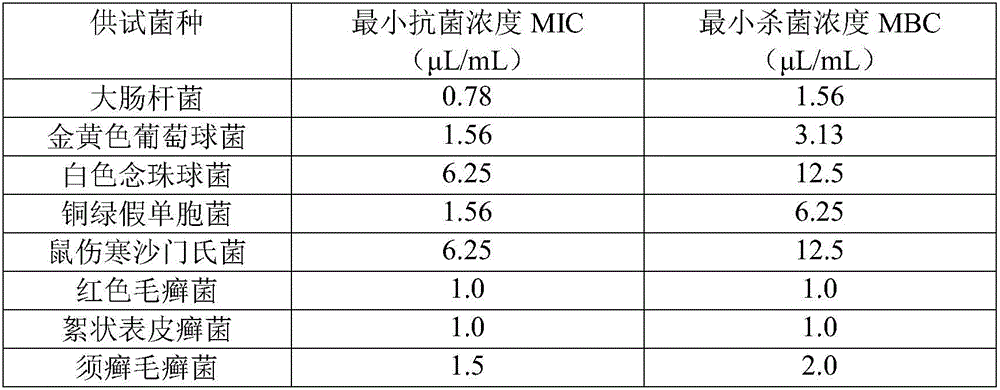

A technology of Atractylodes volatile oil and antibacterial soap, applied in chemical instruments and methods, alkali soap/ammonium soap composition, soap detergent composition, etc., can solve the problems of less plant active substances and high cost, and achieve fragrance and antibacterial activity Improve and inhibit the growth of pathogenic bacteria and fungi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Preparation one of the antibacterial soap containing Atractylodis volatile oil

[0017] Step 1: Weigh 11 kg of palm oil, 20 kg of castor oil, and 30 kg of olive oil, put them in a heat-resistant container in turn, and boil them in a water-proof manner to keep the temperature of the mixed oil at 40°C to 50°C.

[0018] Step 2: Weigh 20 kg of water and 9 kg of sodium hydroxide. First put sodium hydroxide into a glass container, then slowly add water, stir rapidly with an alkali-resistant stirrer while adding, completely dissolve sodium hydroxide in water and cool to 40°C to 50°C to obtain an alkali solution.

[0019] The third step: Slowly pour the alkali solution in the second step into the glass container containing the mixed oil in the first step, and stir continuously with an alkali-resistant stirrer for about 40 minutes to saponify the two until the two are in solution Mix completely to obtain soap base, and then adjust the pH to 7.5-8.

[0020] Step 4...

Embodiment 2

[0023] Embodiment 2: the preparation two of the antibacterial scented soap containing Atractylodis volatile oil

[0024] Step 1: Weigh 12 kg of palm oil, 21 kg of castor oil, and 25.5 kg of olive oil, put them in a heat-resistant container in turn, and boil them with water-proof heating to keep the temperature of the mixed oil at 40°C to 50°C.

[0025] Step 2: Weigh 21 kg of water and 9 kg of sodium hydroxide. First put sodium hydroxide into a glass container, then slowly add water, stir rapidly with an alkali-resistant stirrer while adding, completely dissolve sodium hydroxide in water and cool to 40°C to 50°C to obtain an alkali solution.

[0026] The third step: Slowly pour the alkali solution in the second step into the glass container containing the mixed oil in the first step, and stir continuously with an alkali-resistant stirrer for about 40 minutes to saponify the two until the two are in solution Mix completely to obtain soap base, and then adjust the pH to 7.5-8. ...

Embodiment 3

[0030] Embodiment 3: Preparation three of the antibacterial soap containing Atractylodis volatile oil

[0031] Step 1: Weigh 10 kg of palm oil, 22 kg of castor oil, and 23 kg of olive oil, put them in a heat-resistant container in turn, and boil them with water-proof heating to keep the temperature of the mixed oil at 40°C to 50°C.

[0032] Step 2: Weigh 20 kg of water and 8.8 kg of sodium hydroxide. First put sodium hydroxide into a glass container, then slowly add water, stir rapidly with an alkali-resistant stirrer while adding, completely dissolve sodium hydroxide in water and cool to 40°C to 50°C to obtain an alkali solution.

[0033] The third step: Slowly pour the alkali solution in the second step into the glass container containing the mixed oil in the first step, and stir continuously with an alkali-resistant stirrer for about 40 minutes to saponify the two until the two are in solution Mix completely to obtain soap base, and then adjust the pH to 7.5-8.

[0034] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com