Rosemary natural extract and use of the extract to prepare antibacterial soap and its preparation method and application

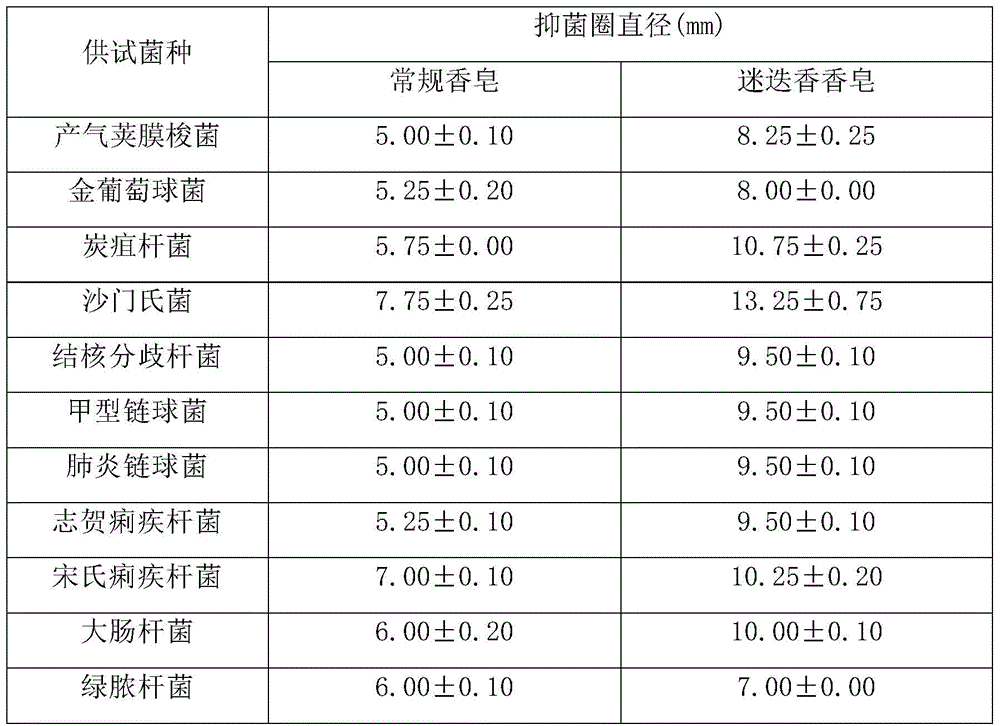

A rosemary extract and rosemary technology, applied in chemical instruments and methods, solid solvent extraction, detergent compositions, etc., can solve the problem of skin inability to tolerate for a long time, safety to be explored, drug resistance, etc. problem, to achieve the effect of inhibiting the growth of pathogenic bacteria, good antibacterial effect, and improved antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation steps of rosemary extract: Weigh 50 kg of rosemary dry sample, grind the rosemary dry sample into powder, soak with 20 times the amount of 80% ethanol for 24 hours, then filter with Buchner funnel, and collect the filtrate. Repeat this operation until the ethanol soaking solution is colorless (3 to 5 times), and combine the filtrates. The filtrate was distilled under reduced pressure with a rotary evaporator, and the filtrate was concentrated until viscous. Transfer the concentrate and dry it in a drying oven at 50°C to obtain the crude extract of rosemary. The crude extract is adsorbed by a macroporous adsorption resin, and after being eluted with 40% ethanol, impurities such as chlorophyll can be removed to obtain about 10 kg of fat-soluble rosemary extract.

Embodiment 2

[0017] Embodiment 2: the preparation one of rosemary antibacterial soap

[0018] Step 1: Weigh 11 kg of coconut oil, 20 kg of soybean oil, and 30 kg of sunflower oil, put them in a heat-resistant container in turn, and boil them with water-proof heating to keep the temperature of the mixed oil at 35°C-40°C.

[0019] Step 2: Weigh 20 kg of water and 9 kg of sodium hydroxide. First put water into a glass container, then slowly add sodium hydroxide, stir rapidly with an alkali-resistant stirrer while adding, completely dissolve sodium hydroxide in water and cool to 35°C to 40°C to obtain an alkali solution.

[0020] The third step: Slowly pour the alkali solution in the second step into the glass container containing the mixed oil in the first step, and stir continuously with an alkali-resistant stirrer for about 40 minutes to saponify the two until the two are in solution Mix completely to obtain soap base, and then adjust the pH to 7.5-8.

[0021] Step 4: Add 8 kg of rosemary...

Embodiment 3

[0024] Embodiment 3: the preparation two of rosemary antibacterial soap

[0025] Step 1: Weigh 12 kg of coconut oil, 21 kg of soybean oil, and 25.5 kg of sunflower oil, put them in a heat-resistant container in turn, and boil them with water-proof heating to keep the temperature of the oil at 35°C to 40°C.

[0026] Step 2: Weigh 21 kg of water and 9 kg of sodium hydroxide. First put water into a glass container, then slowly add sodium hydroxide, stir rapidly with an alkali-resistant stirrer while adding, completely dissolve sodium hydroxide in water and cool to 35°C to 40°C to obtain an alkali solution.

[0027] The third step: Slowly pour the alkali solution in the second step into the glass container containing the mixed oil in the first step, and stir continuously with an alkali-resistant stirrer for about 40 minutes to saponify the two until the two are in solution Mix completely to obtain soap base, and then adjust the pH to 7.5-8.

[0028] Step 4: Add 9 kg of rosemary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com