Coating tableting device

A tablet pressing device and coating technology, which is applied in the field of coating tablet pressing devices, can solve the problems of dust absorption and poor molding of coating tablets, and achieve the effects of guaranteed quality, good cooling effect, and guaranteed molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is further described in detail through specific implementation methods:

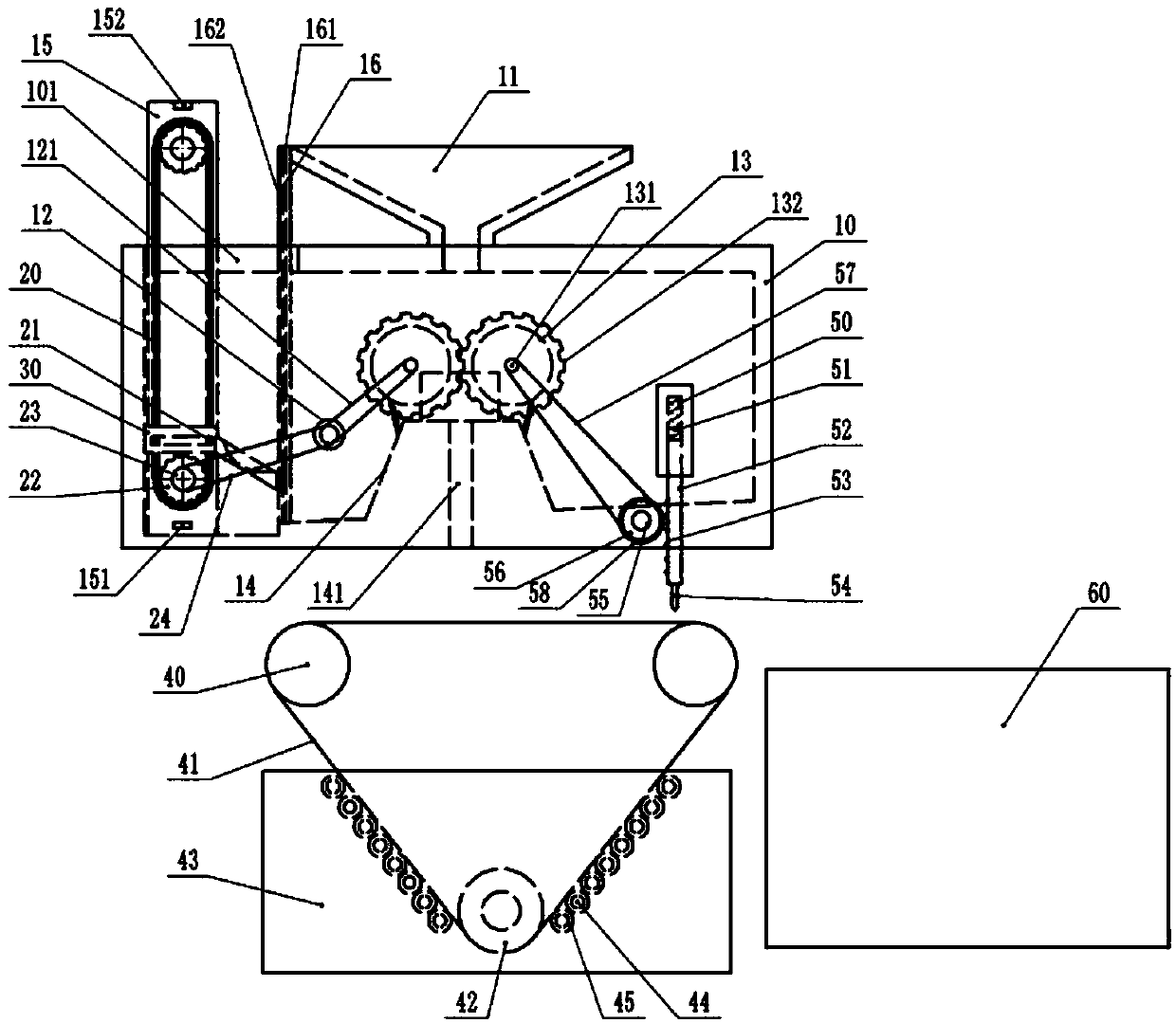

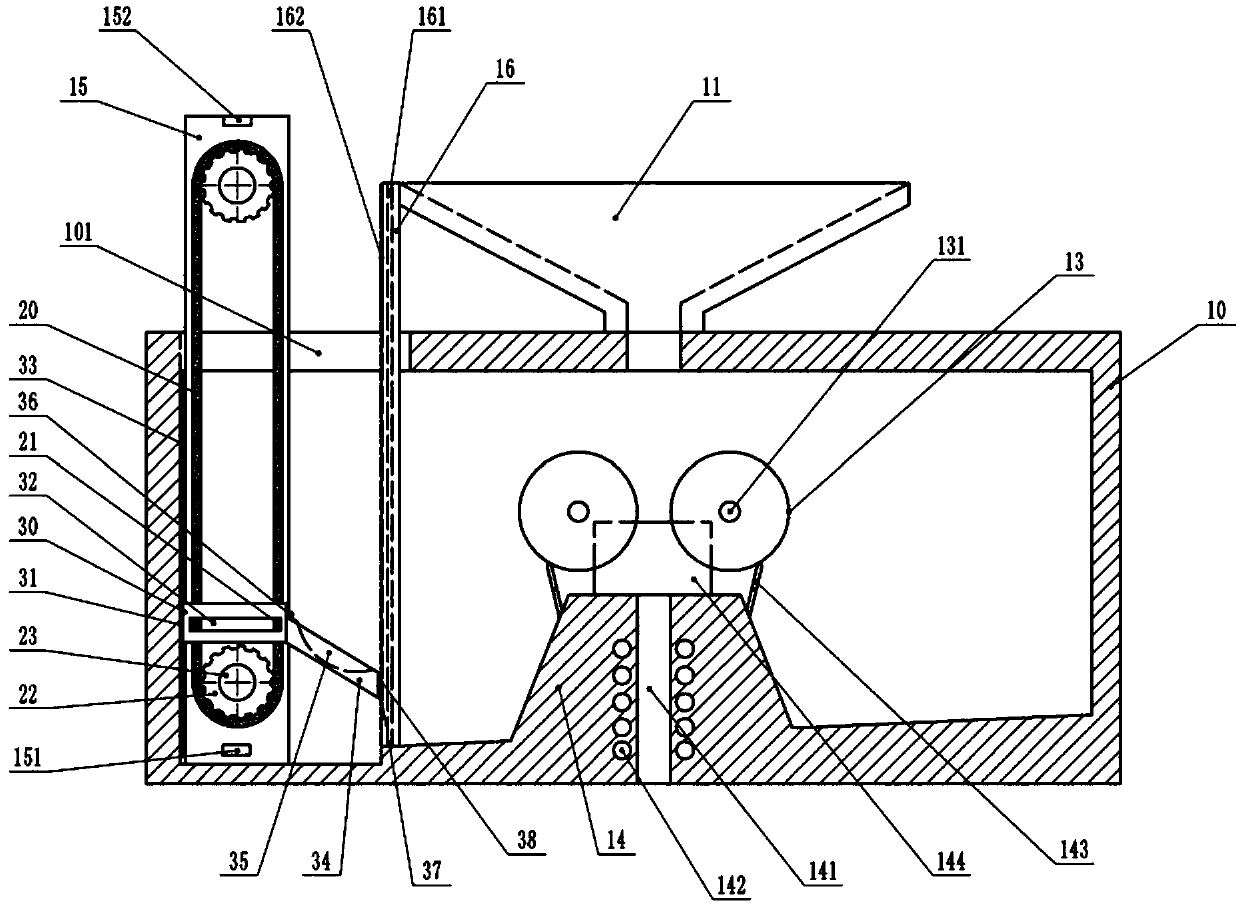

[0036] The reference signs in the drawings of the description include: box body 10, opening 101, feed hopper 11, motor 12, first belt 121, counter roller 13, first rotating shaft 131, counter roller gear 132, boss 14, discharge Mouth 141, cooling channel 142, scraper 143, baffle plate 144, support plate 15, power switch 151, power switch 152, vertical plate 16, electromagnet 161, friction heat generating sheet 162, transmission chain 20, moving block 21, Transmission gear 22, second rotating shaft 23, second belt 24, sliding block 30, protrusion 31, moving cavity 32, chute 33, scoop block 34, groove 35, torsion spring 36, magnetic block 37, friction block 38 , transmission wheel 40, conveyor belt 41, pressing wheel 42, cooling box 43, condensation pipe 44, conduction roller 45, blind cavity 50, extension spring 51, slider 52, rack 53, cutting knife 54, pole 55, roller 56, the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com